Air film hole channel structure based on Tesla valve and application of air film hole channel structure to front edge of turbine blade

A channel structure, air film hole technology, applied in the direction of the stator, engine components, machines/engines, etc., can solve the problem that the front edge of the vane and the end wall near the pressure surface cannot be effectively cooled, so as to prevent the high-temperature gas from flowing backward and cooling Increased flow rate and excellent cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

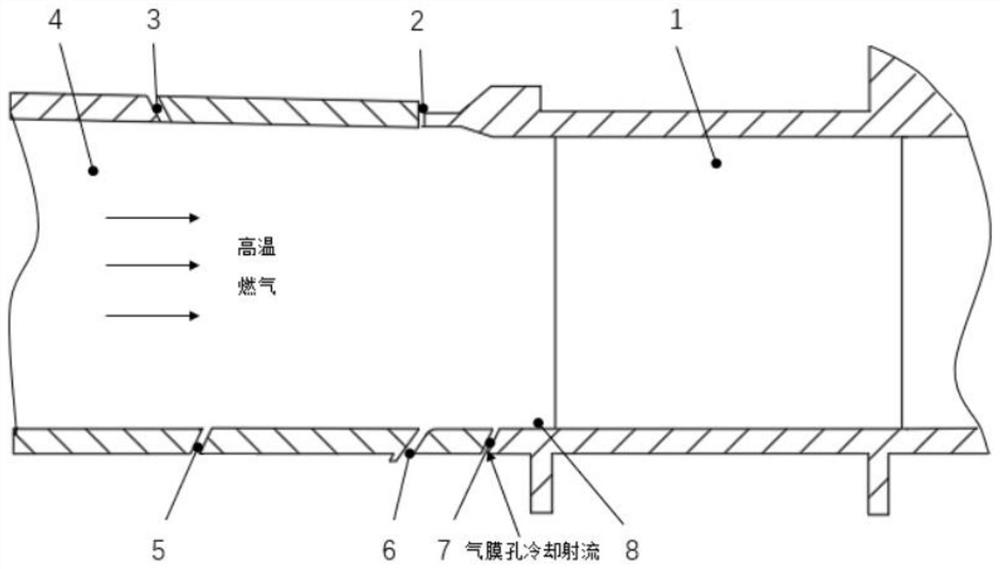

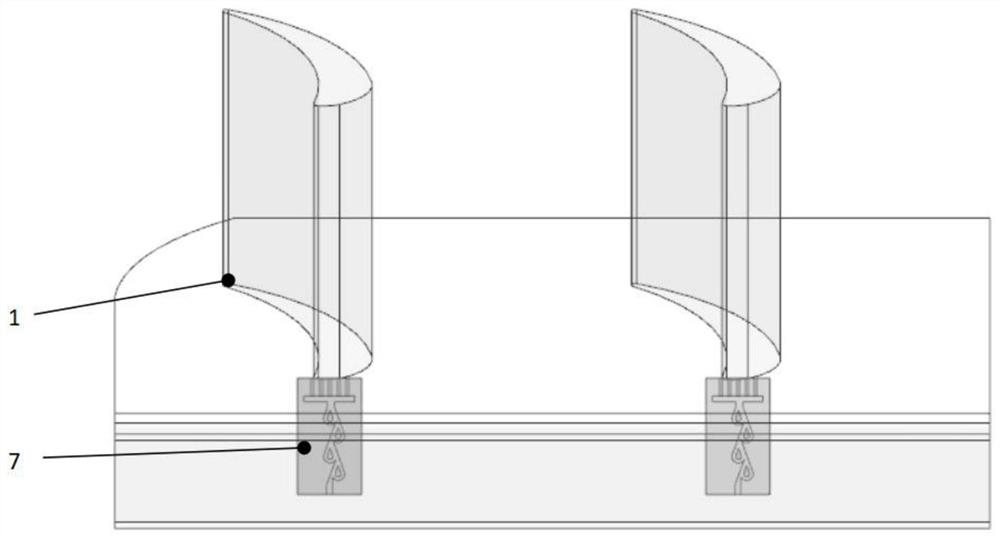

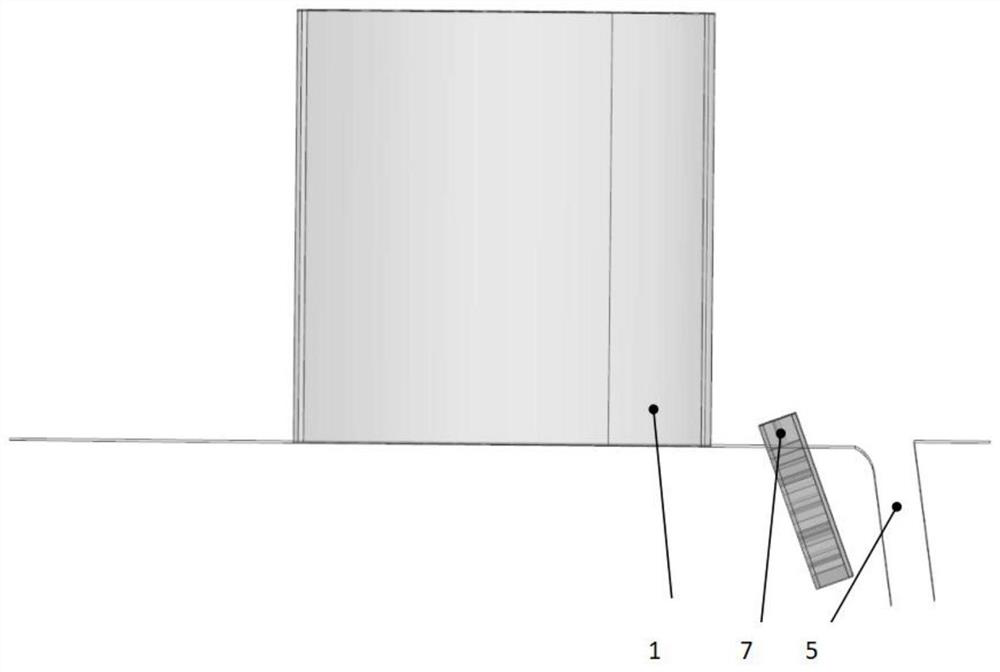

[0045] see Figure 2 to Figure 4 , the gas film hole channel structure based on the Tesla valve in this embodiment corresponds to the position of the leading edge point of the turbine vane, and the gas film hole channel structure of the Tesla valve includes five outlet gas film holes arranged side by side, The film cooling jet introduced from the compressor flows out through the channel of the Tesla valve and the five outlet film holes connected to it. Due to the one-way conduction performance of the Tesla valve, most of the cooling jet can reach the front of the vane The edge end wall greatly reduces the backflow of high temperature airflow.

[0046] see Figure 5 to Figure 8 , the film cooling jet enters the Tesla valve channel from the Tesla valve channel inlet 9 of the lower part of the Tesla valve film hole structure, and flows out through five outlet film holes 10 . In this embodiment, the Tesla valve has a four-stage structure, consisting of four Tesla valve internal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com