Light-emitting diode (LED) optical engine and LED illuminating lamp

A technology of LED light source and light engine, applied in lighting devices, lighting and heating equipment, components of lighting devices, etc., can solve the problems of poor circulation, decreased heat dissipation performance, and no display.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] specific implementation plan

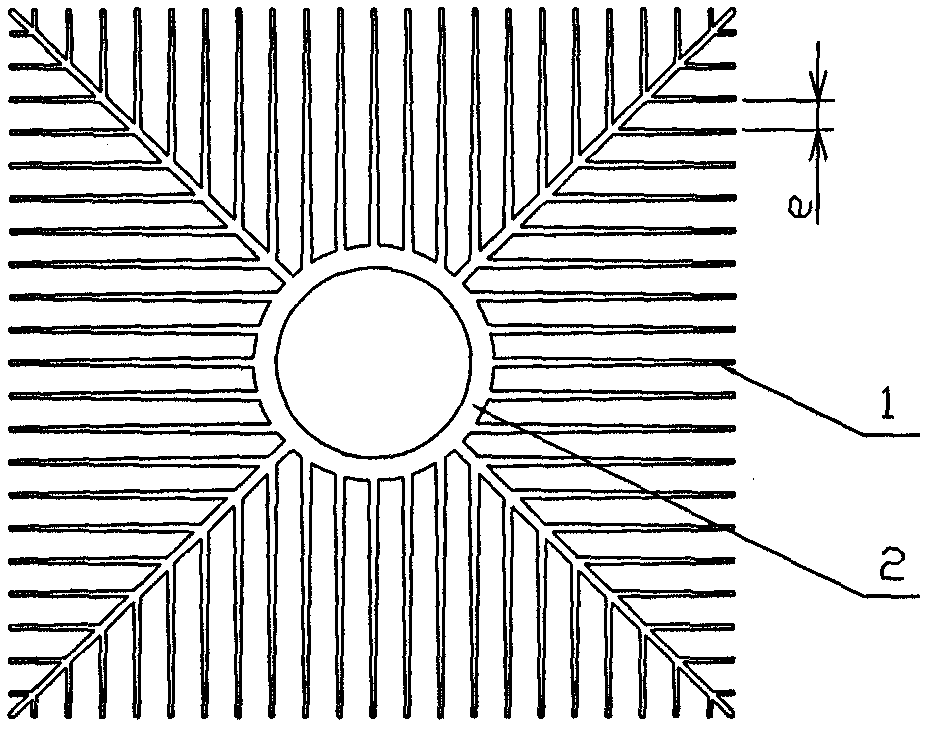

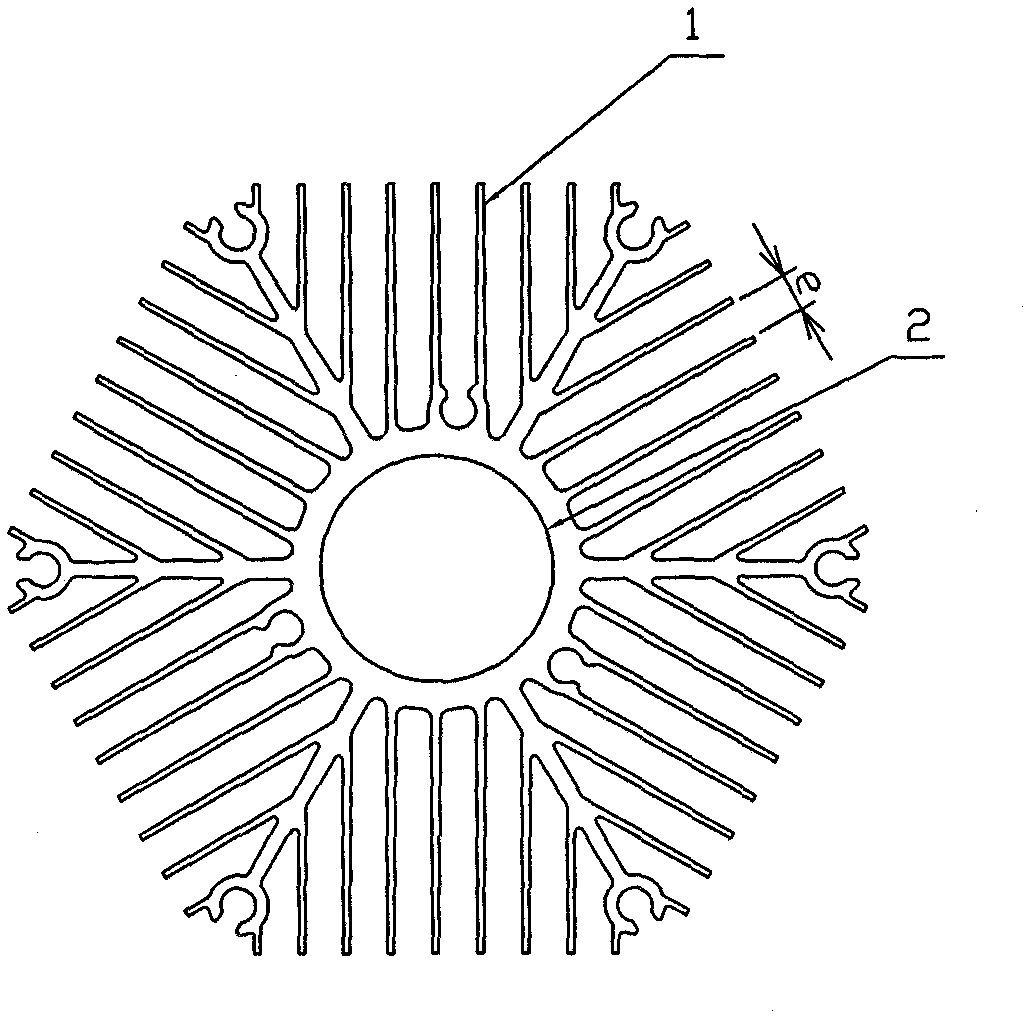

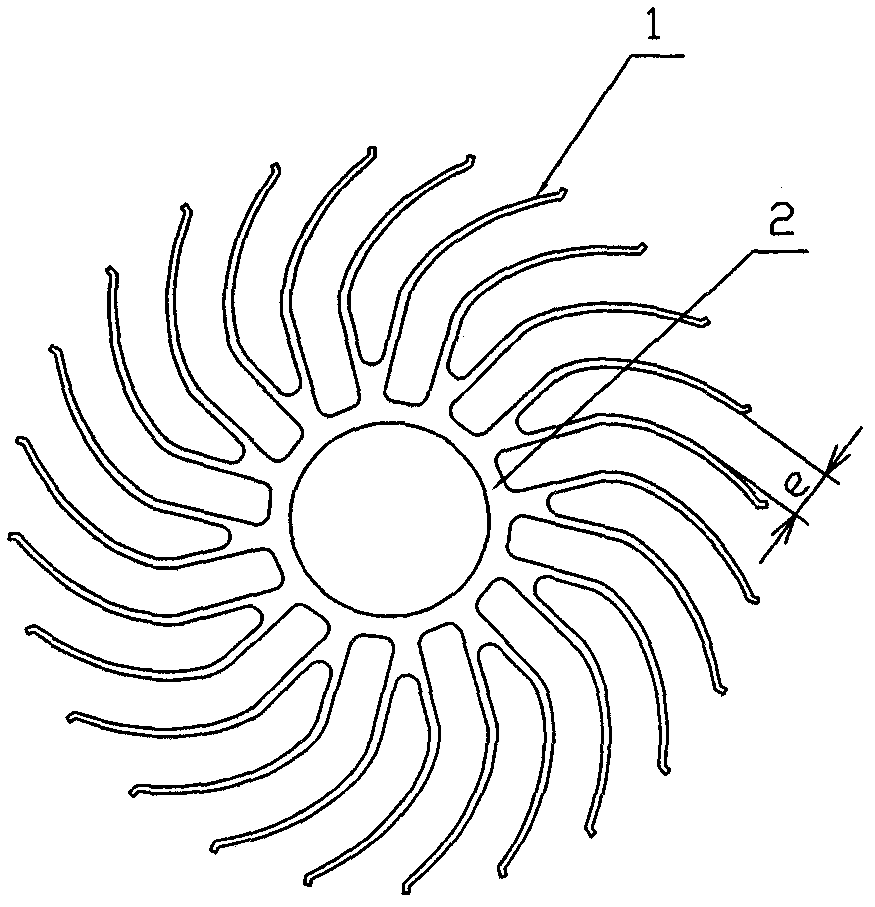

[0024] figure 1 , 2 , 3 show three kinds of sun fancy heat sinks with different shapes, the fins 1 protrude from the side of the heat conduction column 2, and the heat conduction column 2 in the center of the heat sink is a hollow structure. Using the aluminum extrusion method, the profile can be manufactured, and it can be cut to make a sun fancy heat sink. The manufacturing cost is low, and because of the high ribbing efficiency (material saving) and low internal thermal resistance, it is LED. Cooling first choice.

[0025] Figure 4 In the present invention shown, the ribs 1 are divided into three sections by the cross-flow grooves 5 (two cross-flow grooves are provided), and the three-section short ribs 4 are most suitable for the height h of the short ribs to be between 3 and 8 mm. The depth c of the cross-flow groove shown in the figure is greater than half of the rib length L mentioned above. When designing, the cross-flow groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com