Internal mixer

A technology of internal mixer and rotor, which is applied in the field of polymer material processing equipment, can solve the problems of poor mixing effect, long mixing cycle, and low mixing efficiency, and achieve enhanced mixing efficiency and mixing effect, and improved mixing efficiency. The effect of shortening the time, reducing the phenomenon of rubber over-refining or scorching

Inactive Publication Date: 2013-04-24

JIANGSU FARUN GROUP

View PDF1 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

This new design allows for better feedability without being affected by factors like temperature changes that can affect its properties during use. It improves upon existing designs while reducing their impact on productivity.

Problems solved by technology

This patented problem with current internal combustion engines has been that they are time-consuming in their process due to slow down or insufficiently mixed fuel during engine startups.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 2

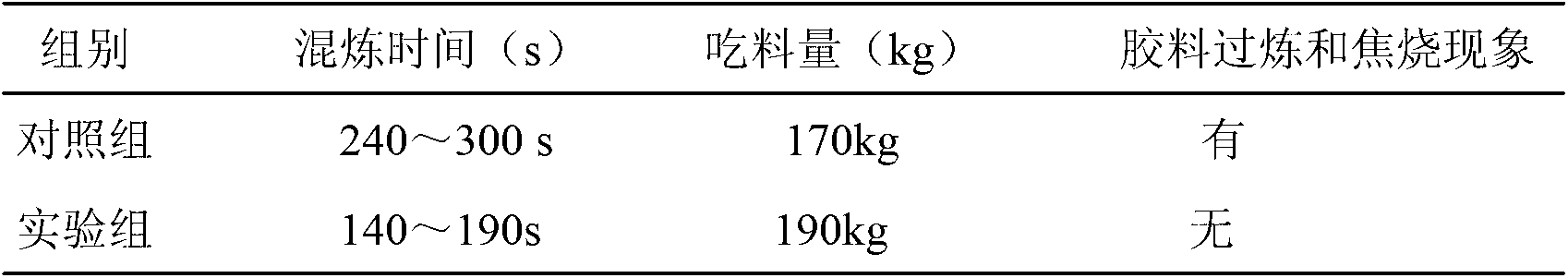

[0016] The initial position of the top bolt is set at the bottom of the cylinder, and the internal mixer with only one main and one auxiliary two convex ribs is used as the control group, and the internal mixer provided by the present invention (Example 1) is used as the experimental group. The results are shown in the table 1.

[0017] Table 1 Comparison of two groups of data

[0018]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

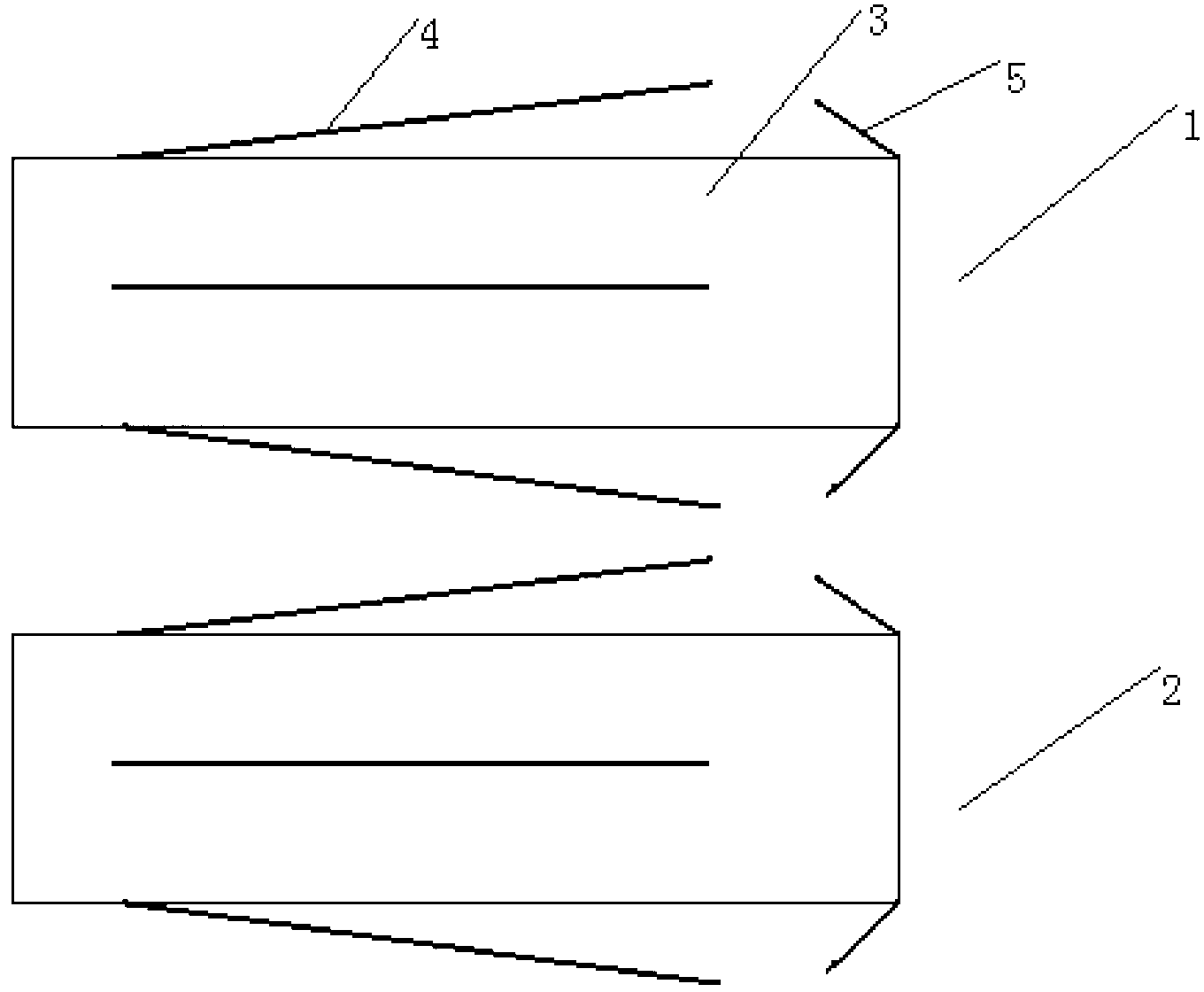

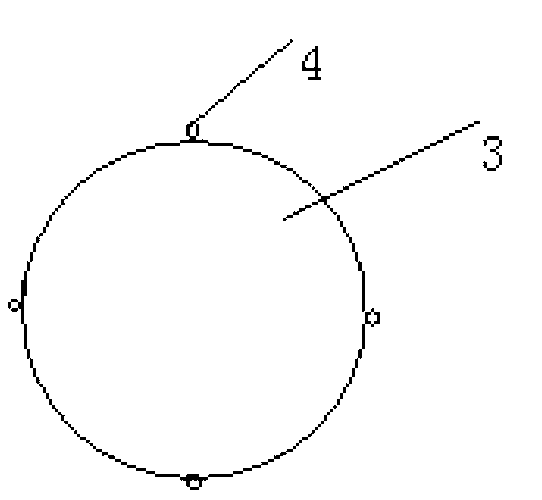

The invention discloses an internal mixer, comprising two rotors which are parallel to each other in reversing rotation, wherein each rotor comprises a rotor body and six ribs arranged on the surface of the rotor; the six ribs comprise four long ribs and two short ribs, the four long ribs are symmetrically distributed at 90 degrees on the cross section of the rotor, and the two short ribs are radially distributed at 180 degrees on the cross section of the rotor; and the internal mixer further comprises a top peg and an air cylinder, in which the top peg is arranged. By changing the initial position of the top peg and the structure of the ribs of the rotors, the internal mixer disclosed by the invention has the advantages of good feeding performance and highly strong processing capability, and is capable of greatly reducing an over-refining or scorching phenomenon of the sizing materials due to shortened mixing time, greatly enhancing the mixing efficiency and effect of the internal mixer, and improving production.

Description

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Owner JIANGSU FARUN GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com