Patents

Literature

54 results about "Short ribs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Short ribs are a cut of beef taken from the brisket, chuck, plate, or rib areas of beef cattle. They consist of a short portion of the rib bone, which is overlain by meat which varies in thickness. There are two major types of cuts: The "flanken", which is cut across the bone and leaves the bone just 1 to 2 inches (2.5 to 5.1 cm) in length, and the "English", which is cut parallel to the bone and leaves the bone up to 6 inches (15 cm) in length. English cut short ribs may be served individually, or three or four may served connected to one another (a style known as the "plate"). Short ribs are popular in many international cuisines.

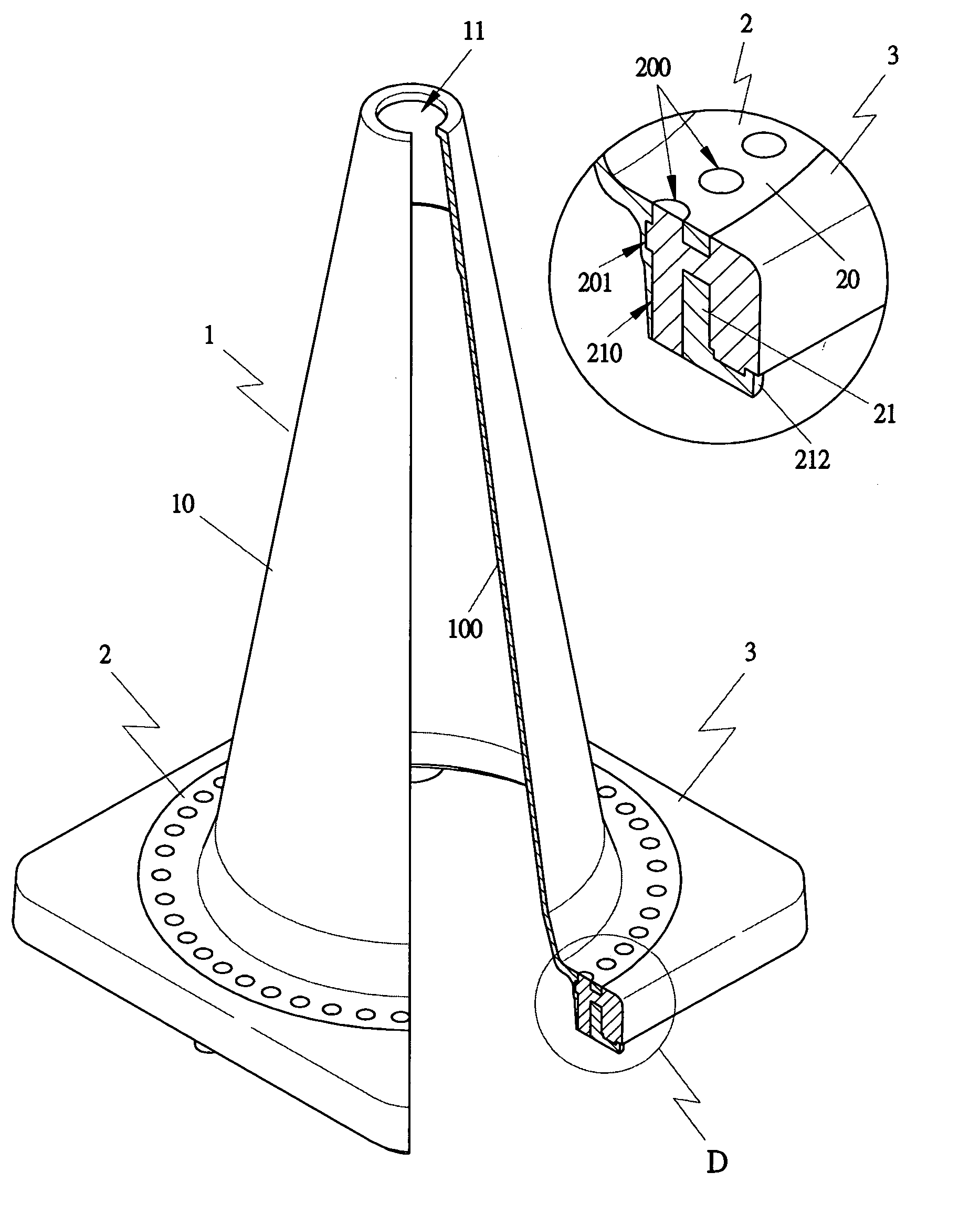

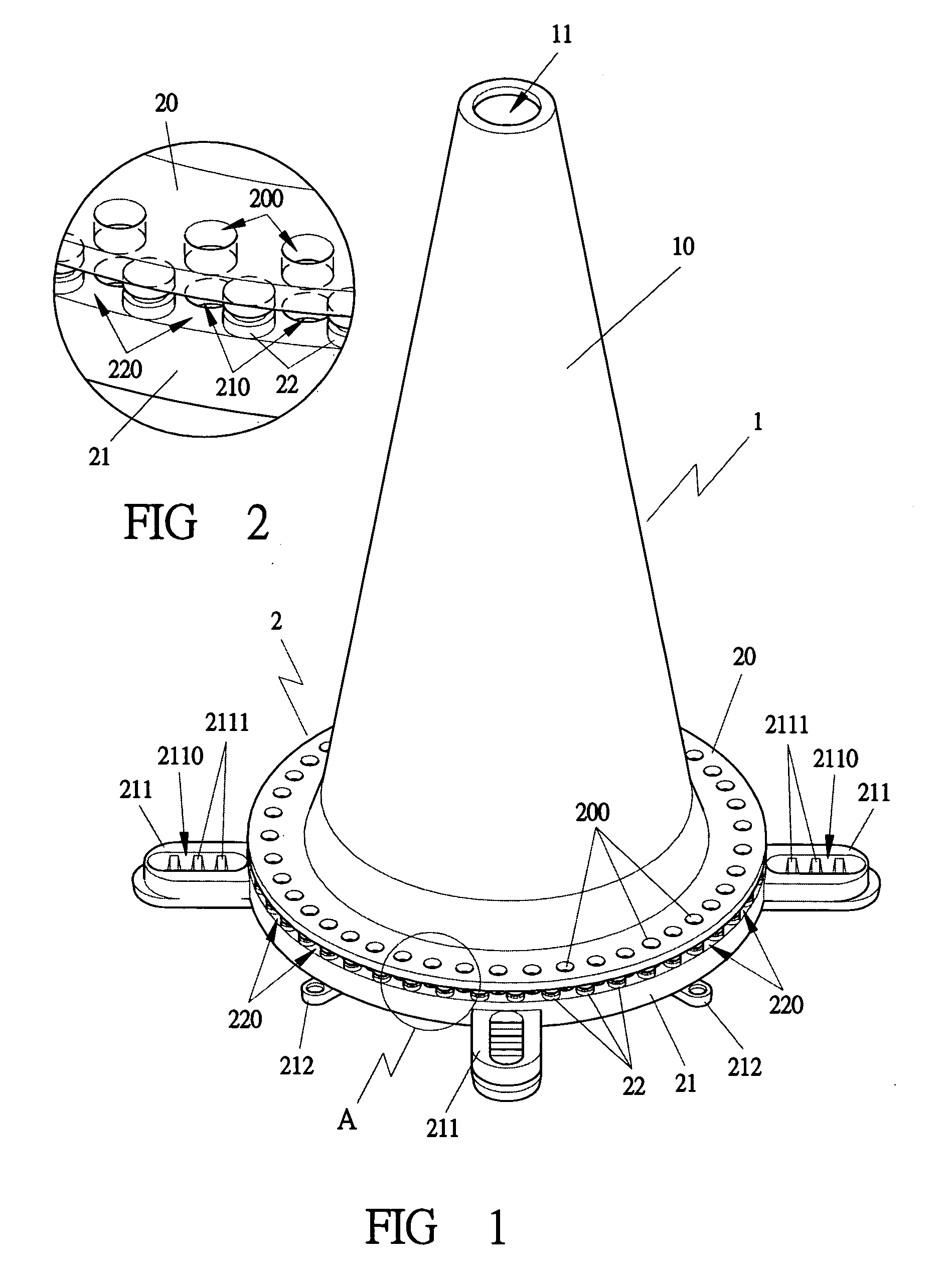

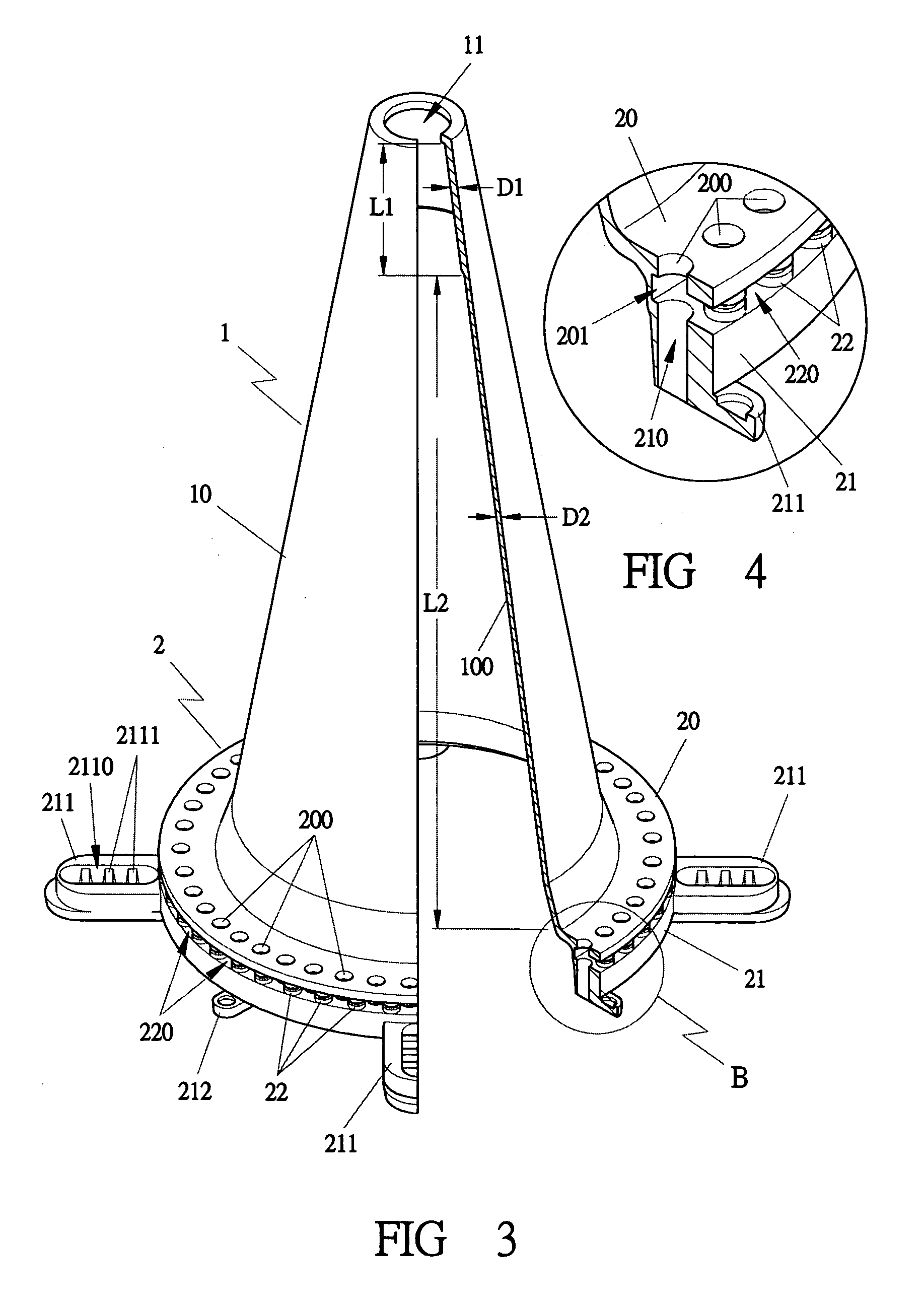

Traffic cone

InactiveUS6929419B1Traffic safetyAvoid large gapsTraffic signalsRoad signsEngineeringStructural engineering

A traffic cone includes a frustum-conical body and a base. The frustum-conical body has a hole in an upper end surface for a signal lamp, and a partial portion of its circumferential wall is thicker than another portion to form a gap between every two traffic cones stacked-up for easily taken off. The frustum-conical body has its bottom formed with a flange consisting of an upper and a lower annular wall and short ribs formed between the upper and the lower annular wall. The upper and the lower annular wall respectively have connect holes facing one another. The upper annular wall has an auxiliary material filling holes beside every connect hole and the lower annular wall has projecting arms. The base has a center hole to fit around the flange of the frustum-conical body to be combined with the same body as integral.

Owner:KUO WEN NAN

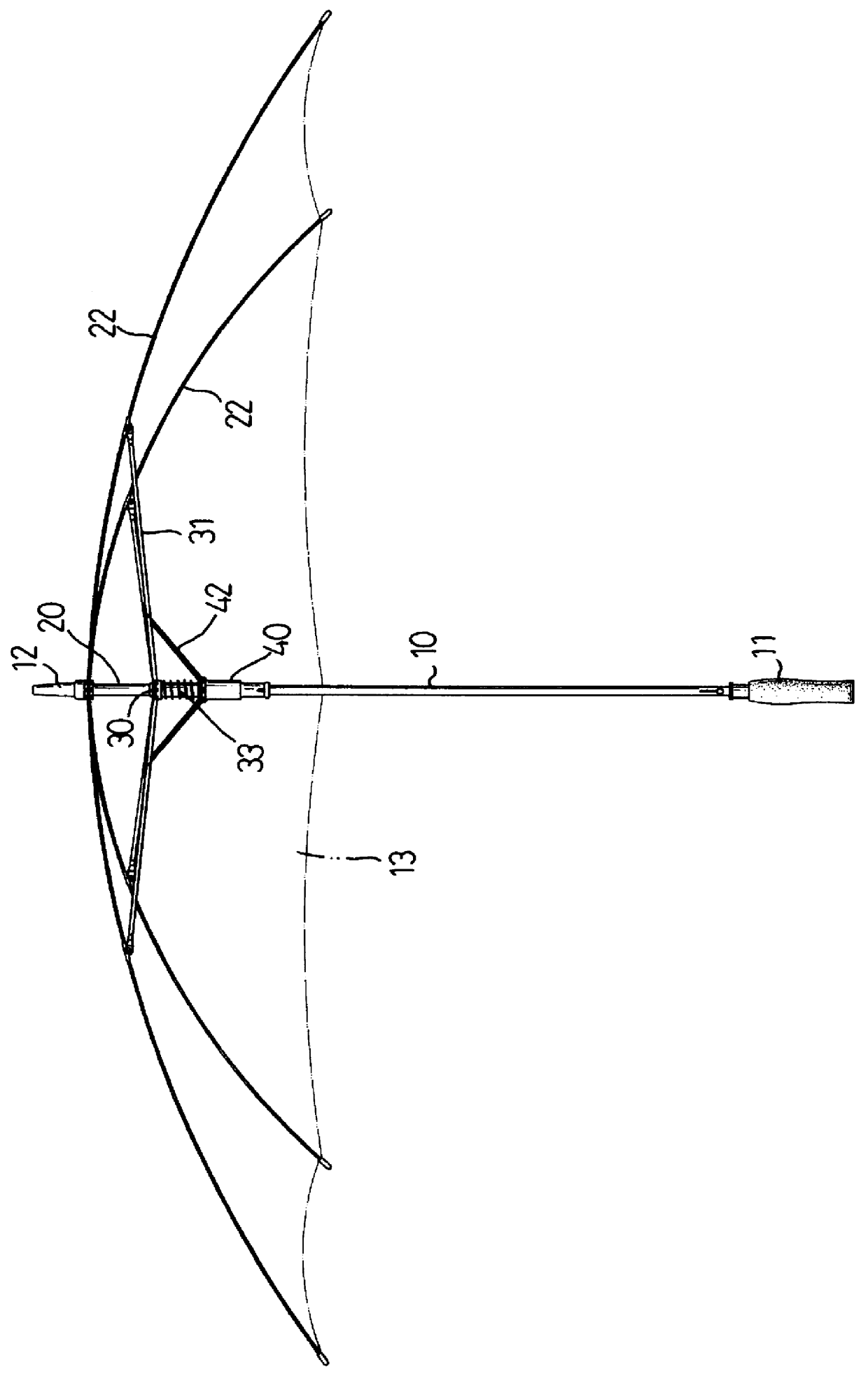

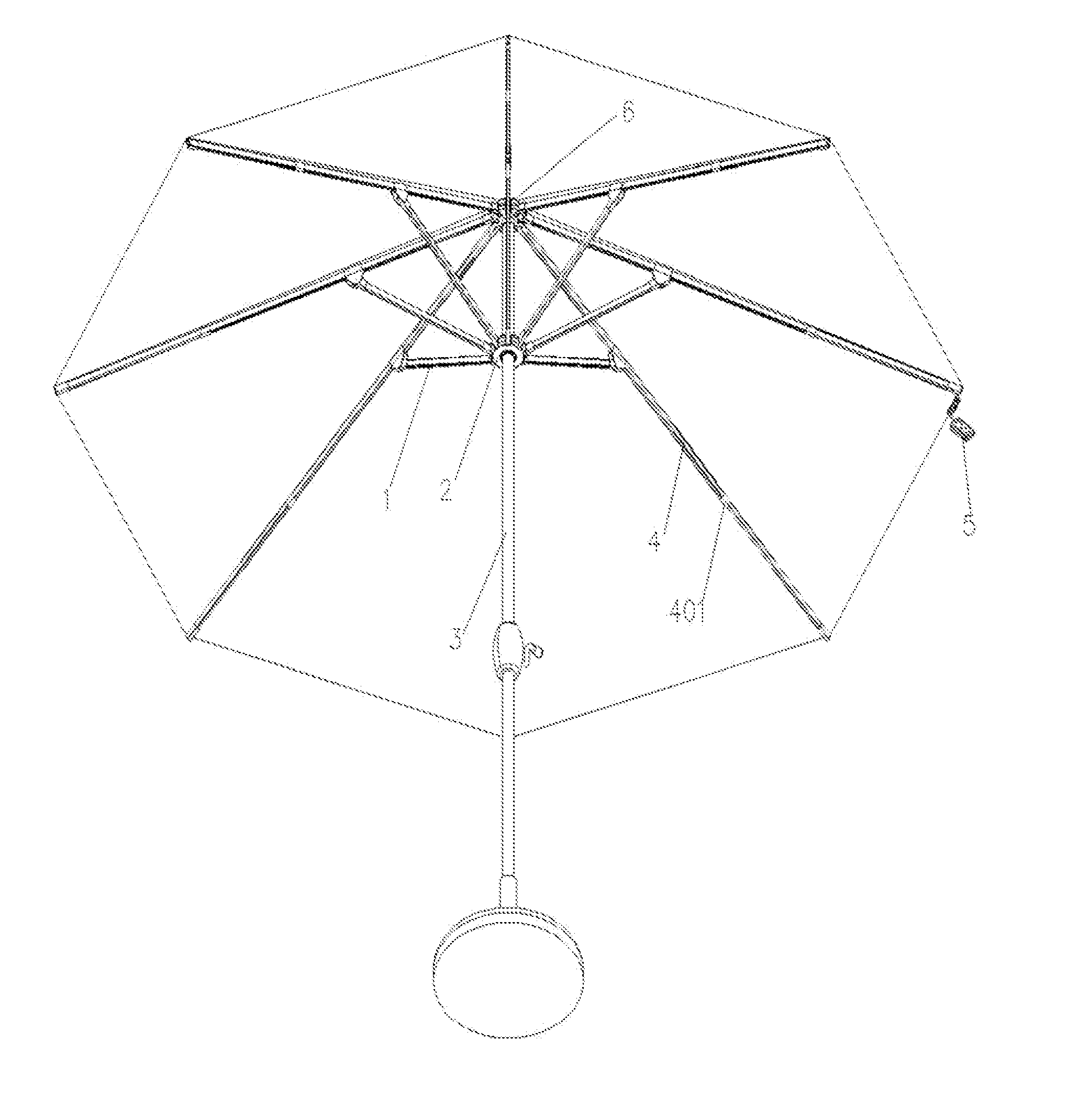

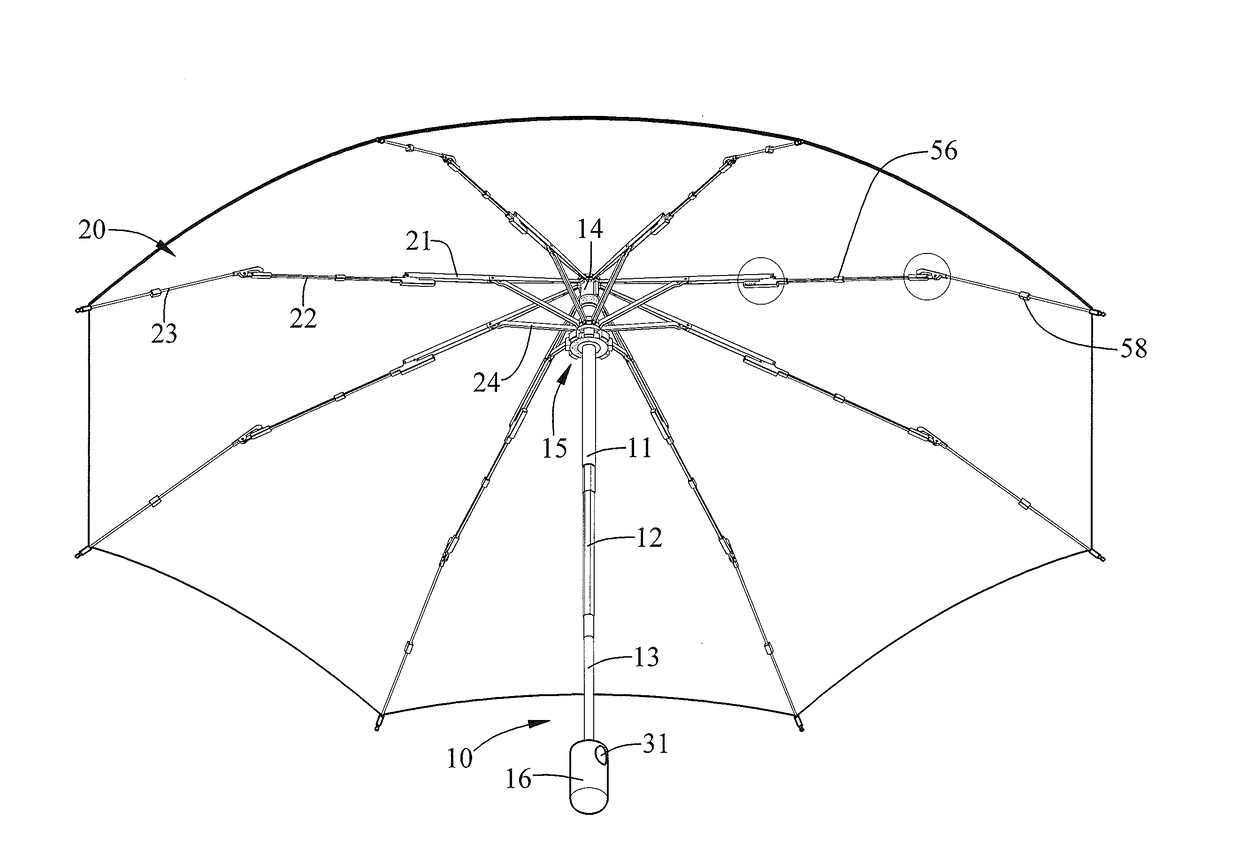

Umbrella frame

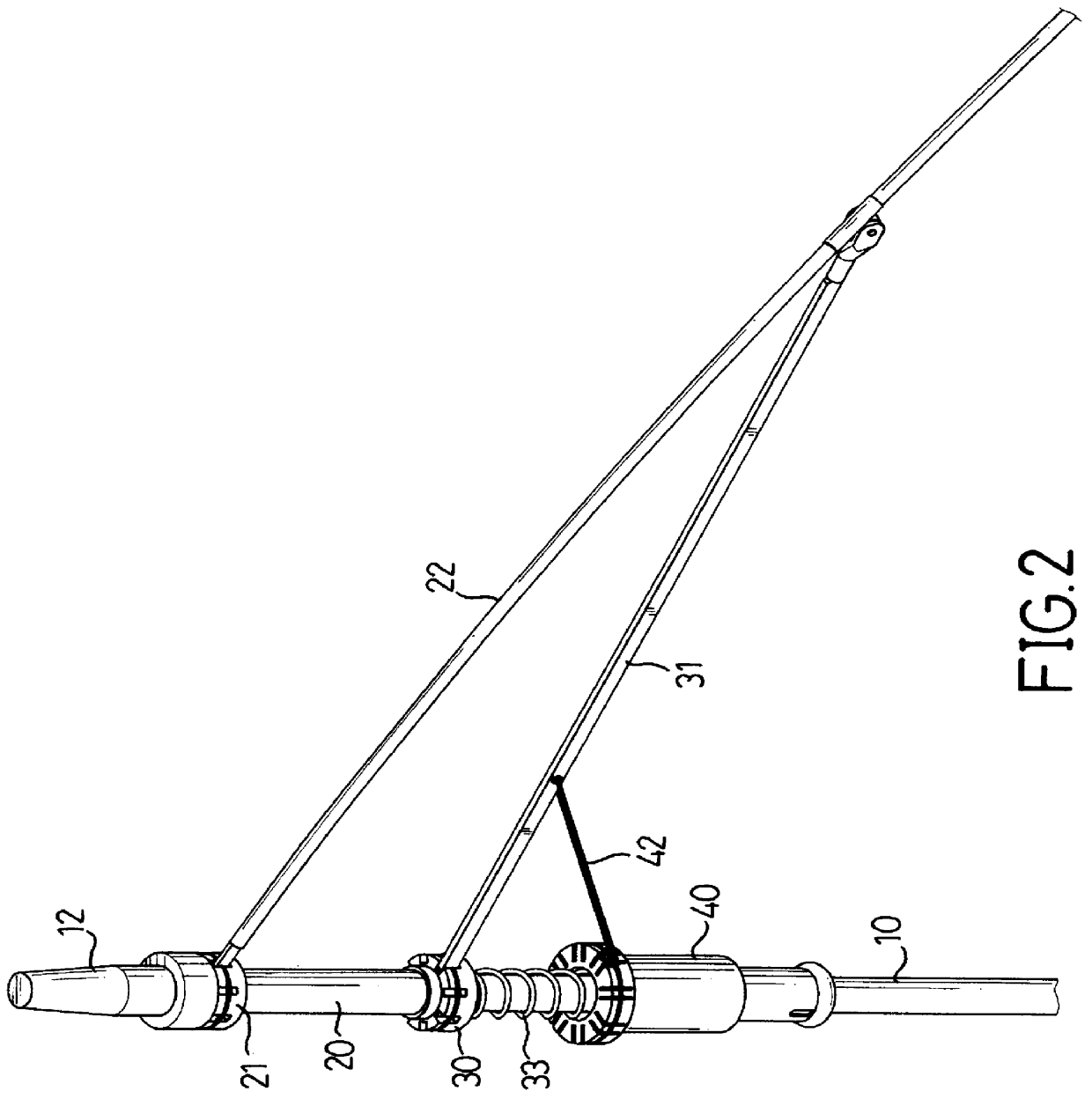

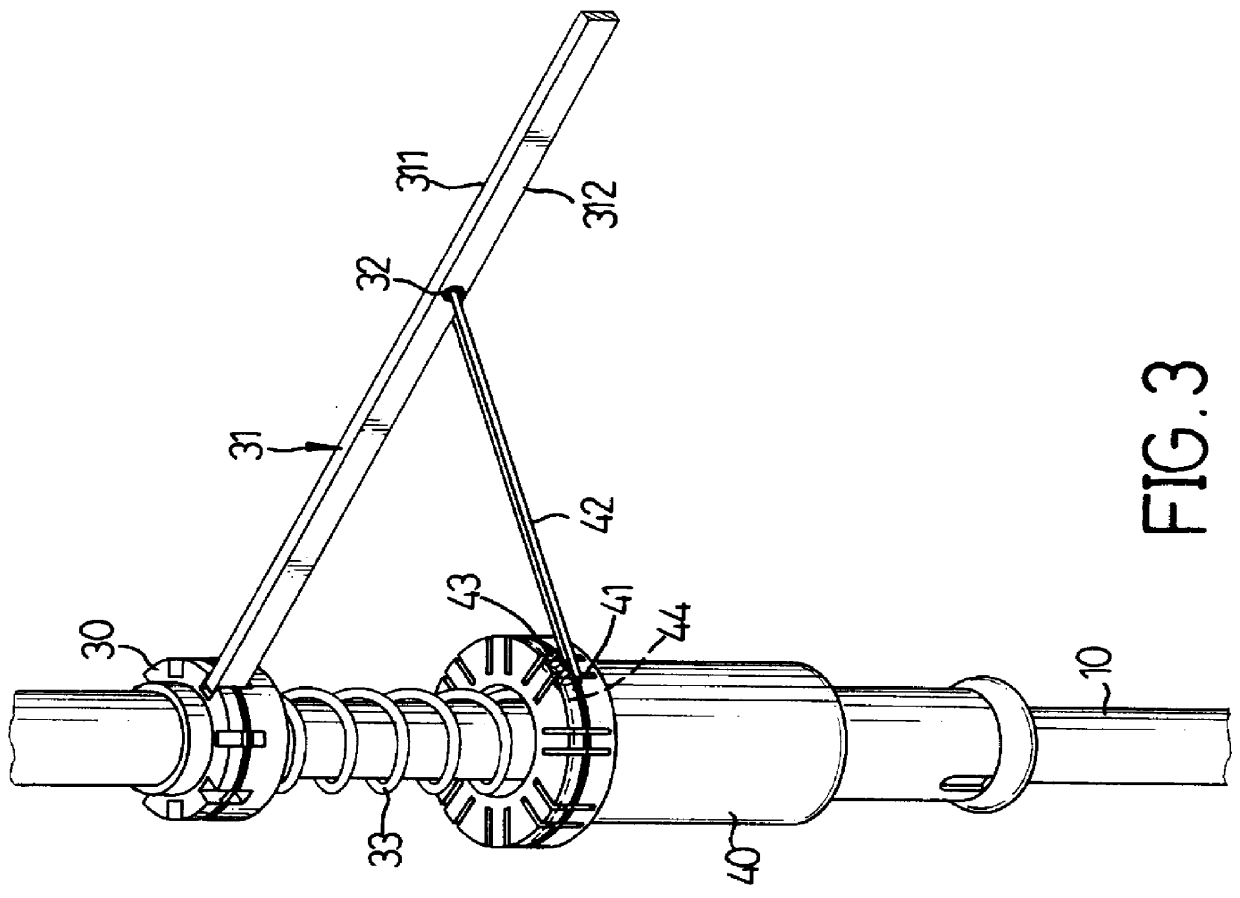

InactiveUS6062242AImprove support strengthAvoid breakingWalking sticksUmbrellasEngineeringShort ribs

An improved umbrella frame comprises a stick having an upper sleeve which has an upper nest set on the topside thereof being installed on the stick. And below the upper sleeve, the stick is further installed a mid runner and a lower runner between which a spring is set. A pluralities of long ribs are radiated around the nest and each of which have a first end pivotally connected thereto. A plurality of short ribs are radiated around the mid runner and each of which have a firs end pivotally connected thereto, and a second end pivotally connected to the long ribs. Wherein, the short ribs are made of fiber material and are formed in a solid rectangular shape with the lateral edge being longer than the top and bottom edge.

Owner:ASIA UMBRELLA IND

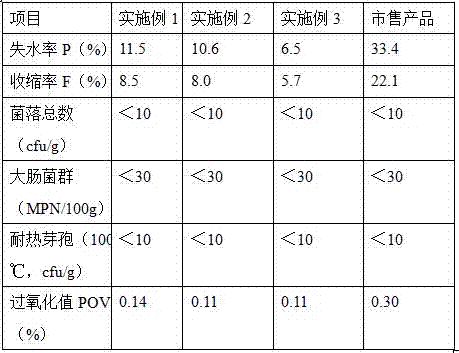

Processing method of sauce-flavor cured pork ribs

The invention relates to the technical field of meat products processing and particularly relates to a processing method of sauce-flavor cured pork ribs. The processing method provided by the invention comprises the following steps of: preparing the pork ribs to the sauce-flavor cured pork ribs by using pork ribs as raw materials, and through such steps as cutting, salting, air drying, roasting, frying, packaging and high temperature sterilizing. The processing method is used for solving the problems of long low temperature air drying time or product quality degradation caused by high temperature roasting of the cured short ribs, solving the problems of flaccid tissues and lacking of chewiness of the sauce spiced pork ribs after being sterilized at high temperature and solving the problems that the cured short ribs lack sauce flavor and the grease is liable to separate out to affect sensory quality after being sterilized. The products processed by the processing method is rich in sauce flavor, fragrant in cured meat flavor and tough and tensile in meat quality, thereby being flavor rib snack food both having the characteristics of rich sauce flavor of the sauce spiced pork ribs and having the advantages of fragrant cured meat flavor of the cured pork ribs.

Owner:TENGQIAO FOOD CO LTD

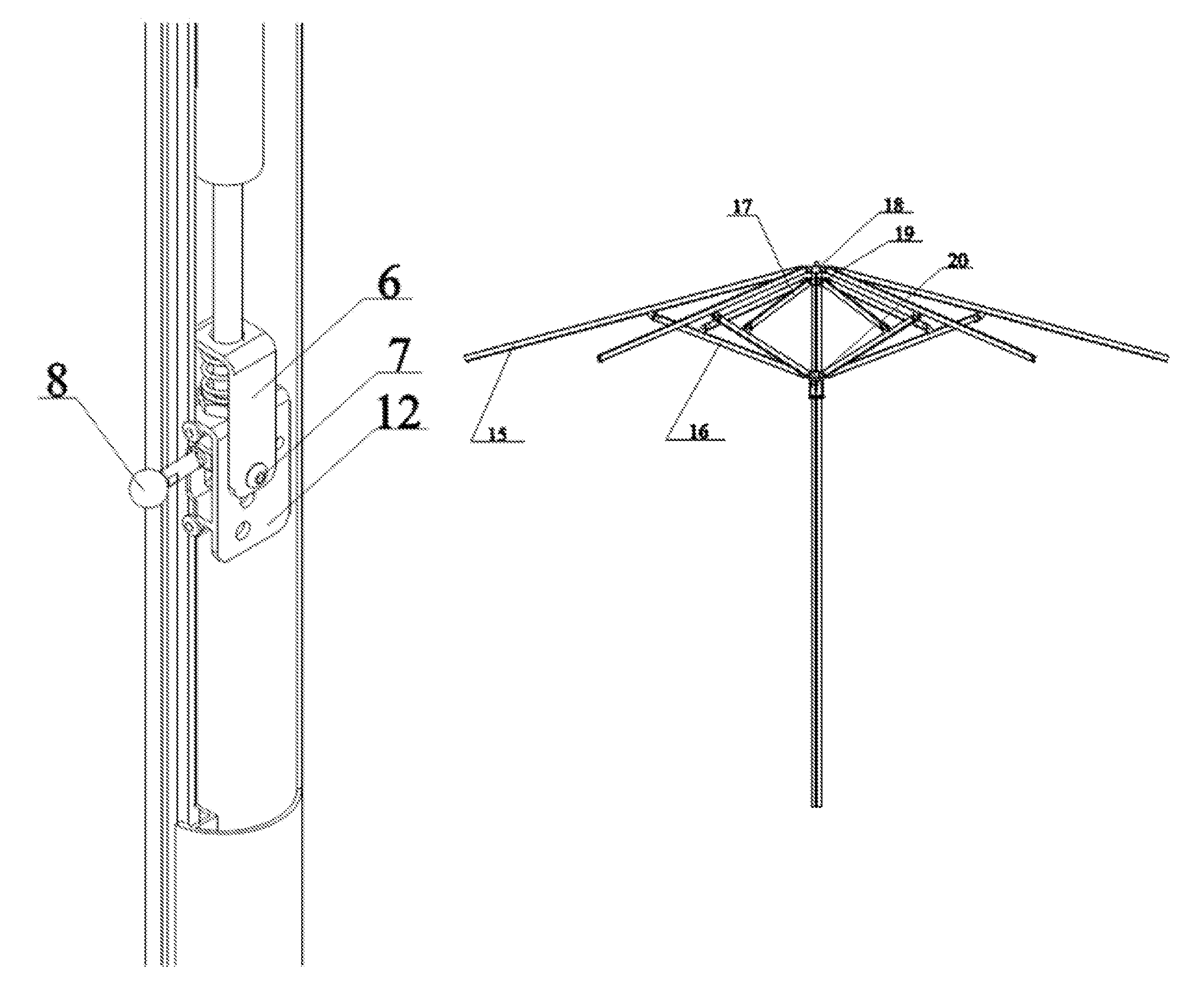

Vehicle sunshade umbrella

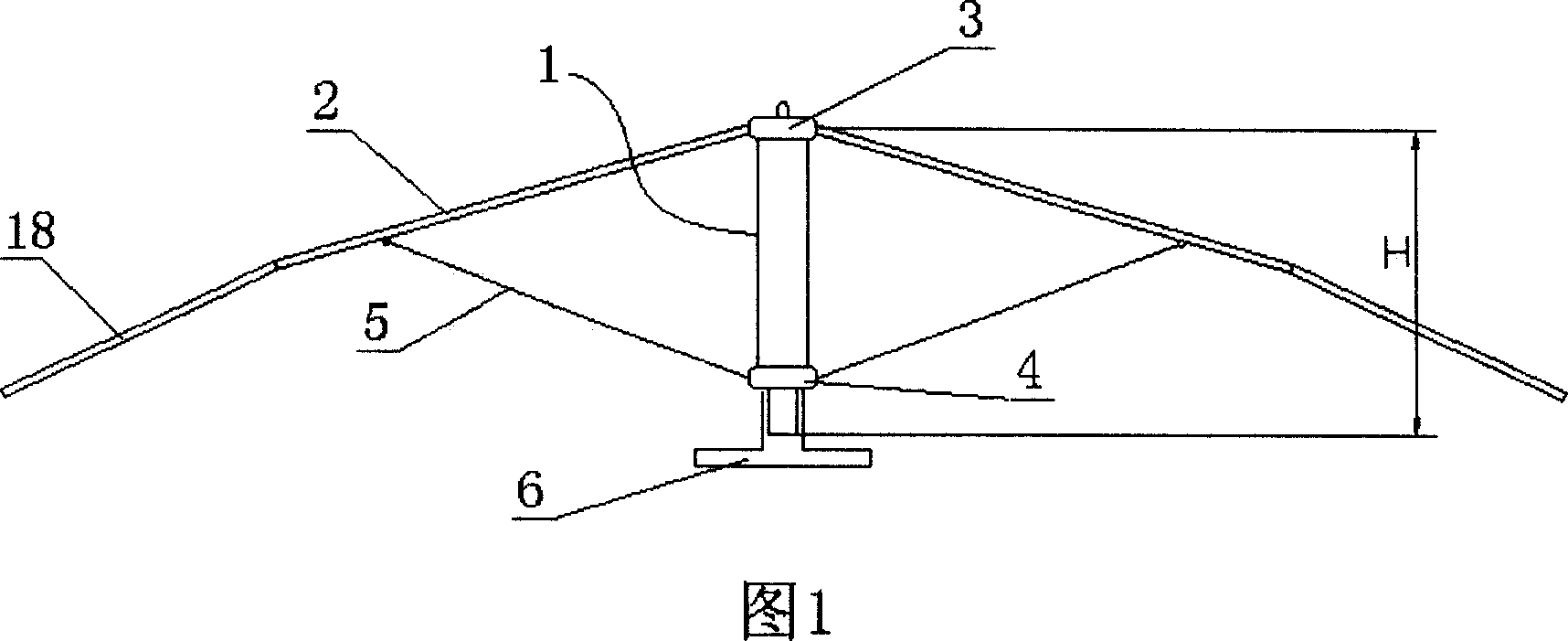

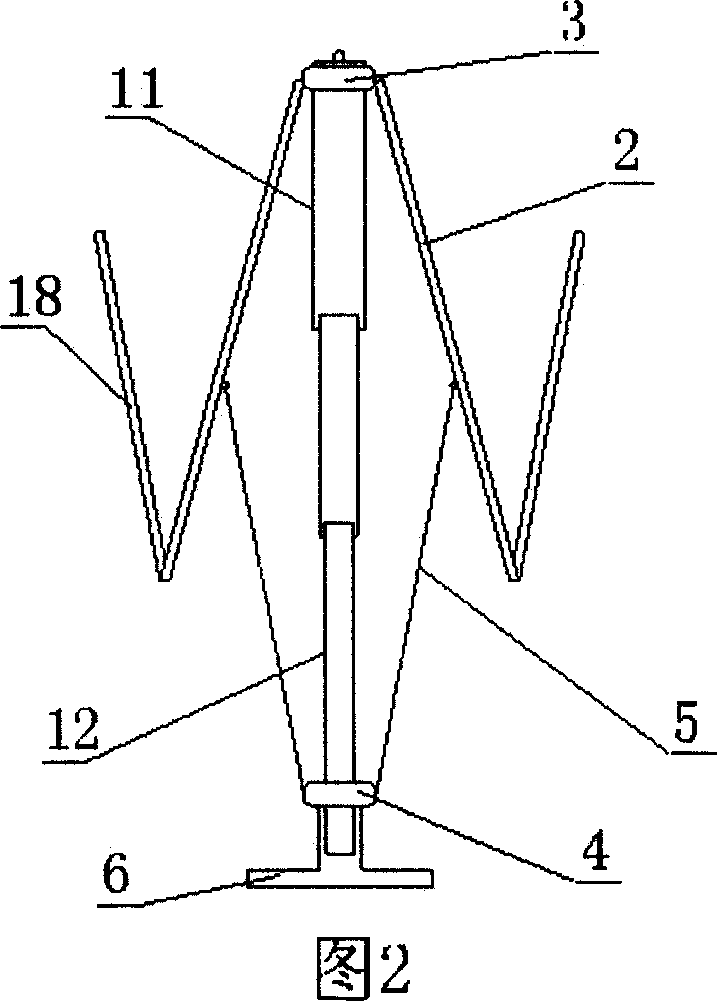

InactiveCN1955027AReduce wind resistanceImprove job stabilityWalking sticksTents/canopiesEngineeringShort ribs

A foldable sunshade umbrella for car is composed of a length adjustable central rod, a group of long ribs with an extended segment, a group of short ribs, the upper and lower nest bodies for hinging said ribs respectively to them, and a bottom fixer for fixing the sunshade umbrella onto the top of car.

Owner:潘国桐 +2

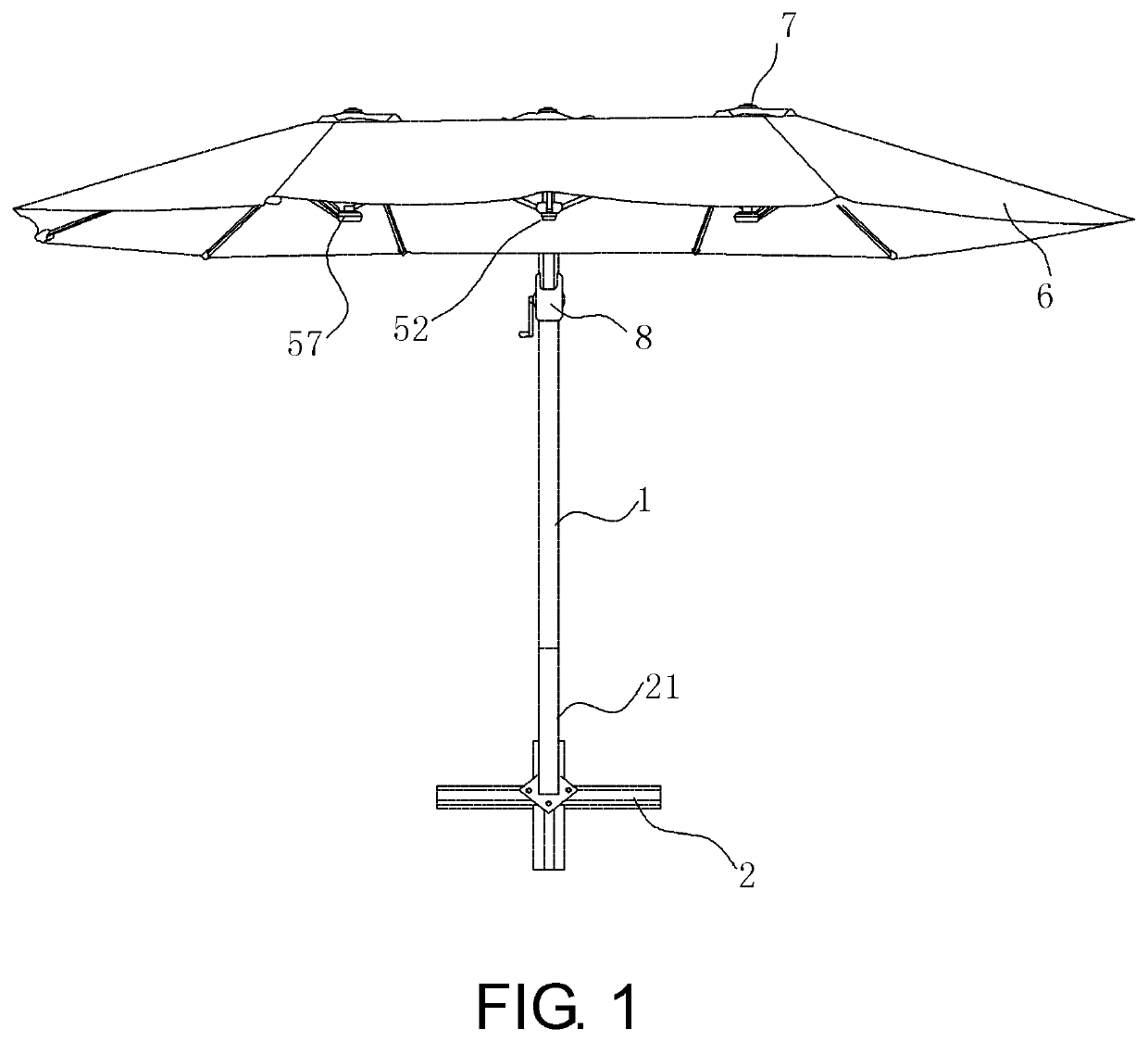

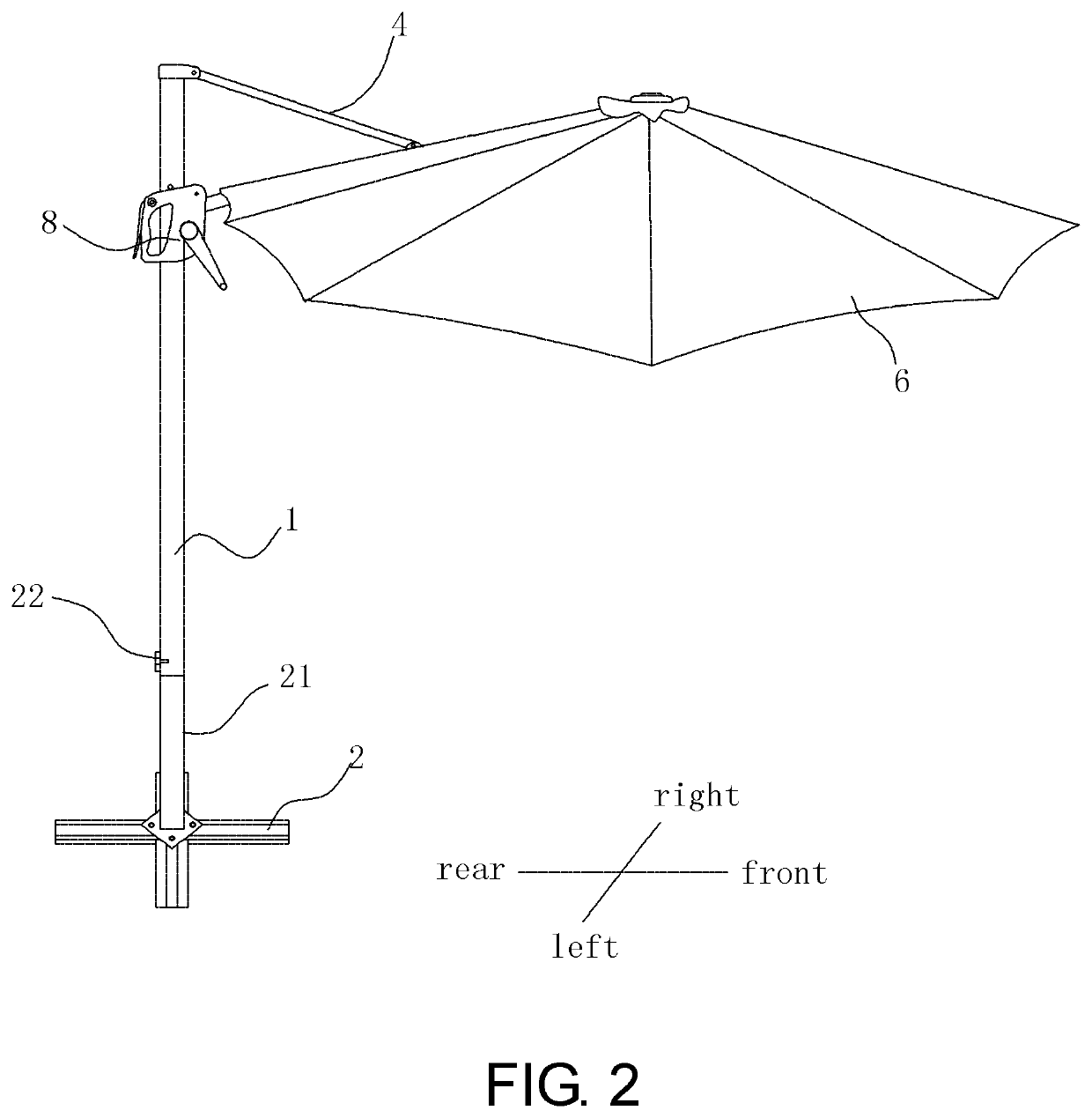

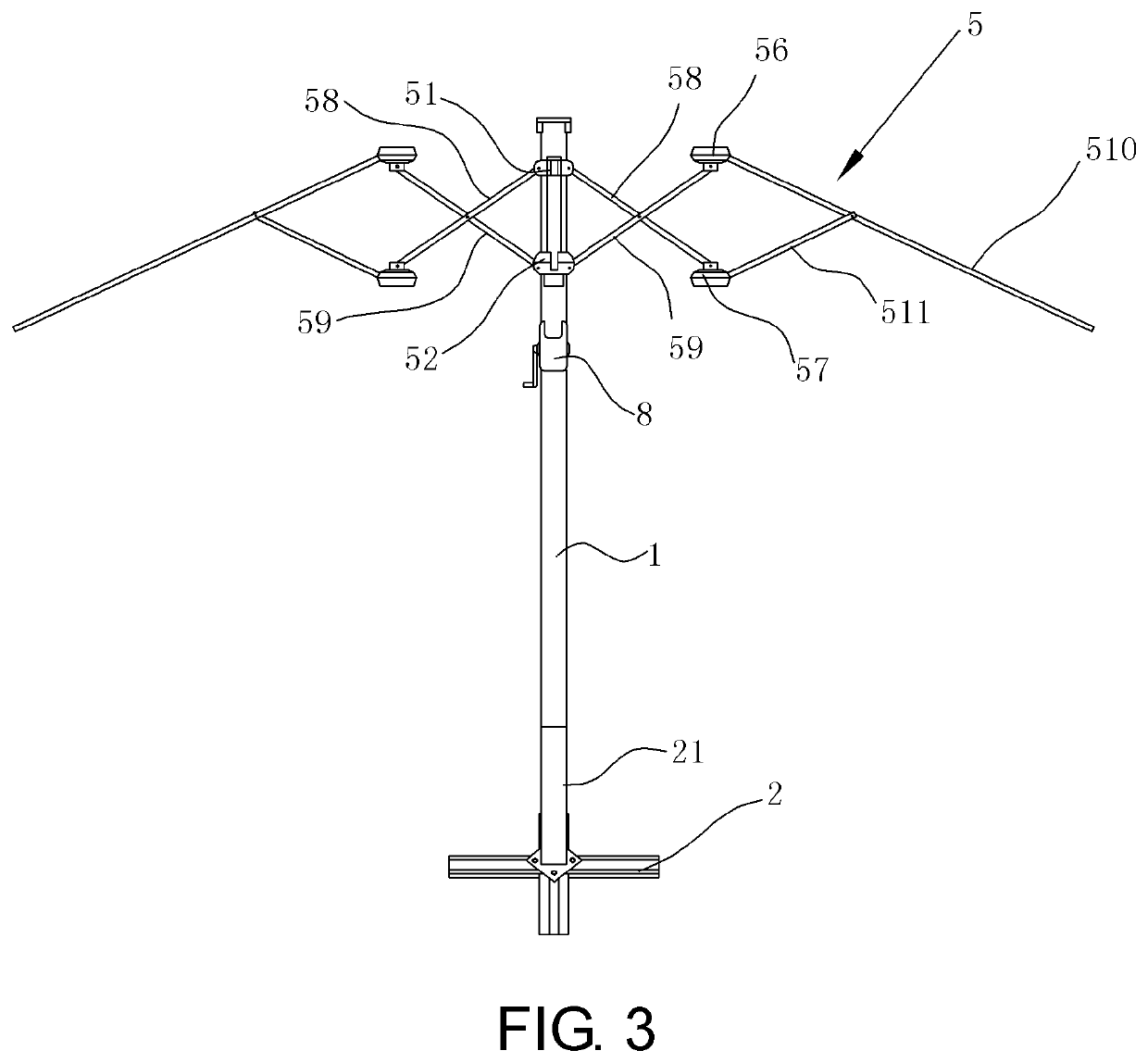

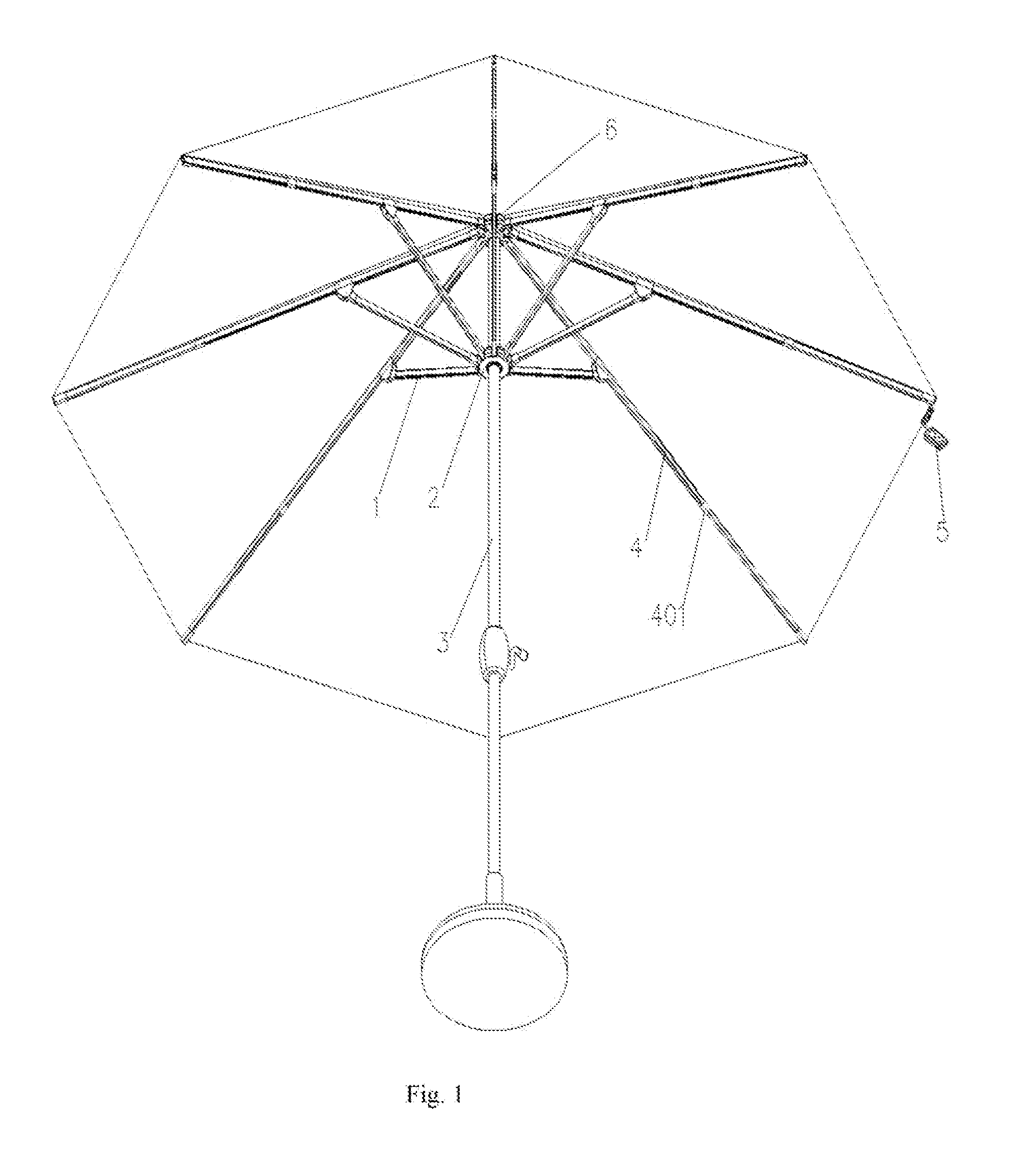

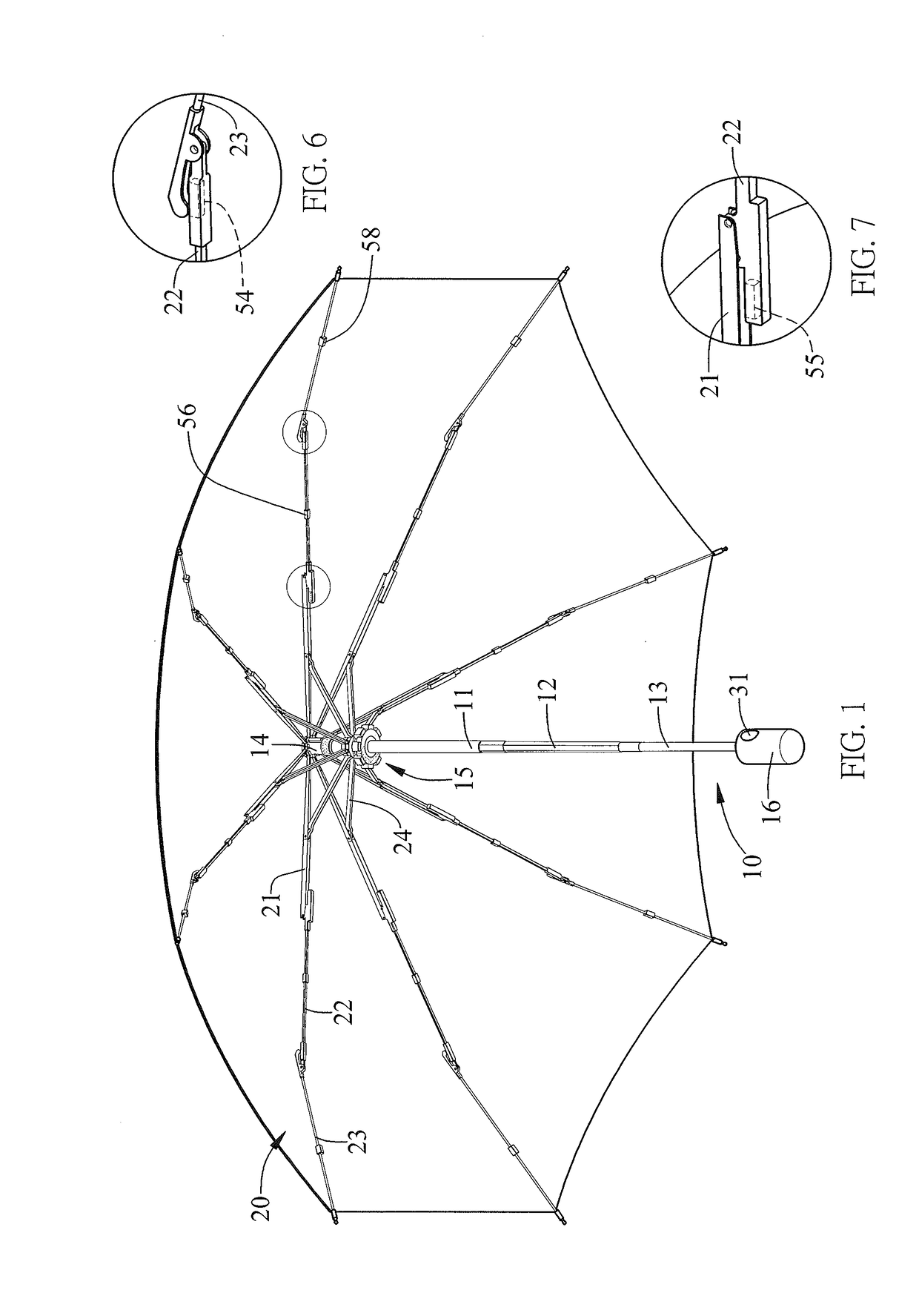

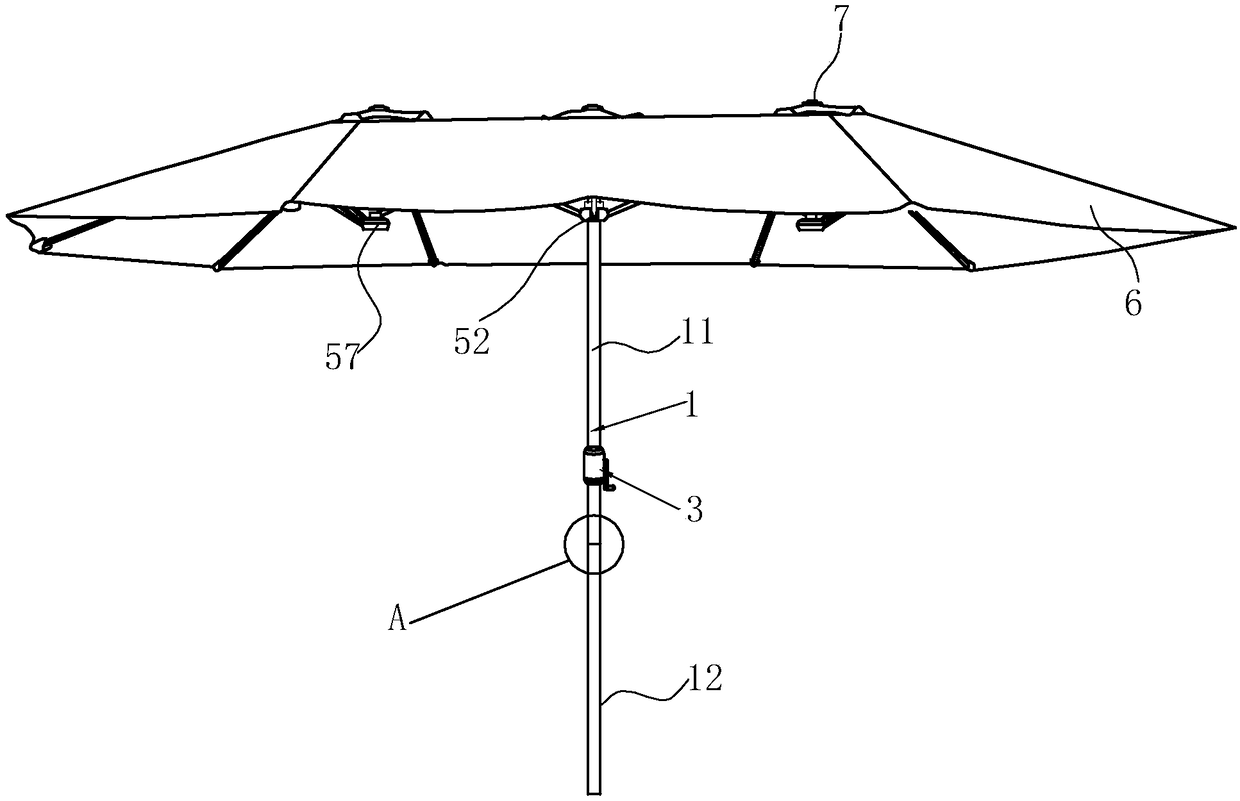

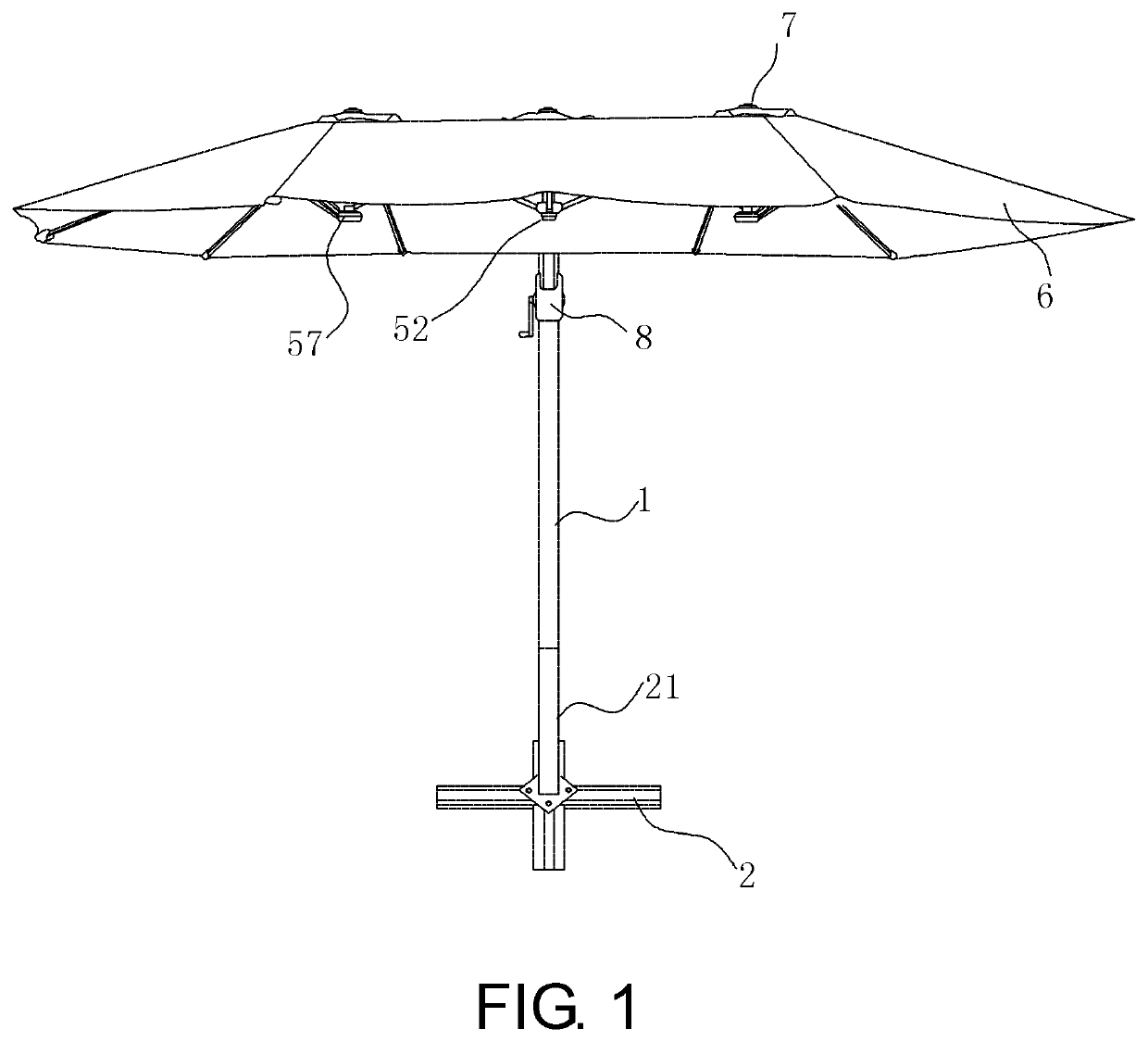

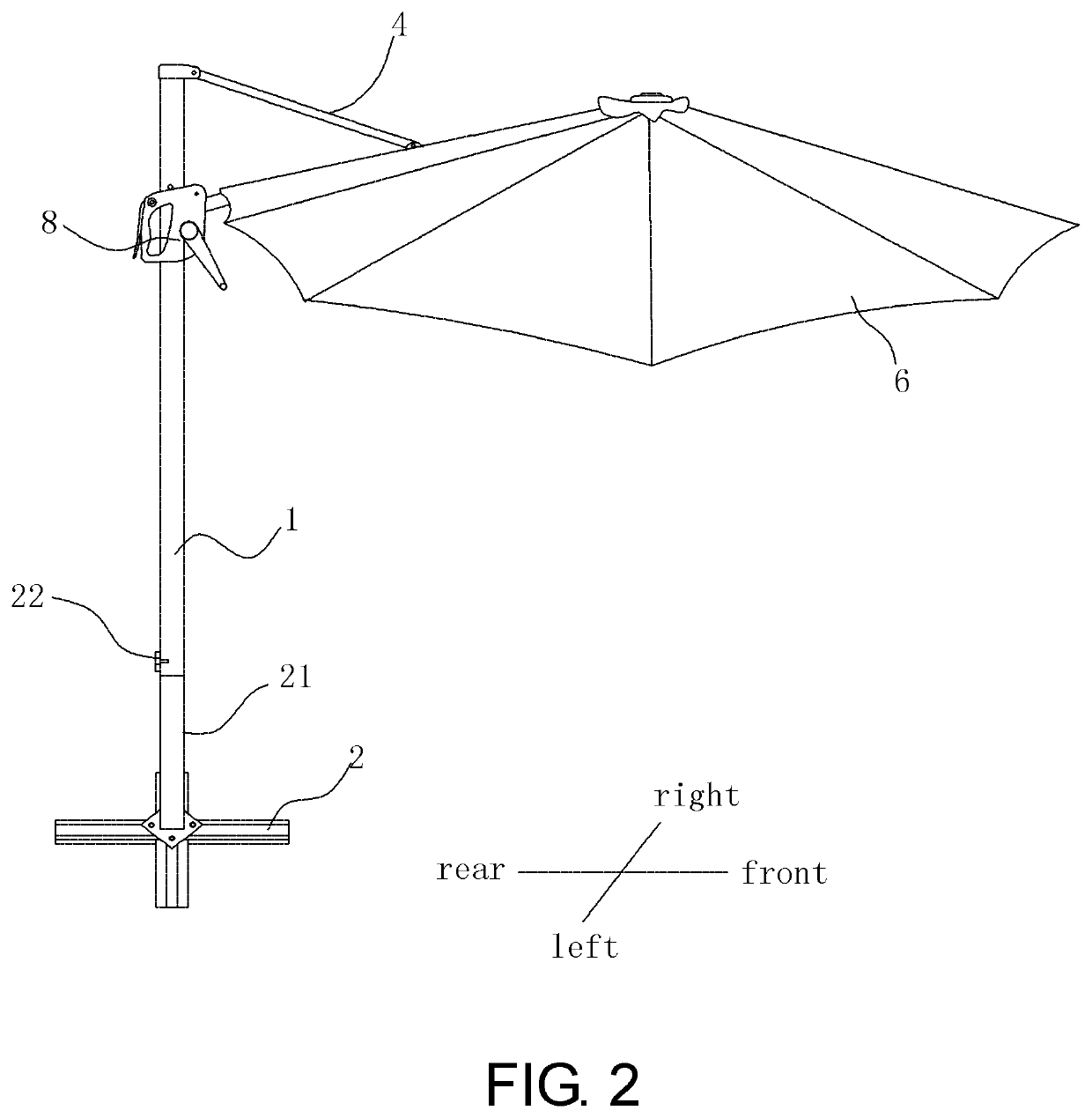

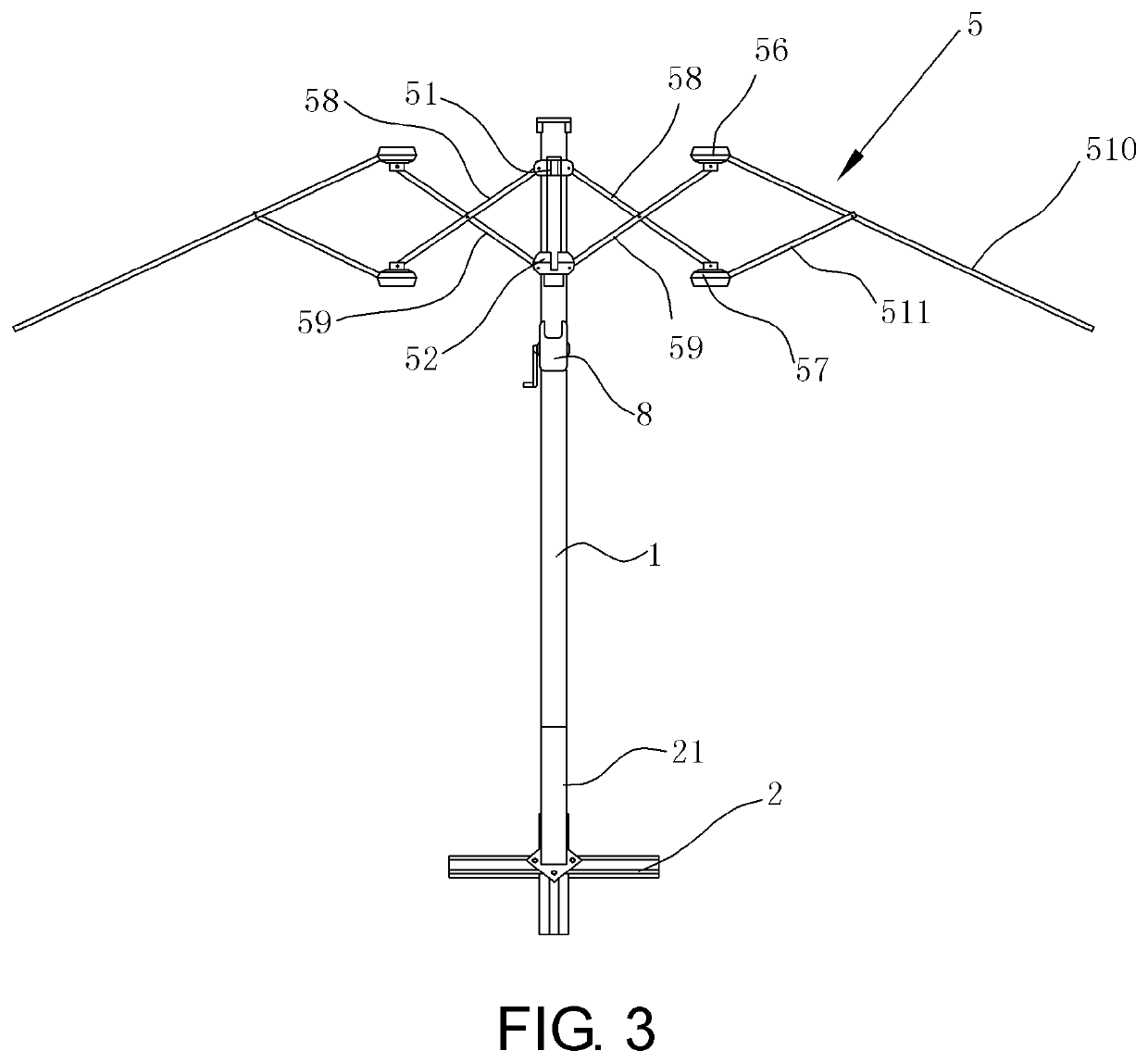

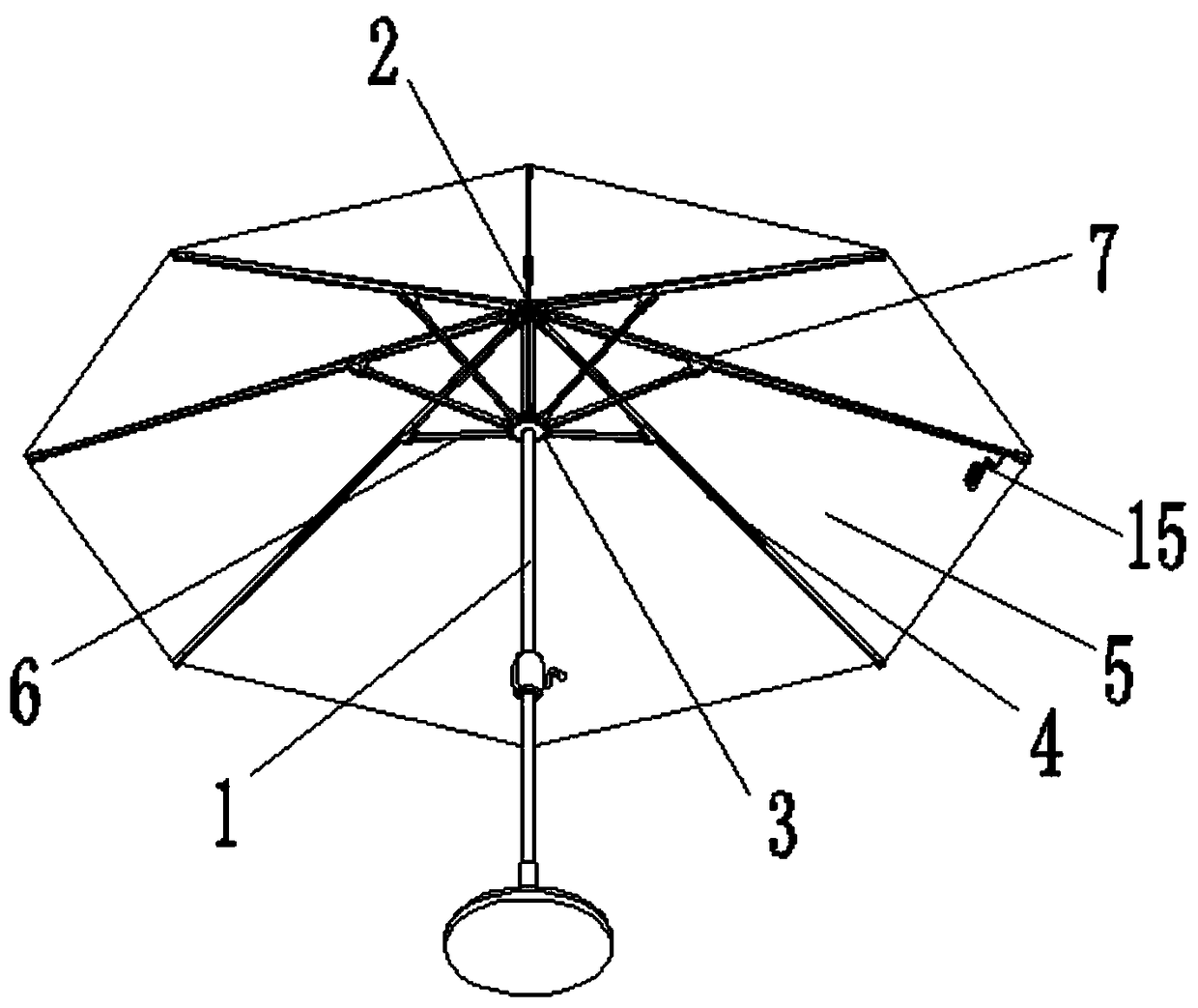

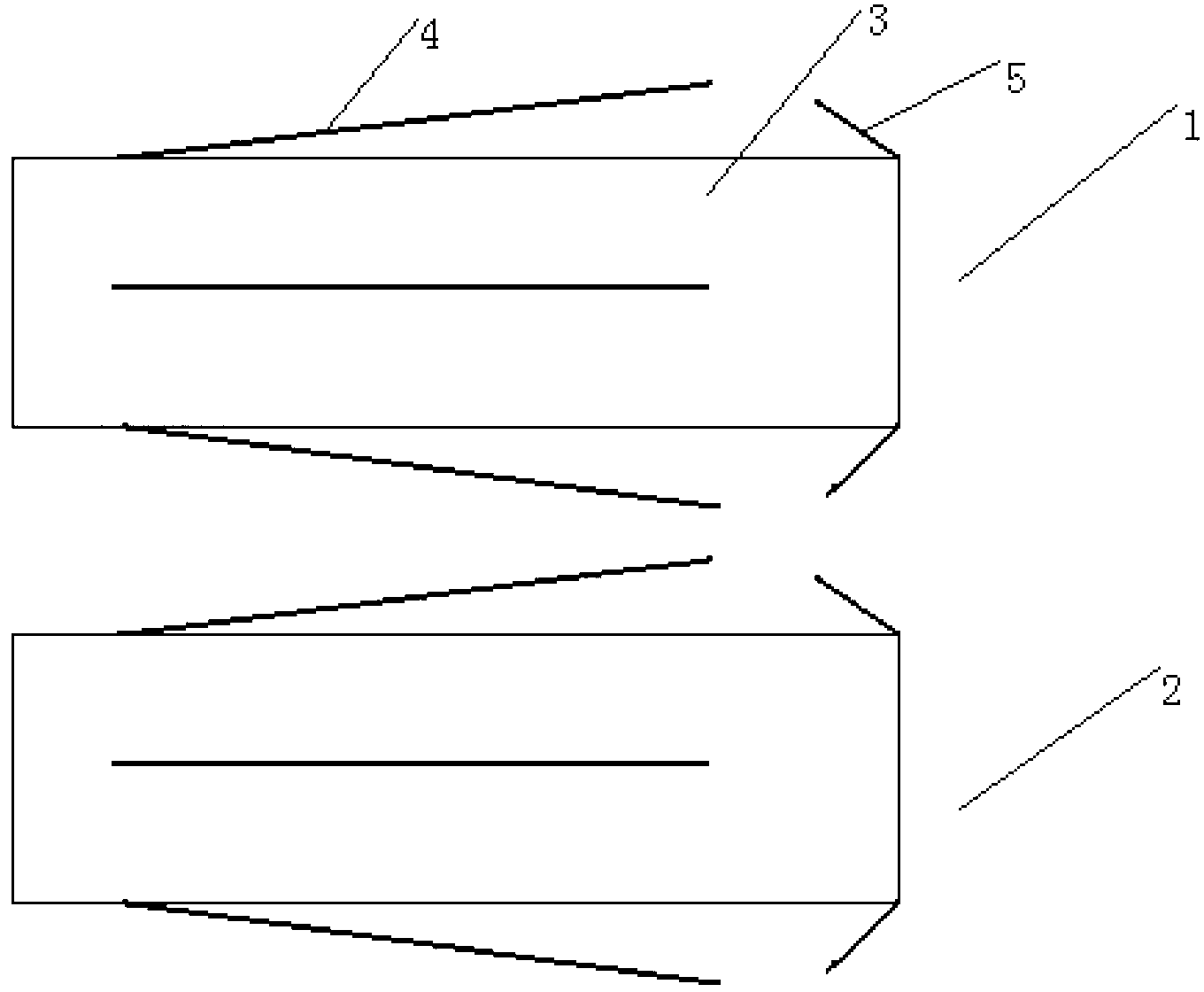

Cantilever umbrella

ActiveUS10932536B2Novel structureIncrease the areaWalking sticksUmbrellasClassical mechanicsShort ribs

A cantilever umbrella including a frame having an upper tray and a lower tray is provided. Two first crossed rods, a transverse rod and a first long rib are articulated to the upper tray. Two second crossed rods and two first short ribs are articulated to the lower tray. One of the two first short ribs is articulated to a middle portion of the transverse rod and the other one is articulated to a middle portion of the first long rib. A middle portion of each second crossed rod is articulated to a middle portion of the first crossed rod on a same side. An end of each first crossed rod is articulated with a short-rib tray which is articulated to a short rib, and an end of each second crossed rod is articulated with a long-rib tray which is articulated to a long rib. The short ribs each has one end articulated to the short-rib tray and another end articulated to a middle portion of one of the long ribs. The upper tray and the two long-rib trays are each disposed with a cap thereon, and a canopy fabric is covered on the long ribs to form three canopies.

Owner:ZHEJIANG DINGSHENG OUTDOOR LIVING PROD CO LTD

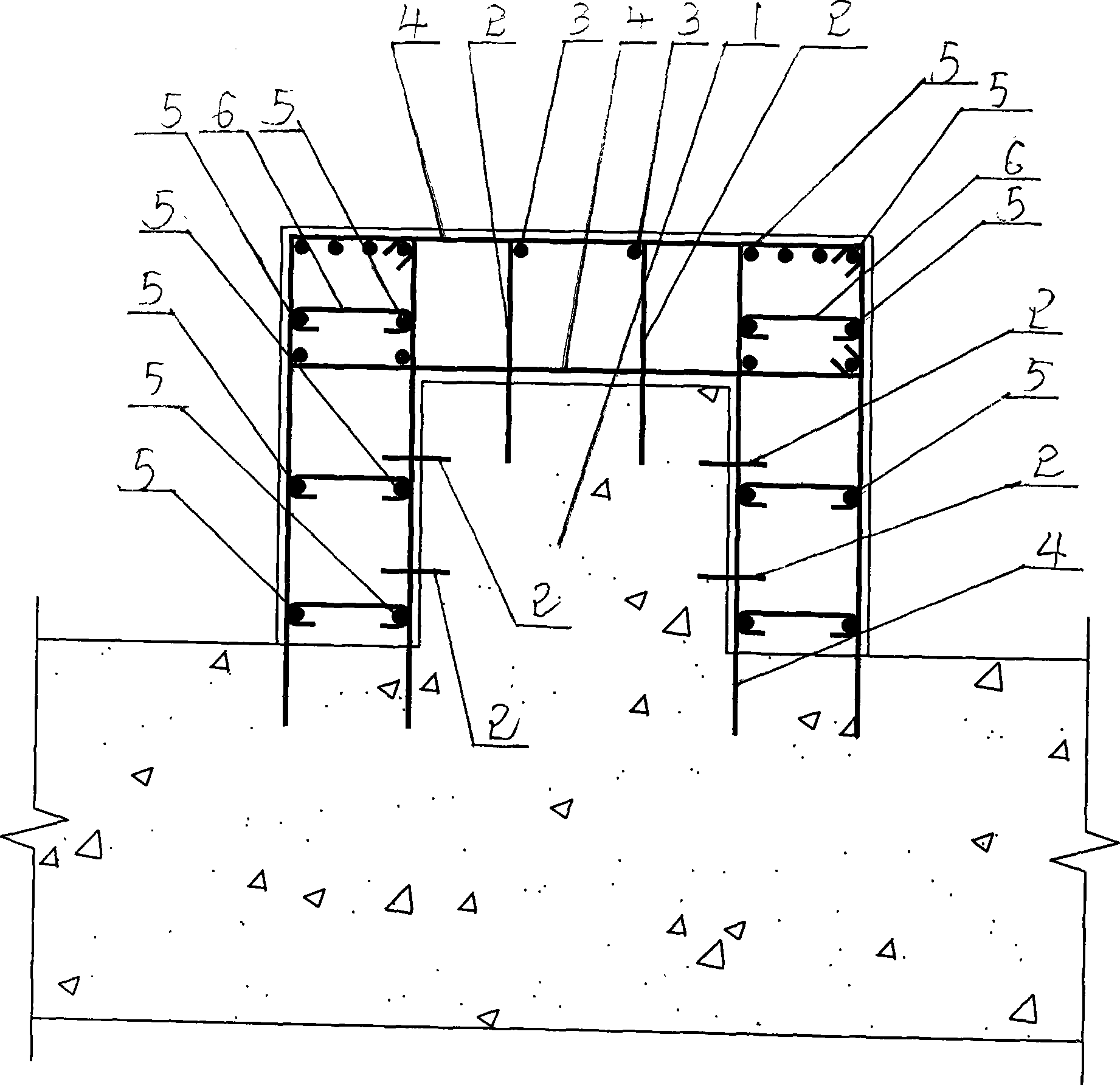

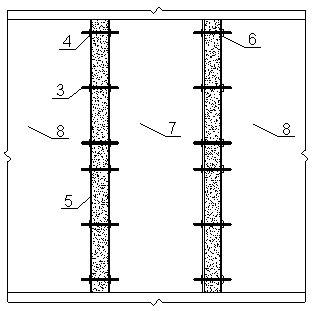

Construction method for reinforcing grade beam

ActiveCN101418574AGuaranteed complete securityGuaranteed continuityFoundation repairEngineeringRebar

The invention relates to a construction method, in particular to a construction method for reinforcing a grade beam, which solves the problem of further reinforcement of a ground foundation after a surface building is heightened in the prior construction method. The construction method for reinforcing the grade beam comprises the following steps: firstly, two main ribs are laid in parallel on the upper side face of a foundation beam and pass through a foundation column which is connected with the foundation beam; secondly, vertical ribs are laid on two outer side faces of the foundation beam; thirdly, short ribs are vertically embedded into the upper side face and the two side faces of the foundation beam, hoop reinforcements are arranged outside the main ribs and the vertical ribs, and both ends of the hoop reinforcements are embedded into a foundation seat of the foundation beam; fourthly, bonding ribs are arranged between adjacent vertical ribs, and the main ribs, the vertical ribs, the short ribs and the hoop reinforcements are bound to form a reinforcing mat; and fifthly, concrete is placed on an external template of the reinforcing mat formed. The construction method mainly has the characteristics that thickening construction treatment is performed on the basis of the prior foundation beam, and a thickened layer is closely connected with the prior foundation beam, so that the loading capacity of the foundation beam is increased and the construction method is suitable for heightening of surface buildings.

Owner:山西太行建设开发有限公司

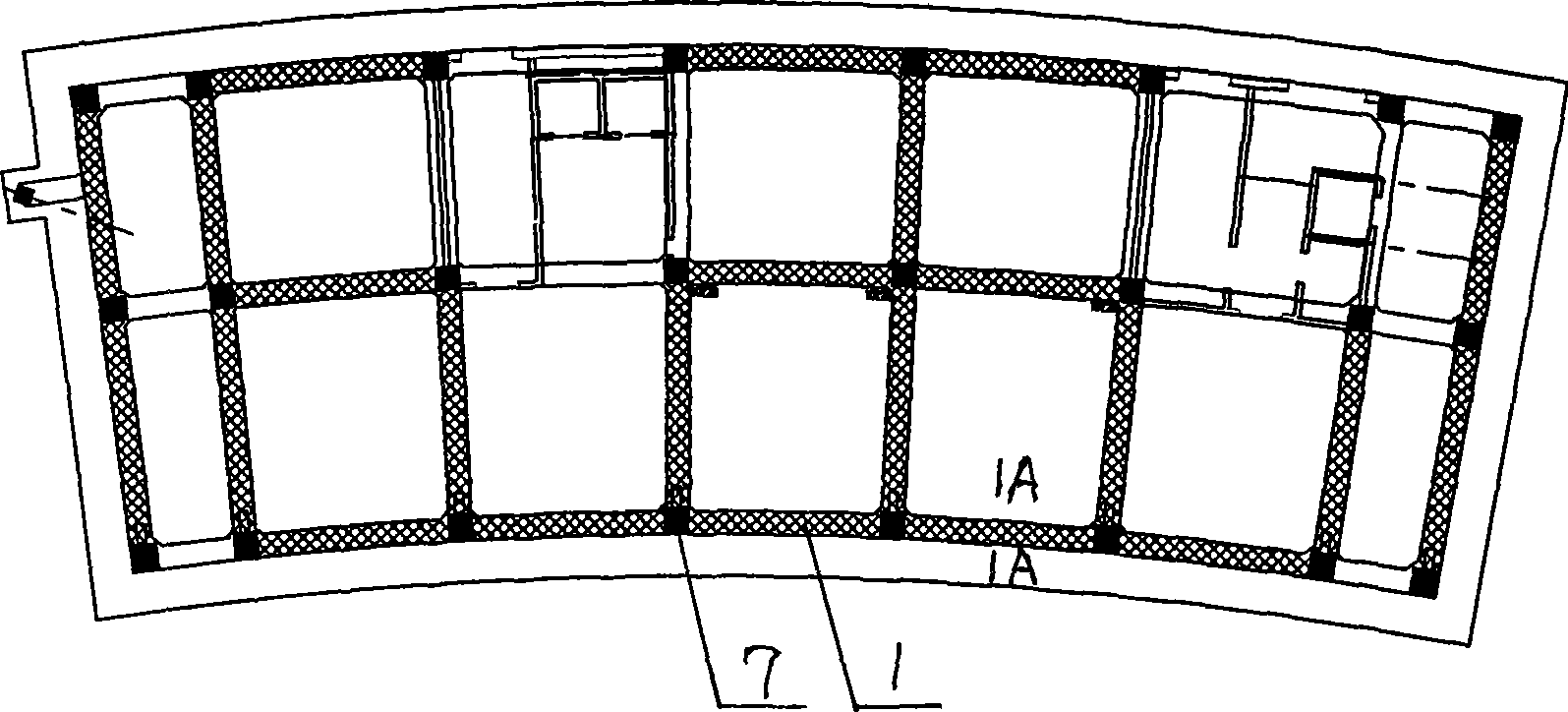

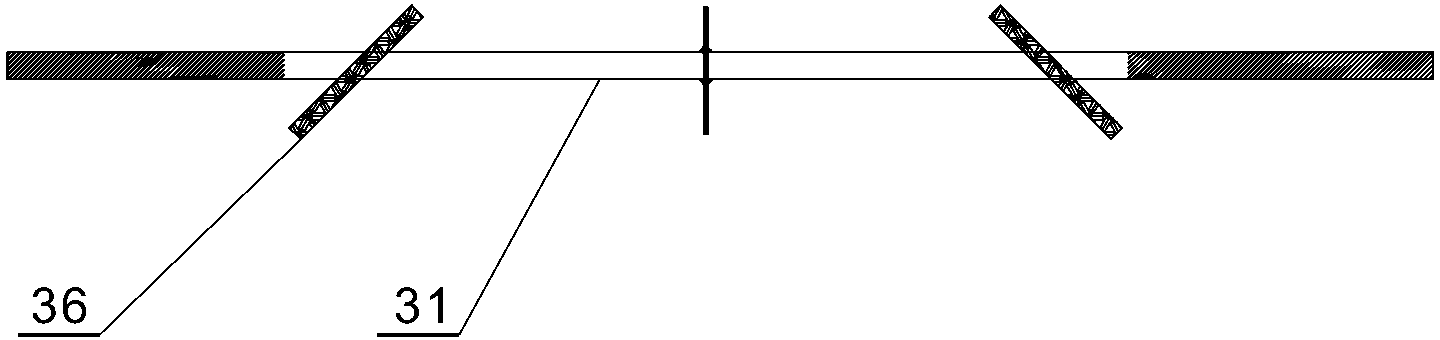

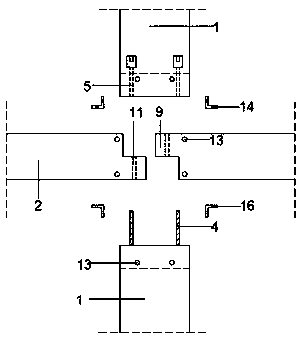

Mould supporting method for trapezoid cross section base of shear wall

InactiveCN103243731AGeometry ControlImproved ability to withstand lateral pressureFoundation engineeringEngineeringShort ribs

The invention discloses a mould supporting method for a trapezoid cross section base of a shear wall. The method adopts a mode that split bolts are fixed with wall plate ribs, support bolts are fixed with base plate ribs and limit short ribs are arranged on the split bolts and the support bolts to determine support mould points of two waist mould plates of the trapezoid cross section base and ensure that the geometrical size of the trapezoid section is controlled. Lateral pressure bearing capability of the waist mould plates is improved by means of reinforcing square columns to prevent deformation and mould expansion. Double-frame pipes, butterfly fasteners and wedge gaskets are adopted to fix the mould plates, the wall plate ribs and the base plate ribs to ensure that the axis of the trapezoid cross section base is not offset in the concrete pouring process.

Owner:CHINA CONSTR SEVENTH ENG DIV SHANGHAI CORP

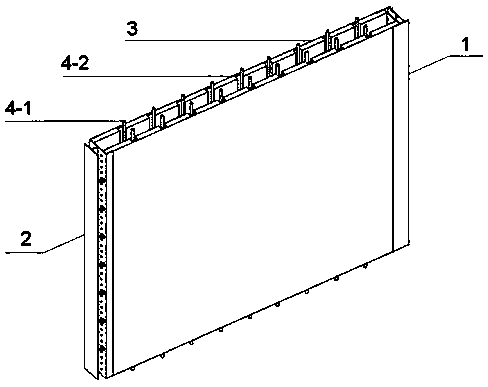

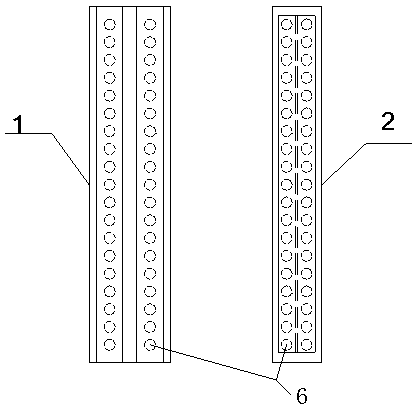

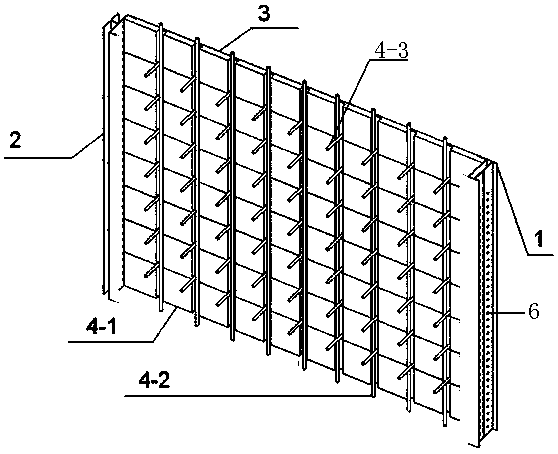

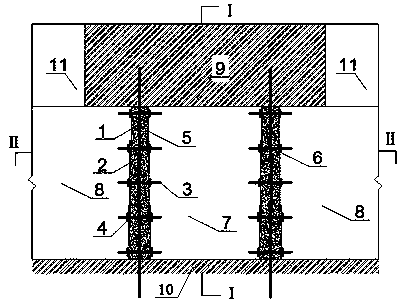

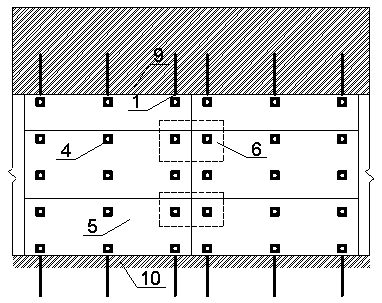

Prefabricated steel structural superposed shear wall and construction method thereof

The invention provides a prefabricated steel structural superposed shear wall and a construction method thereof. According to a prefabricated steel structural superposed shear wall plate, each shear wall comprises two double-faced heat preservation light wall plates; a deep longitudinal groove and a plurality of rows of transverse holes penetrating through the groove are formed in each wall plate;and self-locking components formed by welding a plurality of steel plates are arranged on the left and the right of a wall body, and the wall body can select different chaining lock catches and tailend lock catches according to different joints. The upper, lower, left and right portions of the wall body are all of symmetrical structures, a plurality of rows of transverse penetrating reinforcingsteel bars are arranged in the wall body, longitudinal reinforcing steel bars are connected with the transverse reinforcing steel bars in a lap joint or welded mode, and short bars are welded to the joint points of the transverse reinforcing steel bars and the longitudinal reinforcing steel bars. The construction method of the prefabricated steel structural superposed shear wall comprises the following steps that in-situ wire paying off is conducted, and temporary fixing frames are mounted; the shear wall is assembled and spliced in place, and connected and fixed to the temporary fixing frames; a prefabricated upper layer floor slab is placed in place; hidden beam steel plates and various additional reinforcing steel bars are arranged, and pipelines are arranged; high-fluidity free of vibration concrete is poured; and mounting construction of a next layer is entered in.

Owner:SHENYANG JIANZHU UNIVERSITY

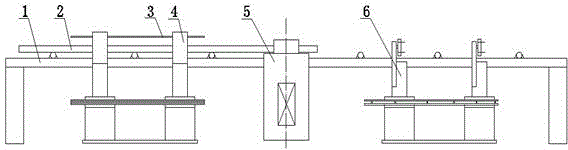

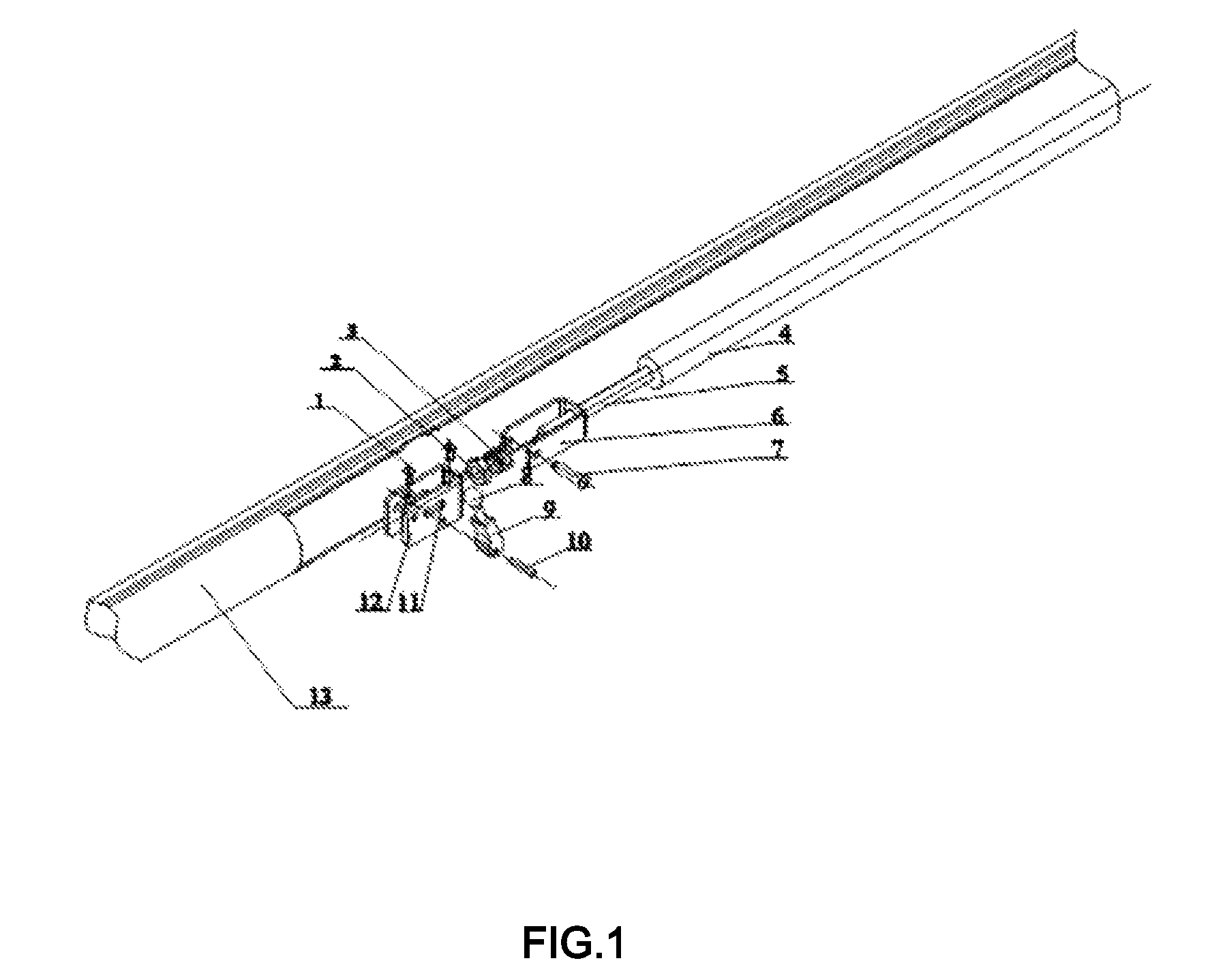

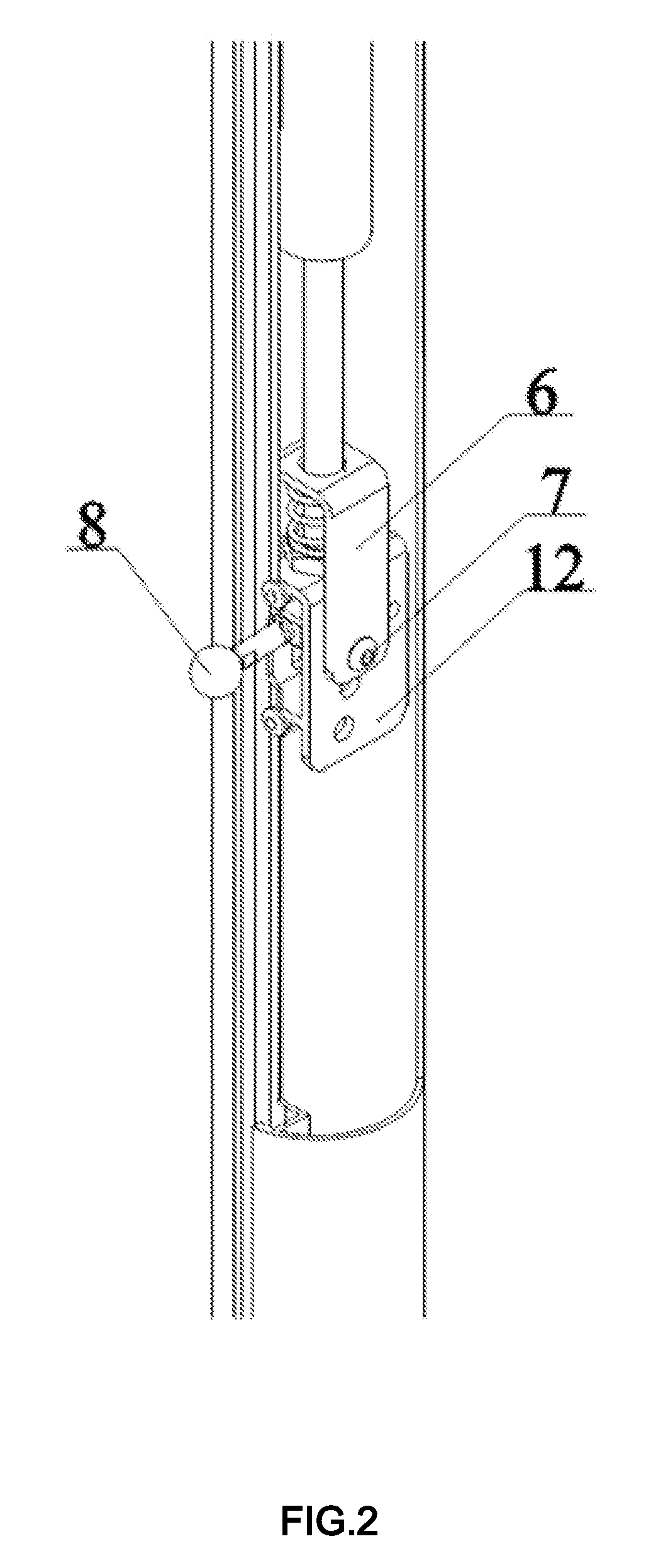

Production welding method for support rebar trapezoid beam of laneway

InactiveCN103949765ALow costImprove welding efficiencyResistance electrode holdersMetal working apparatusAtmospheric pressureRebar

A production welding method for a support rebar trapezoid beam of a laneway is characterized in that round straight rebar long beams are placed in a guide rail by a long beam charging device; round straight rebar short ribs are arranged in a positioning slot of the charging guide rail; the charging guide rail is moved under the action of a servo motor; when a welding point arrives between a left side electrode and a right side electrode, the charging guide rail is stopped, an upside press block compresses the round straight rebar short ribs, and the left side electrode extending from a cylinder at the rear left side and the right side electrode extending from a cylinder at the right side compress two sides of the round straight rebar long beams; when the electrodes are conducted, strong instant current generated between the electrodes at the left and right sides generates resistance heat under the action of the resistance of a rebar, so the welding point is melted to form a melting pool, after the circuit is disconnected and the welding point is cooled and solidified, the cylinders at left and right sides are returned in sequence, and the upside press bock is collected, thus finishing the welding of the round straight rebar short ribs; then the welding of the unwelded round straight rebar short ribs is finished in sequence. The production welding method is simple, the welding quality is reliable and the production efficiency is greatly improved.

Owner:TAIYUAN UNIV OF TECH

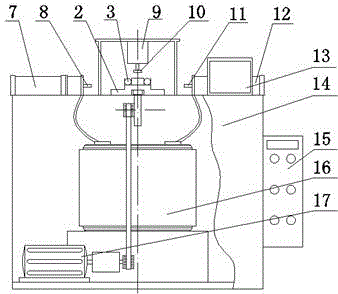

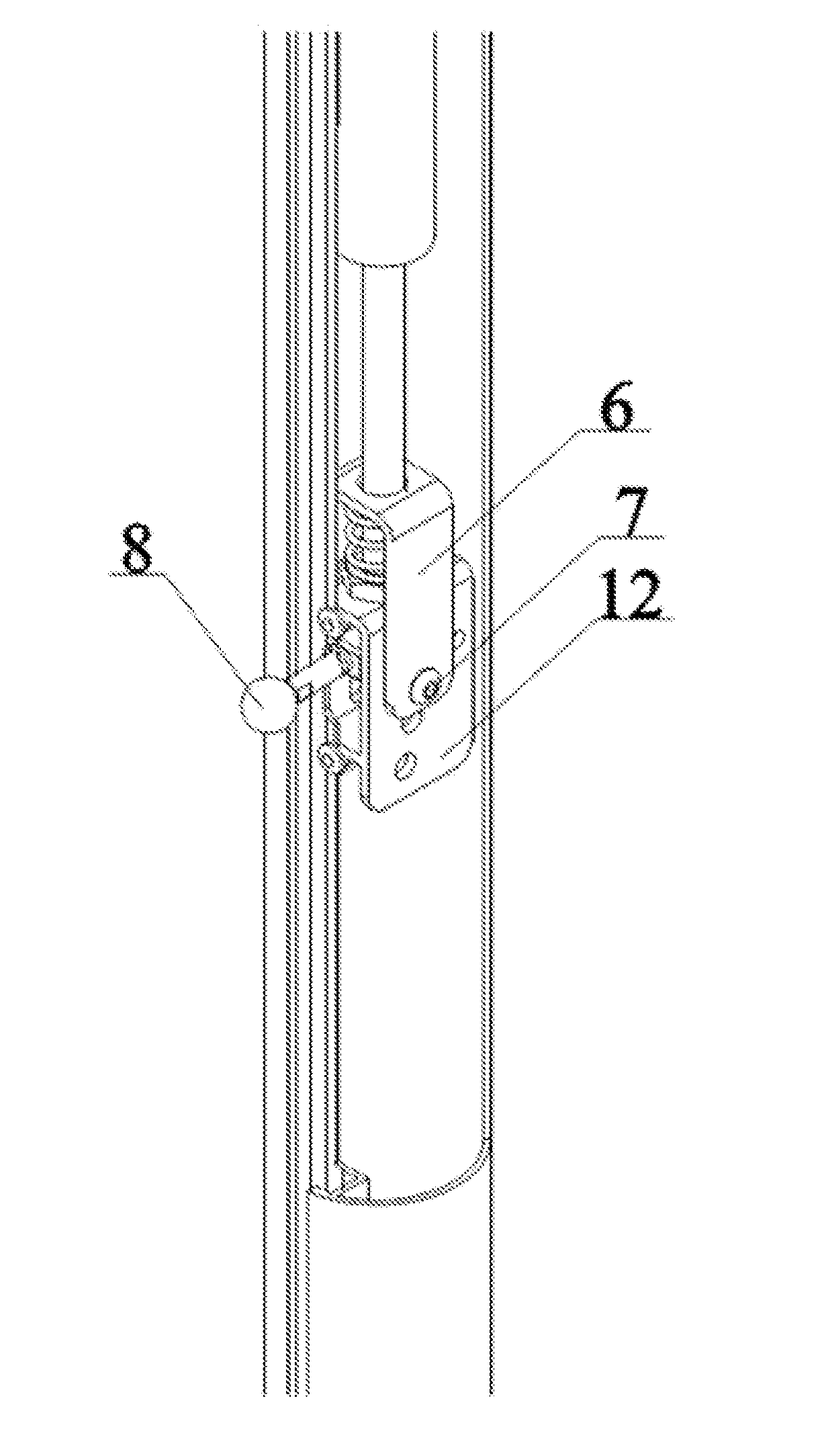

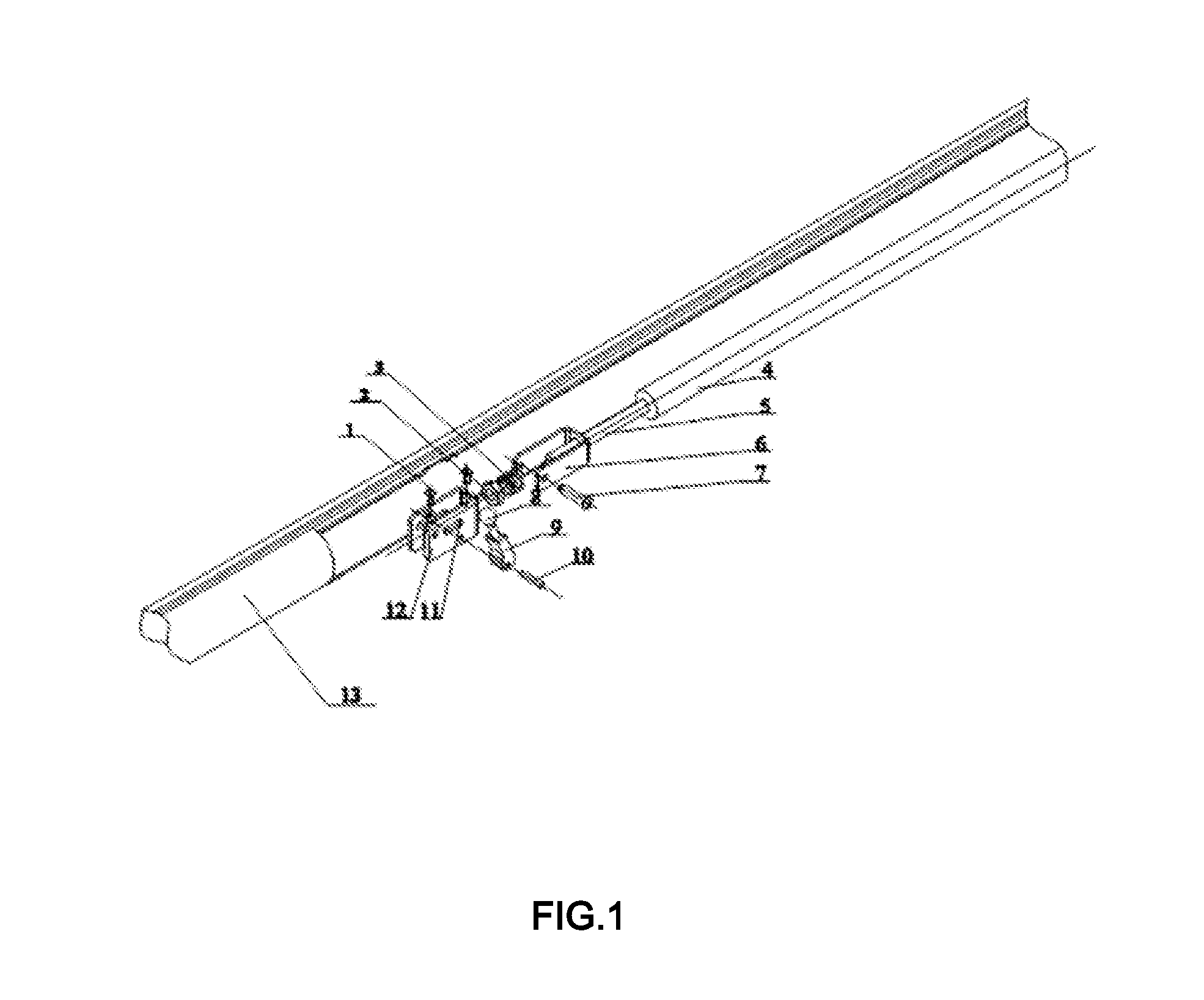

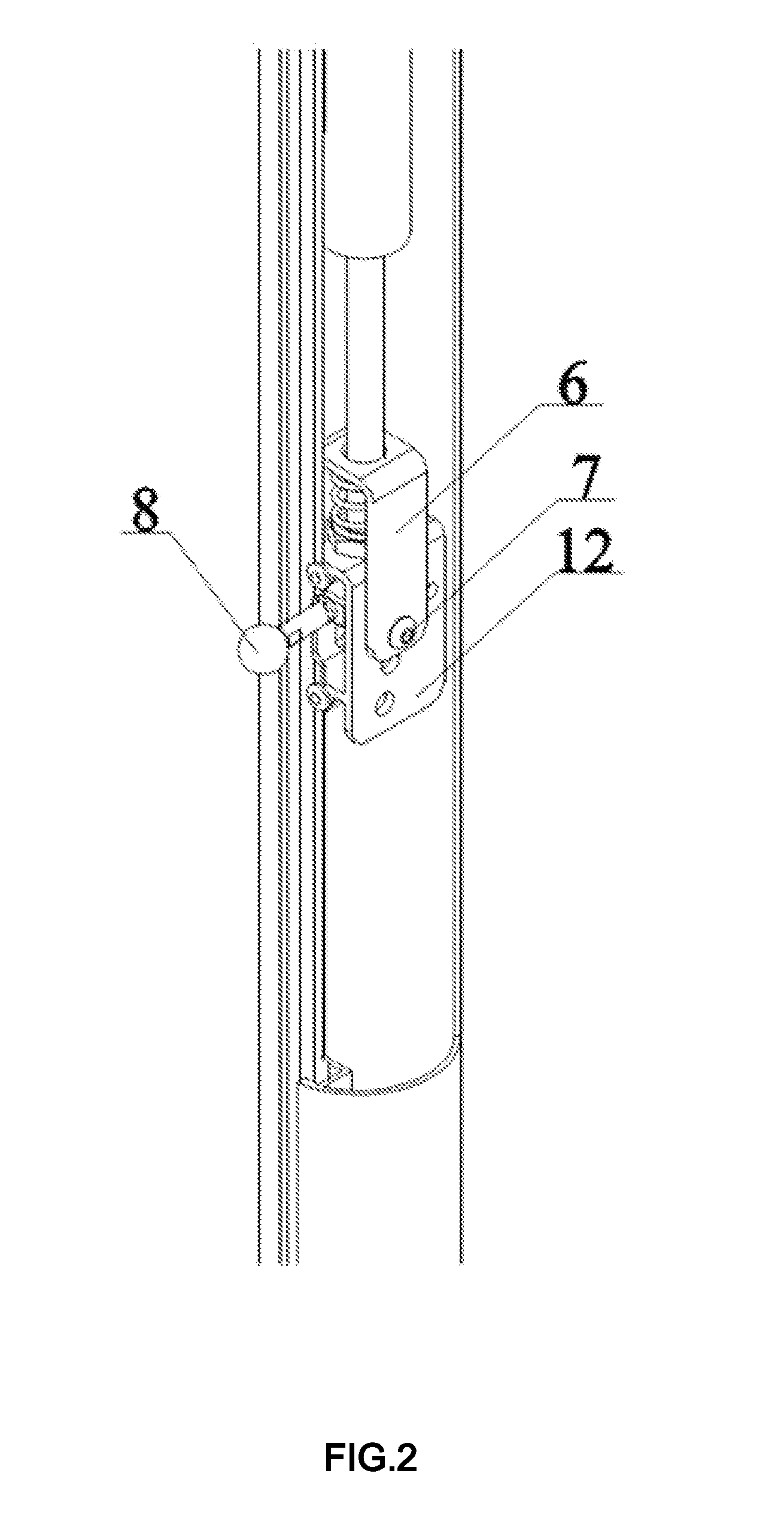

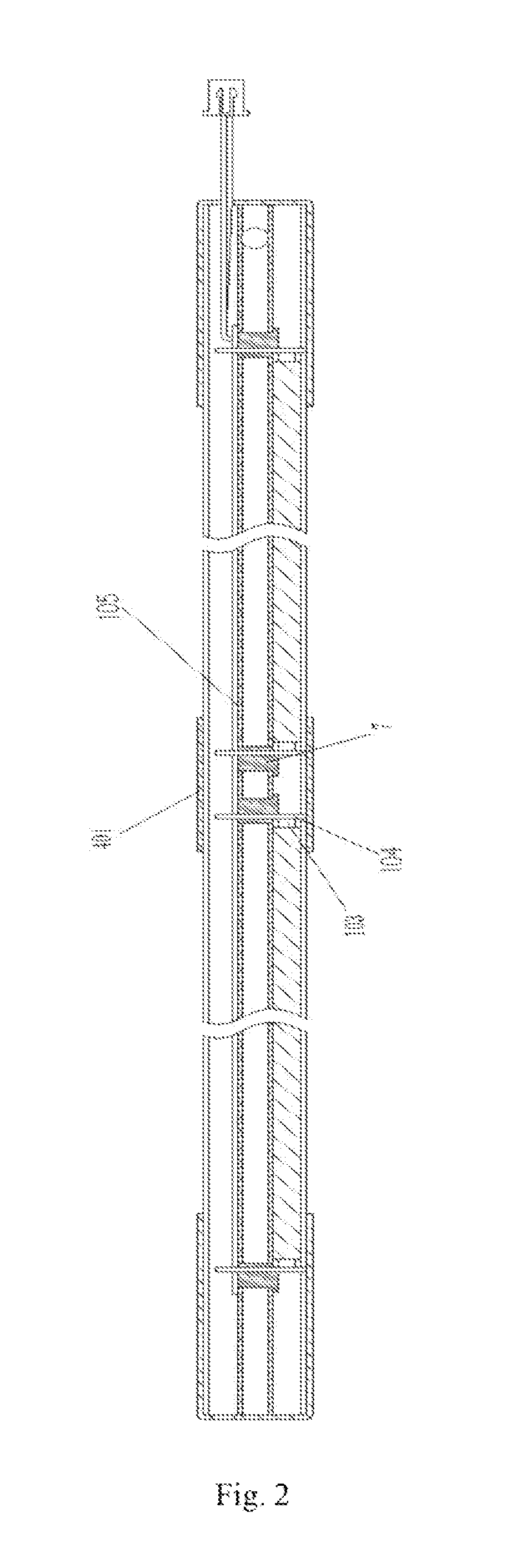

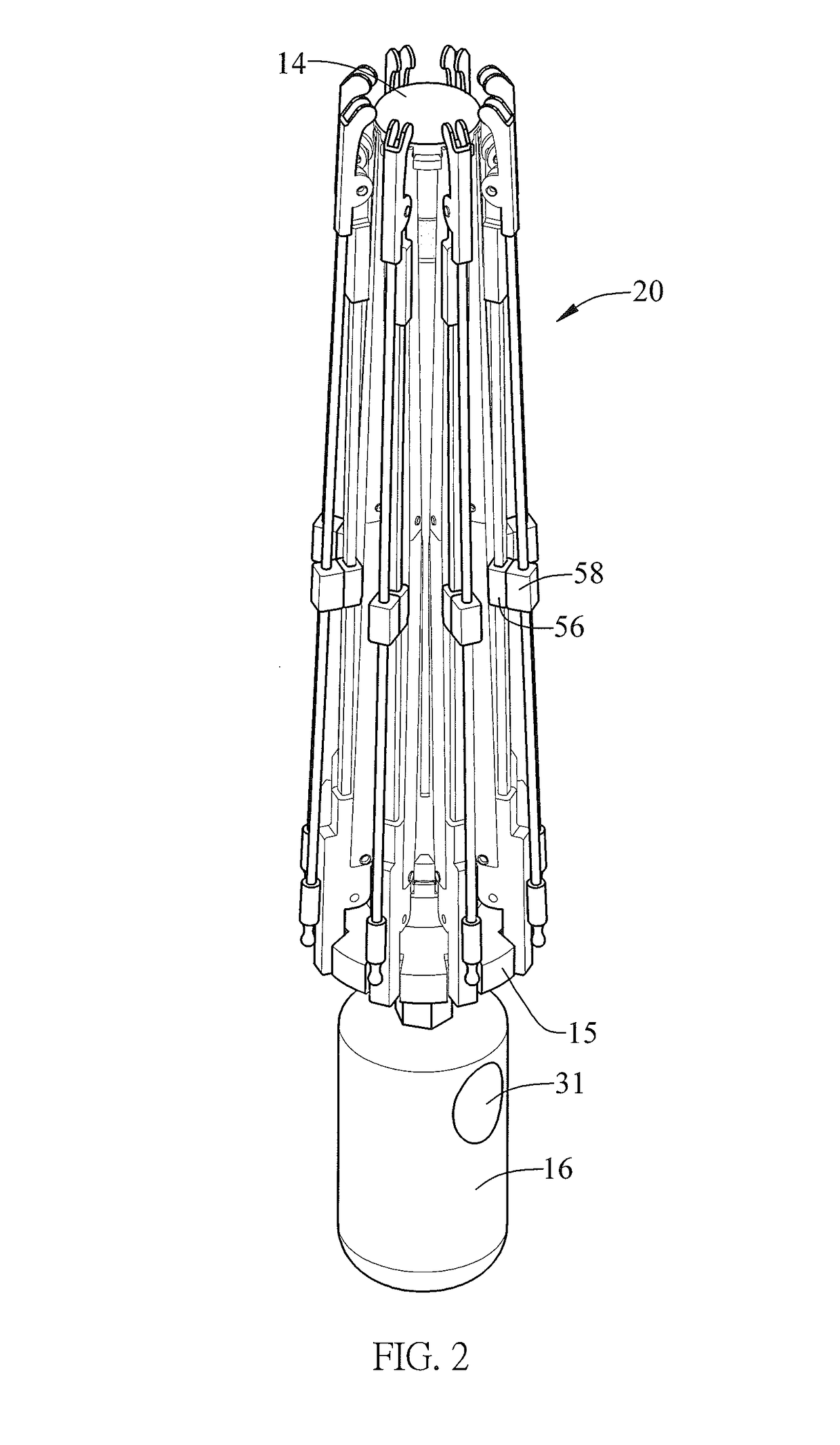

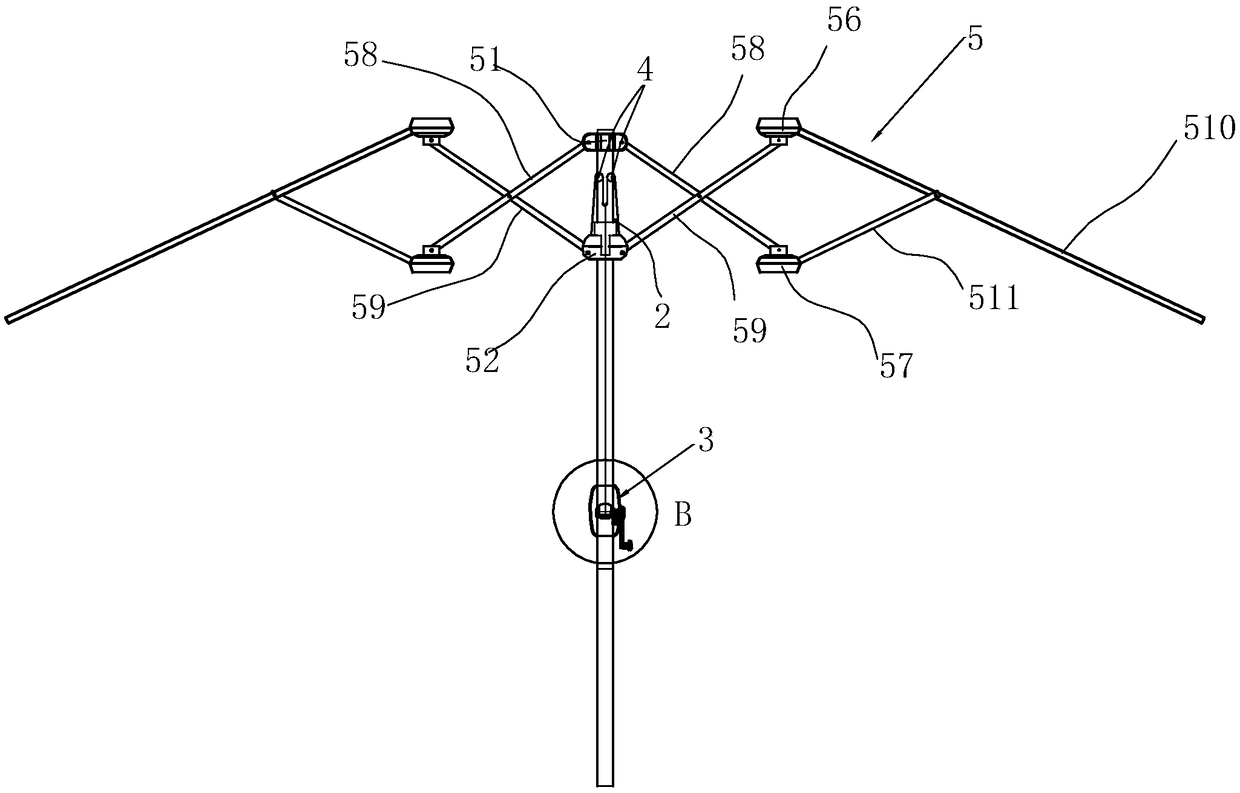

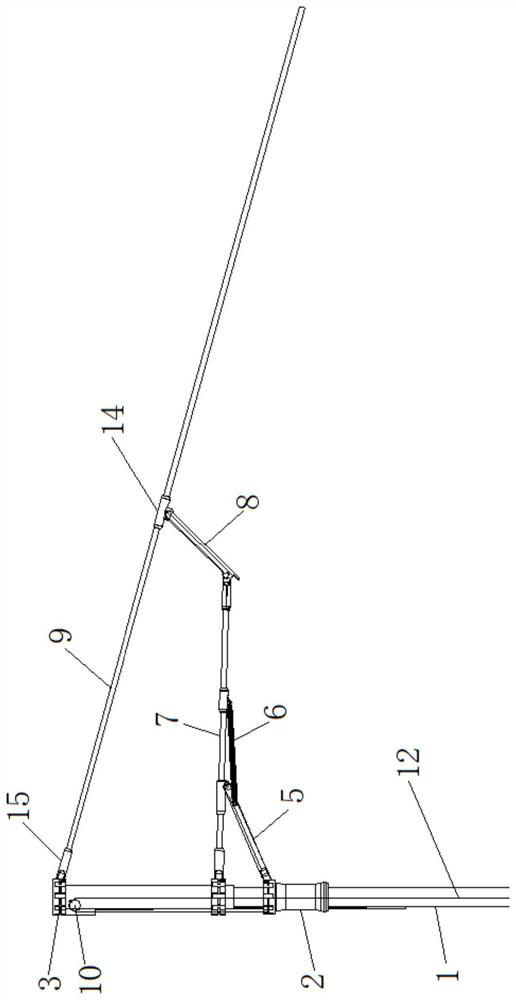

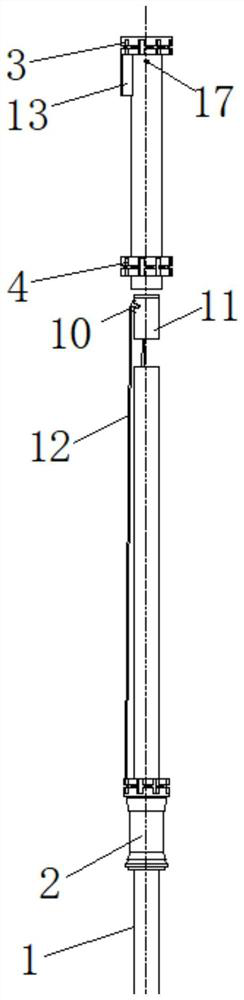

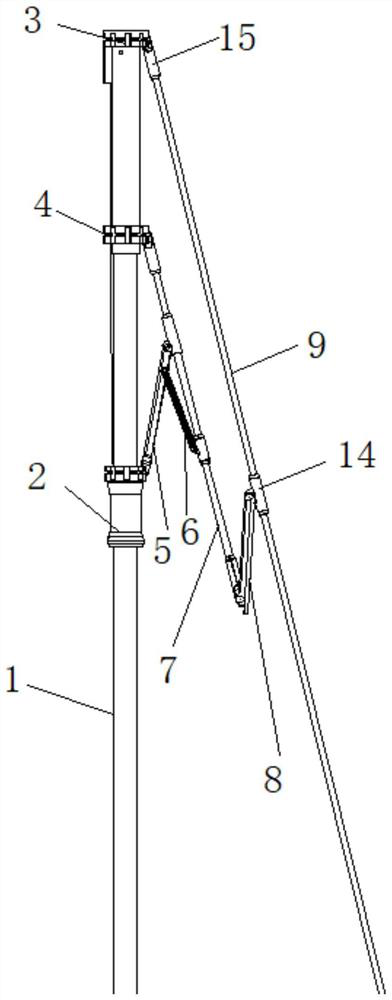

Controllable automatic umbrella unfolding device

A controllable automatic umbrella unfolding device includes an upper runner, a middle runner, a lower runner and a center bar. The upper runner is fixed at the top end of the center bar, the middle runner and the lower runner of the umbrella are movably sleeved on the center bar, the upper runner is connected with long ribs, the long ribs are connected with short ribs, the middle runner is connected with branch ribs, the branch ribs are connected with the short ribs, the short ribs are connected with the lower runner, a gas spring is disposed in the center bar, the tail end of a cylinder barrel of the gas spring is connected with the middle runner of the umbrella, a valve is arranged at the end of a piston rod of the gas spring, and a valve opening device is disposed corresponding to the valve.

Owner:MA ZHUNAN

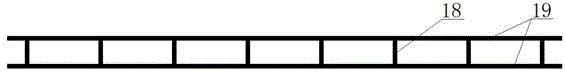

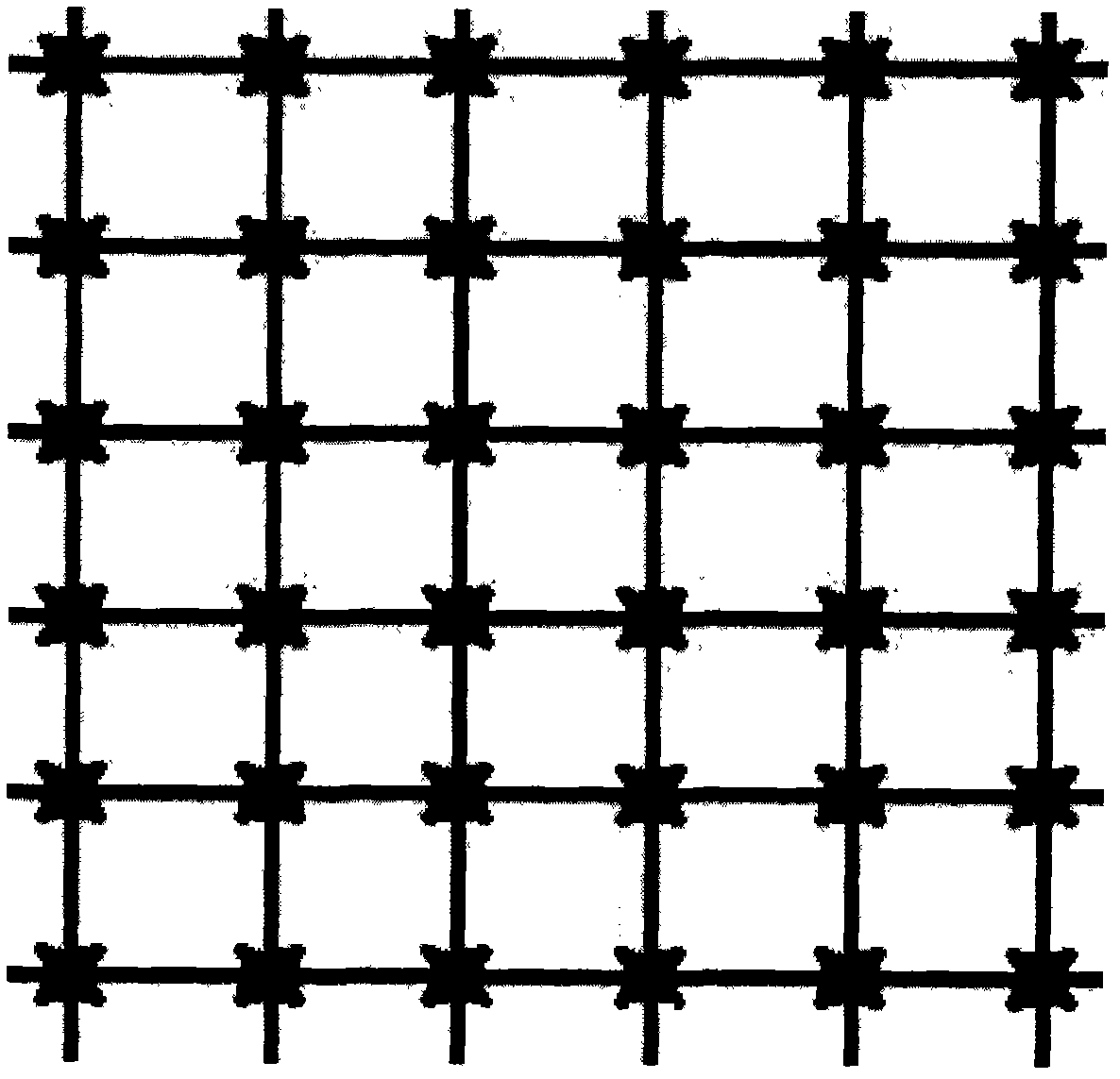

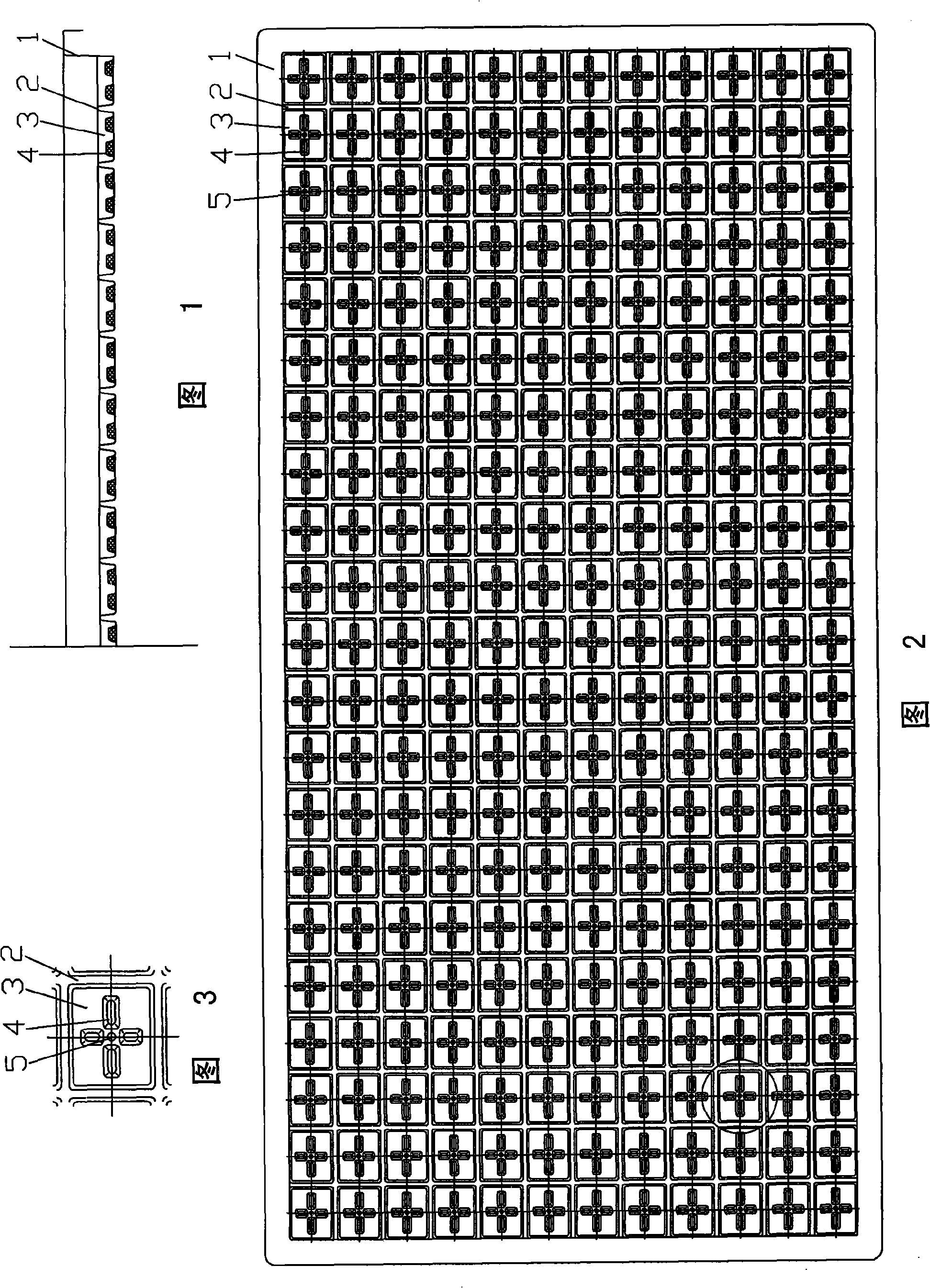

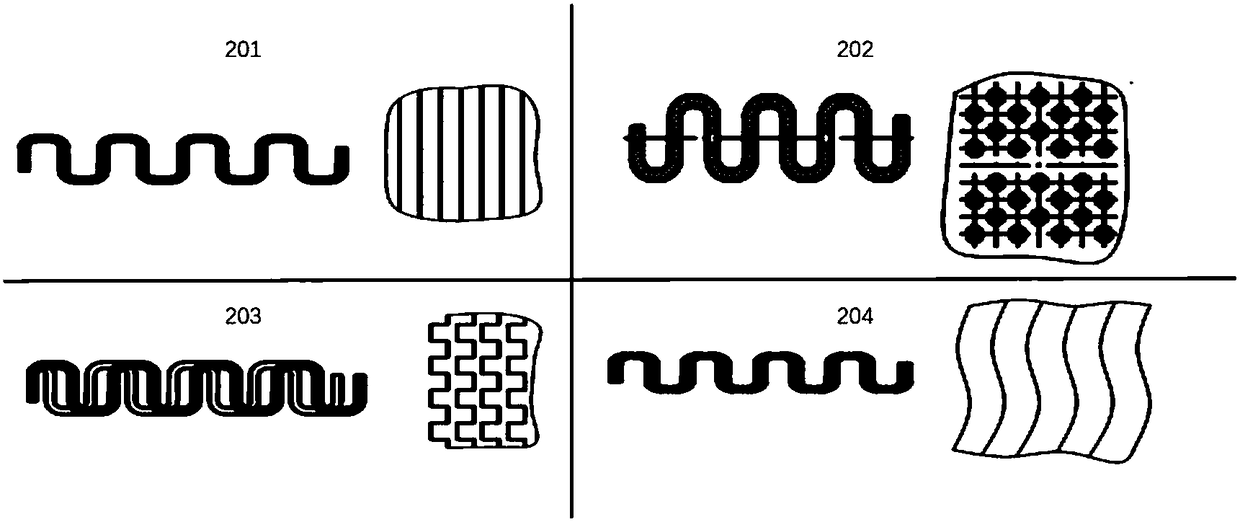

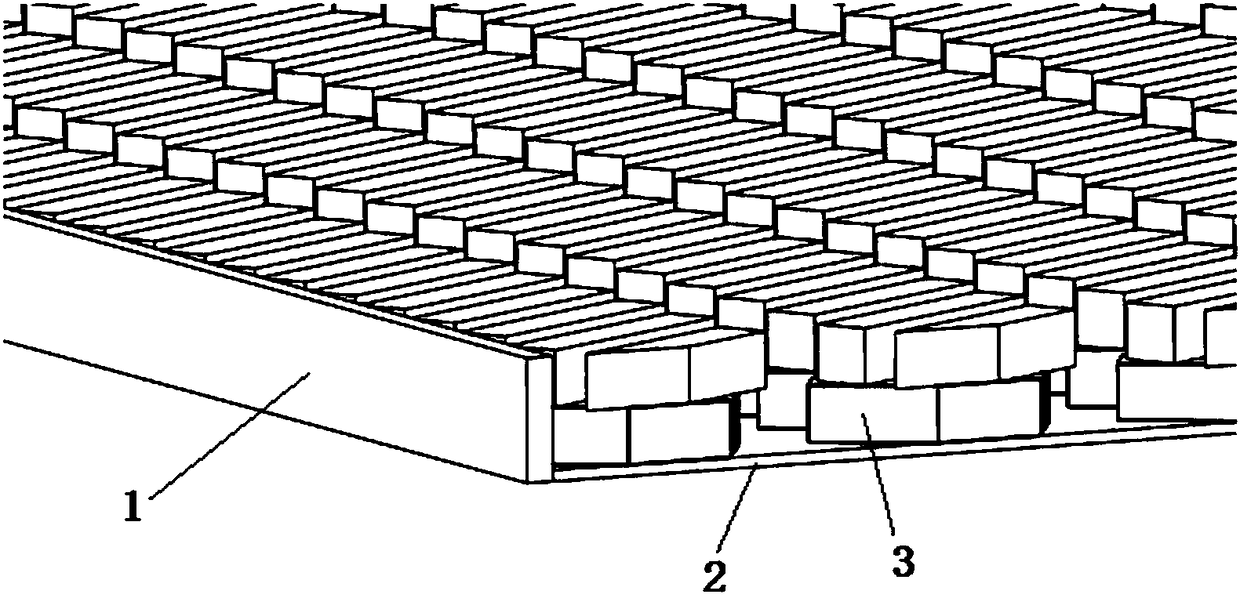

Stinging two-way stretching plastic protective screen and manufacturing method thereof

The invention discloses a stinging two-way stretching plastic protective screen and a manufacturing method thereof. A grating is an integrally formed net-shaped structure, the net-shaped structure comprises a plurality of longitudinal ribs and a plurality of transverse ribs, the longitudinal ribs and the transverse ribs are arrayed alternatively, joints are formed at intersected positions of the longitudinal ribs and the transverse ribs, two short ribs are arranged at each joint, and an included angle between each short rib and the corresponding longitudinal rib and an included angle between each short rib and the corresponding transverse rib are 45 degrees. The stinging two-way stretching plastic protective screen has a warning function, has excellent integral rigidity, and is an excellent safety protection material.

Owner:SHANDONG FEICHENG LIANYI ENG PLASTICS CO LTD

Controllable automatic umbrella unfolding device

The present invention relates to the field of parts of a sunshade umbrella, in particular to a controllable automatic umbrella unfolding device, which comprises an upper runner, a middle runner, a lower runner and a center bar. The upper runner of the umbrella is fixed at the top end of the center bar, the middle runner and the lower runner of the umbrella are movably sleeved on the center bar, the upper runner is connected with long ribs, the long ribs are connected with short ribs, the middle runner is connected with branch ribs, the branch ribs are connected with the short ribs, the short ribs are connected with the lower runner, a gas spring is disposed in the center bar, the tail end of a cylinder barrel of the gas spring is connected with the middle runner of the umbrella, a valve is arranged at the end of a piston rod of the gas spring, and a valve opening device is disposed corresponding to the valve. The automatic umbrella unfolding device has the beneficial effects of: automatic umbrella unfolding, controllable stroke, simple structure, very few components and relatively low cost.

Owner:MA ZHUNAN

Pre-separating seedling plate

The invention relates to a pre-partition seedling tray used for raising rice seedling, belonging to the technical field of agricultural seedling raising implements. A tray bottom of a tray body of the seedling tray is separated into a rectangular tray lattice array by interlaced long ribs, the interior of the tray lattice is divided into matts by four short ribs which are distributed in a cross shape, the four short ribs are not connected with each other and also are not connected with the long ribs at the periphery of the tray lattice, the height of the long ribs is higher than that of the four short ribs, and a water permeable hole is arranged on the part of the tray bottom at the center of the cross shape corresponding to the four short ribs. When seedling is taken, seedling blocks with uniform size and regular shape are easy to be formed in virtue of seedling needles, thus satisfying the requirements of mechanized plantation of super rice. Furthermore, the long ribs and the short ribs are reasonably arranged, so as to not only solve the problem of accurately seedling taking, but also form a water homogenizing structure which can keep the moisture content in each tray lattice at an ideal state, thus being beneficial to avoiding the root rot of rice seedling and water and fertilizer loss, and guaranteeing the normal growth of rice seedling.

Owner:江苏省农业机械技术推广站

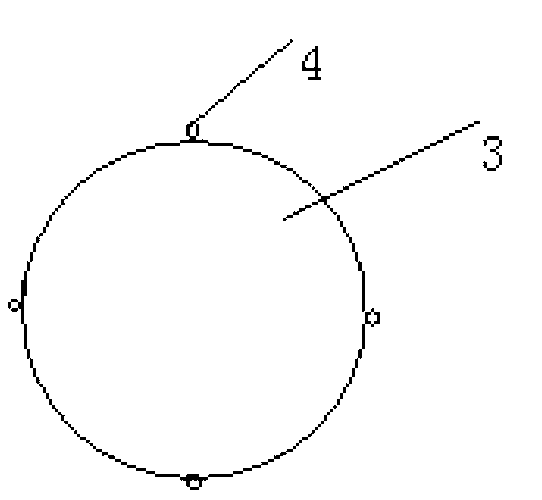

Lighting umbrella

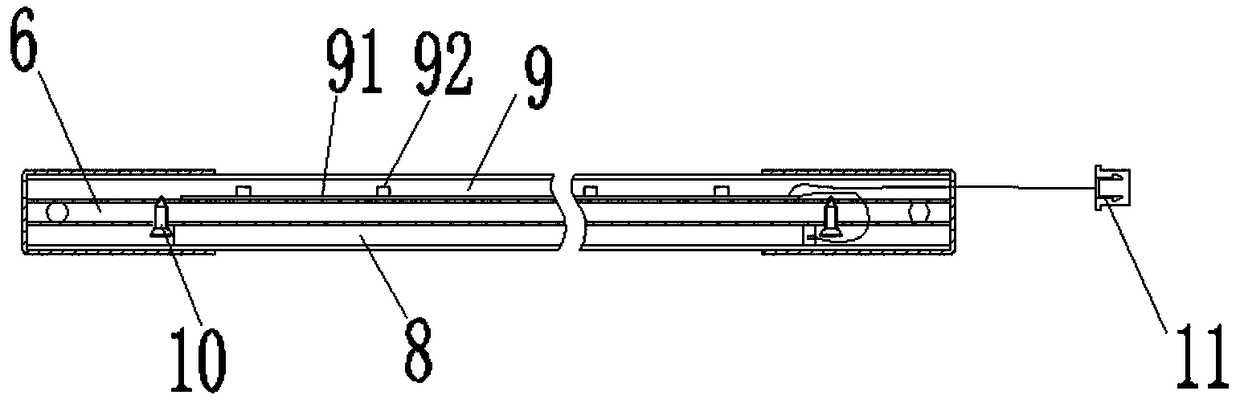

ActiveUS9408444B2Avoid low lightMore convenientMechanical apparatusPoint-like light sourceLight guideEngineering

A novel lighting umbrella, comprising a lower hub (2) and an upper hub (6) secured on the top of a shaft (3), one end of each of long ribs (4) being articulated with the upper hub (6) while the other end thereof supporting a panel, one end of each of short ribs (1) being articulated with the lower hub (2) while the other end thereof being articulated with the middle portion of one of the long ribs (4), characterized in that a notch (101) having a light emitting device therein is formed in one or both of the long ribs (4) and the short ribs (1); the light emitting device comprises a light guide bar (14) clamped inside the notch (101) and provided with a light source on its end surface; and the light source is secured on a fixed base (7) that is fixedly connected to the ribs and sleeved with a stopper (8) for protection.

Owner:LINHAI ZHONGTIAN ELECTRONICS APPLIANCE CO LTD

Sample plate positioning detecting method for Airbus complicated titanium alloy forged pieces

InactiveCN104848770AGuaranteed product needsImprove detection accuracyMechanical counters/curvatures measurementsScriberTitanium alloy

The invention relates to the technical field of complicated forged piece detection, and particularly to the field of auxiliary detection for complicated special forged pieces. Through a method of directly finding a dead center through a positioning sample plate, oblique-surface positioning, directly scratching the center of the upper part of the forged piece according to the central position of the sample plate by a scriber, positioning the inside of a rib at the lower part of the forged piece by the oblique surface, and directly scratching the center of the lower part of the forged piece according to the central position of the sample plate by the scriber, the effect of polishing and rib material shortage to detection of the forged piece maximally. Then leveling through two centers on the forged piece is performed for performing line scratching and positioning, thereby supplying an accurate reference for subsequent machining and detection. In final checking, a reference central hole after rough machining and a reference central line in line scratching are used for determining a method for checking the sample plate in a segmented manufacture manner. A large arc and two short ribs of the upper part in a same plane are arranged in one sample plate. Two high ribs are respectively checked by the other sample plate, thereby realizing a good use effect. The sample plate positioning detecting method has functions of improving detecting precision and efficiency for the forged piece, and ensuring high product quality.

Owner:SHAANXI HONGYUAN AVIATION FORGING

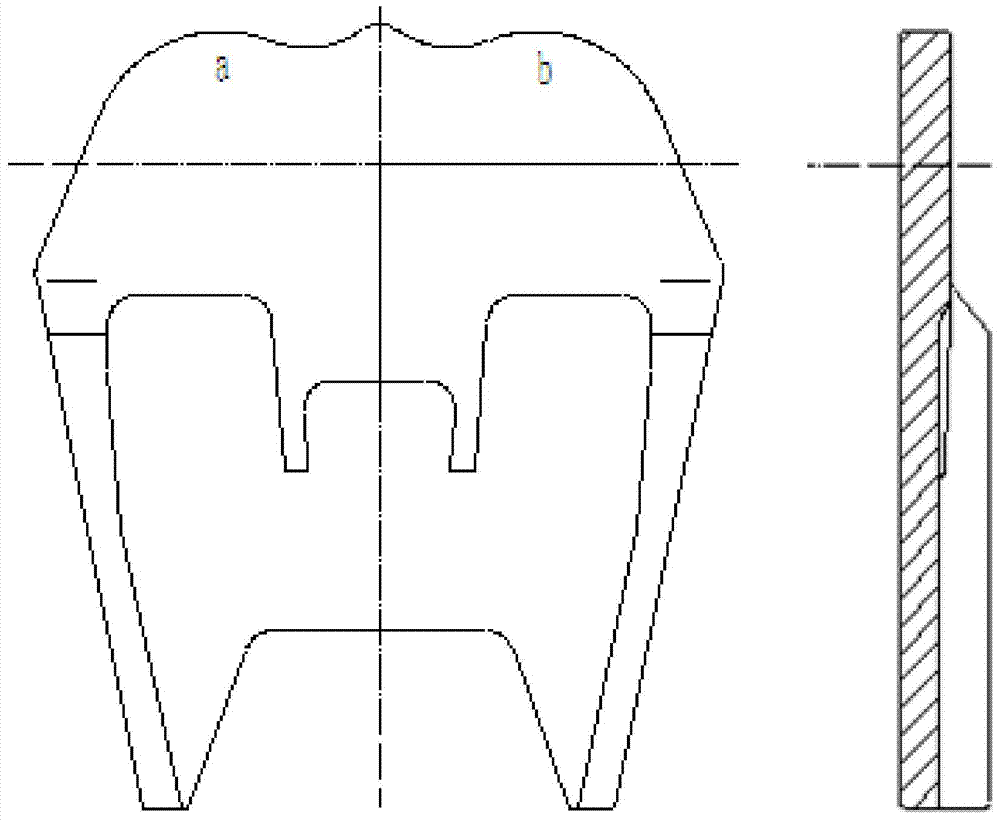

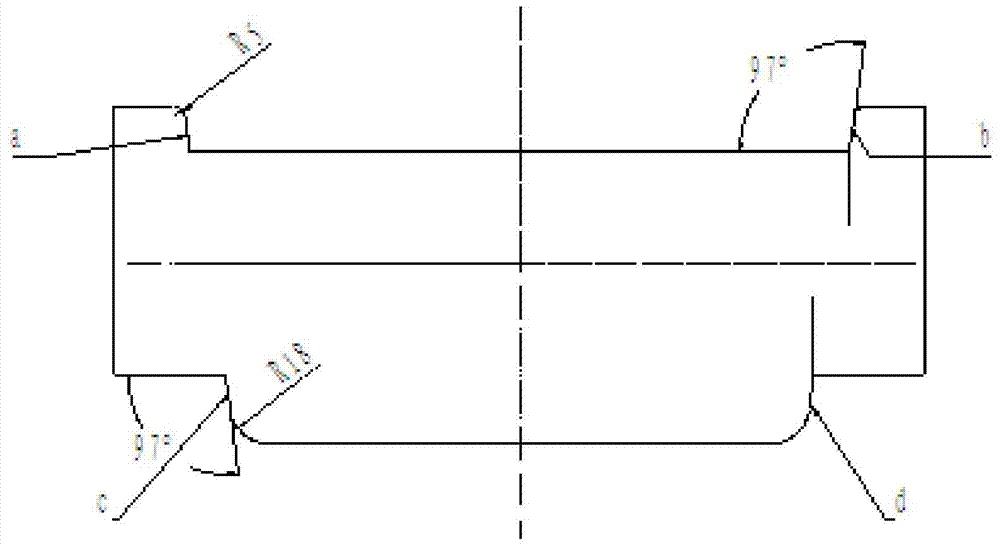

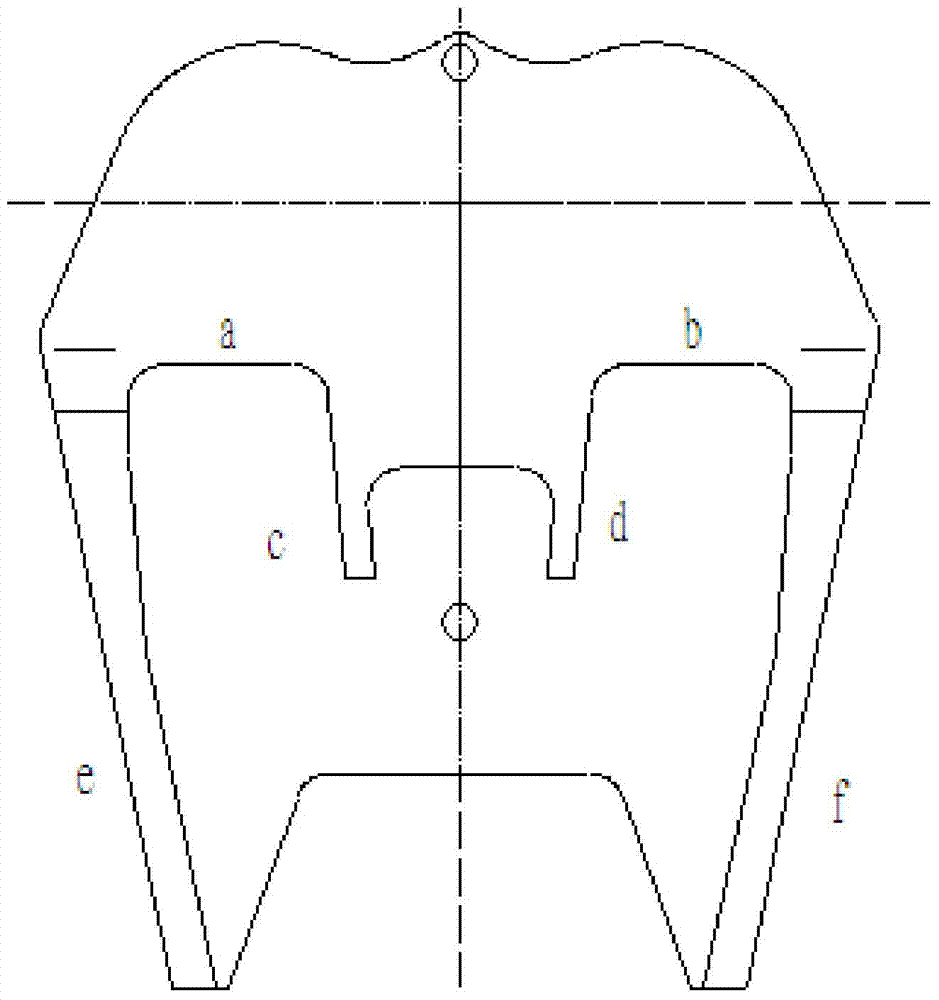

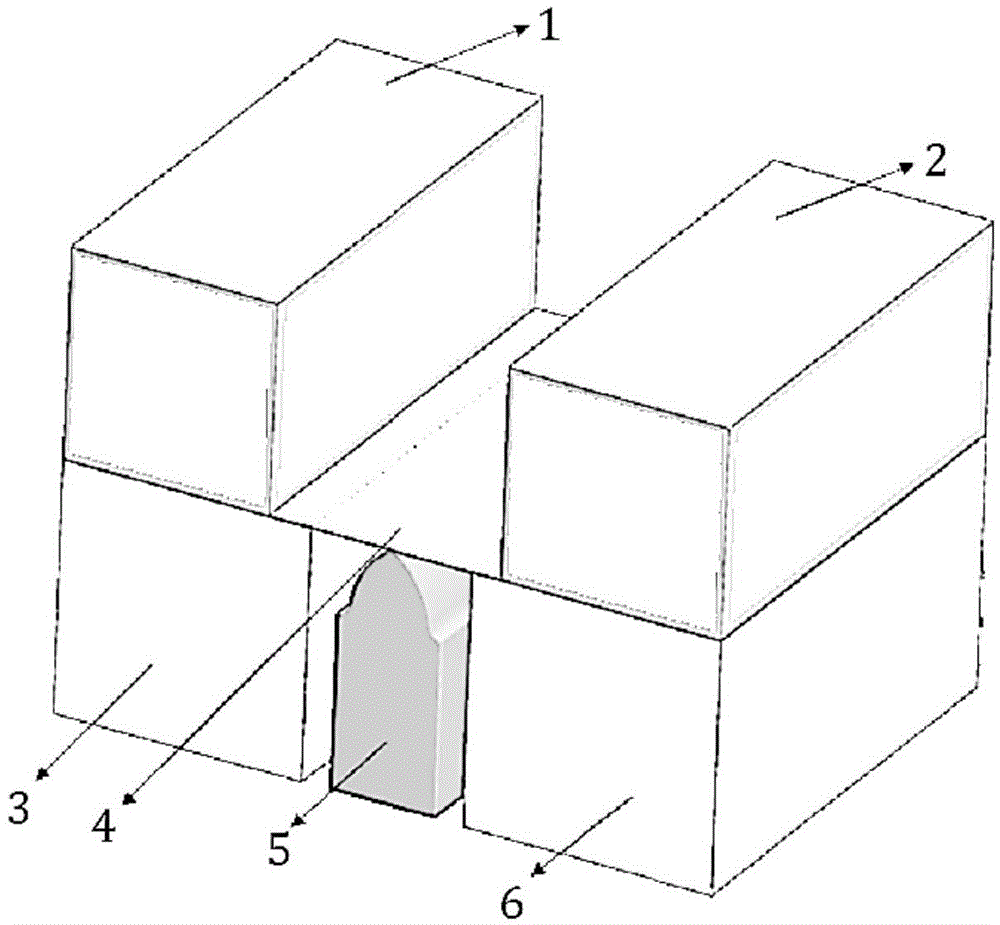

Composite bending and forming process for non-equal-height cross-shaped rib type pieces

ActiveCN104646466AAvoid severe thinningNo severe localized thinningShaping toolsMetal-working feeding devicesEngineeringShort ribs

The invention provides a composite bending and forming process for non-equal-height cross-shaped rib type pieces. The composite bending and forming process comprises the following steps: sequentially carrying out high rib formation and then carrying out short rib formation. A cross-shaped rib crossed region is prevented from being thinned by two steps of the process in sequence. High and short ribs and the crossed region are formed by the matched movement of different slide blocks, an ejection block, a convex die and a concave die, so that the disadvantages caused by the fact that a traditional plastic forming process is used for the non-equal-height cross-shaped rib type pieces can be effectively solved, and the forming force is smaller and the service life of the die is long.

Owner:SHANGHAI JIAO TONG UNIV

Delicious beef and preparation method thereof

The invention relates to preparation methods of foods and in particular relates to delicious beef and a preparation method thereof. The preparation method comprises the following steps: soaking beef short ribs, cutting into blocks, frying the blocks in a frying pan together with spices, green onion sections, fresh ginger and garlic, continuously pouring dry red wine, yellow wine, white wine, rice wine, beer, seafood sauce and broad bean paste, stir-frying for 4-6 minutes, adding a proper amount of water, and braising with low flame for a period of time to obtain the delicious beef. The preparation method is simple. The prepared beef is transparent and rosy and is rich in fragrance, attractive in color and delicious in taste; the sliced beef is relatively complete; the fragrances of the wine, the seafood, the sauce and the spices are fully fused in the beef; the beef is fragrant in taste and tender in mouth feel and is a dish suitable for people of all ages.

Owner:陈勇

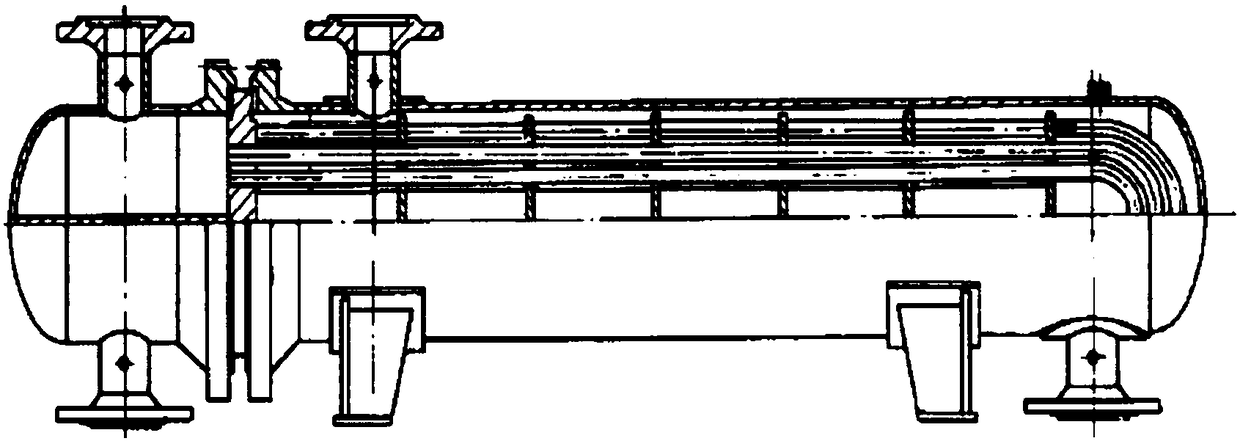

Dot-matrix type core based on bionics of tiny staggered alveolar heat exchanger and heat exchanger

PendingCN108548436AIncrease the degree of blendingImprove performanceHeat exchanger casingsStationary tubular conduit assembliesDot matrixEngineering

The invention discloses a dot-matrix type core based on bionics of a tiny staggered alveolar heat exchanger. The core comprises a shell, the inner part of the core is divided into two layers by a heatexchange plate, a plurality of layers of dot-matrix type rib strip combinations are arranged in each layer of cavities, each layer of the dot-matrix type rib strip combinations is composed of a plurality of columns of discontinuous ribs facing the same direction, and each column of the discontinuous ribs is formed by arranging a plurality of same short ribs in a dashed mode. The facing directionsof every two adjacent layers of the discontinuous ribs are not aligned, the short ribs of every two adjacent layers have contact points, and each layer of the short ribs are supported and fixed by the short ribs of the adjacent layer in contact with corresponding layer of the short ribs. Bionic elements are integrated into the design of the heat exchanger to design the tiny staggered alveolar heat exchanger, the structure improves the performance of the heat exchanger from two aspects including the heat transfer coefficient and the heat transfer area, the structure is light and simple and convenient, and the core is suitable for an aerospace heat exchanger.

Owner:陕西益信伟创智能科技有限公司

Umbrella

An umbrella includes a shaft, a cap connected to the shaft, a runner movable on the shaft, long and short ribs, a controller unit and rib-collapsing units. The runner includes recesses. Each of the long ribs includes upper, middle and lower sections. The short ribs connect the upper sections of the long ribs to the runner. The controller unit is operable to allow the long ribs to stretch and collapse. Each of the rib-collapsing units includes a cap magnet connected to the cap, a runner magnet inserted in a corresponding one of the recesses and two middle-section magnets. The first middle-section magnet is connected to the middle section of a corresponding one of the long ribs and adapted for attraction to the cap magnet. The second middle-section magnet is connected to the middle section of a corresponding one of the long ribs and adapted for attraction to the runner magnet.

Owner:CHO CHIN HSING

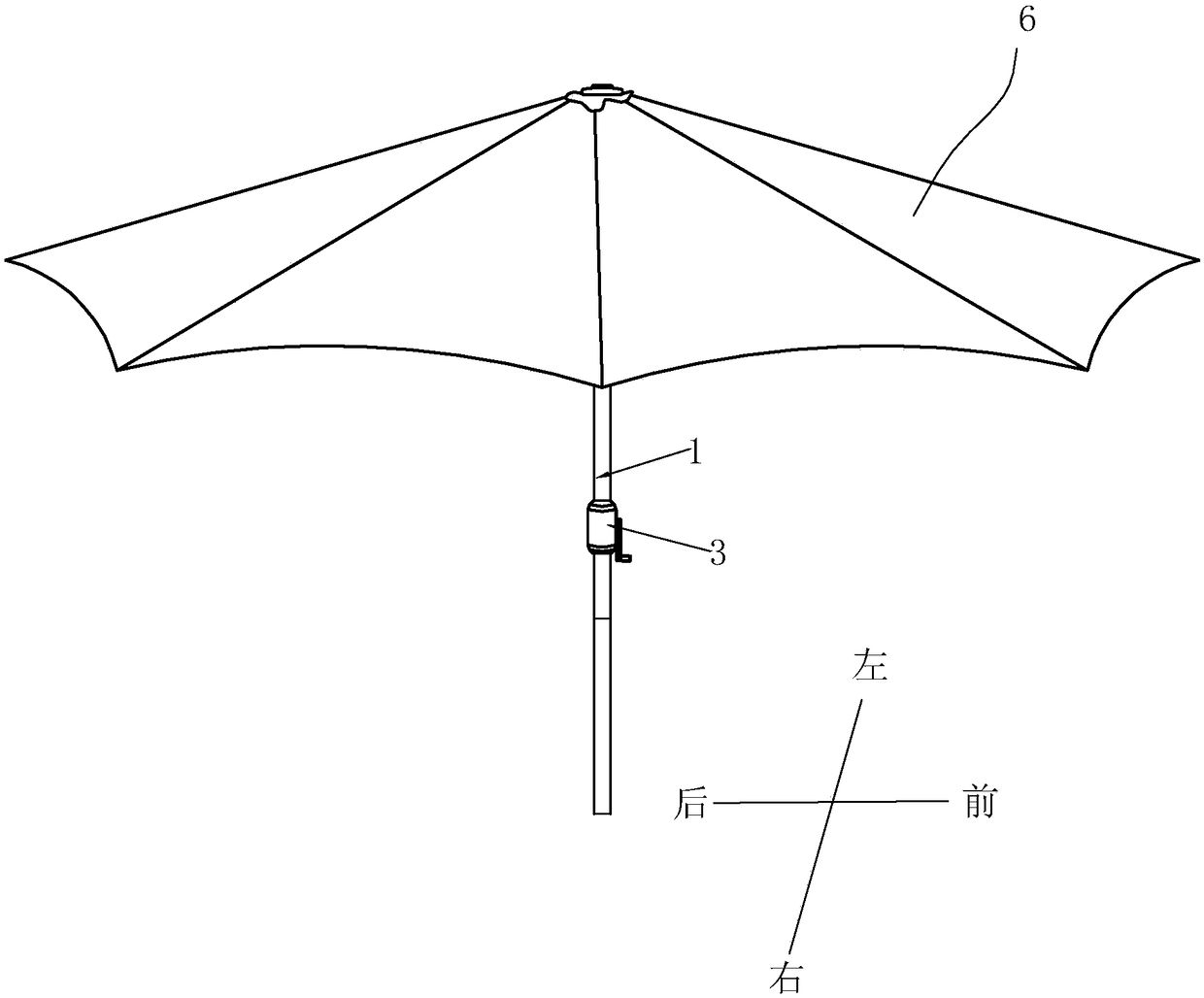

Sun-shading umbrella

PendingCN108741495ALarge effective shading areaIncrease the effective shading areaWalking sticksUmbrellasEngineeringShort ribs

The invention provides a sun-shading umbrella. An upper umbrella disc is hinged with two first crossed rods, a first long rib and a second long rib; a lower umbrella disc is hinged with two second crossed rods and two first short ribs; the two first crossed rods are located at left and right sides of a stand column; the first long rib and the second long rib are located at front and rear sides ofthe stand column; one first short rib is hinged to the middle part of the first long rib and the other first short rib is hinged to the middle part of the second long rib; the second crossed rods arelocated at the left and right sides of the stand column; the middle parts of the second crossed rods are hinged to the middle parts of the first crossed rods; end parts of the first crossed rods are hinged with short rib umbrella discs; end parts of the second crossed rods are hinged with long rib umbrella discs; the long rib umbrella discs are hinged with long ribs; the short rib umbrella discs are hinged with short ribs; one end of each short rib is hinged onto the corresponding short rib umbrella discs and the other end of each short rib is hinged to the middle part of the corresponding long rib; umbrella caps are arranged on the upper umbrella disc and the two long rib umbrella discs; umbrella cloth covers the long ribs to form three umbrella tops. The sun-shading umbrella is novel instructure; the area is large when the sun-shading umbrella is unfolded and the sun-shading coverage area is increased; the sun-shading umbrella has a firm and stable structure.

Owner:ZHEJIANG DINGSHENG OUTDOOR LIVING PROD CO LTD

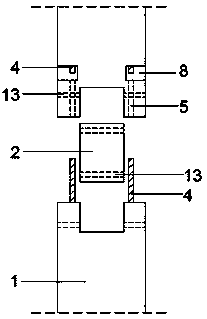

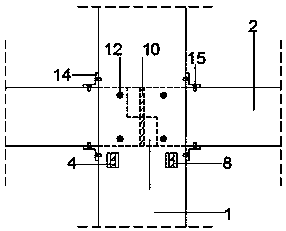

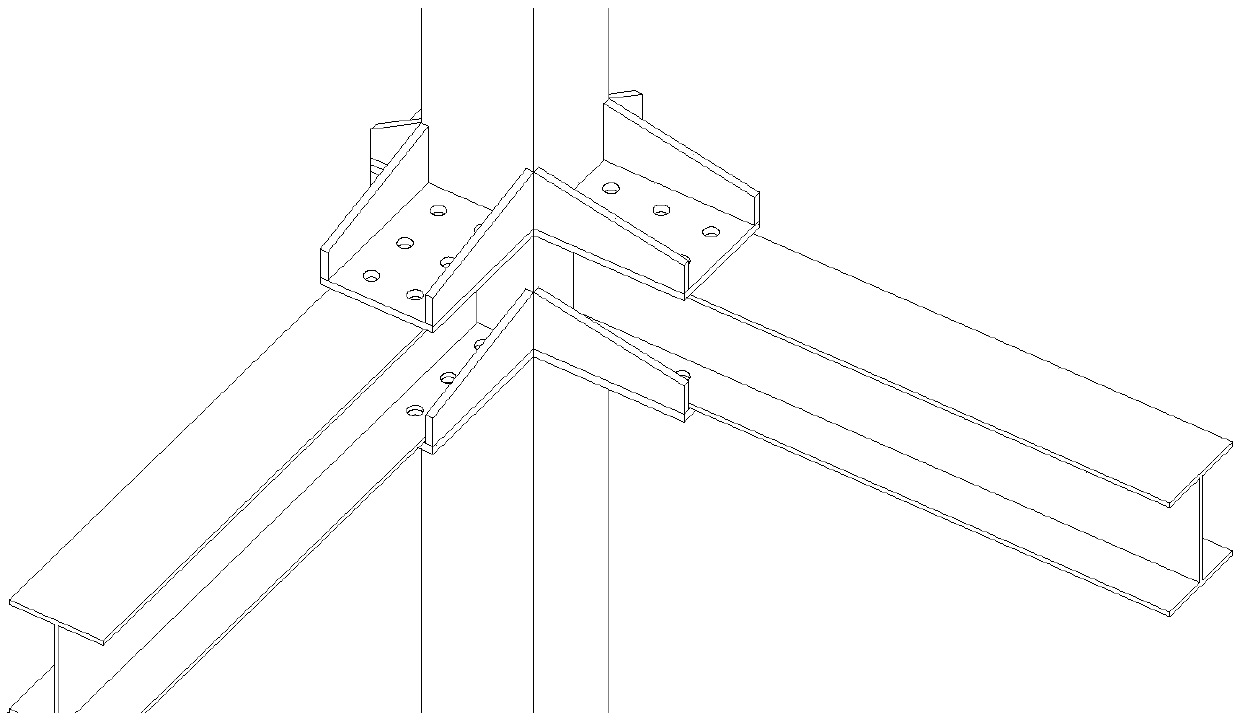

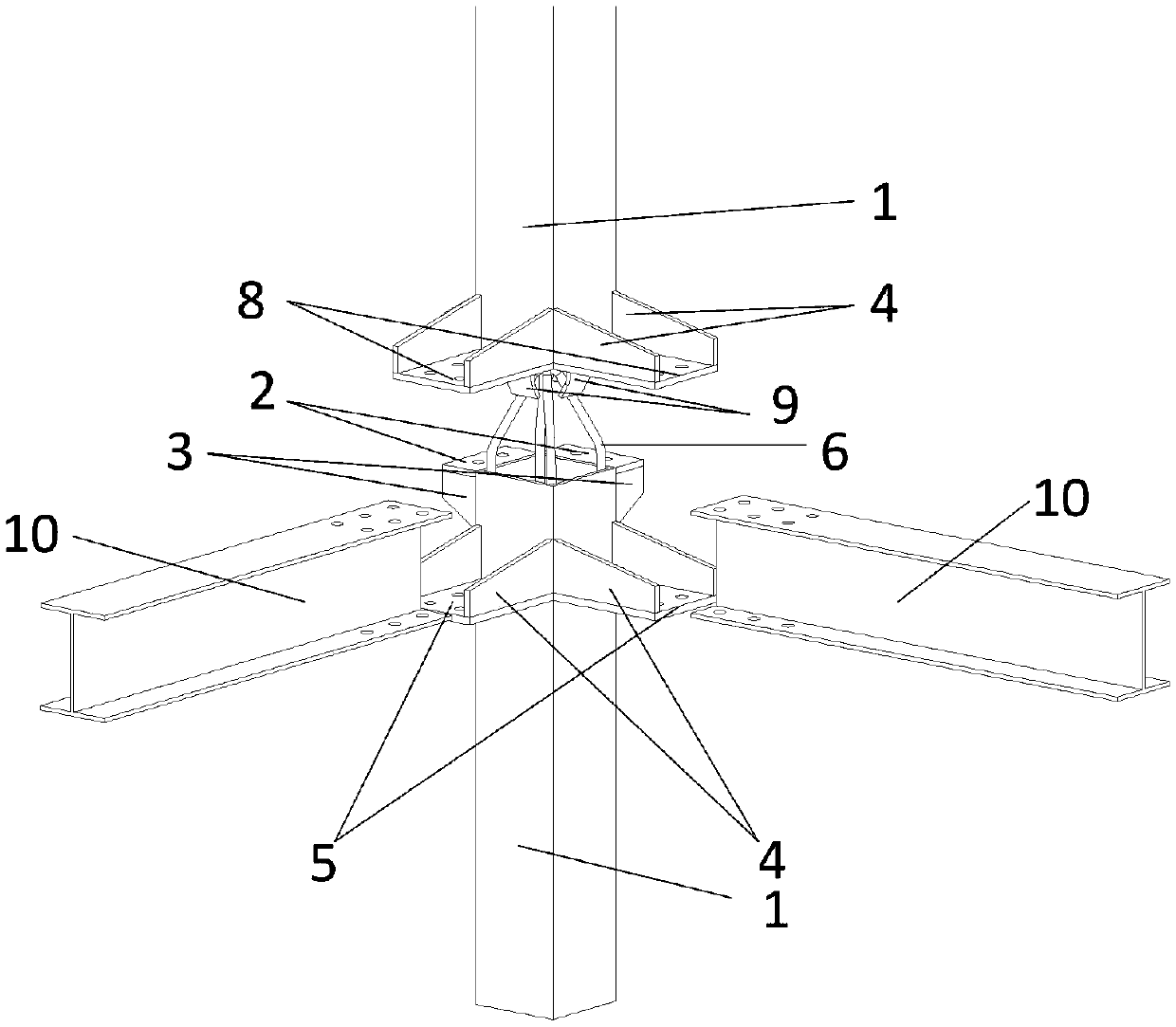

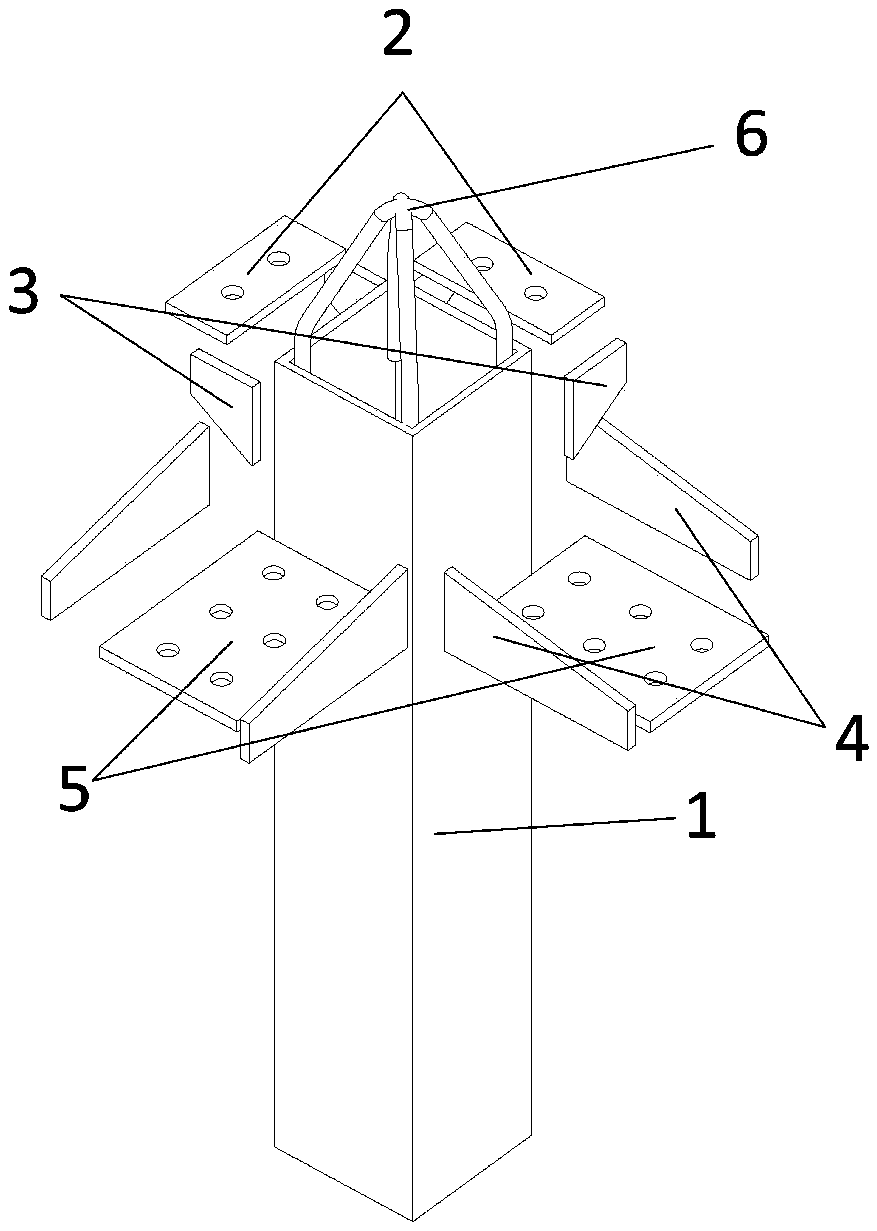

Reinforced fabricated beam-column connection joint

InactiveCN110241917AImprove stabilityAdapt to the development of assemblyBuilding constructionsHigh intensityRebar

The invention relates to a reinforced fabricated beam-column connection joint, and belongs to the technical field of buildings. Pre-reserved rectangular grooves on the upper and lower columns are butted, and the right and left rectangular connection ribs on the two adjacent beams are butted in a fitting mode and connect the beams through beam-connection threaded short ribs; after connection, the beams are placed in the rectangular grooves on a prefabricated column on the lower side, an upper prefabricated column is arranged, L-shaped grooves are arranged on the cross sections of the upper and lower columns, L-shaped connection reinforced steel plates are arranged in the upper and lower prefabricated columns and connected with the upper and lower prefabricated columns through high-intensity connection rebar, the structure is connected into a whole through the high-intensity joint connection rebar, the high-intensity joint connection rebar penetrates through the fabricated beams, and at the same time, the fabricated columns and the L-shaped steel plates are fixed by the high-intensity joint connection rebar; between the upper and lower columns, main rebar of the upper and lower columns extends out to be welded to ensure the stability of the whole structure. According to the reinforced fabricated beam-column joint, the structure connection is simple, the overall stability is high, joint connections can be reinforced and treated, and the reinforced fabricated beam-column connection joint is suitable for fabricated and integrated development.

Owner:SHENYANG JIANZHU UNIVERSITY

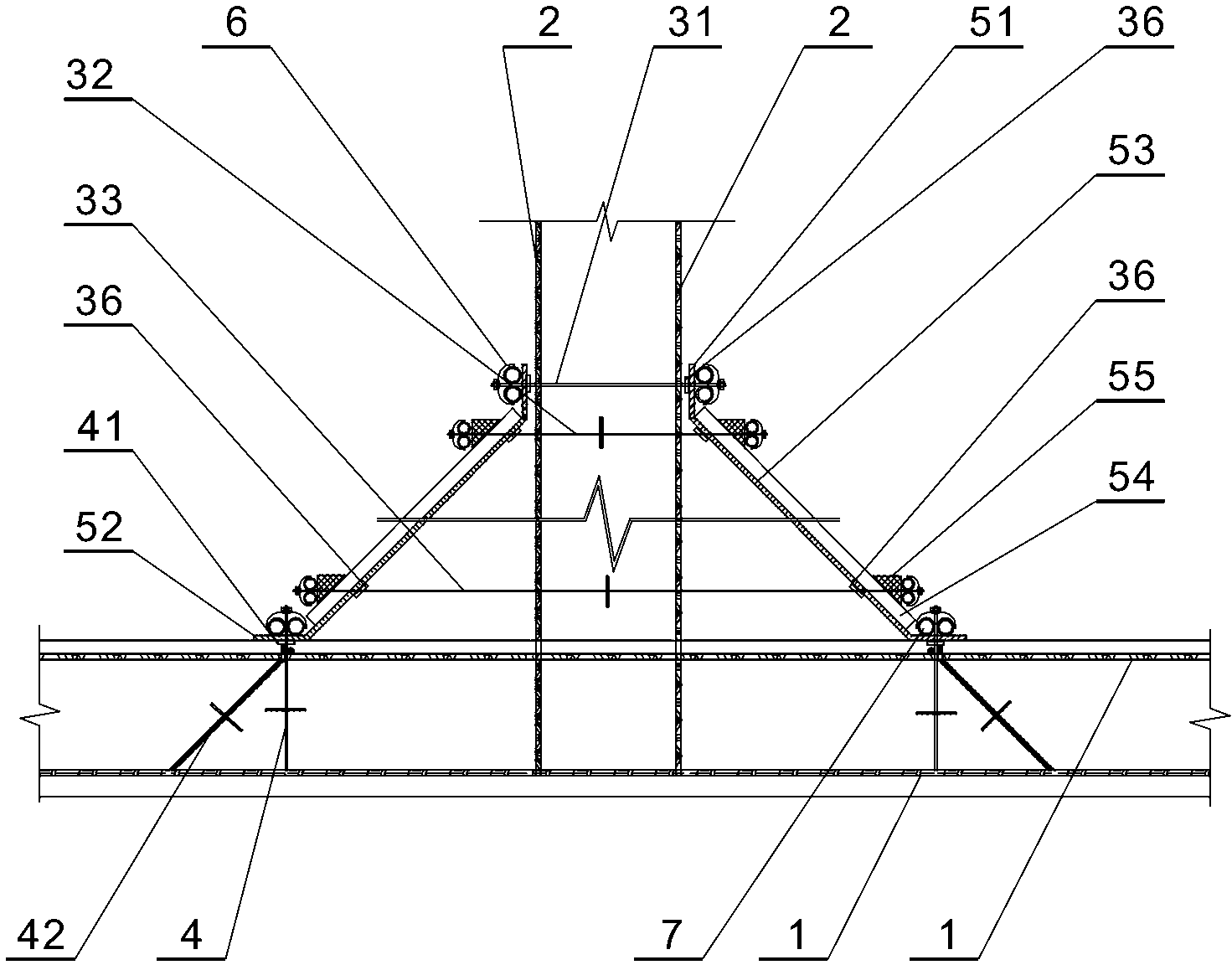

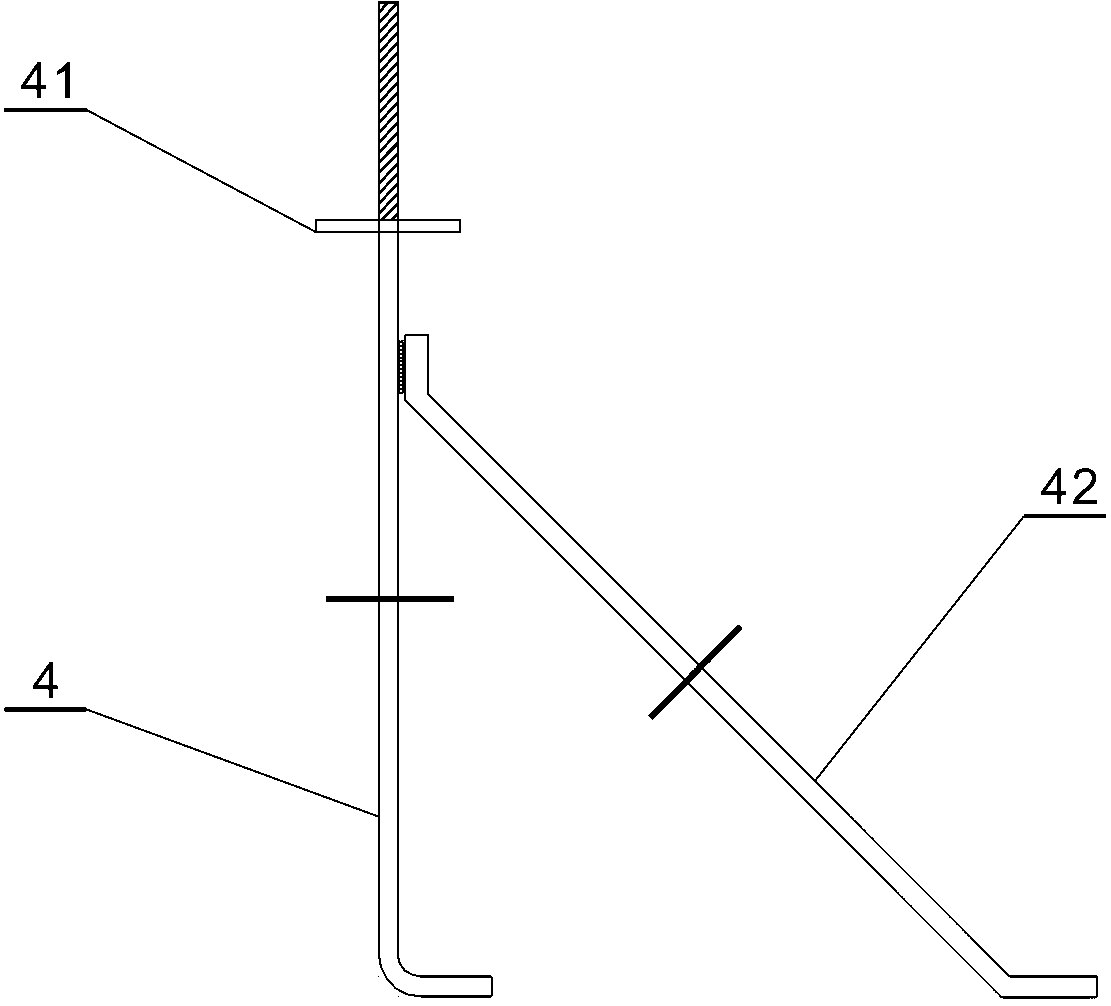

Construction method of anchor plate artificial prosthetic roadway

ActiveCN110529179AGuaranteed airtightImprove securityUnderground chambersMaterial fill-upRebarShort ribs

The invention discloses a construction method of an anchor plate artificial prosthetic roadway. The construction method comprises the steps: 1, selecting a construction place and direction according to engineering requirements of an upper ore body, and determinng a space size according to the required service function of the later stage; 2, marking roadway lines on site according to the place, thedirection and the size, and drilling anchor rod holes in a top plate ore column and a bottom plate ore rock according to the marking lines at certain intervals, wherein the anchor rod holes are symmetric up and down, and are arranged on a same plumb line; 3, after the anchor rod holes are drilled, mounting anchor rods, wherein the anchor rods inserted into the top plate ore column and the bottomplate ore rock are connected in a steel bar suspension connection mode through binding steel bars to form the inner vertical ribs, and meanwhile, the inner vertical rib structure is on the same plumbline; and 4, short ribs with threads at the two ends are fixed through binding at equal intervals on the inner vertical ribs which are connected between the top plate ore column and the bottom plate ore rock. The construction method is simple in process, high in safety, short in construction period, low in cost and capable of saving engineering materials.

Owner:CHINA MINMETALS CHANGSHA MINING RES INST

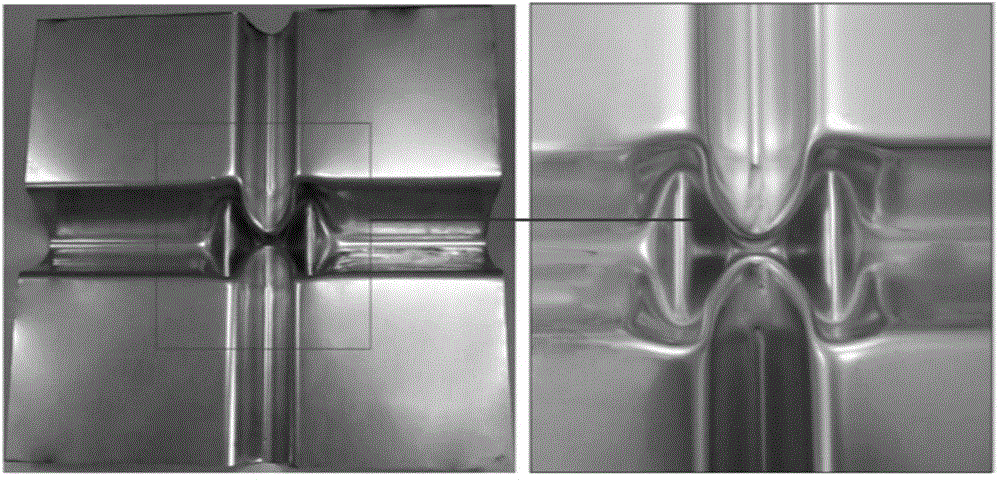

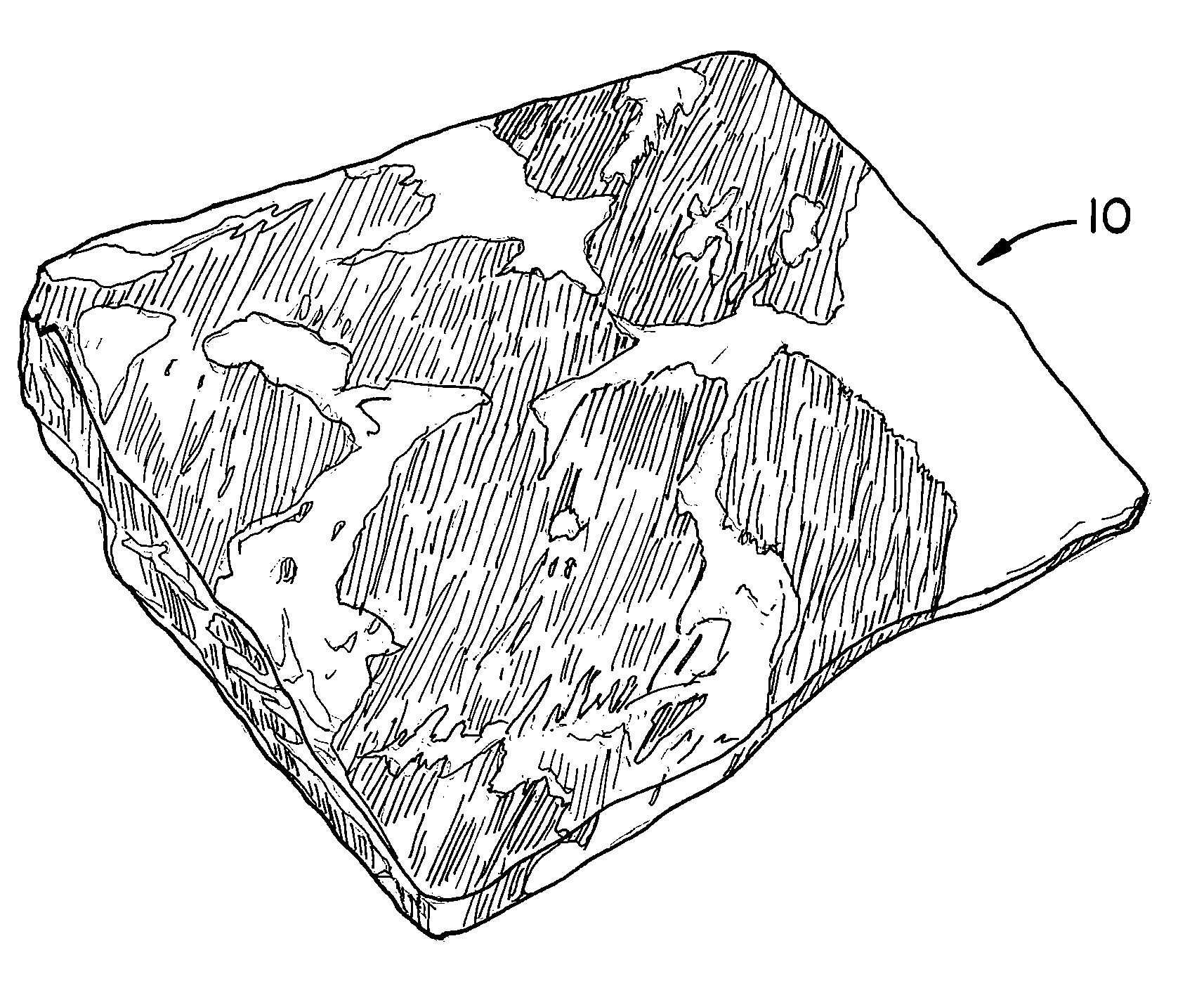

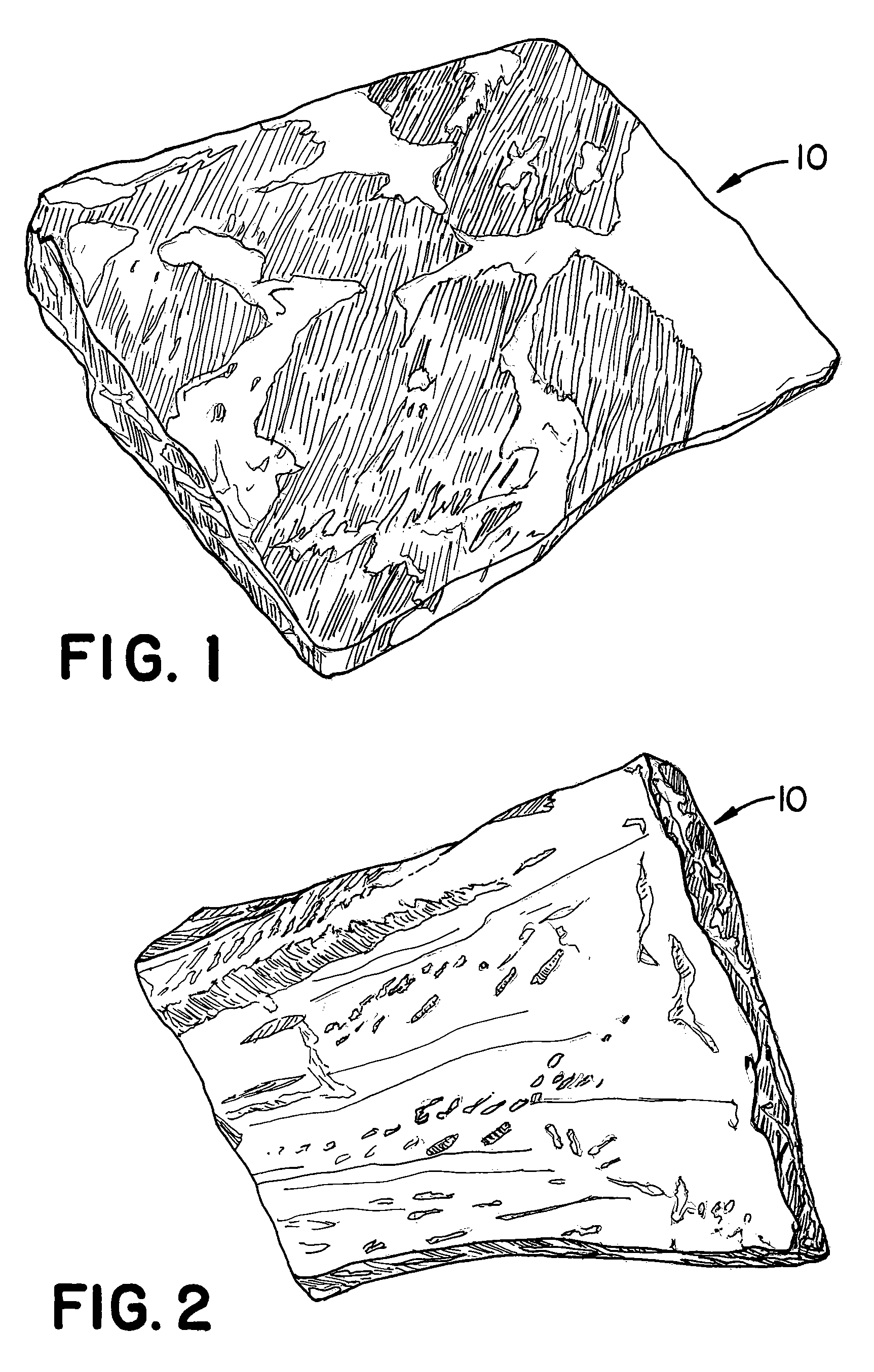

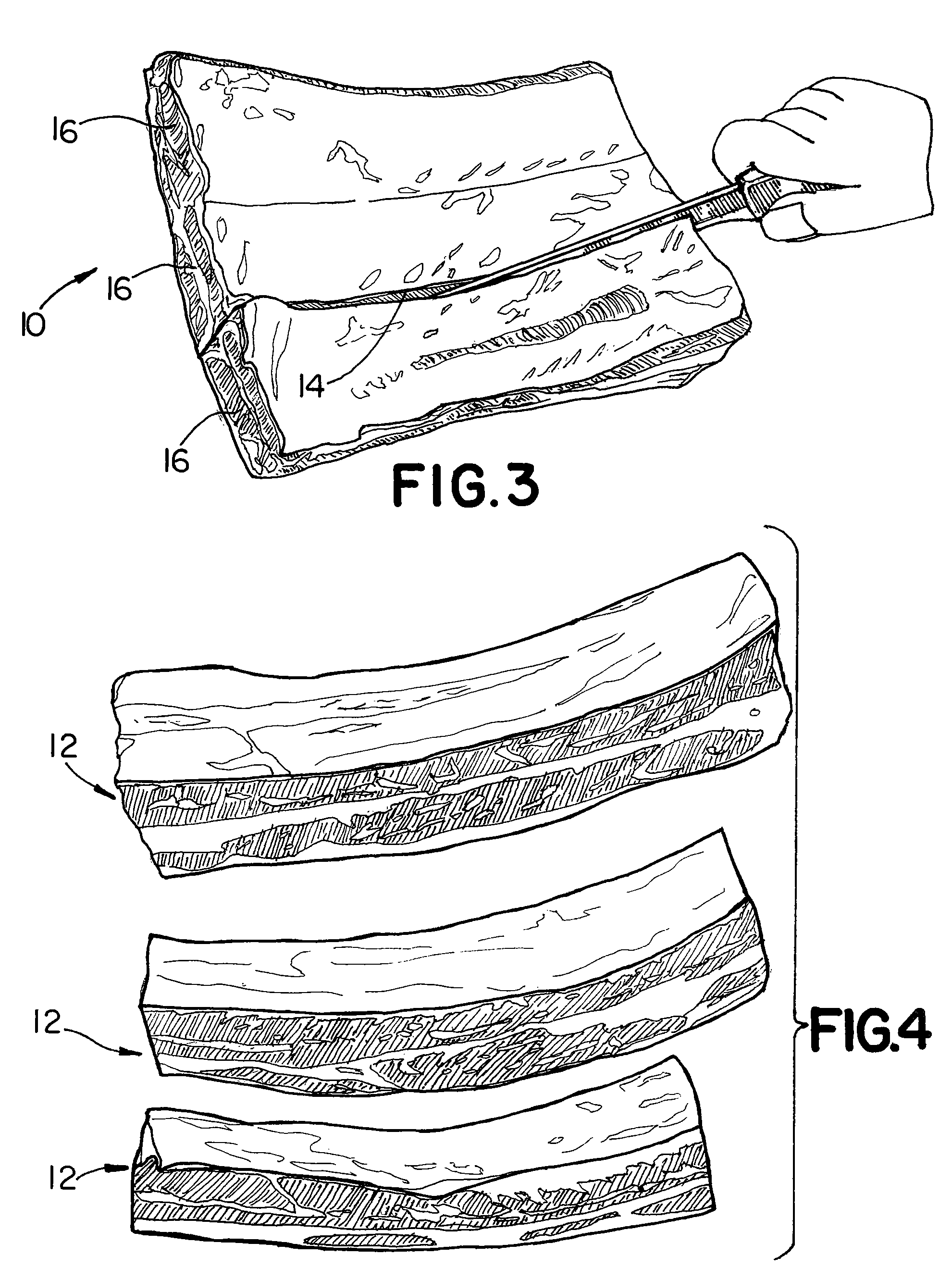

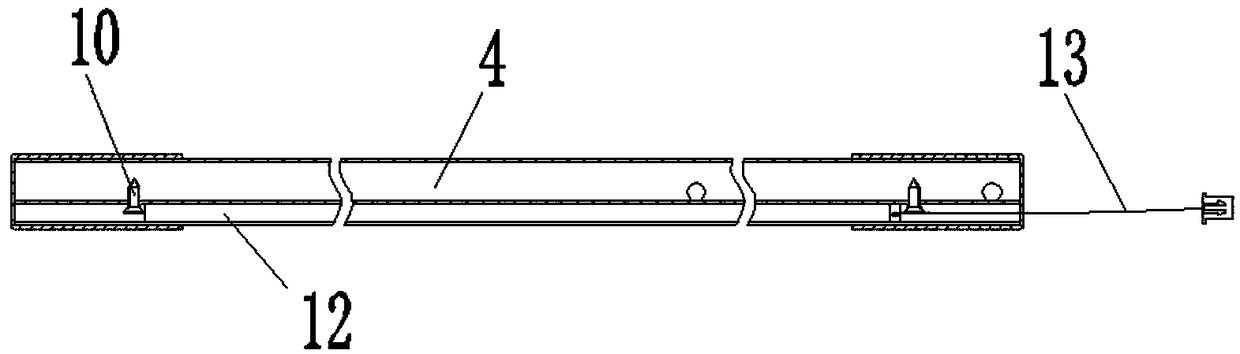

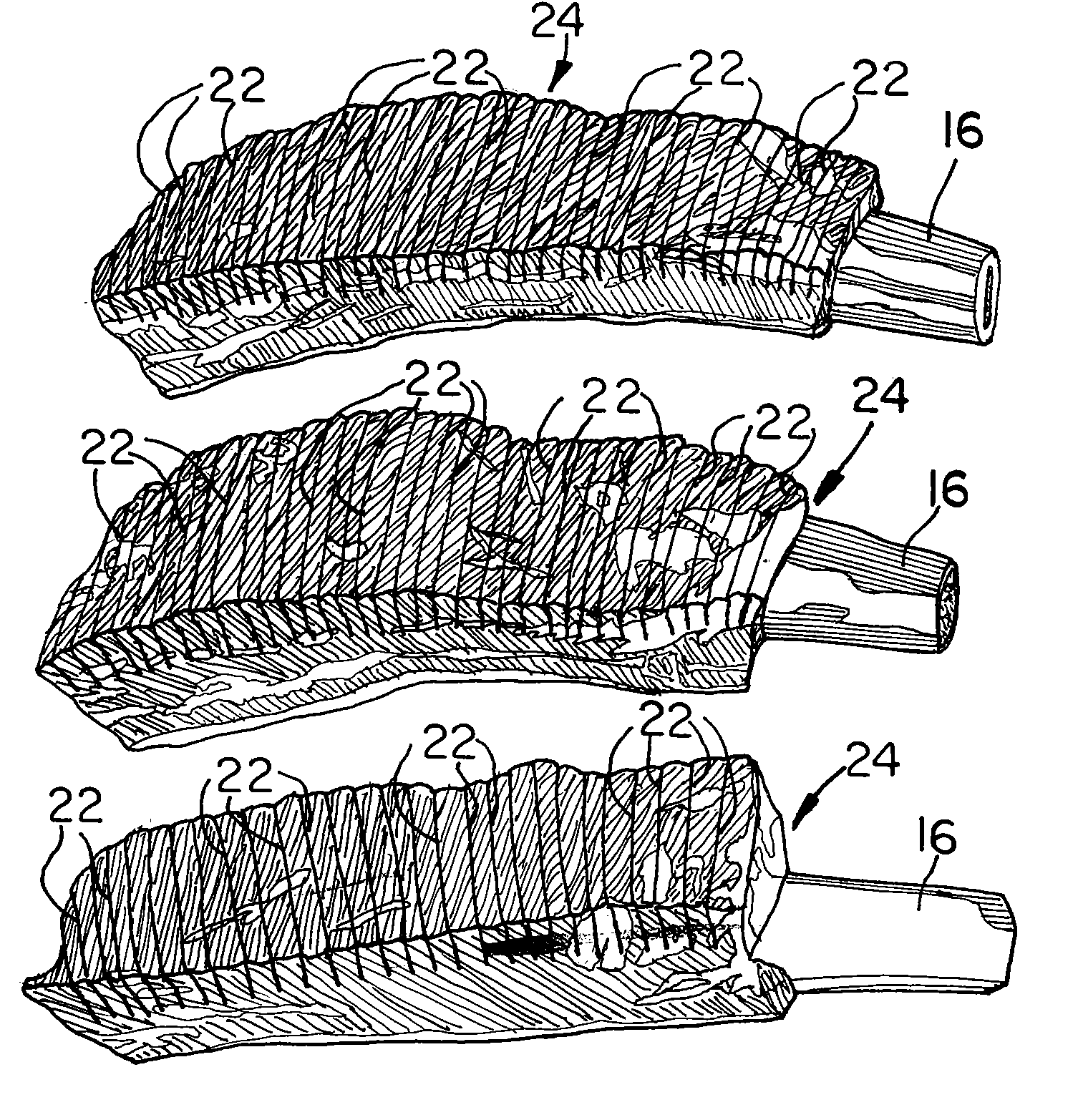

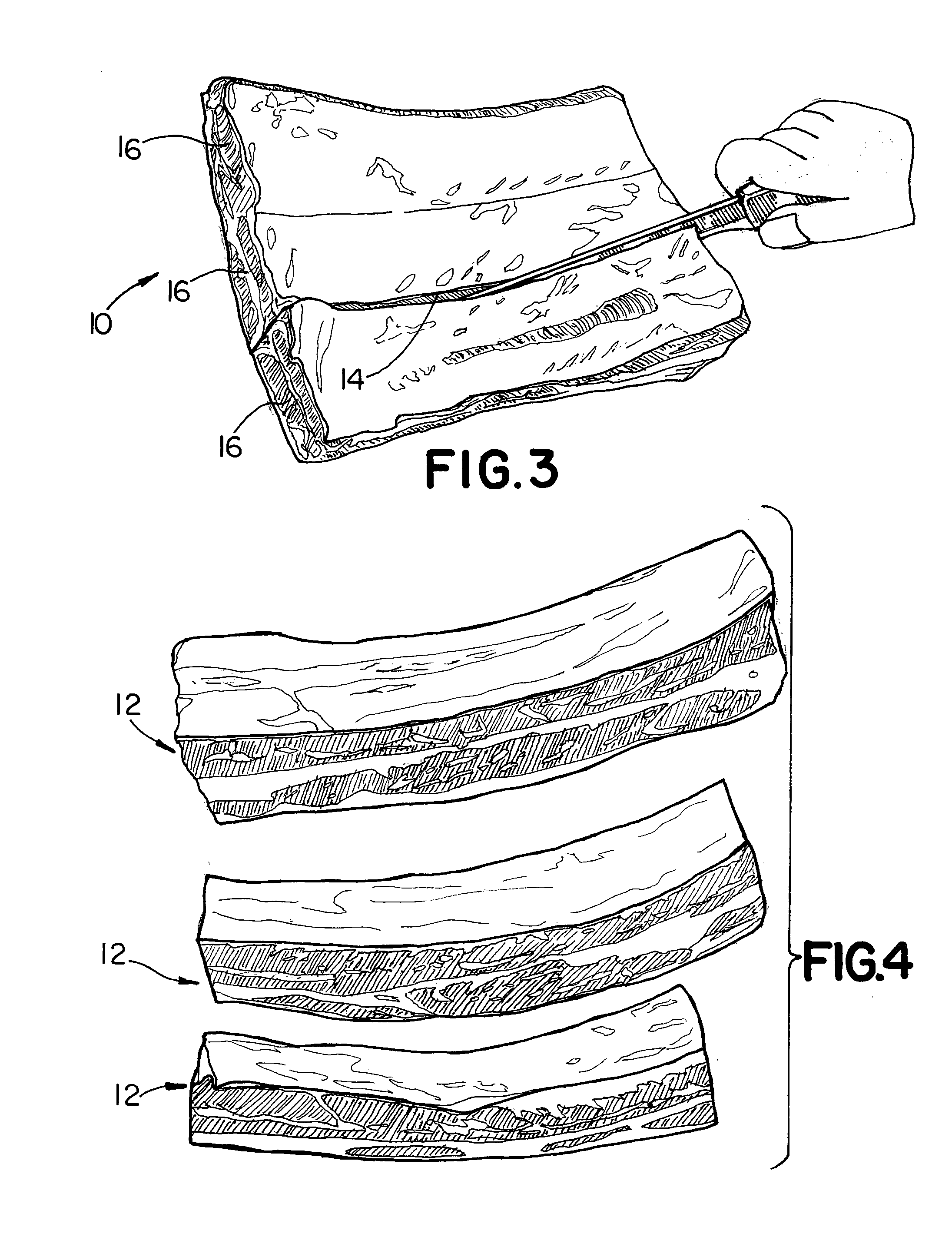

Method of cutting beef short ribs and beef products produced by the method

A method of cutting beef short ribs having a first, concavely shaped inside surface and a second convexly shaped outside surface comprises the steps of: separating the short ribs into a plurality of generally equally sized individual rib meat portions, each having a rib bone, by cutting completely through the short ribs from the first surface to the second surface along cut lines extending generally midway between and generally parallel to the rib bones; and making a series of generally parallel cuts into the meat on at least one of the first and second surfaces of each of the rib portions, the cuts made into each rib portion extending generally perpendicular to the rib bone along the entire length of the meat from one end of the rib bone to the other end of the rib bone and being spaced apart from each other by a first predetermined distance.

Owner:BANK OF AMERICA NAT TRUST & SAVINGS ASSOC +1

Straight rib type automatic opening and closing umbrella rib structure

The invention discloses a straight rib type automatic opening and closing umbrella rib structure which comprises a middle rod, a lower nest, a double-layer integrated upper nest, an umbrella rib support, a pulley assembly and an umbrella handle control assembly, wherein the double-layer integrated upper nest is formed by combining an upper layer nest and a lower layer nest; the umbrella rib support is composed of a plurality of umbrella skeletons; the umbrella handle control assembly for controlling opening and closing of an umbrella; the umbrella skeleton comprises a supporting rib, an umbrella folding tension spring, a foldable short rib and a long rib, wherein the foldable short rib is formed by combining an inner short rib and an outer short rib; and the pulley assembly comprises a pulley, a pulley base and a pull wire. According to the straight rib type automatic opening and closing umbrella rib structure, through the arrangement of the upper nest, the umbrellaribstructure and the pulley assembly, when the umbrella is used, the lower nest drives the supporting ribs to pull the umbrella closing spring, and the foldable short ribs formed by combining the inner short ribs and the outer short ribs are linked, so that the purpose of effectively shortening the moving stroke of the lower nest when the umbrella is opened and closed is achieved; the umbrella handle key device can be set conveniently, and a solid foundation is laid for realizing automatic umbrella opening and closing; and the straight rib type automatic opening and closing umbrella rib structure has the characteristics of stable structure, convenience in opening and closing, quickness in opening and closing, safety and convenience and the like.

Owner:田宗明

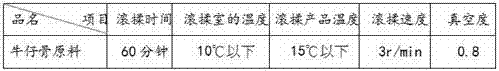

Processing method of beef short ribs

The present invention belongs to the field of food processing and particularly relates to a processing method of beef short ribs. Based on a ratio of 100 kilograms of the beef short ribs, an accessory material A comprises 150-180 g of a phosphorus providing agent (a food additive), 80-110 g of black pepper powder, 500-700 g of margarine, 1,000-1,900 g of a black pepper marinating material and 1,000-2,000 g of white granulated sugar; an accessory material B comprises 1-3 kg of soybean proteins, 1-4 kg of soy sauce and 4-6 kg of modified starch; the accessory material A, accessory material B and a certain amount of water at 60-80 kg are added into a rolling machine to be subjected to a vacuum rolling with the beef short ribs together; and a temperature of a rolling chamber, a temperature of rolled products and a rolling time are controlled well to prepare the beef short rib products with a unique flavor, a fresh and tender meat quality, an attractive color and luster, and a long shelf life.

Owner:PUTIAN CHENGXIANG DISTRICT CHENGWEI FOOD CO LTD

Cantilever umbrella

ActiveUS20200063462A1Novel structureIncrease the shade areaWalking sticksUmbrellasClassical mechanicsShort ribs

A cantilever umbrella including a frame having an upper tray and a lower tray is provided. Two first crossed rods, a transverse rod and a first long rib are articulated to the upper tray. Two second crossed rods and two first short ribs are articulated to the lower tray. One of the two first short ribs is articulated to a middle portion of the transverse rod and the other one is articulated to a middle portion of the first long rib. A middle portion of each second crossed rod is articulated to a middle portion of the first crossed rod on a same side. An end of each first crossed rod is articulated with a short-rib tray which is articulated to a short rib, and an end of each second crossed rod is articulated with a long-rib tray which is articulated to a long rib. The short ribs each has one end articulated to the short-rib tray and another end articulated to a middle portion of one of the long ribs. The upper tray and the two long-rib trays are each disposed with a cap thereon, and a canopy fabric is covered on the long ribs to form three canopies.

Owner:ZHEJIANG DINGSHENG OUTDOOR LIVING PROD CO LTD

An assembled steel structure beam-column joint connection device

InactiveCN106812214BIncrease rigid connectionPlay an anchoring roleBuilding constructionsEngineeringShort ribs

Owner:BEIJING UNIV OF TECH

Light umbrella with light guiding strips

InactiveCN109330127AConvenient lightingBeautify the night environmentWalking sticksUmbrellasAdhesiveLight guide

The invention discloses a light umbrella with light guiding strips. The light umbrella comprises the first light guiding strips, the second guiding strips, backlight light strips, a short rib wire connecting plate, a light source wire, short rib tail wires, a long rib wire connecting plate, long rib tail wires, a solar panel and a switch. Single-sided grooved aluminum ribs are adopted as long ribs, and the first light guiding strips are clamped into grooves of the single-sided grooved aluminum ribs and integrally connected with the single-sided grooved aluminum ribs through self-tapping screws; double-sided grooved aluminum ribs are adopted as short ribs, each second light guiding strip is clamped into one groove of the corresponding double-sided grooved aluminum rib and integrally connected with the corresponding double-sided grooved aluminum rib through self-tapping screws, and the backlight light strips are clamped into other grooves of the double-sided grooved aluminum ribs and integrally bonded to the double-sided grooved aluminum ribs through an double-sided adhesive. According to the technical scheme, the problems that existing light umbrellas are complicated in structure and poor in integrity are solved, and the effects of being simple in structure, reliable in connection, good in integrity, unlikely to be damaged and convenient to maintain are achieved.

Owner:LINHAI ZHONGTIAN ELECTRONICS APPLIANCE CO LTD

Method of cutting beef short ribs and beef products produced by the method

InactiveUS20090169711A1Enhanced per pound valueIncrease valueFood shapingSlaughtering accessoriesShortened ribsShort ribs

A method of cutting beef short ribs having a first, concavely shaped inside surface and a second convexly shaped outside surface comprises the steps of: separating the short ribs into a plurality of generally equally sized individual rib meat portions, each having a rib bone, by cutting completely through the short ribs from the first surface to the second surface along cut lines extending generally midway between and generally parallel to the rib bones; and making a series of generally parallel cuts into the meat on at least one of the first and second surfaces of each of the rib portions, the cuts made into each rib portion extending generally perpendicular to the rib bone along the entire length of the meat from one end of the rib bone to the other end of the rib bone and being spaced apart from each other by a first predetermined distance.

Owner:BANK OF AMERICA N A +1

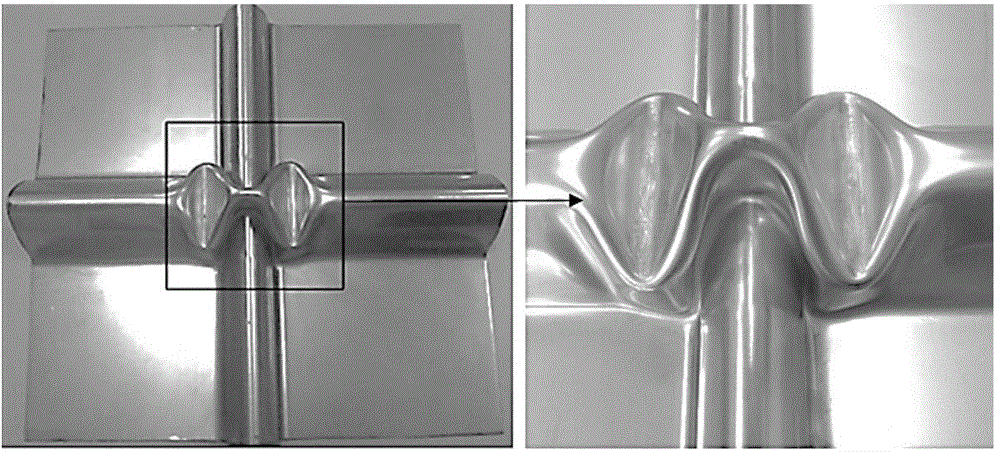

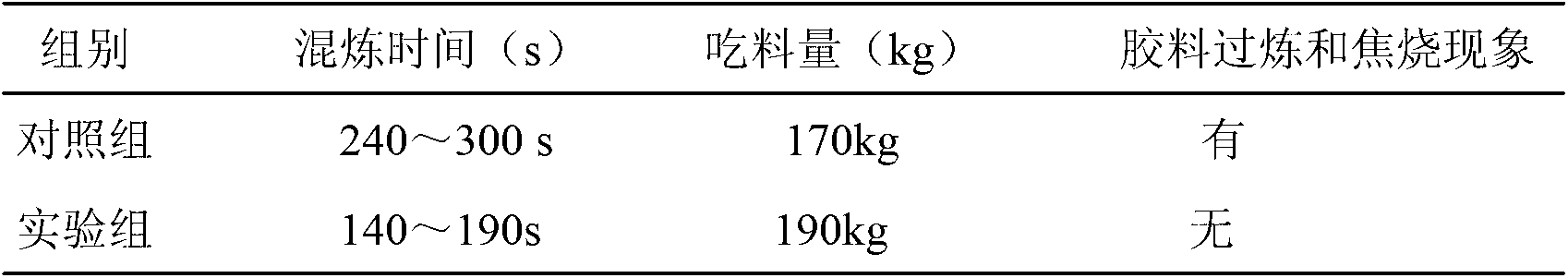

Internal mixer

Owner:JIANGSU FARUN GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com