Patents

Literature

41results about How to "Increase extrusion pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

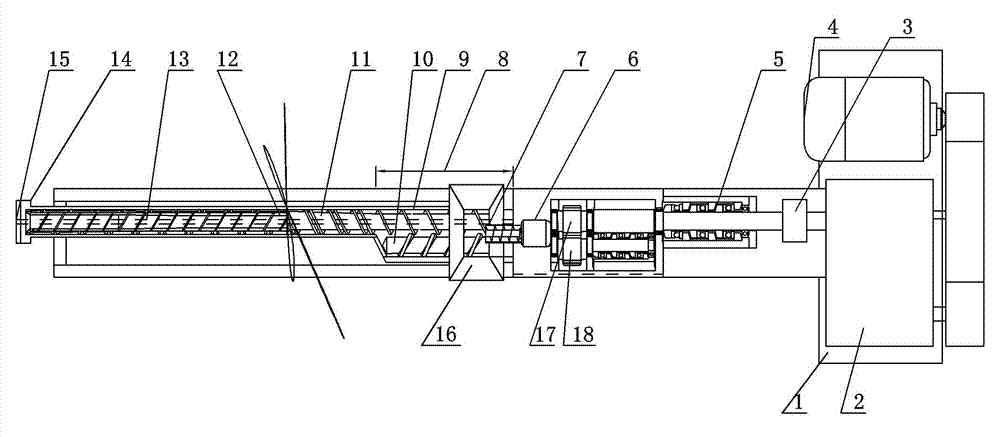

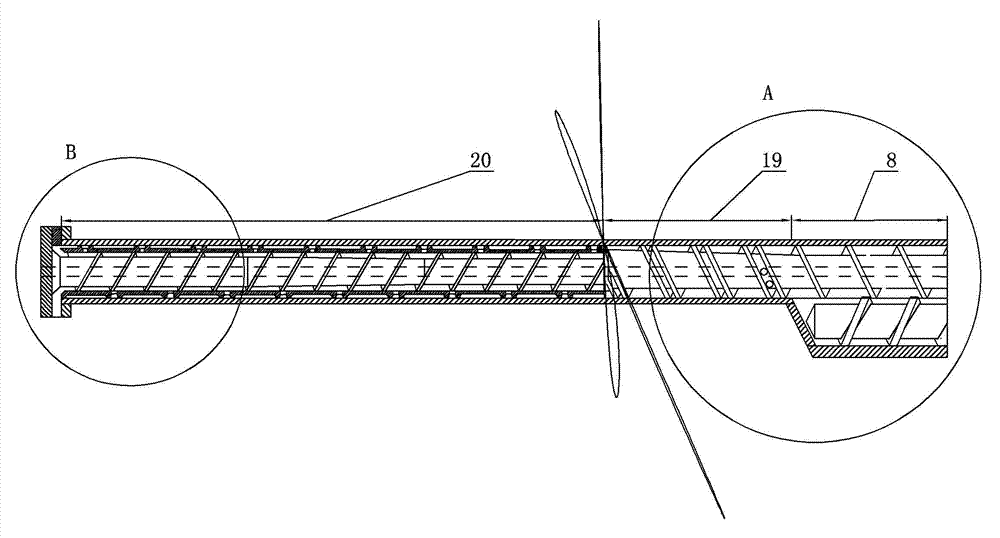

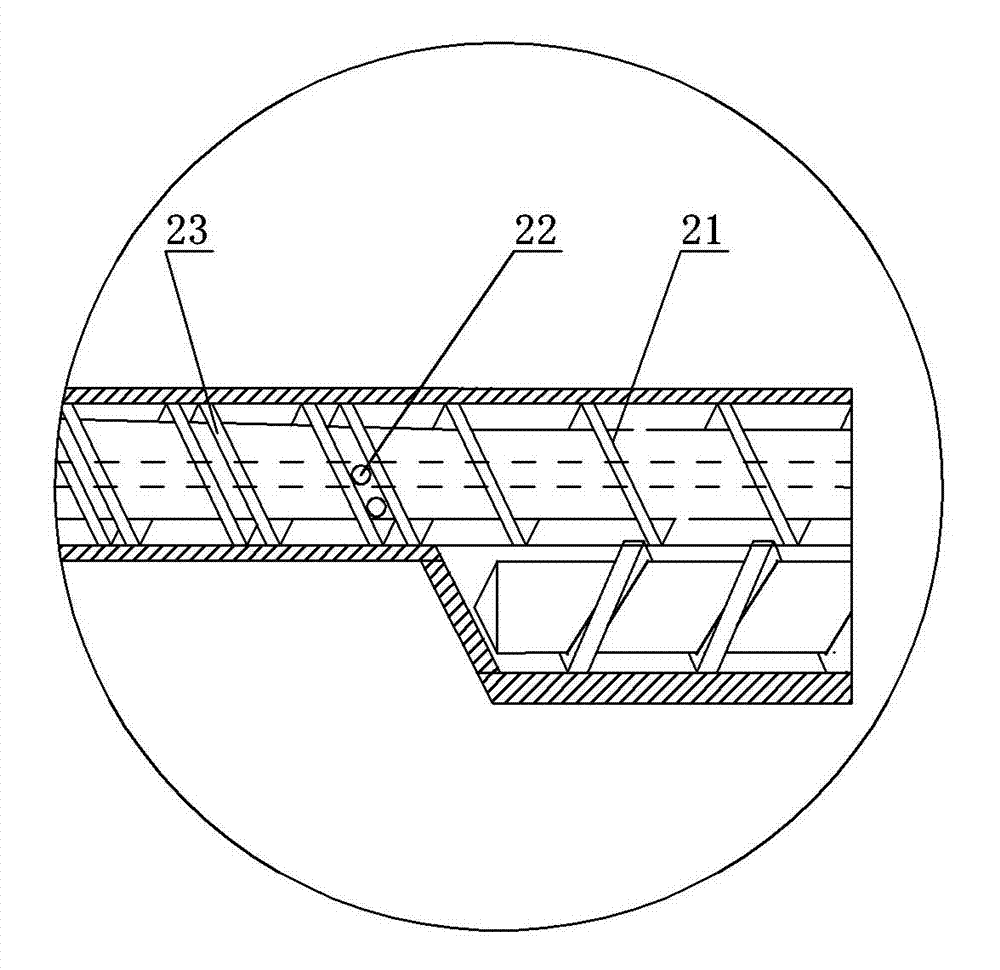

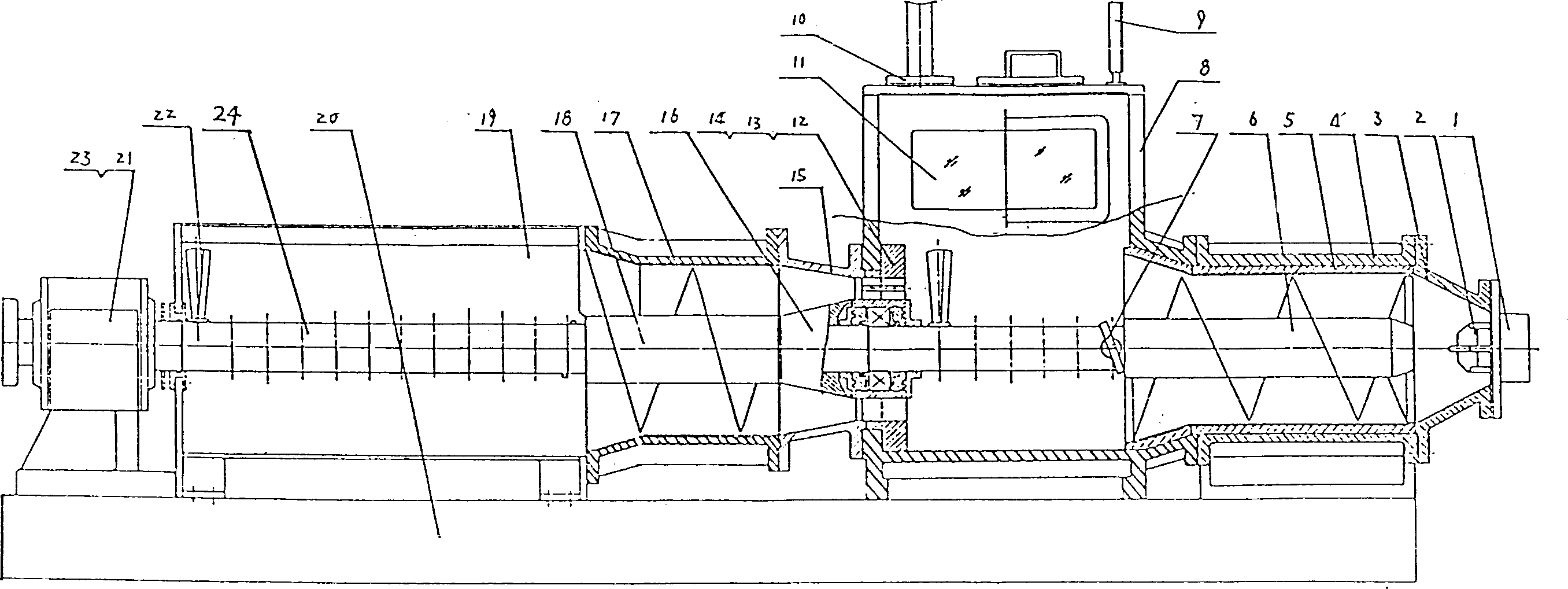

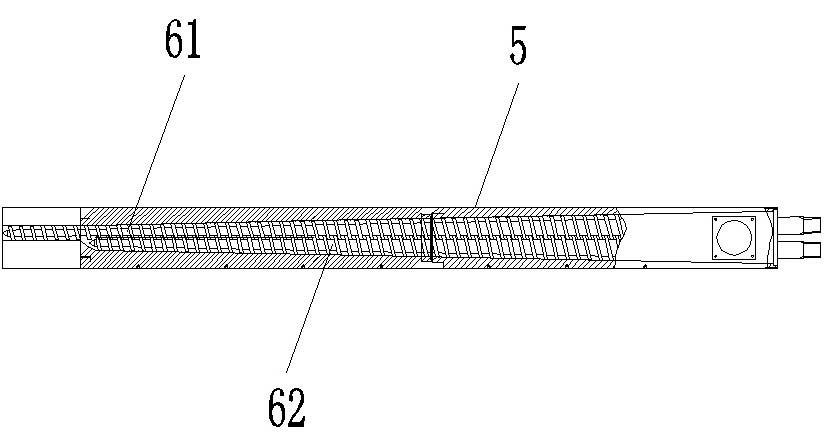

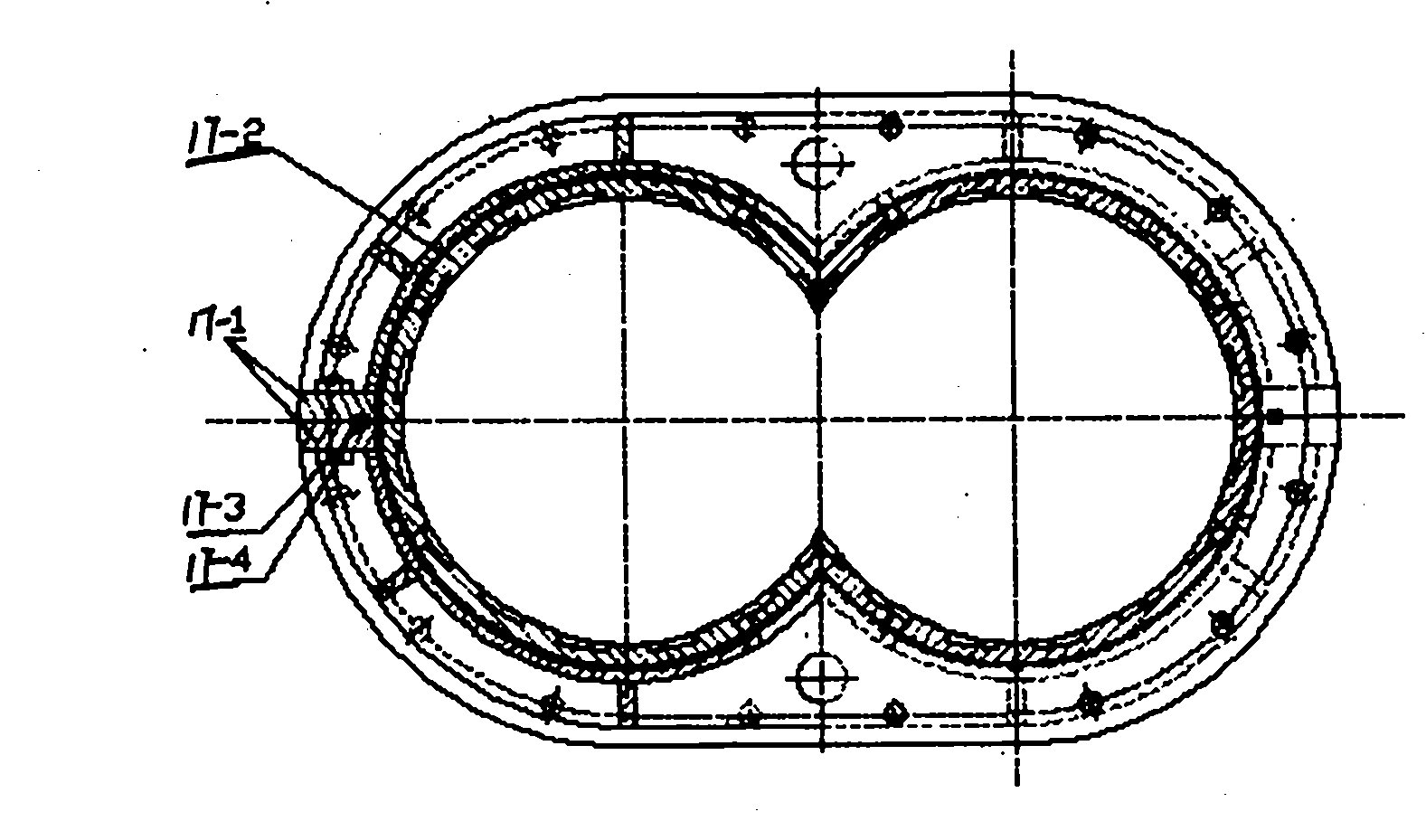

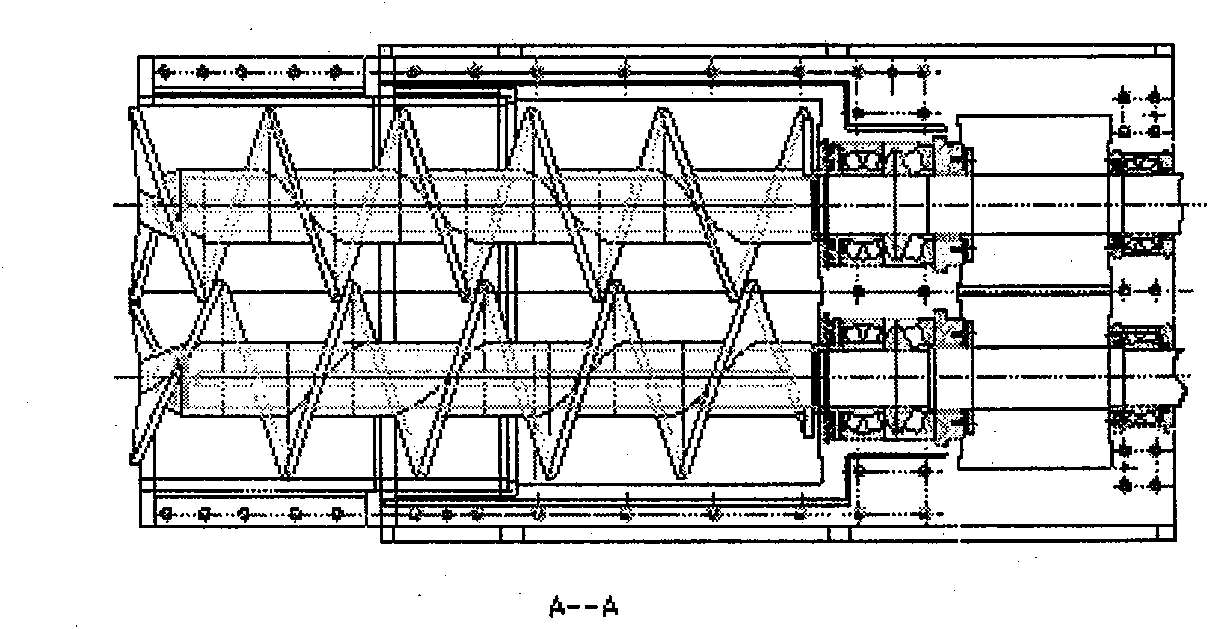

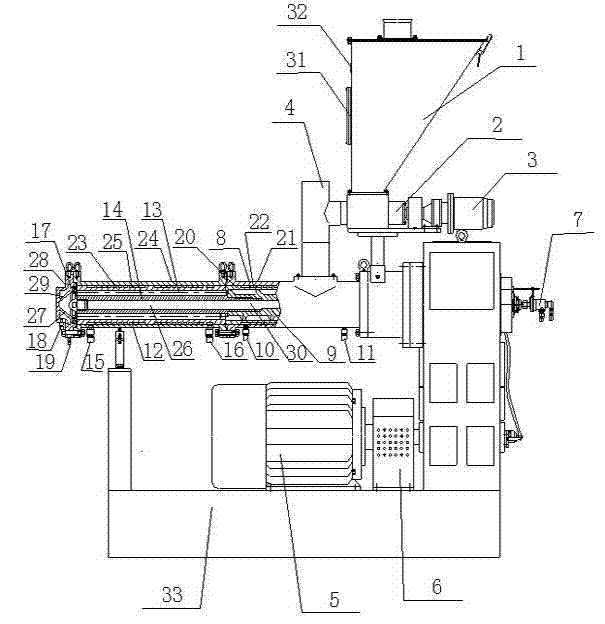

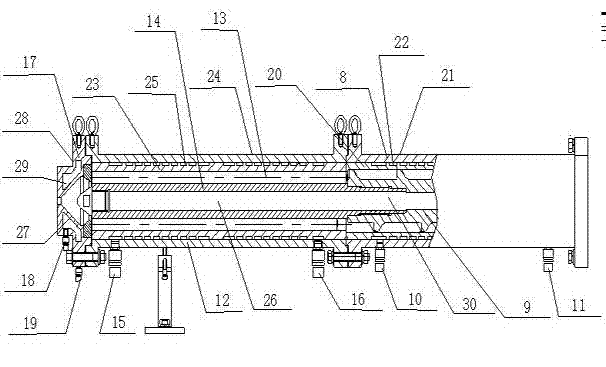

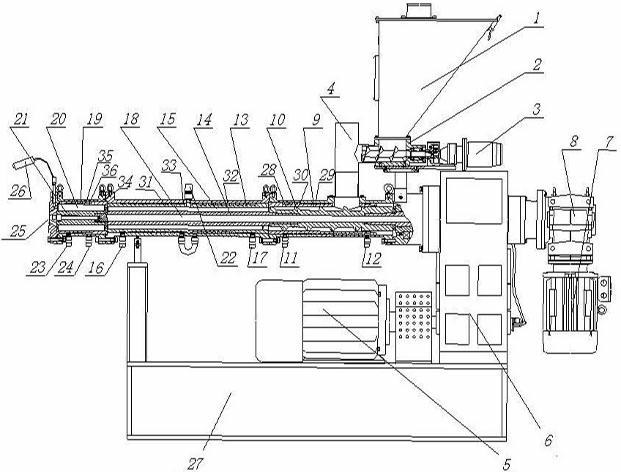

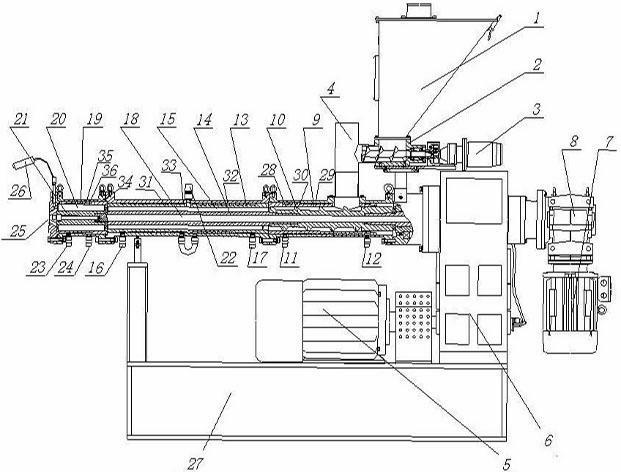

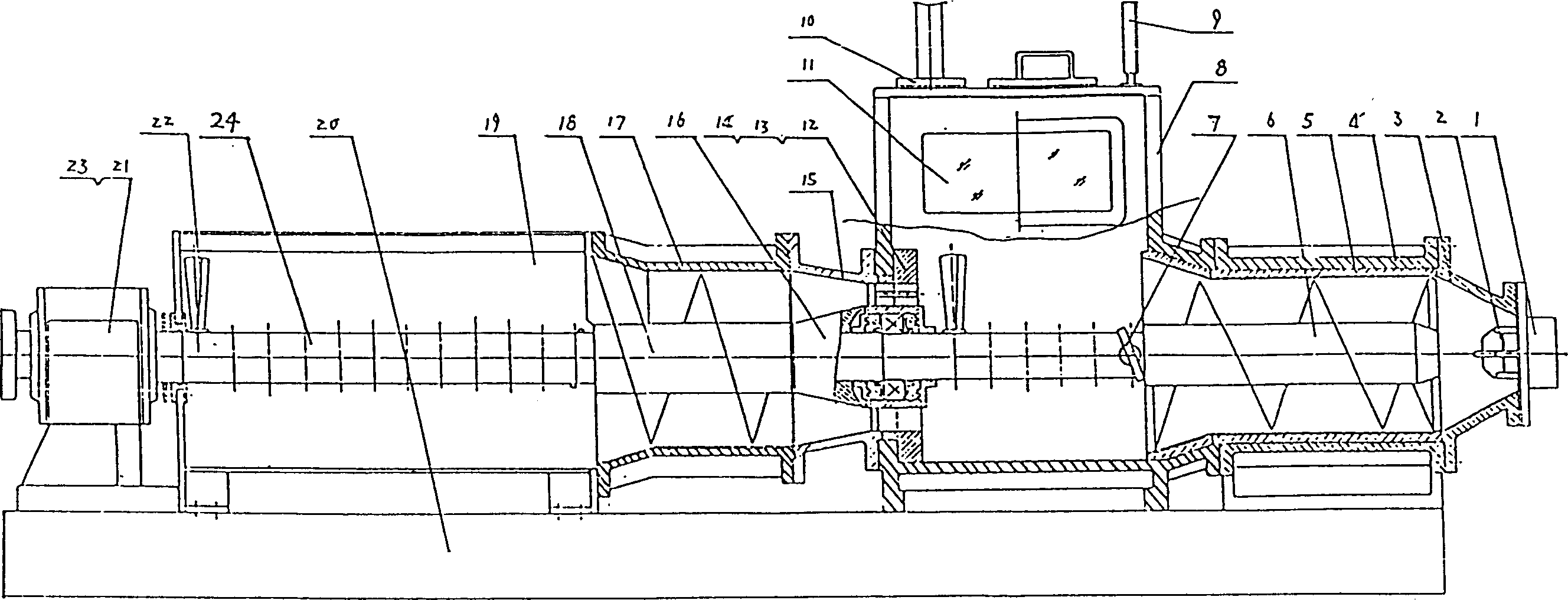

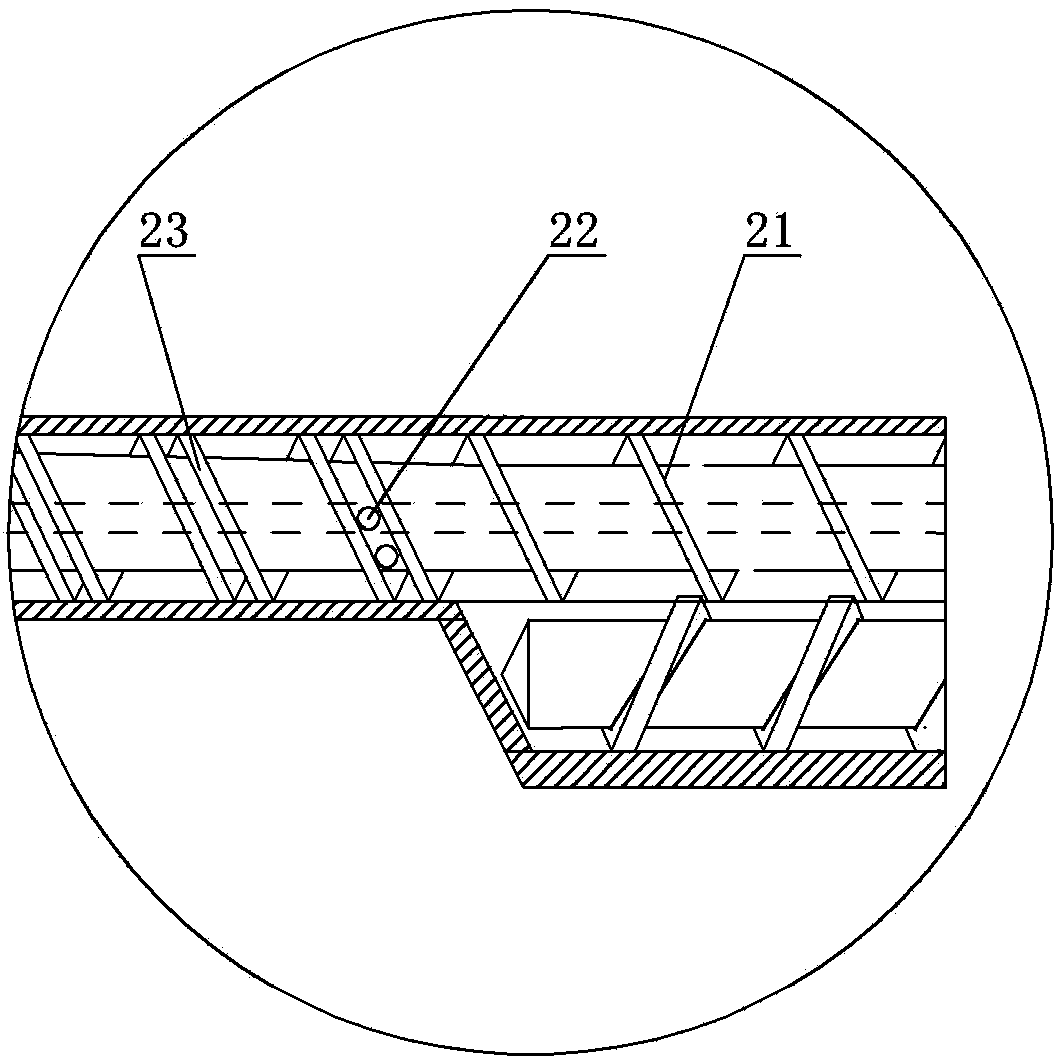

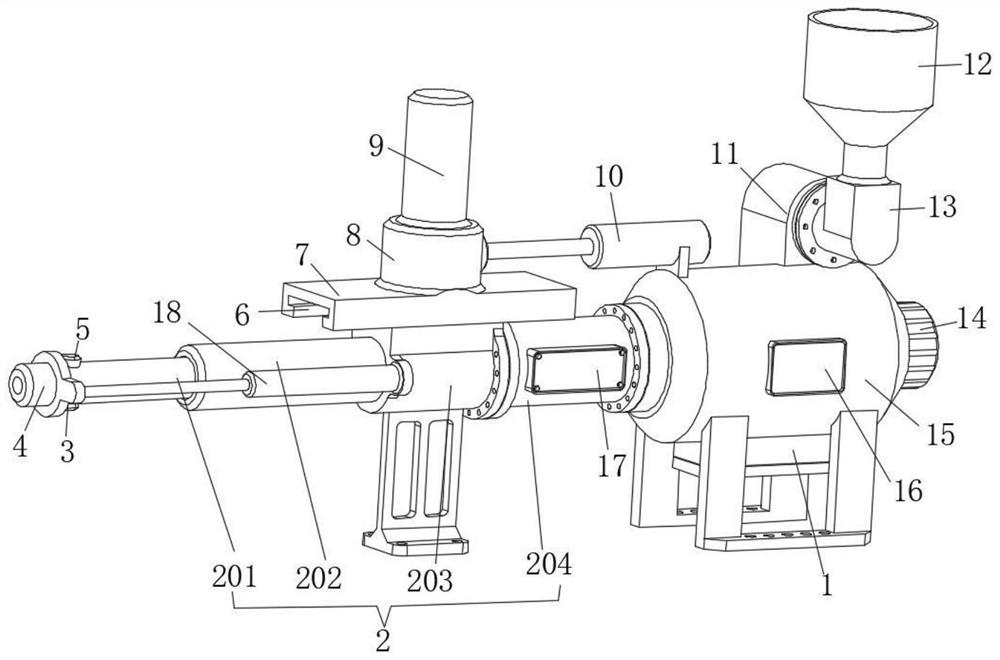

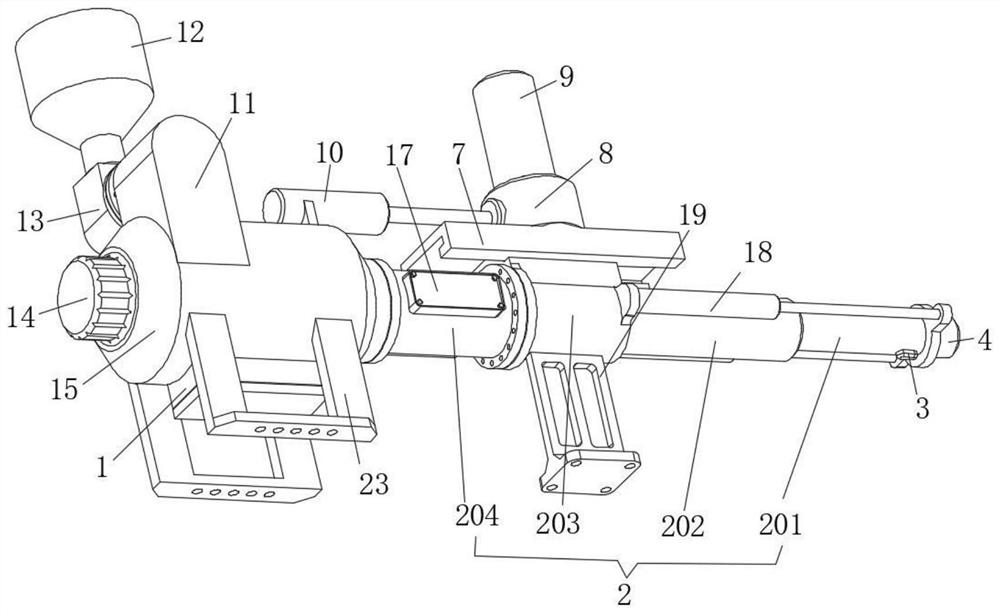

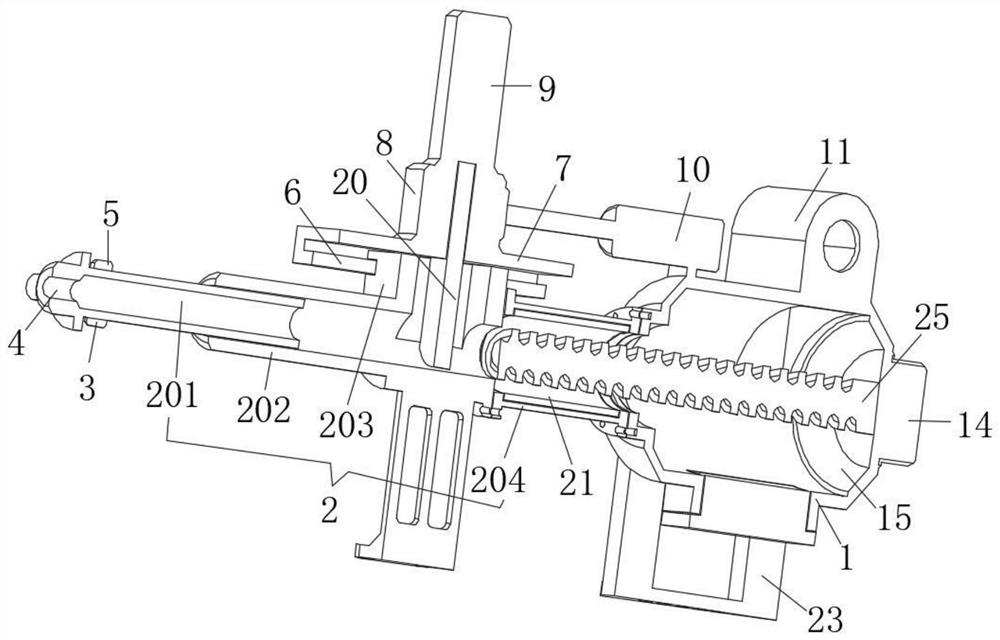

Internal exhaust type parallel counter-rotating multi-screw extruder

The invention discloses an internal exhaust type parallel counter-rotating multi-screw extruder and relates to extrusion molding equipment using at least two screw rods which are not meshed with each other. The internal exhaust type parallel counter-rotating multi-screw extruder has the advantages of high extrusion pressure, enhanced plasticizing capacity, reduced energy consumption, remarkable energy saving effect, good feeding performance, exhaust performance and material overflowing prevention performance, and convenience in screw machining, and is suitable for various plastic and rubber machining. The internal exhaust type parallel counter-rotating multi-screw extruder is structurally characterized in that the left end of a main screw rod has a hollow structure, the built-in left end is fixed on an inner screw rod on an end cover, the direction of threads on the inner screw rod is opposite to that of threads on the main screw rod, the right end of the main screw rod is internally provided with an exhaust channel which is communicated with an exhaust channel in the inner screw rod, threads on the main screw rod corresponding to an auxiliary screw rod are single threads, other threads on the main screw rod are double threads, a first through hole connected with the exhaust channel is arranged in the main screw rod between two screw arrises of the double threads, a plurality of second through holes are arranged between the two screw arrises of the double threads on the main screw rod outside the inner screw rod, the end cover is provided with a melt outlet communicated with a cavity between the main screw rod and the inner screw rod, and the center of the end cover is provided with an exhaust port connected with the exhaust channel.

Owner:金世源

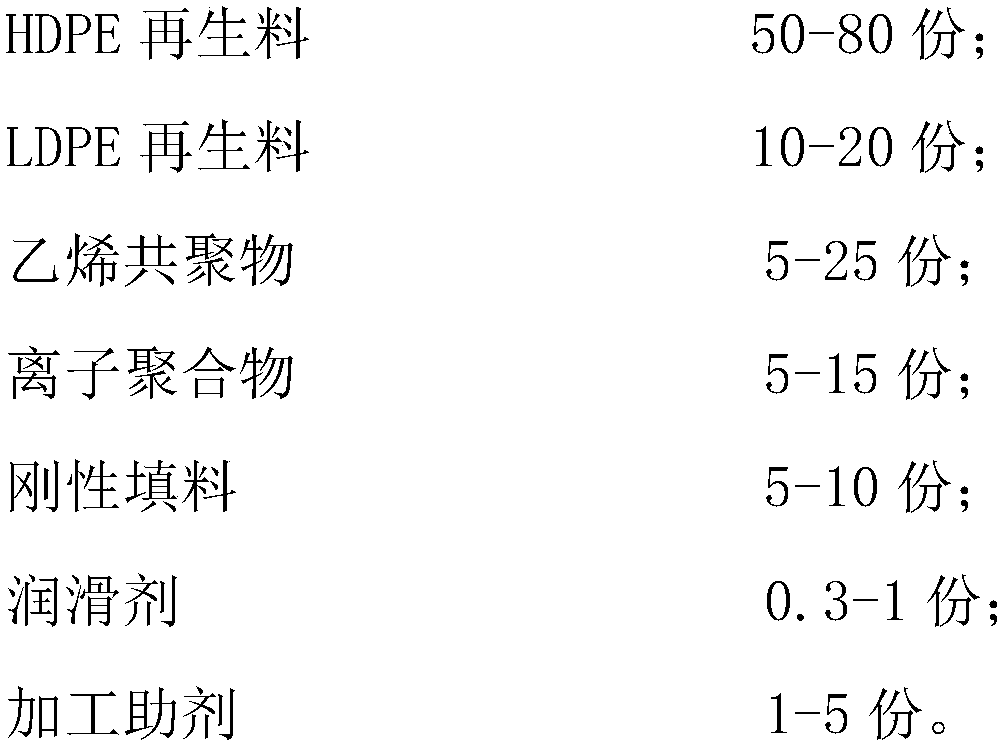

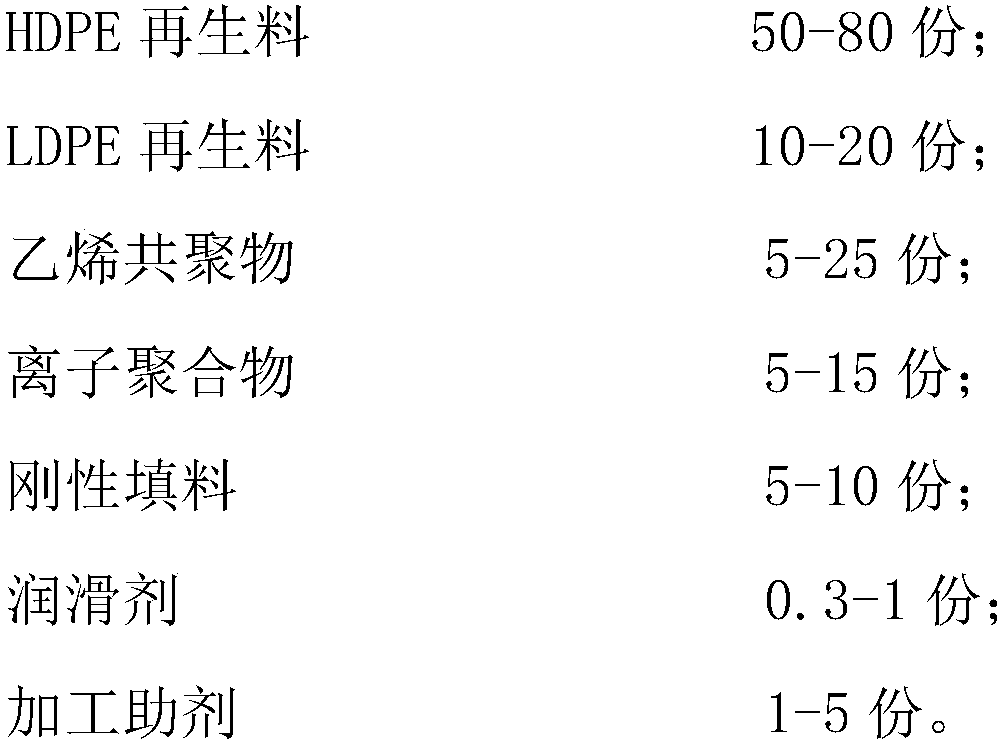

Modified recyclable recycled high-impact-resistant PE (Polyethylene) applied tofor plastic tray and preparation method thereof

The invention is suitable for the technical field of resource recycling, and provides a modified recyclable recycled high-impact-resistant PE (Polyethylene) and a preparation method thereof. The modified recyclable recycled high-impact-resistant PE is characterized in that: PE waste plastic is prepared by adopting multipathobtained by recycling through multiple ways, wherein the total proportion of the recyclable recycled plastic and the stuffing is 90 percent or more, ethylene copolymer and ionic polymer are added, and rigid inorganic particles are added, so that a material is enhanced, meanwhile, the toughness and abrasion resistance of the material can be improved greatly; the impaction resistance of the prepared modified recyclable recycled particles is increased by 1 to 2 times compared withhigher than the conventional recyclable particles; moreover, the inorganic stuffing can be added, thereby improving the rigidity of the material is improved, meanwhile, the material is taken asthe stuffing, so thatand reducing the cost of the material is lowered; the plastic tray has the advantages of low preparation cost and high plastic tray performance.

Owner:GEM WUHAN URBAN MINE RECYCLING IND PARK DEV +1

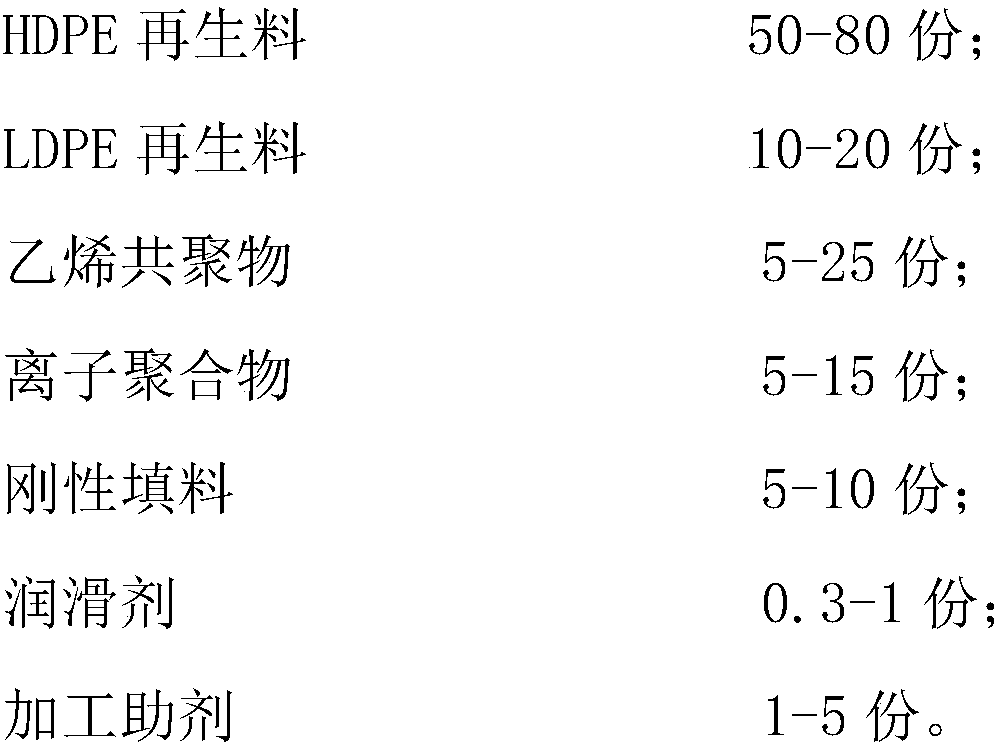

Preparation method of silicon carbide ceramic heat-exchange tube and product prepared by method

The invention provides a preparation method of a silicon carbide ceramic heat-exchange tube and a product prepared by the method. The preparation method comprises the following steps: (1) uniformly mixing silicon carbide micro powder, carbon black and a water reducing agent, then adding a mixture consisting of water, a dispersing agent, a binder and a lubricant, and carrying out stirring; (2) carrying out pugging on the material obtained in the step (1) under a pressure of 1.0-1.5 MPa and a vacuum degree of -0.08 MPa to 0.1 MPa, repeating the process for 3-5 times until the water content is 15-30wt%; (3) carrying out aging on the material obtained in the step (2) and then carrying out forming treatment to obtain a heat-exchange tube biscuit; (4) raising the temperature of the heat-exchangetube biscuit treated by the step (3) to 60-80 DEG C, and carrying out heat preservation and drying; (5) uniformly spraying a sintering aid onto the surface of the heat-exchange tube biscuit treated by the step (4), carrying out heating to 600-1100 DEG C, then introducing protective gas, continuously carrying out heating to 1500-1700 DEG C, carrying out heat preservation, and then carrying out natural cooling to 25-200 DEG C. According to the invention, the sintering aids such as B4C, Y2O3 and the like are not required in the raw materials of the invention, so that the influence of free metalsilicon on the performance of silicon carbide ceramic is reduced, the strength of the biscuit is high, and the rate of finished products is improved.

Owner:潍坊六方碳化硅陶瓷有限公司

Vacuum extruder of brick or tile

InactiveCN1382570AIncrease vacuumReduce energy consumptionCeramic shaping apparatusBrickPulp and paper industry

A vacuum extruder for making bricks and tiles is composed of stirring unit, extruding-out unit and a vacuum chamber between them. The stirring shaft passes through said stirring unit, vacuum chamber and extruding-out unit. The stirring teeth in stirring box and vacuum chamber can perform the stirring, feeding and quatitative transmission functions. Its advantages are simple structure and high extruding out effect.

Owner:程玉全

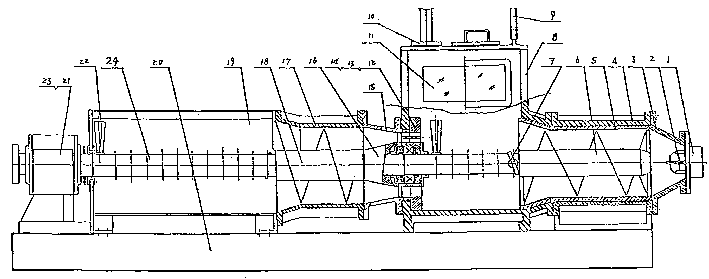

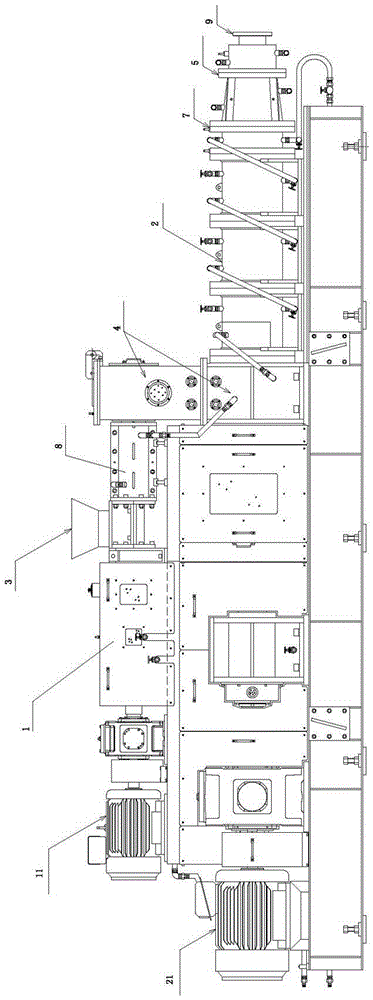

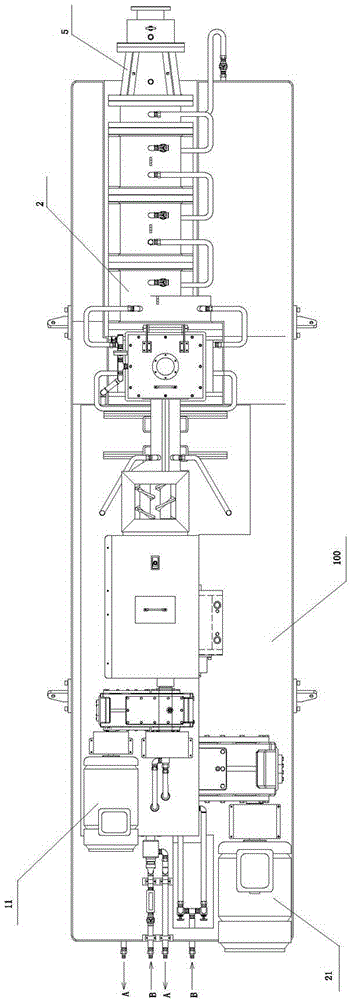

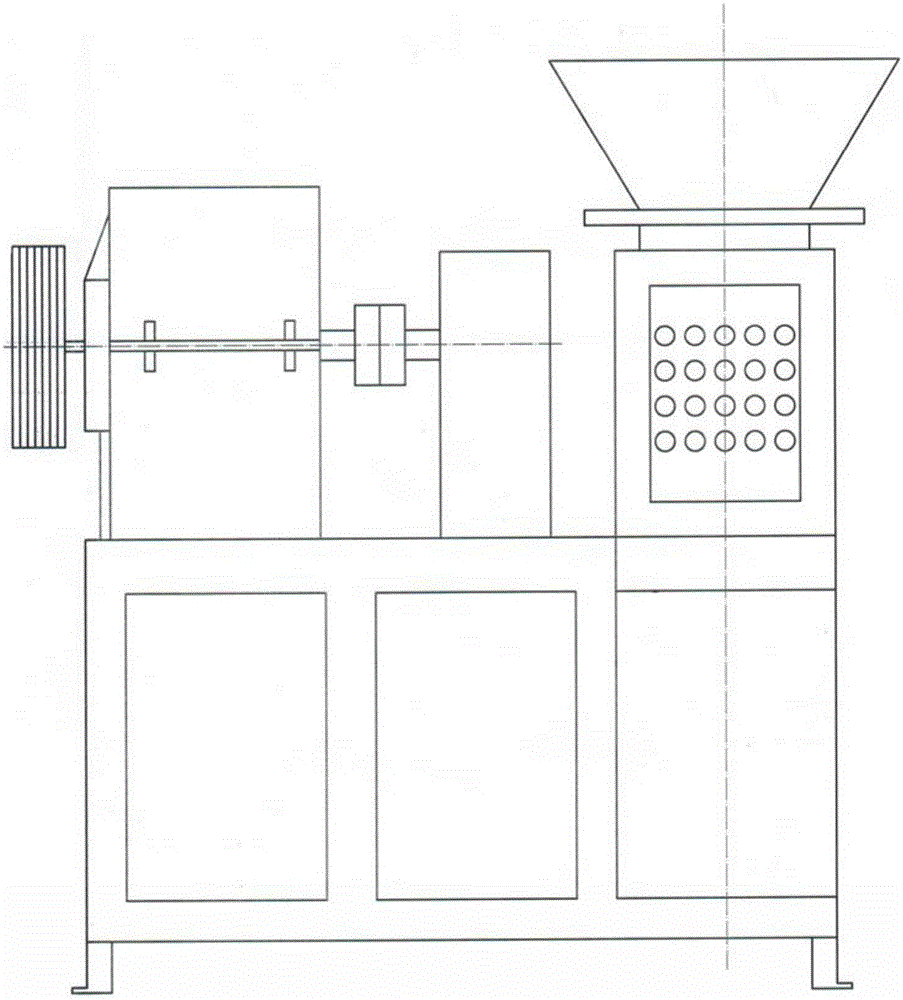

Double-screw extruder

The invention relates to a double-screw extruder, and belongs to the field of plastic mechanical manufacturing. At present, a double-screw extruder with simple structure, reasonable design and two screws of different lengths is unavailable. The double-screw extruder comprises a driving motor, a distribution box with a driving gear and a driven gear, a reduction box, a machine cylinder, an exhaust system, a hopper, a feed system and a machine frame, wherein the driving motor, the distribution box, the reduction box and the machine cylinder are arranged on the machine frame; the reduction box, is connected with the driving motor; the driving gear in the distribution box is connected with the reduction box, and is matched with the driven gear; the feed system is connected with the machine cylinder; and the exhaust system is arranged on the machine cylinder. The double-screw extruder is characterized by also comprising a long screw and a short screw which are arranged on the driving gear and the driven gear; and the long screw and the short screw are both positioned in the machine cylinder. The double-screw extruder has reasonable structural design, scientific layout, stable pressure and excellent extruding performance, and combines the advantages of a single-screw extruder and the double-screw extruder.

Owner:吴汉民

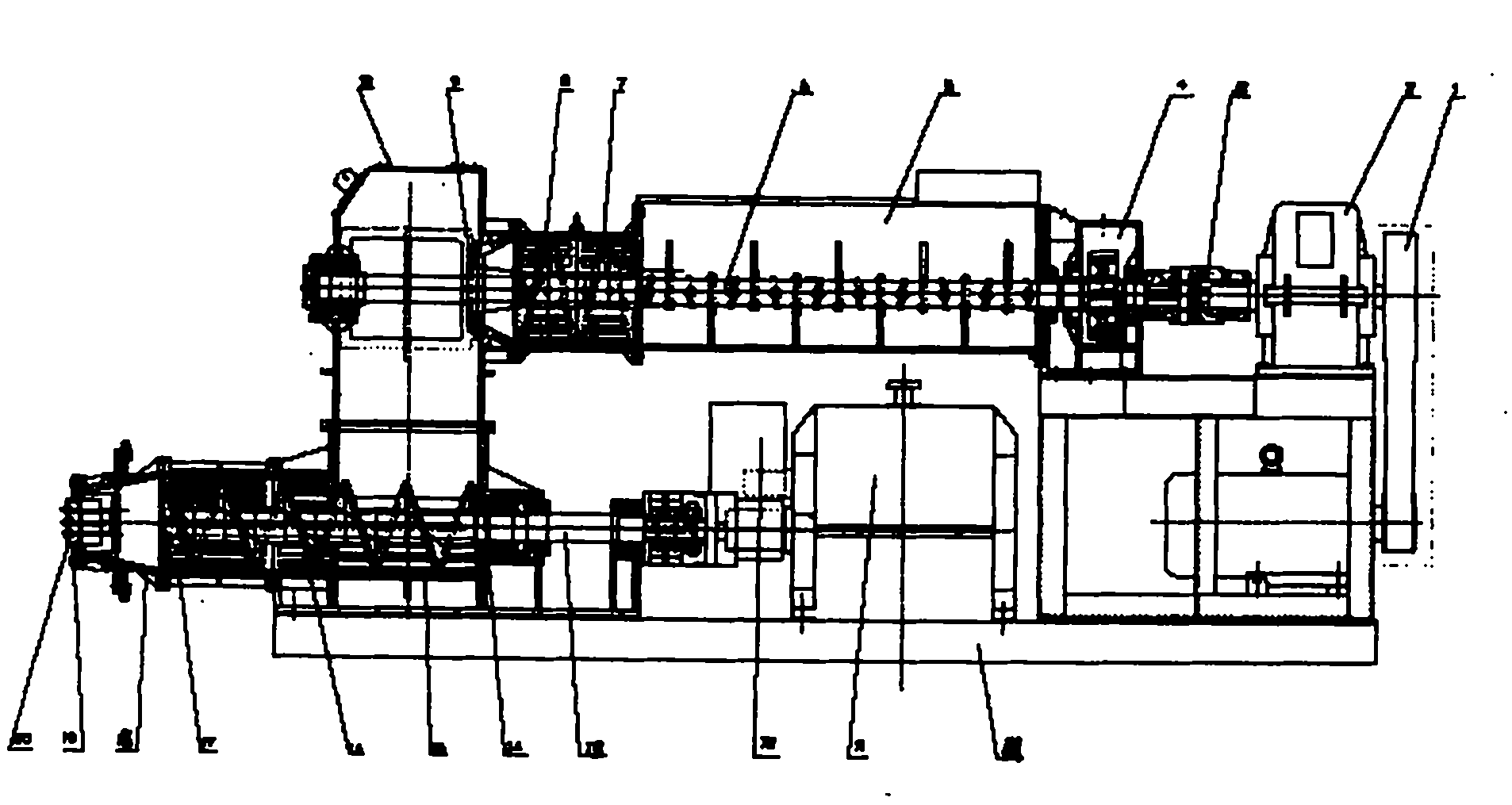

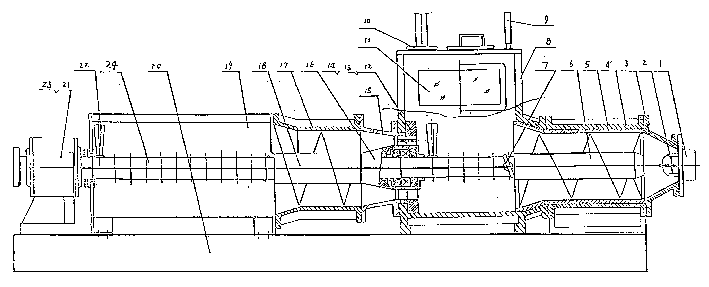

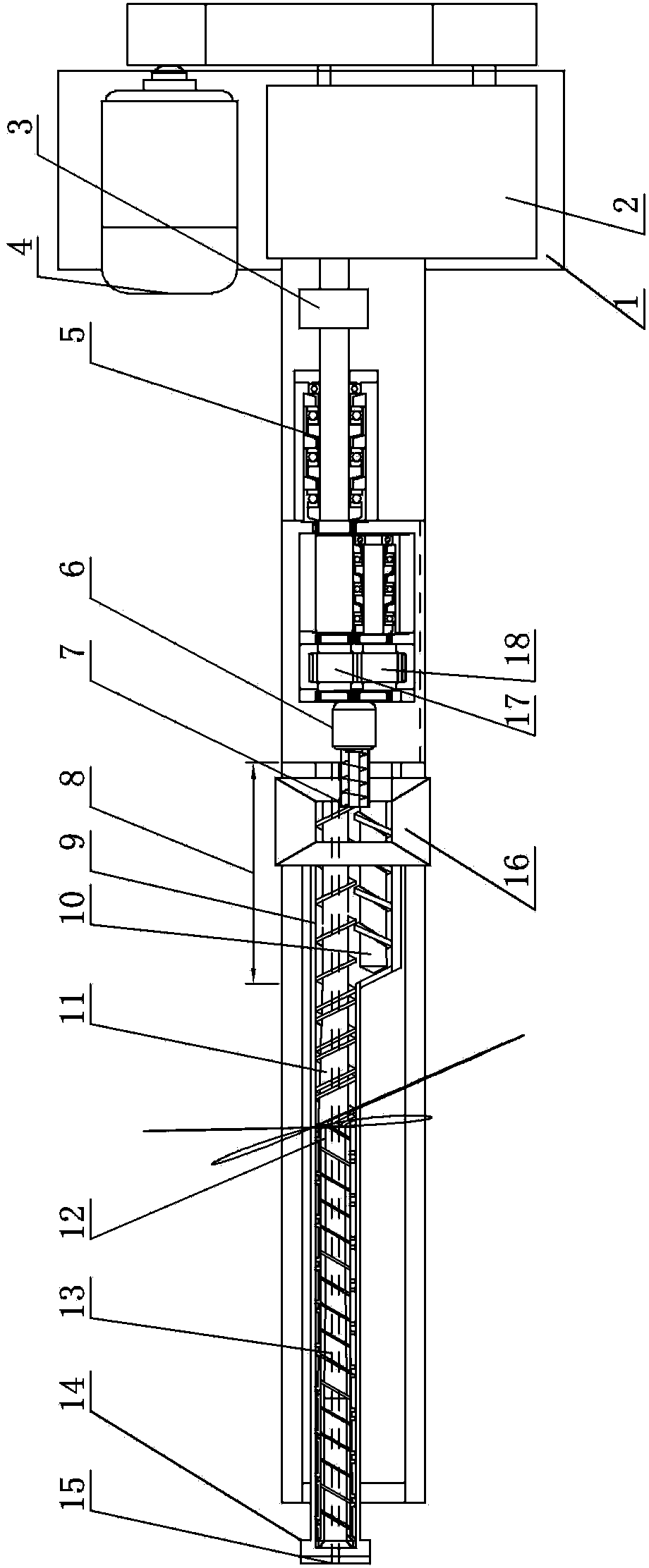

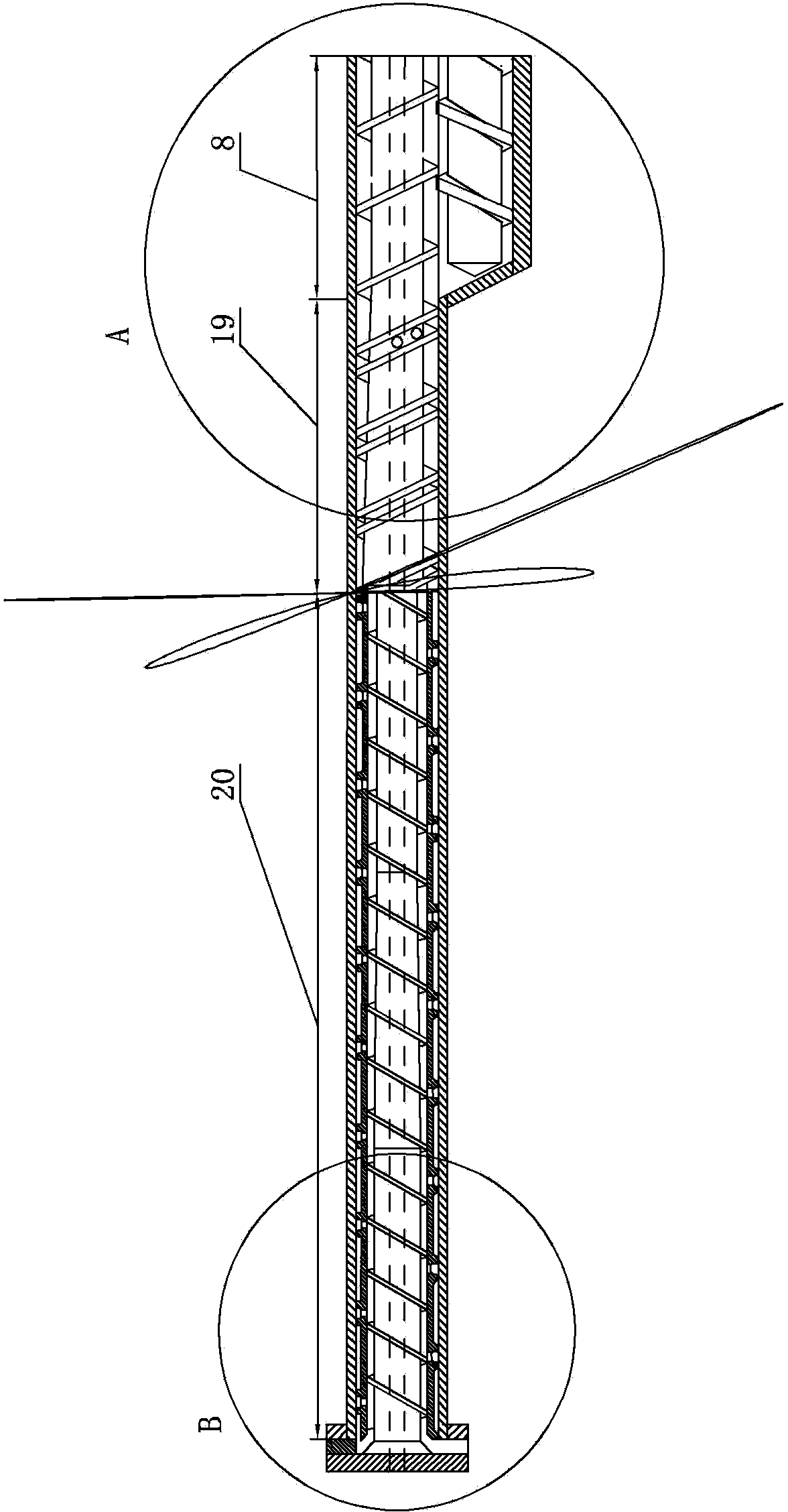

Double-cylinder multi-strip semi-hard plastic vacuum extruder

InactiveCN102166785AIncrease extrusion pressureIncrease productionCeramic shaping apparatusBrickSludge

The invention aims to design a double-cylinder multi-strip semi-hard plastic vacuum extruder for improving the working efficiency and having good energy-saving effects. The vacuum extruder comprises an upper-stage mechanism for mixing, stirring and extruding the materials, and a lower-stage mechanism for continuously extruding and pressing, and extrusion moulding the materials; wherein the upper-stage mechanism and the lower-stage mechanism are communicated through a vacuum chamber, and are respectively driven by a drive motor independently. Compared with the background technique, the vacuum extruder has the following characteristics that: 1, the extruding pressure is large, and the output is high, which is two times of the output of a rimer brick machine with the same model and the same diameter; 2, the energy consumption of a single green brick (building block) is lowered by 10-15%; 3, the structure design is novel and simple, and a sludge pressing plate is removed to save the raw materials by 10-15%; 4, semi-hard plastic vacuum extruding can be suitable for making bricks with non-clay raw materials, such as shale, coal gangue and the like; and 5, baked bricks and sintering heat-preservation building blocks with various models can be manufactured.

Owner:程永科

Smart energy water resistant tree-shaped intermediate voltage cable and production technology

InactiveCN106098239ACompact structureImprove waterproof performancePower cables with screens/conductive layersInsulated cablesLinear low-density polyethyleneElectrical conductor

Owner:FAR EAST CABLE +2

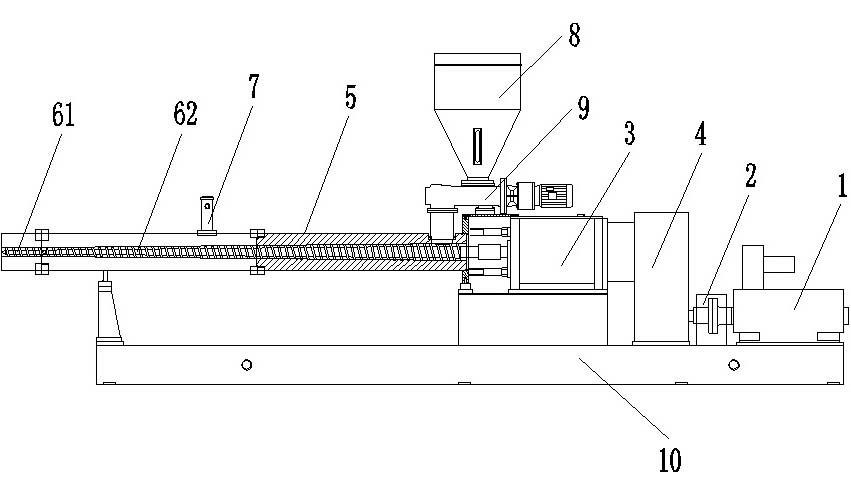

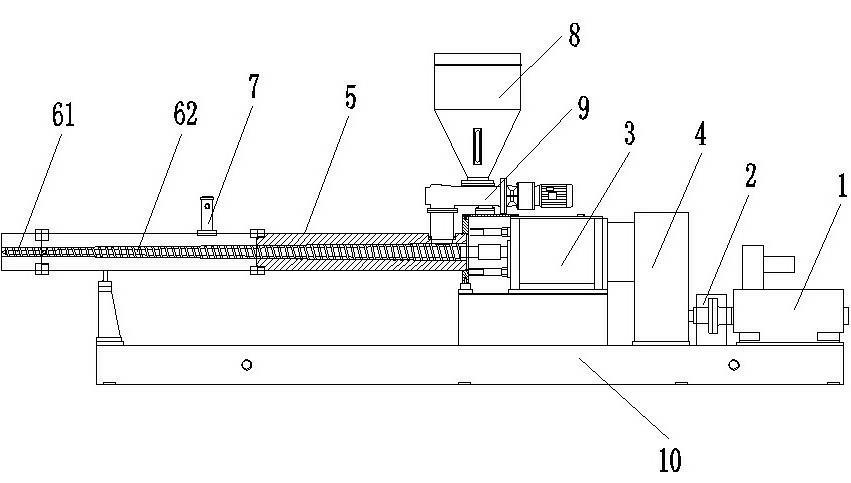

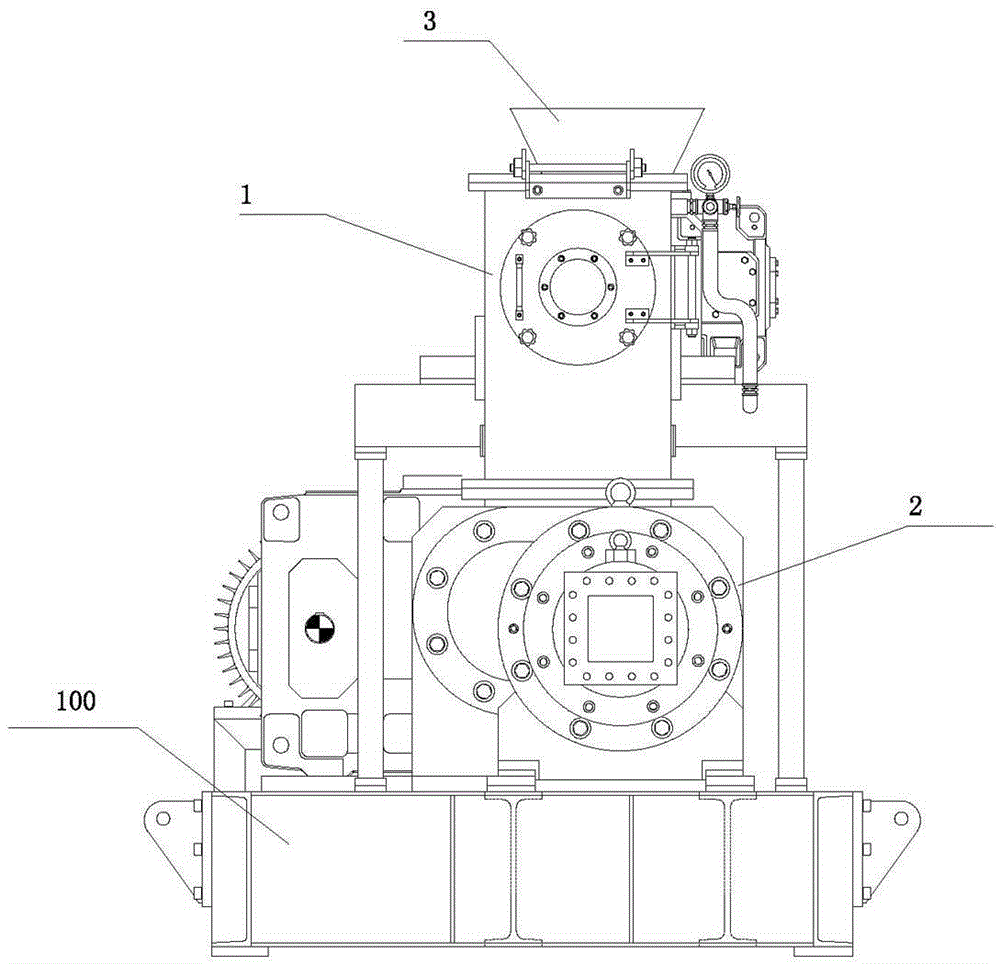

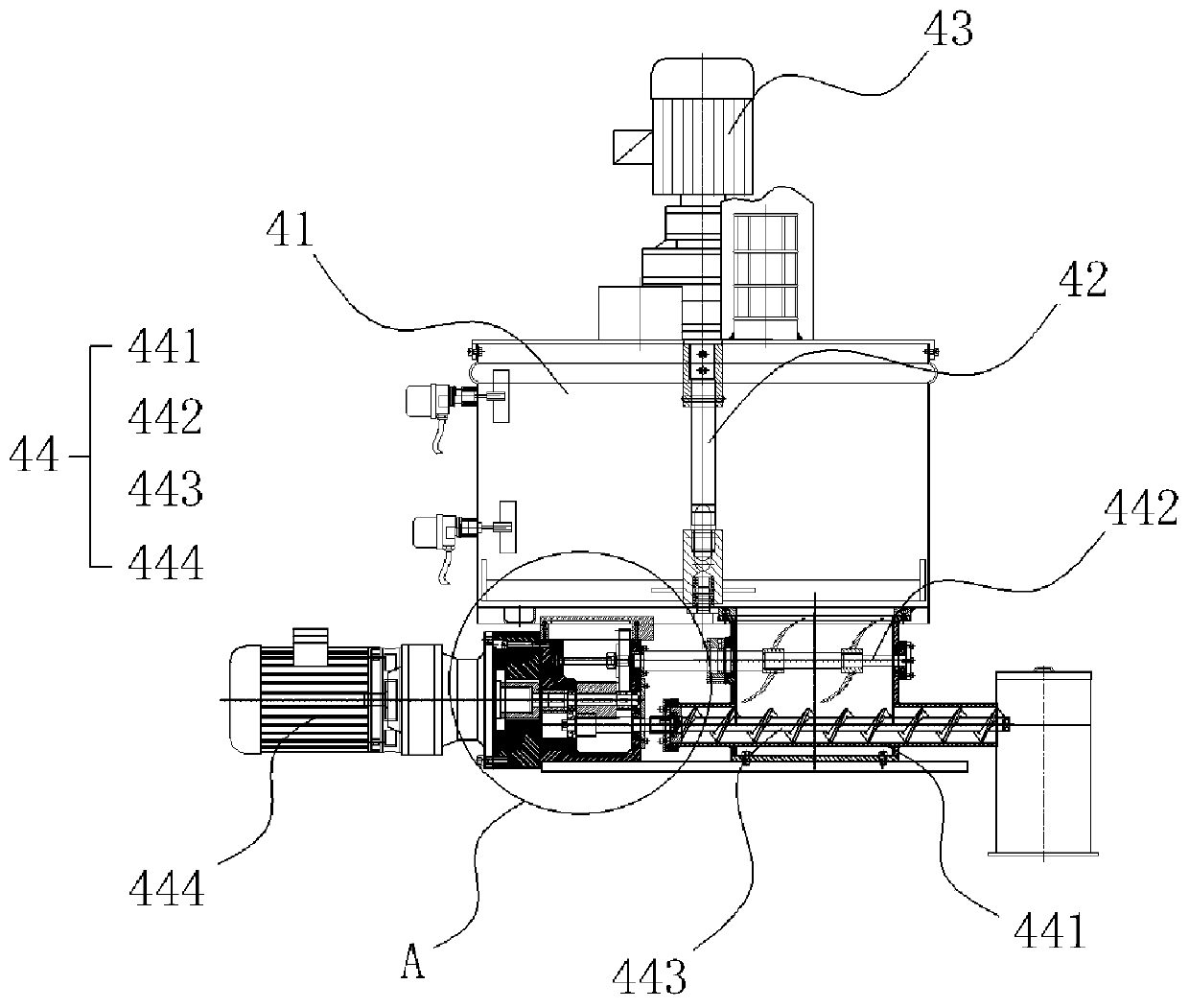

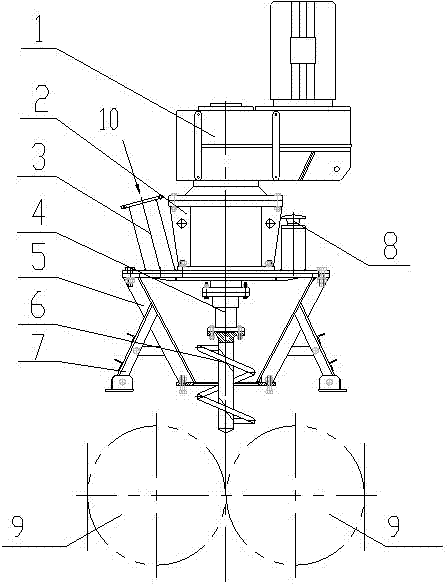

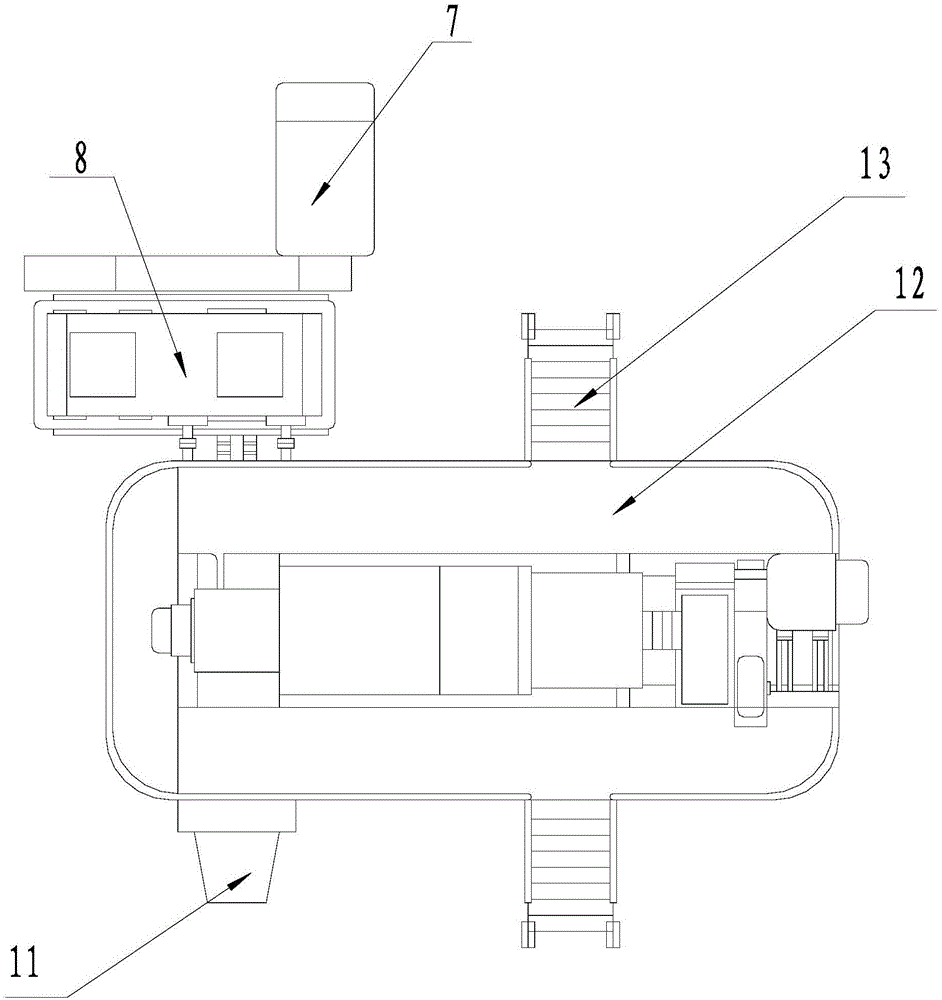

Multiscrew pressurizing extruder

The invention discloses a multiscrew pressurizing extruder which comprises a pedestal and a feeding section, a delivery section and a discharging section successively arranged on the pedestal, wherein an extruding pressurizing plasticizing section is arranged between the feeding section and the discharging section, an output shaft of a variable-frequency speed-regulating main motor is in fixed connection with an input shaft of a speed reducer, an output shaft of the speed reducer directly drives the feeding section and the extruding pressurizing plasticizing section in fixed connection with the feeding section, and the discharging section is connected with the back end of the extruding pressurizing plasticizing section. According to the invention, plasticizing and pressurizing of a material are integrated together, and only a set of a driving device is employed; not only a good plasticizing effect is obtained, but also a sufficiently great extrusion force, low energy consumption and great output are realized, so the multiscrew pressurizing extruder has a high practical value.

Owner:SHANGHAI LONGSHANFENG MACHINE MFG +1

High-pressure extrusion molding machine

ActiveCN105172091AAchieve smooth extrusionMeet the continuous extrusion production processMolding machineLower grade

The invention provides a high-pressure extrusion molding machine which comprises an upper-grade feeding mechanism and a lower-grade feeding mechanism. The upper-grade feeding mechanism is connected with a hopper, and the upper-grade feeding mechanism and the lower-grade feeding mechanism both transversely convey materials through screw rods and are connected through a vacuum chamber; the conveyed materials are extruded and conveyed by the upper-grade feeding mechanism, then pass through the vacuum chamber and enter the lower-grade feeding mechanism to be secondarily extruded and conveyed; an outlet of the lower-grade feeding mechanism is connected with an extending pipe. The high-pressure extrusion molding machine further comprises a cooling loop system. According to the high-pressure extrusion molding machine, the structures and extrusion sections of the screw rods are improved, 15MPa high-pressure extrusion molding is achieved, and the requirements of a continuous extrusion production process for thin-walled selective catalytic reduction (SCR) honeycomb type catalysts can be met; the technical problem of continuous extrusion production of horizontal large-hole-diameter thin-walled honeycomb type SCR catalysts is solved, the production efficiency is improved, and the manufacturing cost of products is lowered.

Owner:ZHEJIANG GUANGHAN ENVIRONMENTAL PROTECTION TECH

Fish ball making device and using method thereof

InactiveCN113349237AEasy to operateQuality improvementMeat processingStructural engineeringMechanical engineering

The invention provides a fish ball making device and a using method thereof, and belongs to the technical field of food equipment. The fish ball making device comprises a pressure bearing block, an extrusion block, a feeding hole, a plurality of discharging holes, a feeding mechanism, a driving mechanism and a cutting mechanism, wherein an extrusion groove is formed in the upper side surface of the pressure bearing block; the extrusion block is arranged in the extrusion groove in an up-down sliding manner; the feeding hole is horizontally formed in the left side surface of the pressure bearing block; the feeding hole communicates with the bottom of the left side wall of the extrusion groove; the discharging holes are sequentially and horizontally formed in the right side surface of the pressure bearing block at intervals; the discharging holes communicate with the bottom of the right side wall of the extrusion groove; the feeding mechanism can inject fish ball raw materials into the feeding hole; the driving mechanism can drive the extrusion block to slide up and down; and the cutting mechanism can cut off fish ball strips extending out of the discharging holes. The fish ball making device can quickly make fish balls, and the making efficiency and the quality of the fish balls are improved.

Owner:ZHEJIANG INT MARITIME COLLEGE

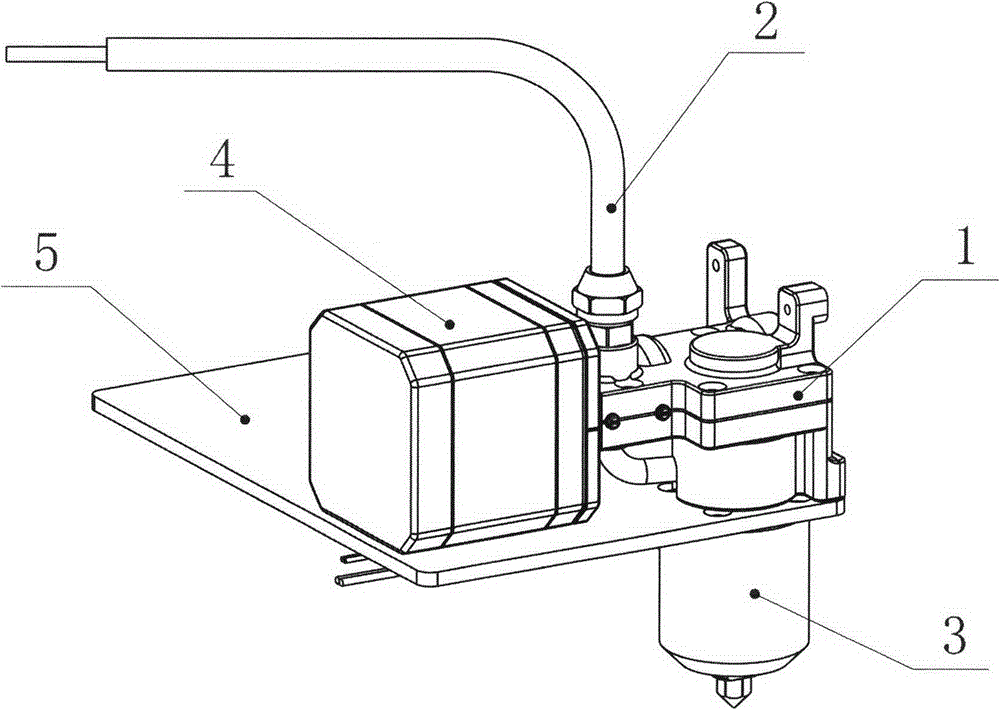

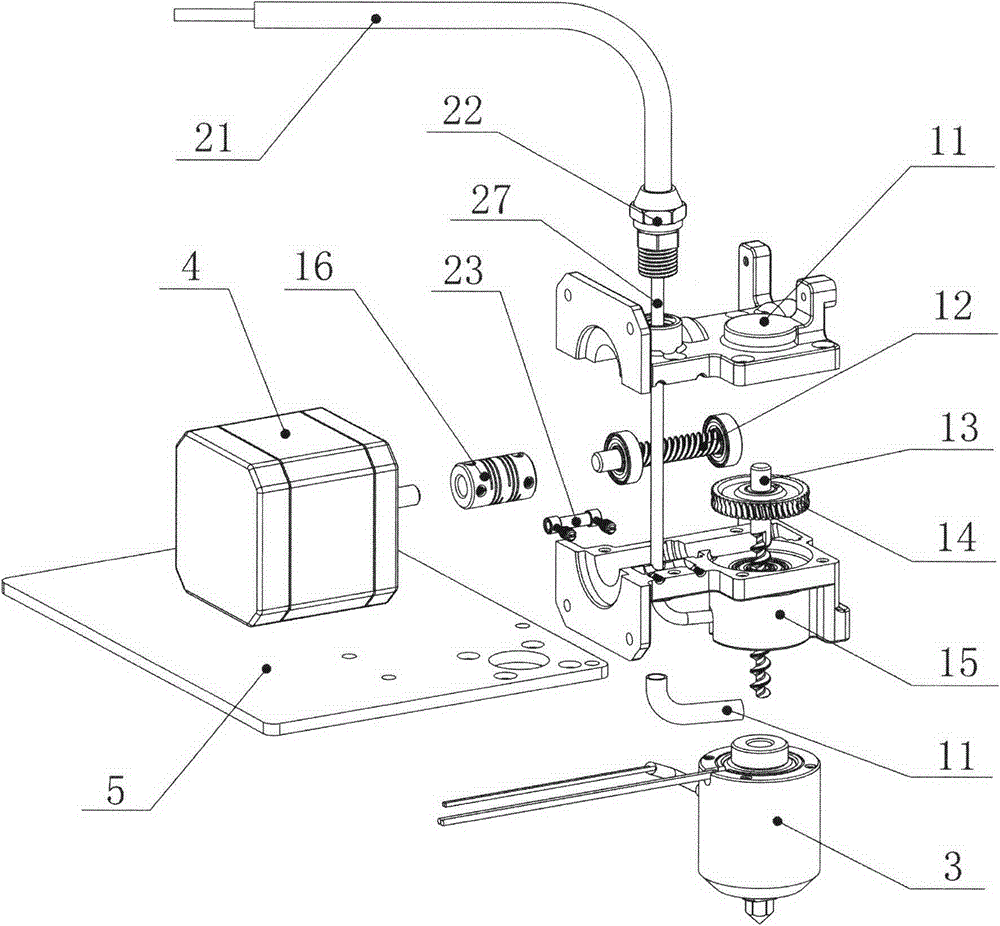

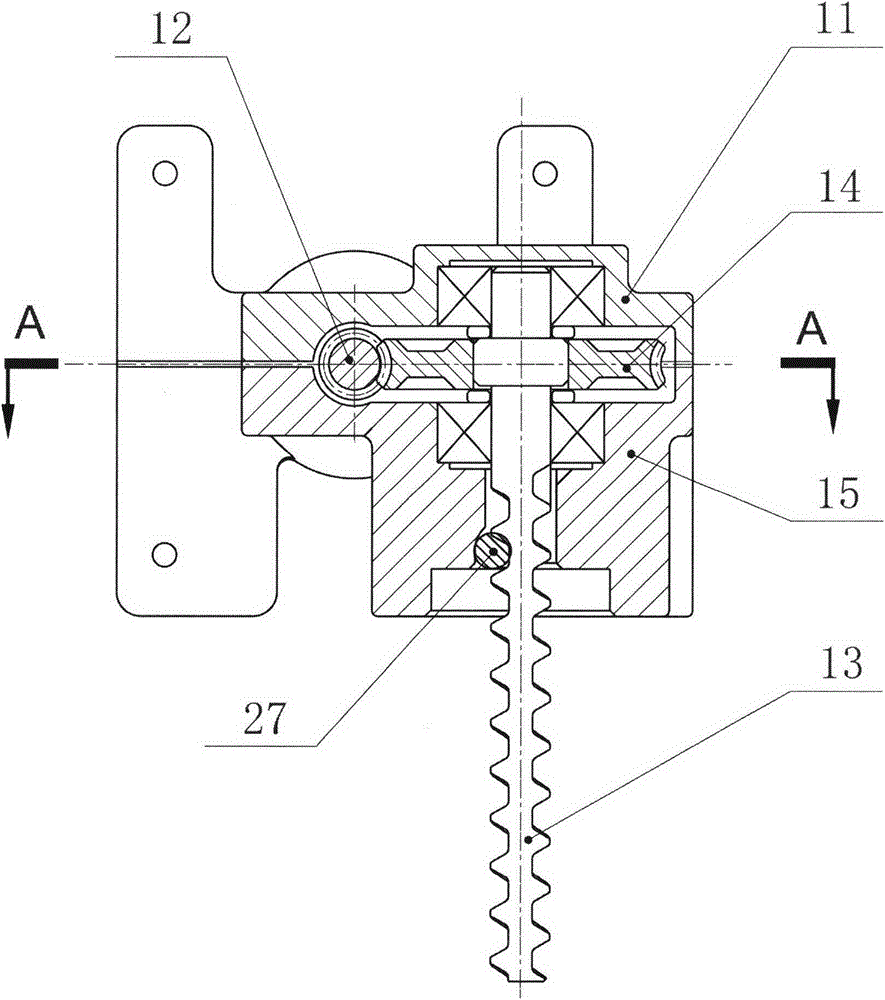

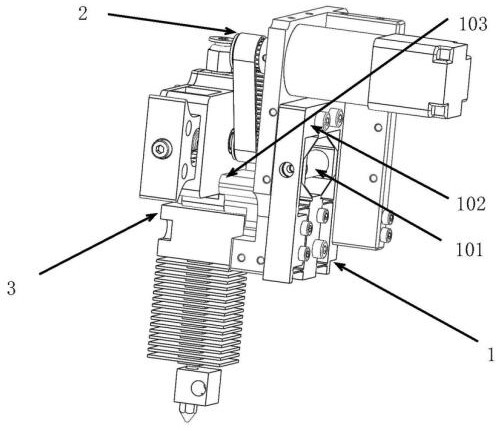

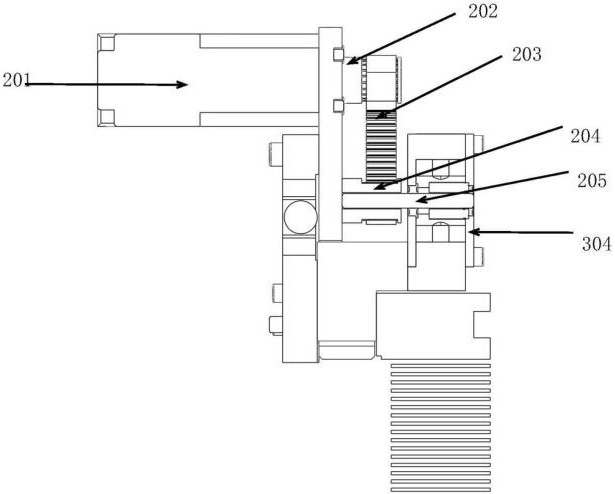

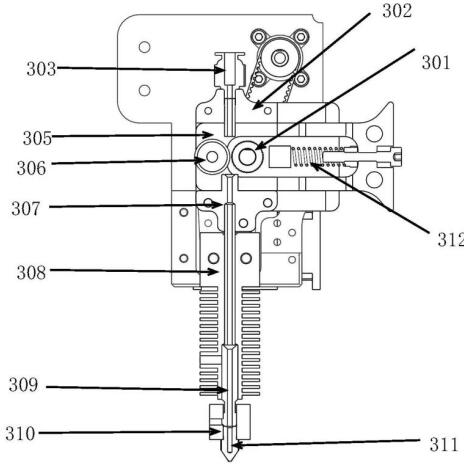

Screw extrusion device of fusion deposition modeling technology-based 3D printer

InactiveCN104441559APrecise speed controlAccurate control precisionAdditive manufacturing apparatus3D object support structuresHot meltEngineering

The invention relates to a screw extrusion device of a fusion deposition modeling (for short: FDM) technology-based 3D printer, and belongs to the field of 3D printing technologies. The screw extrusion device comprises a speed reduction mechanism, a feeding mechanism, a hot melt spray head, a motor and a supporting plate, wherein the speed reduction mechanism conveys a thermofuse into the hot melt spray head through the feeding mechanism under the driving of the motor, the hot melt spray head heats the thermofuse so as to enable the thermofuse to be fused, the fused thermofuse is extruded from the hot melt spray head through a screw in the speed reduction mechanism which is retarded by a worm and a worm gear. The screw extrusion device is compact in design, accurate to control, large in extrusion pressure, and applicable to thermofuses with different sizes and precisions, the precision of the fusion deposition modeling technology-based 3D printer can be effectively improved, the speed of the fusion deposition modeling technology-based 3D printer can be effectively increased, and the discharge unevenness and plugging phenomena can be effectively reduced.

Owner:NANJING RONGHUIZICE INVESTMENT MANAGEMENT

Degradable sheet extrusion molding machine

The invention discloses a degradable sheet extrusion molding machine. The degradable sheet extrusion molding machine comprises a twin-screw extruder, a single-screw extruder, an automatic constant temperature device, a blanking control device and a die head hoisting device, a discharge port of the twin-screw extruder communicates with a feeding port of the single-screw extruder, and the position of the twin-screw extruder is higher than the single-screw extruder. The blanking control device is arranged on a feeding port of the twin-screw extruder, an extrusion die head is arranged on a discharge port of the single-screw extruder, and the top of the extrusion die head is fixedly connected with the die head hoisting device. Machine cylinders of the twin-screw extruder and the single-screw extruder are divided into a plurality of independent temperature control sections, cooling channels which reduce the temperature of the machine cylinders are formed in the temperature control sections,cast aluminum heaters for heating materials sleeve the outer walls of the temperature control sections, and the temperature of the temperature control sections of the twin-screw extruder and the single-screw extruder is controlled by the automatic constant temperature device. The degradable sheet extrusion molding machine can effectively reduce the production cost, ensure the quality and stabilityof products, and greatly improve the working efficiency.

Owner:SHANTOU LONGSHENG INDAL

Dual-drive multi-screw extruder

The invention provides a dual-drive multi-screw extruder, comprising a base as well as a feeding device, a delivering device and a main plasticizing device which are sequentially arranged on the base, wherein a pressurizing and extruding device is arranged at the rear end of the main plasticizing device. The dual-drive multi-screw extruder provided by the invention not only enables plasticized materials to reach an optimal uniform degree but also enables the plasticized materials to be extruded out in a centralized pressure manner, and has the advantages of large output, low energy consumption and higher practical values.

Owner:SHANGHAI LONGSHANFENG MACHINE MFG +1

Method for multilayered system differentiation plugging

InactiveCN106481307AIncrease extrusion pressureImprove seal strengthSealing/packingHigh densityCement paste

The invention discloses a method for multilayered system differentiation plugging. The method comprises the following steps that a potential-free layer with the high permeability is found out and determined from multilayered system oil layers of a full well section; the potential-free layer with the high permeability is shielded and plugged by squeezing in low-density cement paste in a high-displacement mode; then, squeezing in high-density cement paste in a low-displacement mode is adopted for simultaneous plugging of the full well section. In order to solve the problem that the plugging effect is affected by different starting pressures of plugging layers when multilayered system potential-free oil layers need to be plugged at the same time, the stratum extrusion pressure is increased by shielding the potential-free layer with the high permeability by pumping in low-density cement paste in a large-displacement mode at first, the high-density cement paste is applied for simultaneous plugging of the full well section, the plugging strength is improved, and the plugging effect is ensured.

Owner:CHINA PETROLEUM & CHEM CORP +1

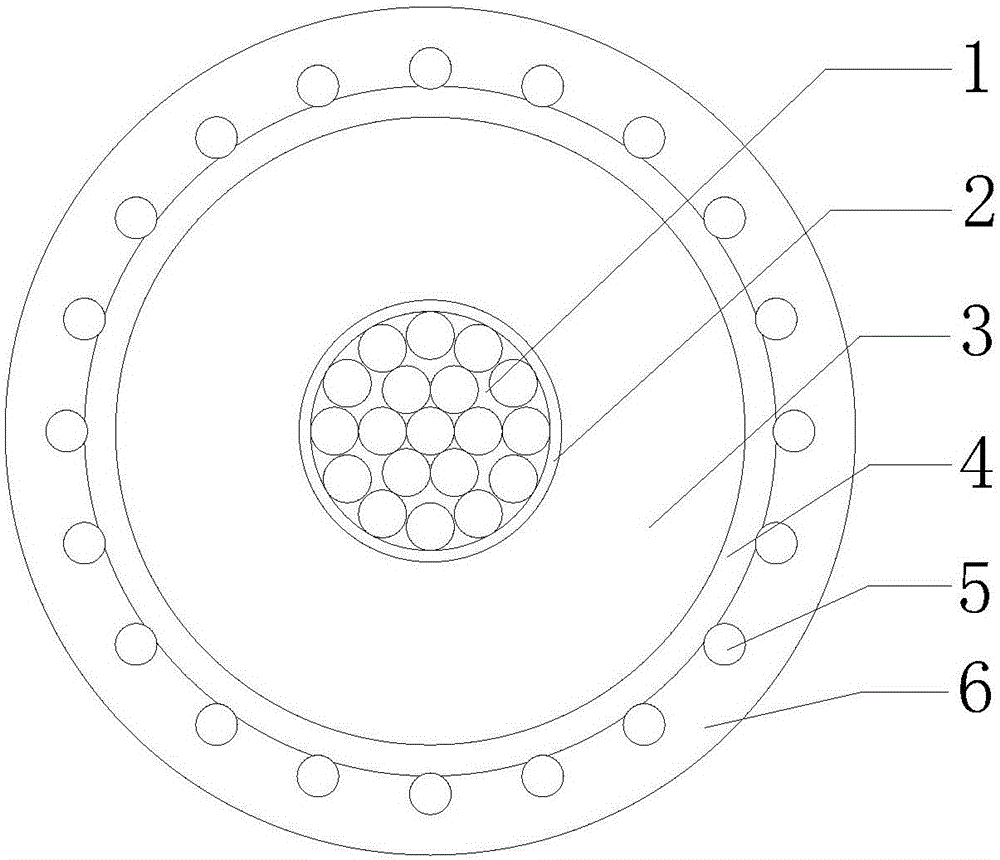

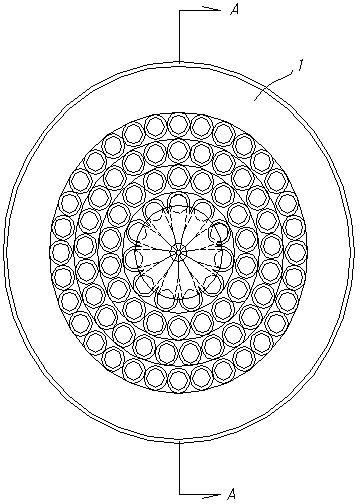

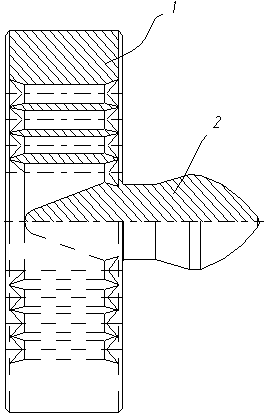

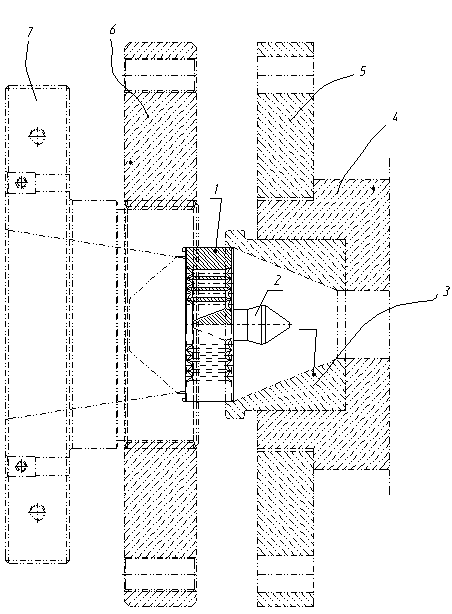

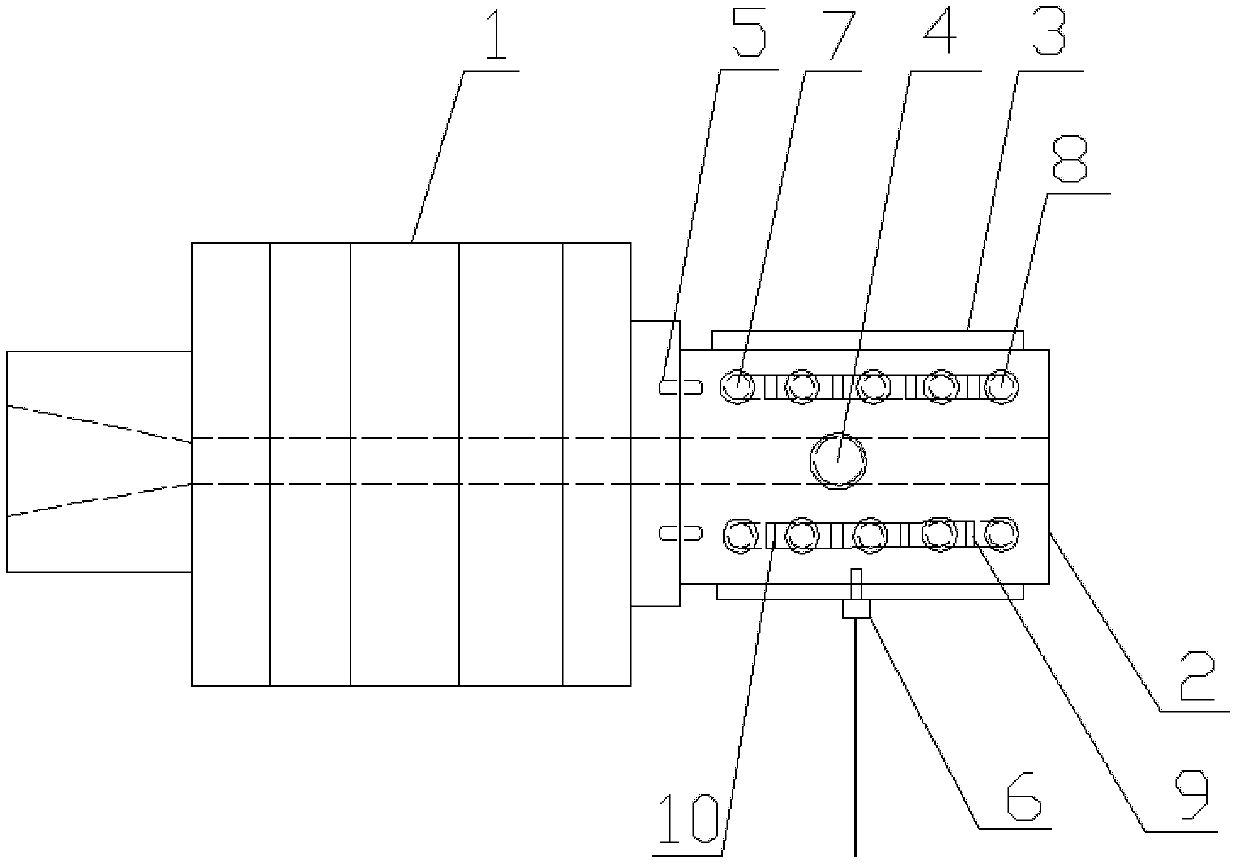

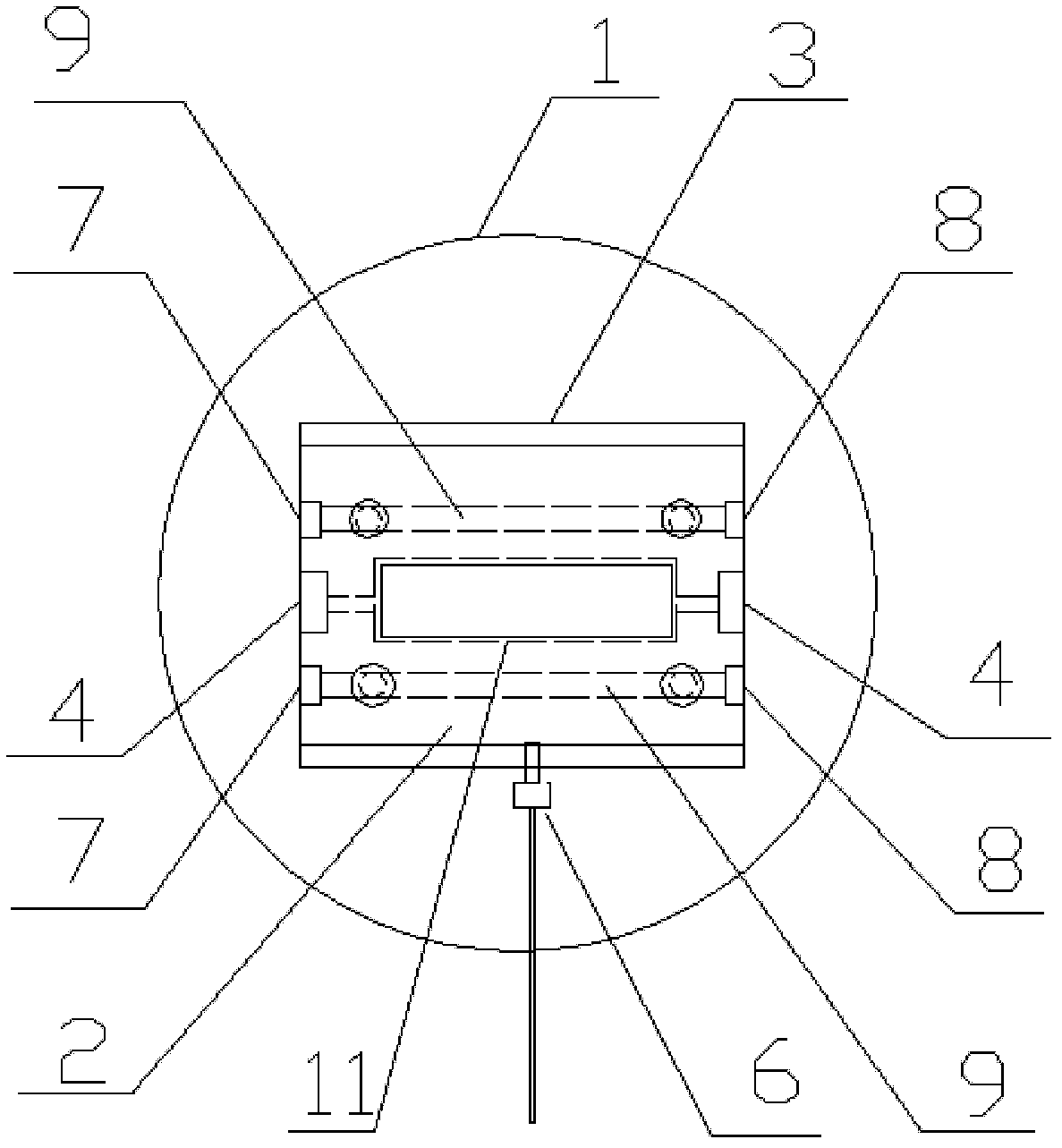

Supercharge mixed flow perforated plate for wood plastic profiled bar extrusion mold

The invention discloses a supercharge mixed flow perforated plate for a wood plastic profiled bar extrusion mold. The perforated plate is a circular plate (1) in which a plurality of circles of concentric rings are formed; the center of the circular plate (1) is fixedly connected with a spindle-shaped mixed flow hammer (2) perpendicular to the plate surface; and the two ends of the mixed flow hammer (2) are conical, wherein one end is inlayed in the through hole in the circular plate. By adopting the supercharge mixed flow perforated plate, the smoothness of the large face of the sectional bar and the simulation degree of wood grain shape are effectively enhanced, and the physical property and surface quality of the sectional bar are improved.

Owner:ANHUI NAIKE EXTRUSION SCI & TECH

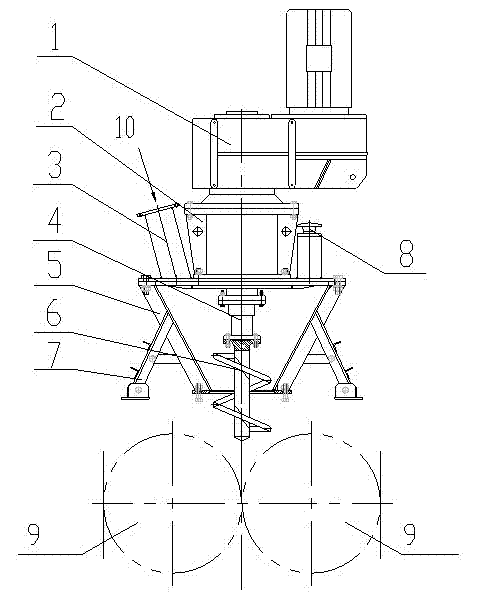

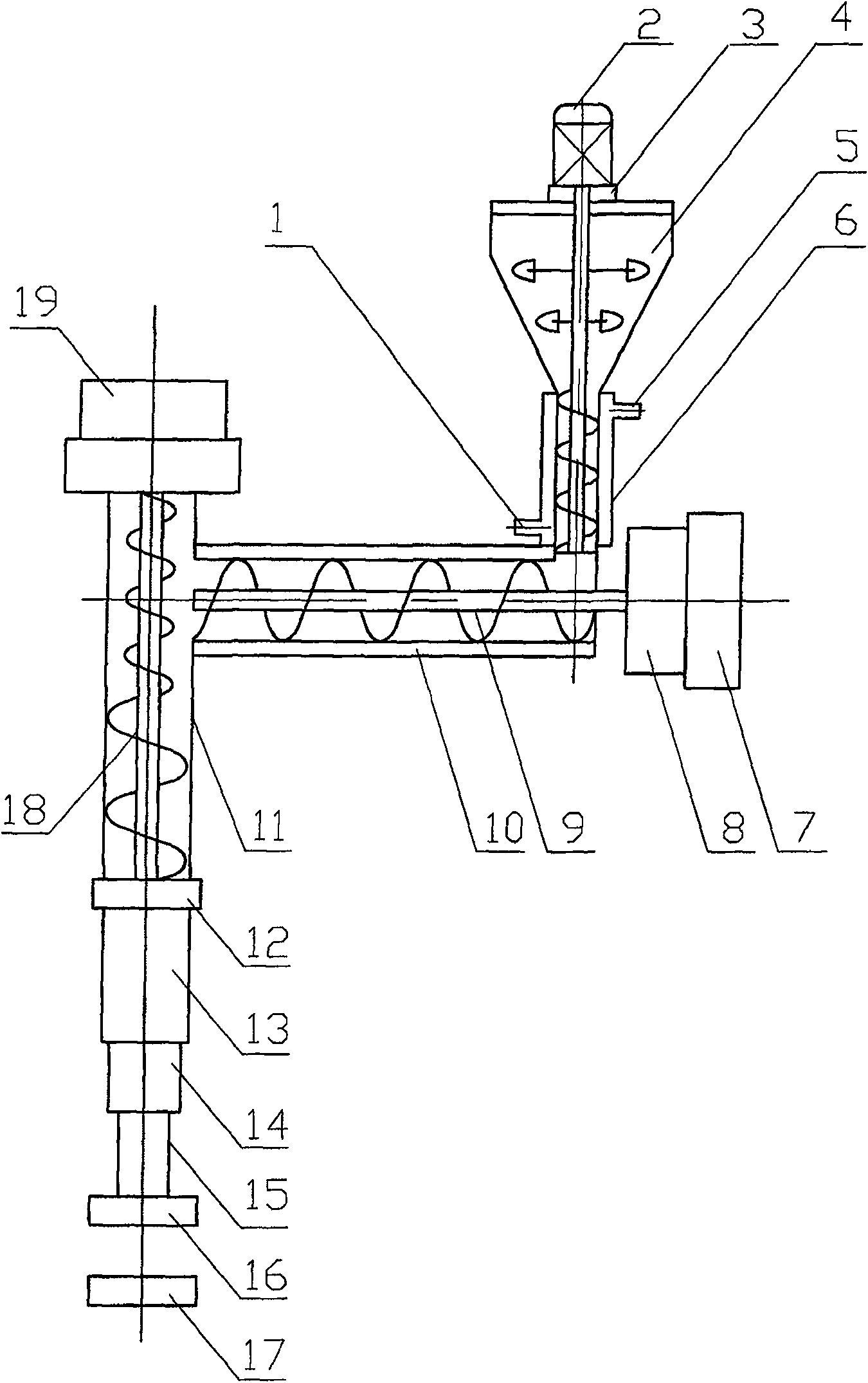

Spiral forced feed system

InactiveCN102500278AIncrease extrusion pressureImprove product qualityGranulation by pressingFiltrationFlange

The invention relates to a feed device, in particular to a spiral forced feed system, which is characterized by comprising a motor, a bearing seat, a blanking hopper cover, a connection flange, a blanking hopper for storing a material, an extrusion spiral, a support for supporting, a ventilation cap and extrusion rollers, wherein the motor is connected with the blanking hopper cover through the bearing seat, the connection flange drives the extrusion spiral to rotate so as to provide forced downward extrusion force to the material in the blanking hopper, the blanking hopper cover is arranged on the blanking hopper so as to support the bearing seat and the motor, the ventilation cap is connected on the blanking hopper cover for ventilation and filtration, and the extrusion rollers are connected on the support so as to extrude the material to be molded. The spiral forced feed system discloses by the invention has the advantages that the extrusion pressure is improved, the quality of a product is improved, and the production efficiency is greatly improved.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

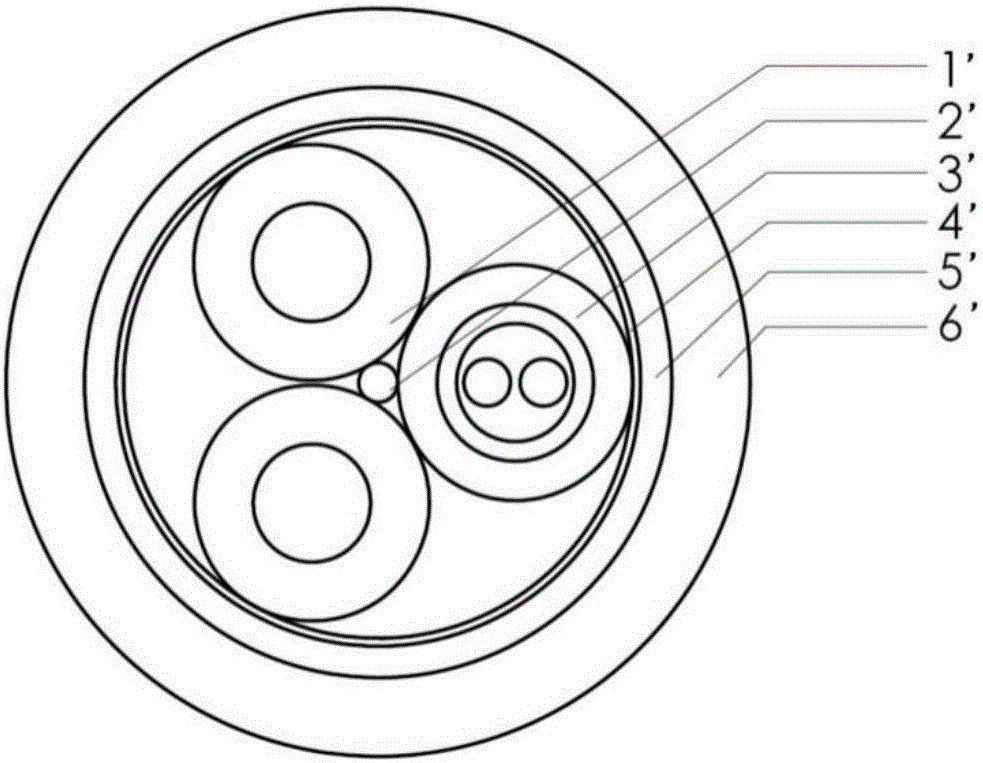

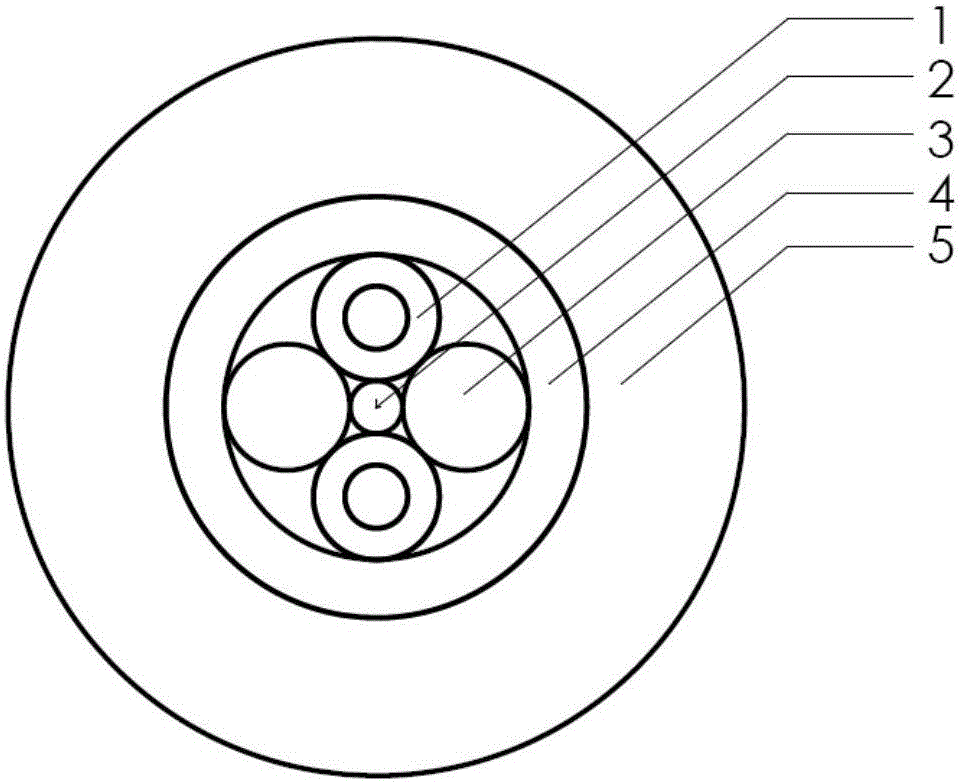

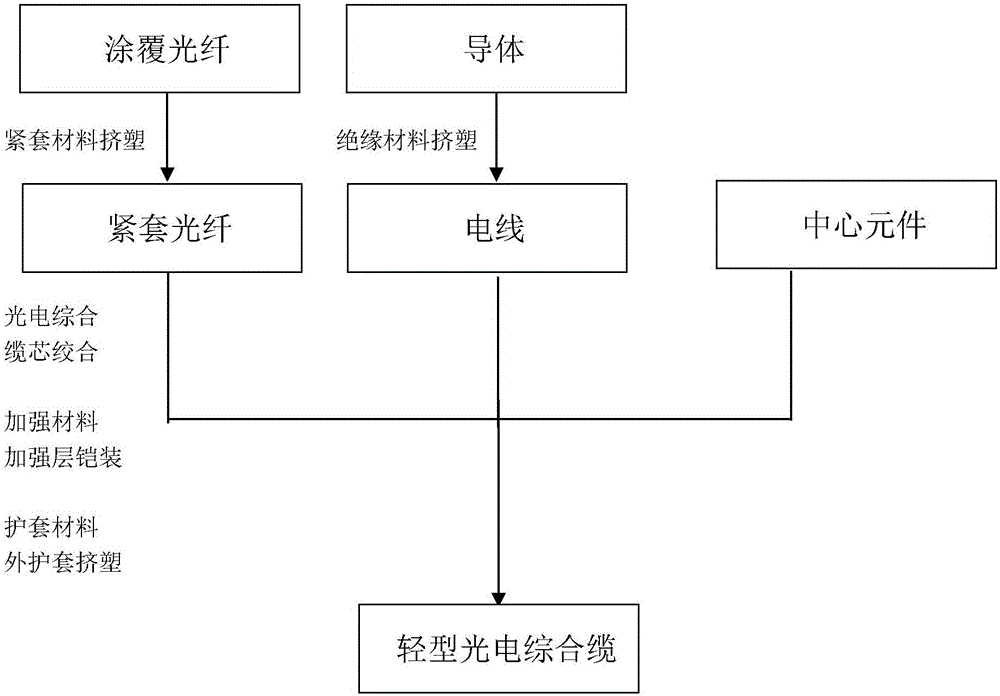

Photoelectric composite cable

InactiveCN106847389AImprove flexibilityVersatilityCommunication cablesFlexible cablesEngineeringCentral element

The invention discloses a photoelectric composite cable. The photoelectric composite cable comprises a cable core, a reinforcing layer and an outer sheath, which are arranged in sequence from inside to outside, wherein the cable core is of a four-core symmetrical interval stranded structure formed by stranding two tight buffered optical fibers with the same outer diameter and two electric wires on one central element; each tight buffered optical fiber comprises an optical fiber provided with a coating layer and a tight buffered layer; the diameter of each optical fiber is 0.2mm to 0.4mm; meanwhile, the invention further discloses a method for preparing the photoelectric composite cable; and the method comprises the following three steps: preparing the tight buffered optical fibers, preparing the electric wires and stranding the photoelectric composite cable core, and armoring a reinforcing layer and extruding the outer sheath. The photoelectric composite cable provided by the invention is novel in structural design, reasonable in material selection and stable and reliable in product performance; the outer diameter and weight of the photoelectric composite cable are extremely reduced; special requirements of rapidly, conveniently and repeatedly deploying and retracting the cable by a single person are met; meanwhile, a machining manner of molding in one step is adopted, so that machining procedures are effectively reduced and the production efficiency is improved; the structure of the photoelectric composite cable is more compact and performances are stable and reliable.

Owner:上海传输线研究所

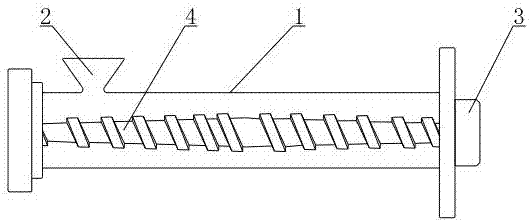

Plastic extruder with special-shaped conical threaded rod

The invention discloses a plastic extruder with a special-shaped conical threaded rod. The plastic extruder comprises a feed cylinder, a feed hopper and a discharge port are arranged at the two ends of the feed cylinder separately, the threaded rod is arranged in the feed cylinder, and the threaded rod is in a conical shape with a thick middle and two thin ends. The conical threaded rod with the thick middle and the two thin ends is adopted, so the extrusion pressure of a plastic extruder with a single threaded rod is further increased, the shearing force of the plastic extruder with the single threaded rod is greatly improved, the material crushing and blending effect is improved, and production efficiency and product quality are improved.

Owner:韦福才

Electric caulking joint gun

InactiveCN101104164AImprove productivityEasy to carryLiquid surface applicatorsCoatingsArchitectural engineeringPiston

The invention relates to the waterproof seal or the upholster industry in the building trade, in detail, the invention provides an electric caulking gun, which is used for waterproof seal. The structure includes a casing, the front part inside the casing is connected with a sleeve, a head cover is arranged on the sleeve, a motor is arranged in the casing, the motor is connected with a screw arranged in the center of the casing by a transmission device, the front part of the screw is connected with a combined piston, and the rear part thereof is connected with a hook, the motor is connected with a switch arranged on the casing. Compared with the prior art, the invention is characterized by reasonable design, simple structure, convenient operation, environment protection without pollution, good construction effect and high working efficiency.

Owner:李彦构 +1

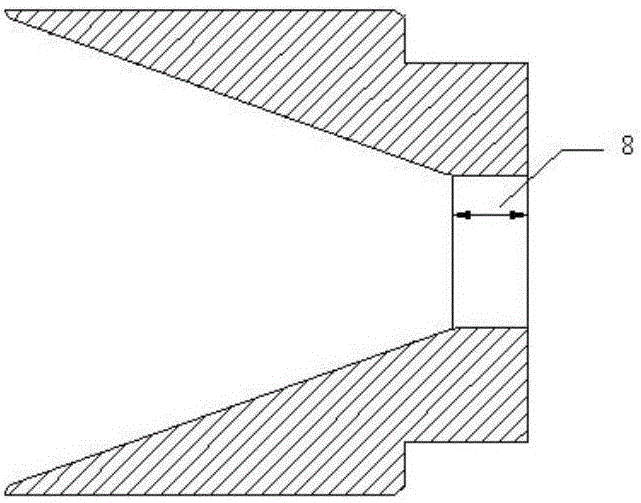

Extruding mould applicable to PET (Polyethylene Terephthalate) profiled bar

The invention relates to an extruding mould applicable to a PET (Polyethylene Terephthalate) profiled bar. The extruding mould comprises a mould head, a sizing mould, a vacuum exhausting opening, a sizing mould water channel, a water inlet and a water outlet, and further comprises a heating plate, a positioning pin and a sizing mould heat sensor. Compared with the prior art, the extruding mould disclosed by the invention overcomes the problems that the strength of a smelt body is low, the back pressure is low, the crystallization is fast and the mechanical performance is reduced in the PET profiled bar extruding process; the extruding mould can ensure that the PET profiled bar is stably produced through controlling the temperature of the sizing mould; the structure of the mould can obviously increase the extruding pressure of PET in the extruding production process and slows down the cooling speed, so that the PET is sufficiently crystallized and the high mechanical performance is obtained.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

Vacuum extruder of brick or tile

InactiveCN1180923CIncrease vacuumReduce energy consumptionCeramic shaping apparatusBrickPulp and paper industry

A vacuum extruder for making bricks and tiles is composed of stirring unit, extruding-out unit and a vacuum chamber between them. The stirring shaft passes through said stirring unit, vacuum chamber and extruding-out unit. The stirring teeth in stirring box and vacuum chamber can perform the stirring, feeding and quatitative transmission functions. Its advantages are simple structure and high extruding out effect.

Owner:程玉全

Hot melt rubber stick extrusion machine

The invention relates to an extruder for a hot melt adhesive rod. A spire propel discharging device (6) is arranged under a hopper (4), wherein, a propel screw is drive jointed with an agitating shaft of the hopper (4); a cooling water circular water jacket of a water inlet (1) and a water outlet (5) are arranged around the spire propel discharging device (6); an extruder (10) with a heating unit is connected with lower part of the spire propel discharging device (6), outer end of an extrude screw (9) of the extruder (10) is drivingly connected with a extruded power unit (7); output of the extruder (10) is connected with the extruder head (12) and output of the extruder head (12) is connected with a cooling water groove (13), and a discharge end of the cooling water groove (13) is in serried connected with a first traction roll (14) and a second traction roll (16). The mixed material is enforcedly pushed into the extruder by the spire propel discharging device under momentum function, so quality and productivity of the hot melt adhesive rod are improved.

Owner:曹永良

Metal seamless pipe extrusion forming device and forming method

ActiveCN106513452BSimple structureReduce operating costsExtrusion diesRams/plungersMachiningMaterials science

The invention relates to the technical field of extrusion molding machining, in particular to an extrusion molding device and method for metal seamless pipes. The device comprises a concave mold; the concave mold comprises blank cavities and pipe extrusion channels which communicate with each other; the device further comprises a pipe core, a supporting assembly and an extrusion device for extruding materials from the blank cavities into the pipe extrusion channels; the supporting assembly is arranged in the blank cavities; the extrusion device is arranged on the supporting assembly in a reciprocating sliding manner; and the pipe core is arranged in the pipe extrusion channels. The device is simple in structure, the operation cost is low, and power provided by a hydraulic press can be used, so that the extrusion device can provide the relatively high extrusion pressure.

Owner:GUANGDONG UNIV OF SCI & TECH

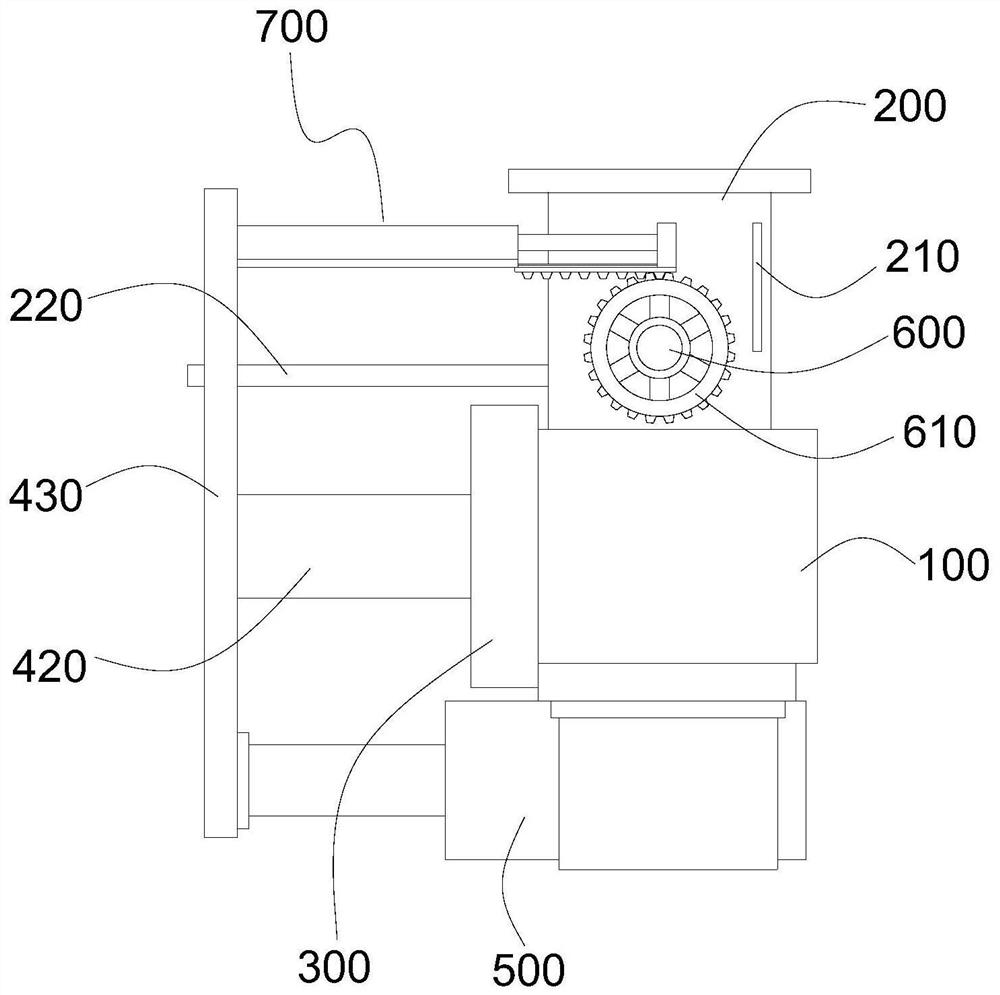

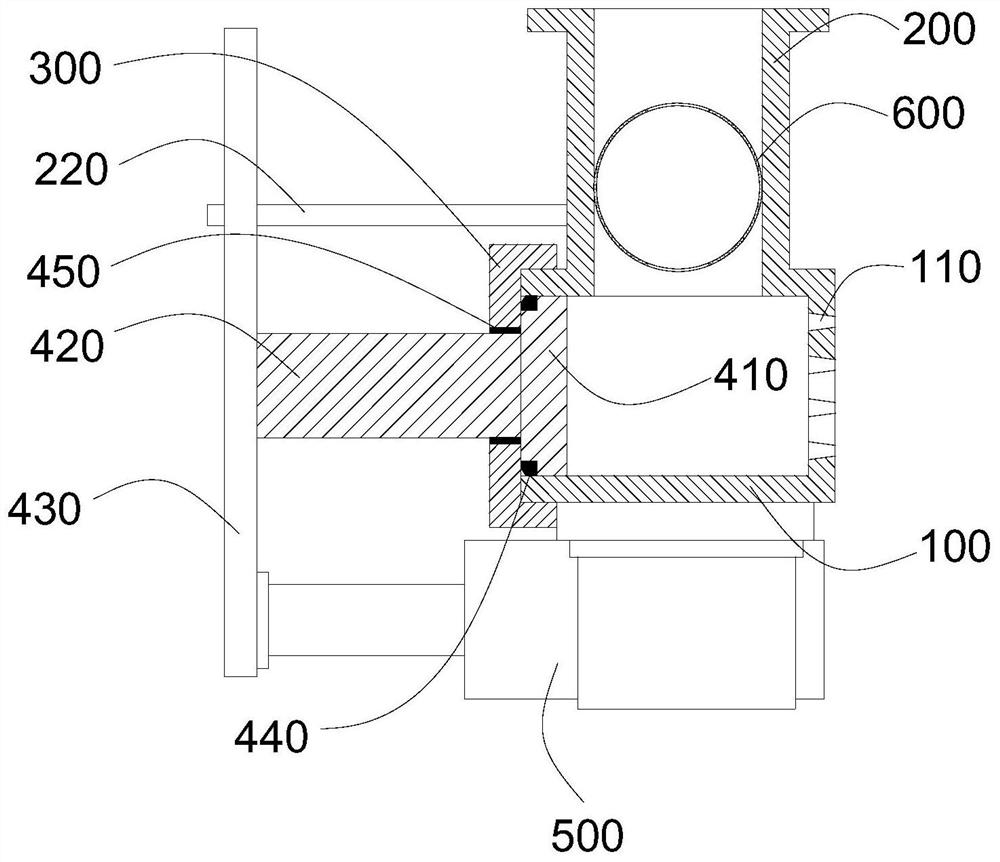

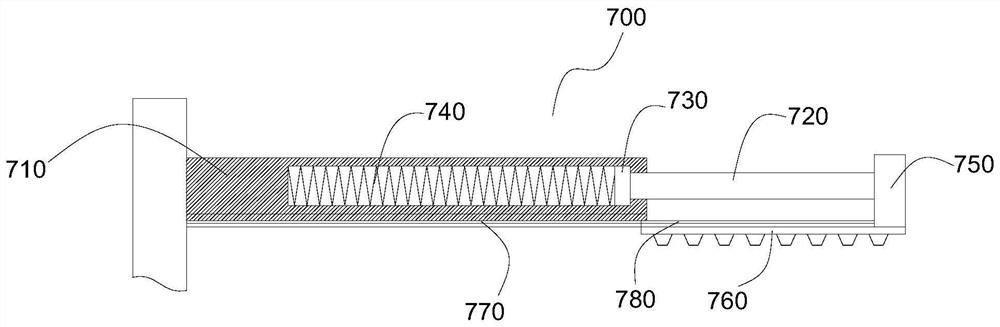

High-frequency vibration 3D printing nozzle

PendingCN114506076ALimit industrial applicationsIncrease extrusion pressure3D object support structuresApplying layer meansPiezoelectric actuatorsEngineering

The invention discloses a high-frequency vibration 3D printing nozzle which can be used for improving the interlayer bonding degree of an FDM printed part and enhancing the mechanical property of the part. The device is characterized by comprising a vibration mechanism, a transmission mechanism and a melt extrusion mechanism, the vibration mechanism comprises a piezoelectric actuator and a micro-displacement amplification mechanism, the vibration mechanism is connected with the melt extrusion mechanism through a load connecting block, and the effect of vibrating the spray head is achieved through high-frequency vibration of the piezoelectric actuator and displacement amplification of the micro-displacement amplification mechanism; the transmission mechanism transmits the rotation of the extrusion motor to the extrusion wheel so as to convey consumables to the melt extrusion mechanism; and the melt extrusion mechanism is used for melting and extruding the consumables. The device is simple in structure, and the interlayer bonding degree of a printed piece is improved through high-frequency vibration, so that the mechanical property of the printed piece is enhanced.

Owner:SICHUAN UNIV

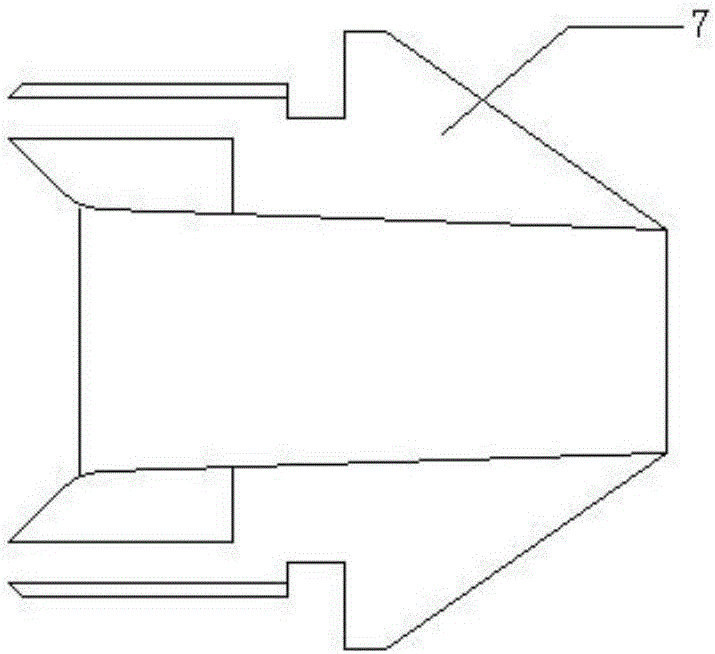

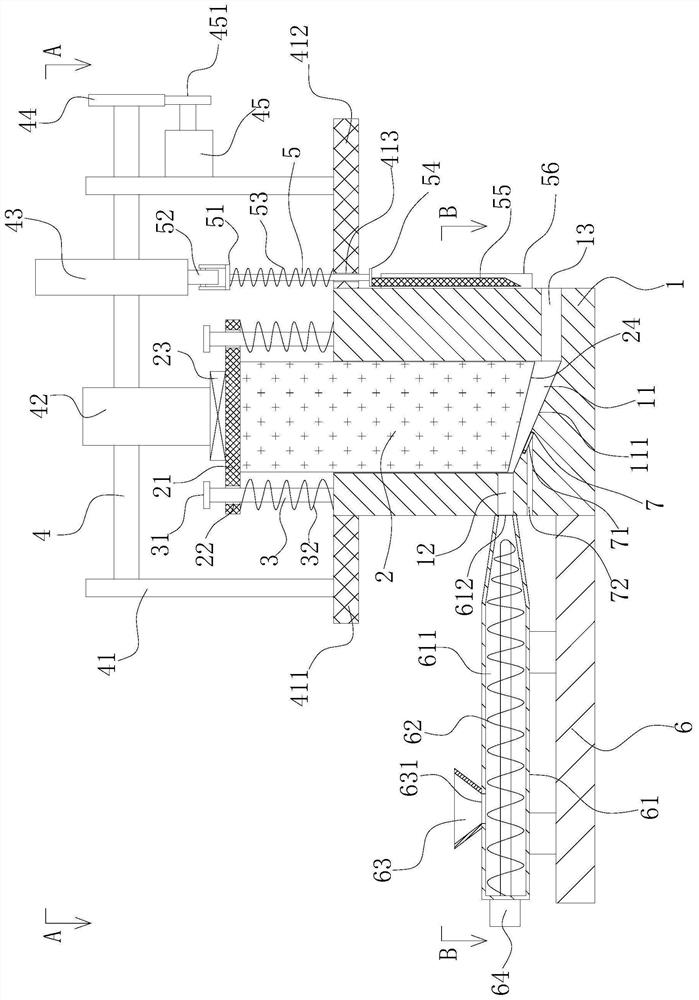

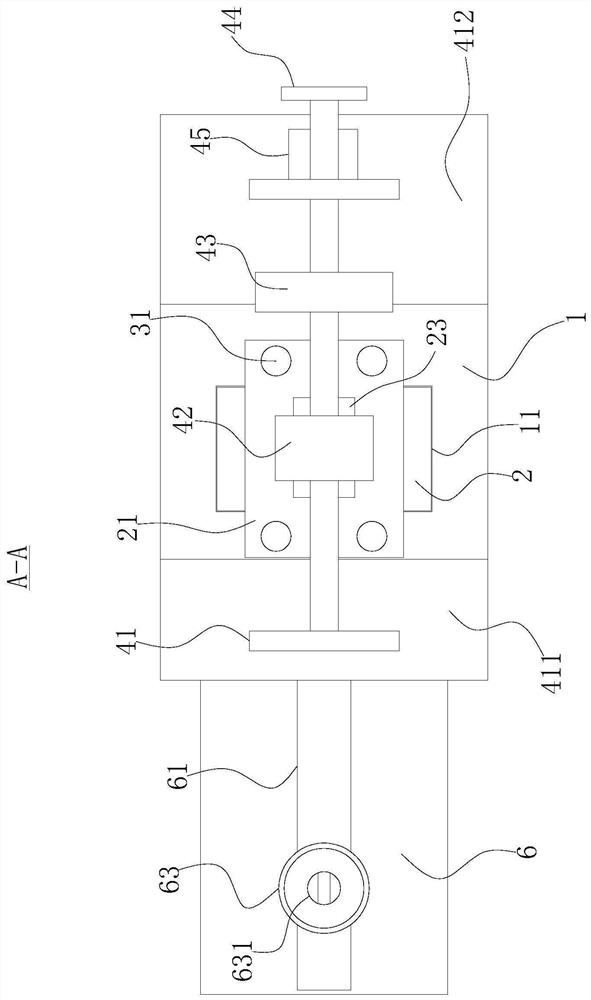

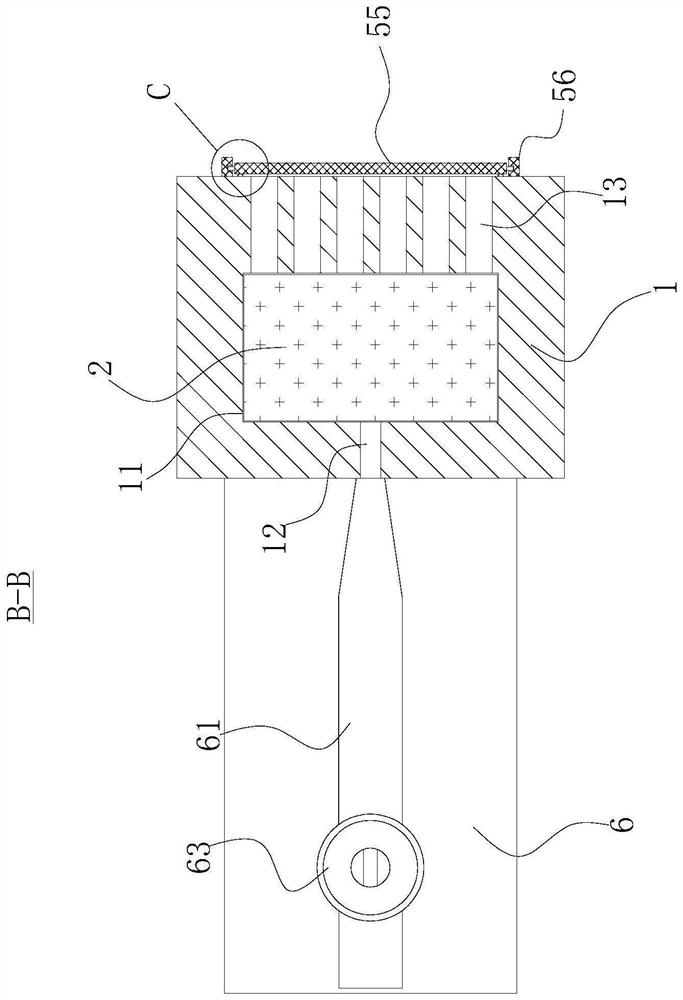

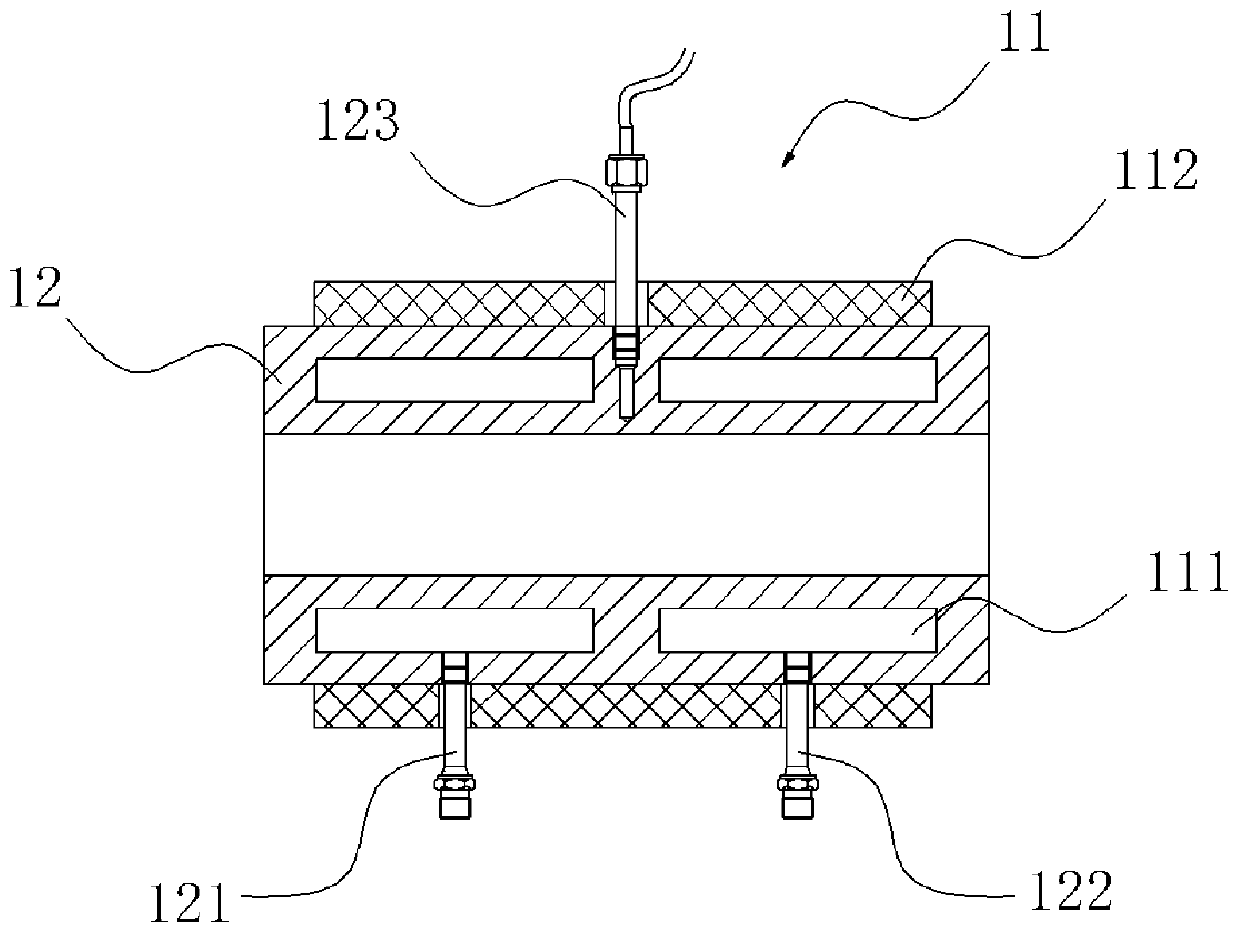

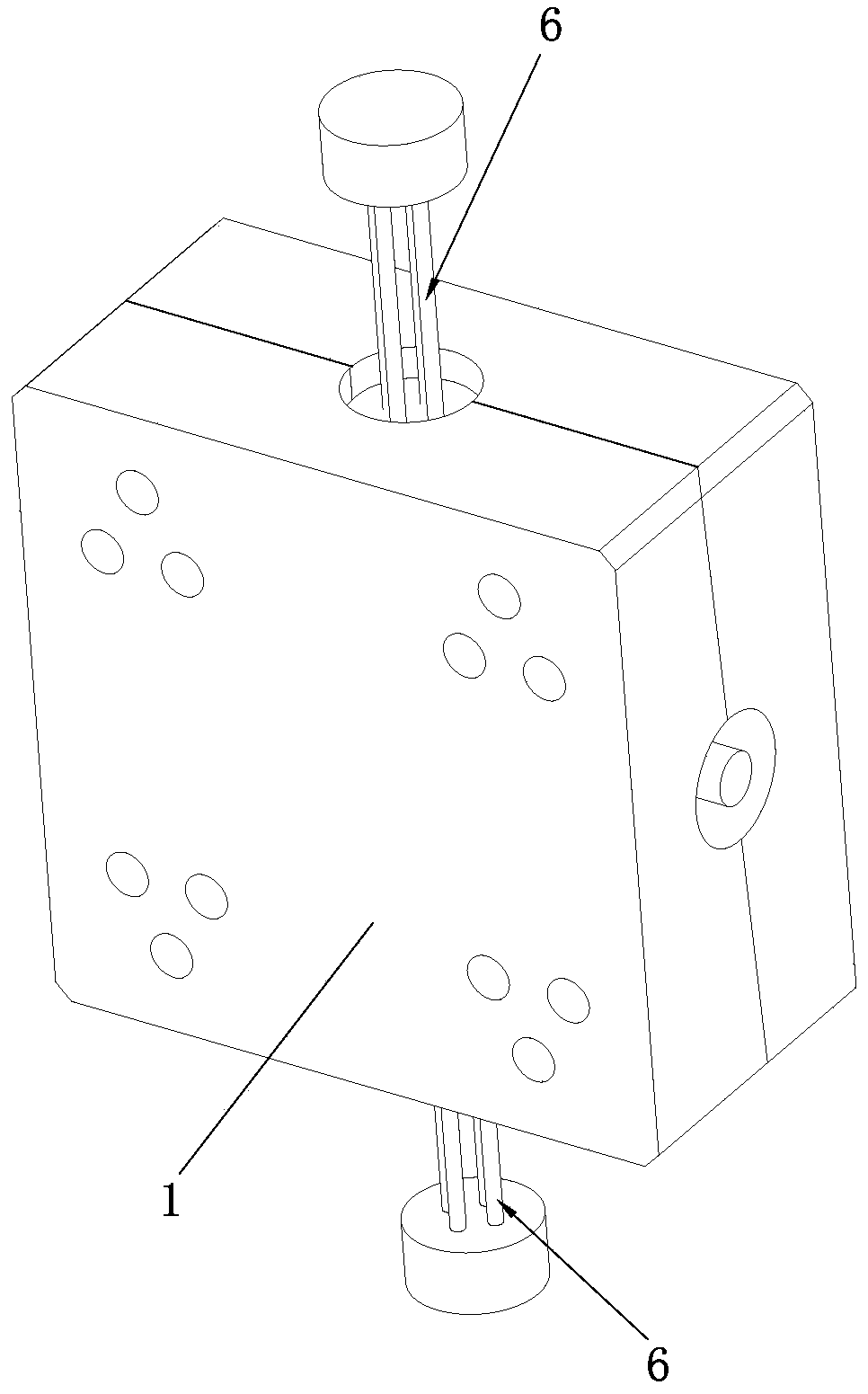

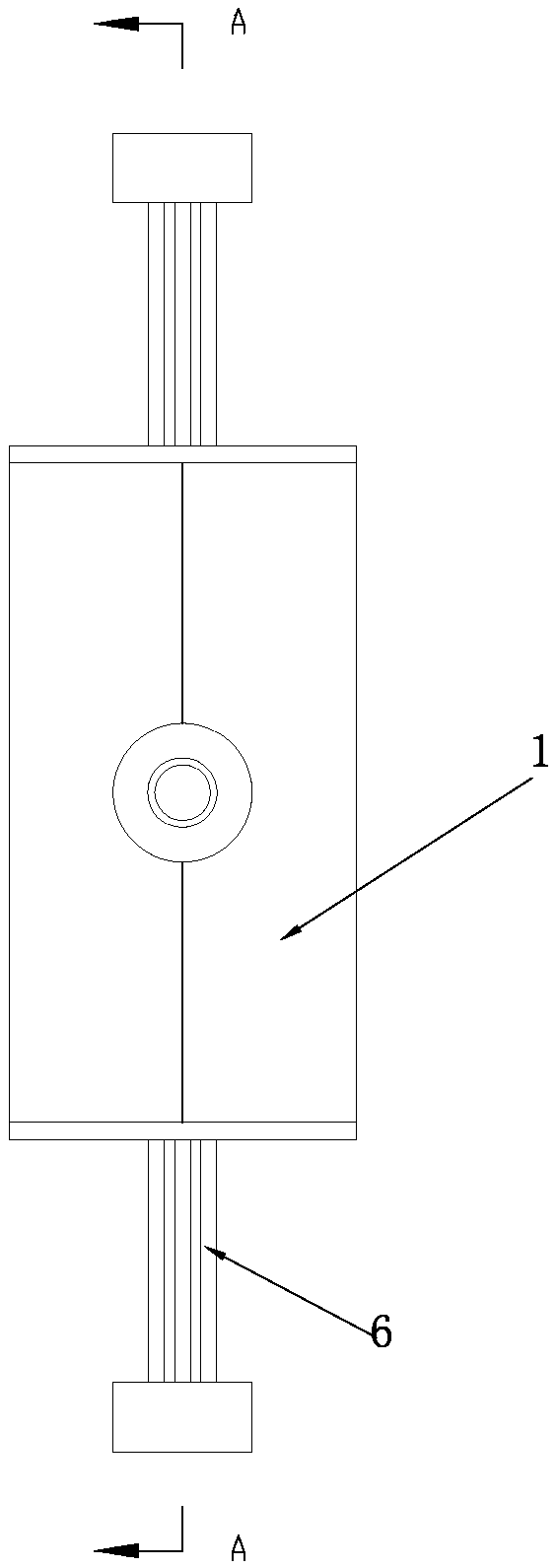

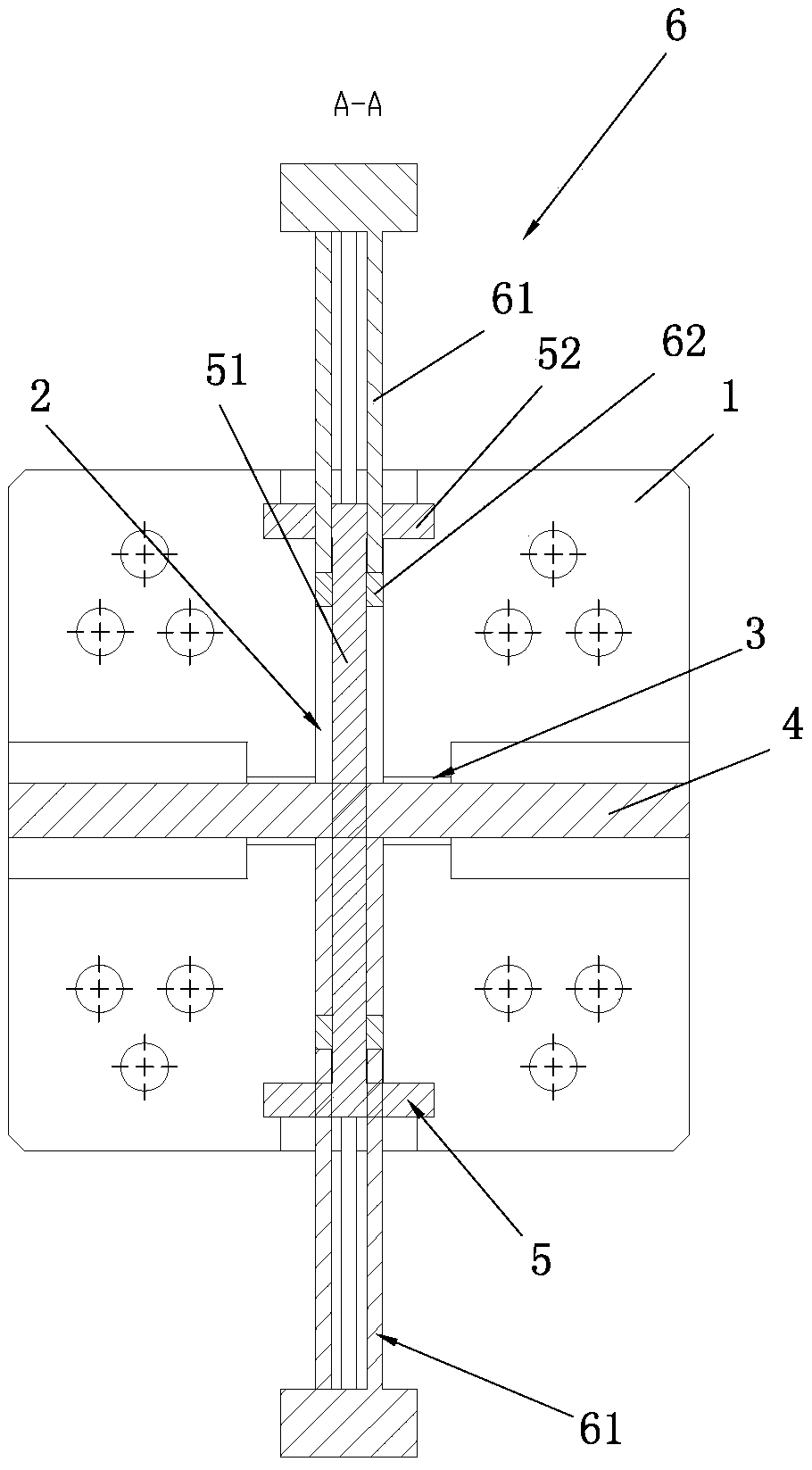

Granulation die head device for increasing extrusion pressure

The invention discloses a granulation die head device for increasing extrusion pressure. The granulation die head device comprises a transversely-arranged first pipe body, a second pipe body is arranged at the top of the first pipe body in a communicating mode, one end of the first pipe body is sealed, a plurality of discharging holes are formed in the sealed end, an end cover is arranged at the other end of the first pipe body, and a through hole is formed in the middle of the end cover; a piston block is slidably arranged in the first pipe body, a pressing rod is arranged in the middle of the end, away from the discharging hole, of the piston block, and the piston block is matched with the inner wall of the first pipe body; the end, away from the piston block, of the pressing rod is connected with a pressing plate, a hydraulic cylinder is fixedly installed at the bottom of the first pipe body, and the end of a piston rod of the hydraulic cylinder is fixedly connected with the pressing plate; and a ball valve is installed on the second pipe body, a pushing piece is installed on the pressing plate, and the transversely-moving pressing plate drives the ball valve to be opened or closed through the pushing piece. The granulation die head device is novel in structure, materials retained in the die head can be effectively reduced before batch production and machining are stopped, excessive material solidification is prevented, the preheating time of subsequent machining is shortened, consumption is reduced, and efficiency is improved.

Owner:清远市合意氟塑电线有限公司

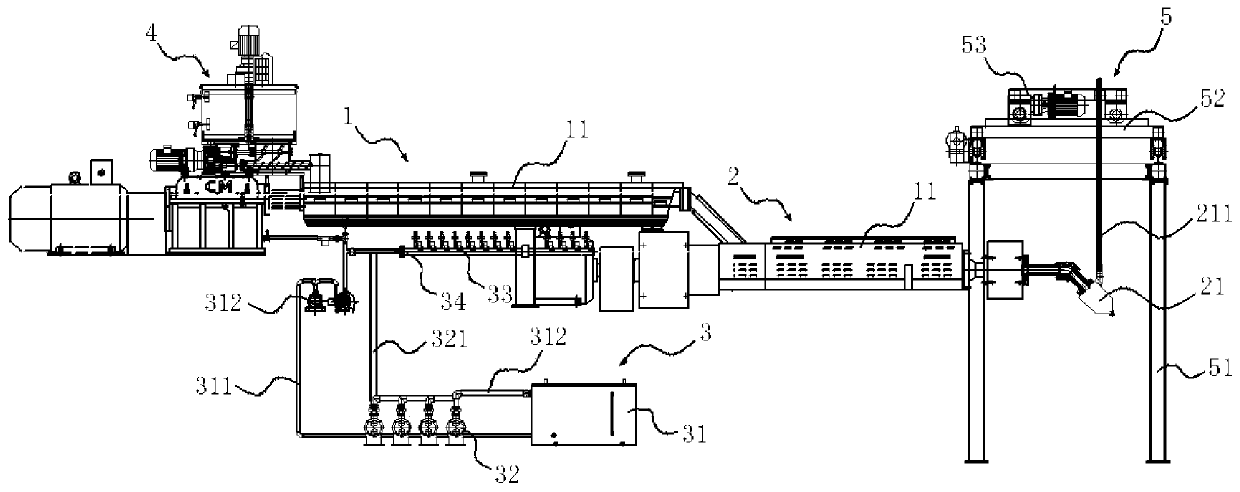

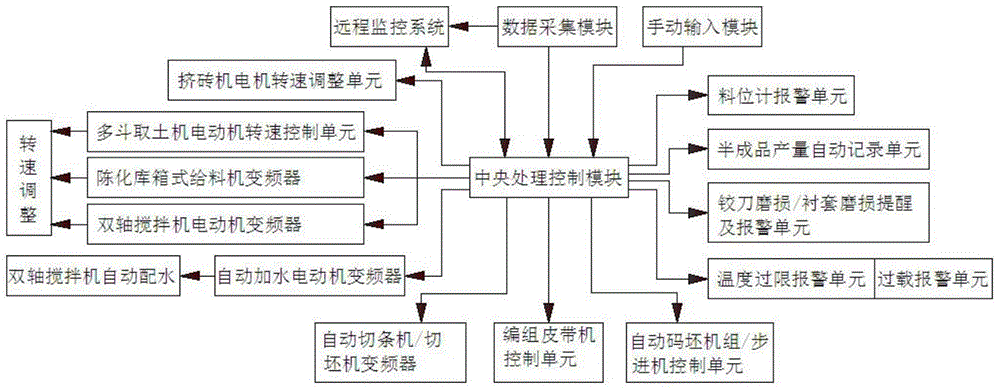

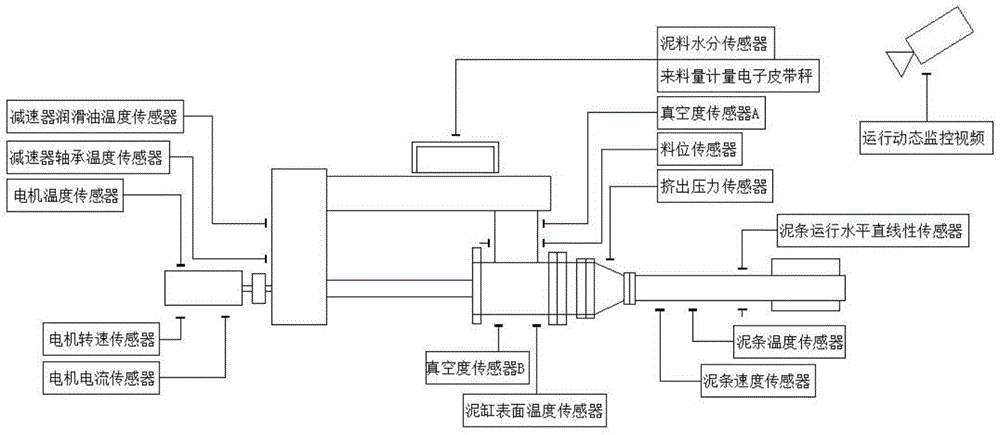

A Control System of a Compact Vacuum Brick Extruder

ActiveCN104786347BRealize unattendedQuality improvementCeramic shaping apparatusTotal factory controlFrequency changerAutomatic control

The invention provides a compact type control system for a vacuum brick extruding machine. The signal output end of a data collecting module and the signal output end of a manual input module are connected with the signal input end of a central process and control module respectively. The central process and control module outputs a control signal through the signal output end after being processed to control a rotating speed control unit of a motor in the brick extruding machine in an executing module, a rotating speed control unit of a motor of a multi-hopper soil taking machine, a frequency converter of a brick raw material warehouse type feeding machine, a frequency changer of a motor of a double-shaft mixer and a frequency changer of an automatic water-adding motor to conduct corresponding rotating speed adjustment. According to the compact type control system for the vacuum brick extruding machine, automatic control is achieved by designing a computer expert software, a function of automatically improving equipment running rate, reminding, warning and recording is possessed, at the same time, remote control is conducted through the network, the purpose of improving equipment running rate and lowering the consumption is achieved, the quality of a clay lath is comparatively high, the quality of a semi-finished product of a hollow brick is guaranteed, the rejection rate is lowered in the drying and sintering process, and the yield and the quality are improved.

Owner:贵州省建筑材料科学研究设计院有限责任公司 +2

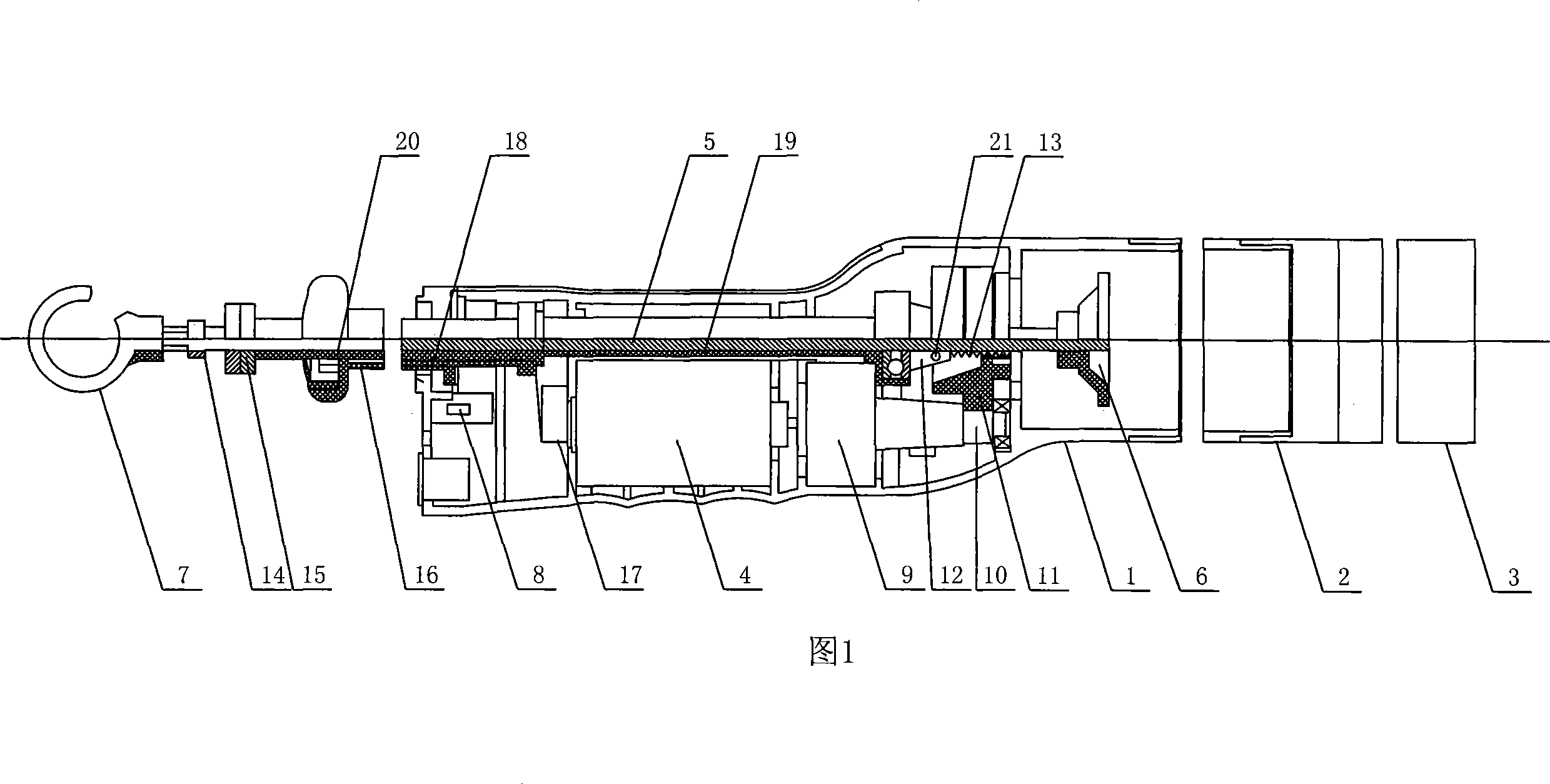

Internal exhaust type parallel counter-rotating multi-screw extruder

The invention discloses an internal exhaust type parallel counter-rotating multi-screw extruder and relates to extrusion molding equipment using at least two screw rods which are not meshed with each other. The internal exhaust type parallel counter-rotating multi-screw extruder has the advantages of high extrusion pressure, enhanced plasticizing capacity, reduced energy consumption, remarkable energy saving effect, good feeding performance, exhaust performance and material overflowing prevention performance, and convenience in screw machining, and is suitable for various plastic and rubber machining. The internal exhaust type parallel counter-rotating multi-screw extruder is structurally characterized in that the left end of a main screw rod has a hollow structure, the built-in left end is fixed on an inner screw rod on an end cover, the direction of threads on the inner screw rod is opposite to that of threads on the main screw rod, the right end of the main screw rod is internally provided with an exhaust channel which is communicated with an exhaust channel in the inner screw rod, threads on the main screw rod corresponding to an auxiliary screw rod are single threads, other threads on the main screw rod are double threads, a first through hole connected with the exhaust channel is arranged in the main screw rod between two screw arrises of the double threads, a plurality of second through holes are arranged between the two screw arrises of the double threads on the main screw rod outside the inner screw rod, the end cover is provided with a melt outlet communicated with a cavity between the main screw rod and the inner screw rod, and the center of the end cover is provided with an exhaust port connected with the exhaust channel.

Owner:金世源

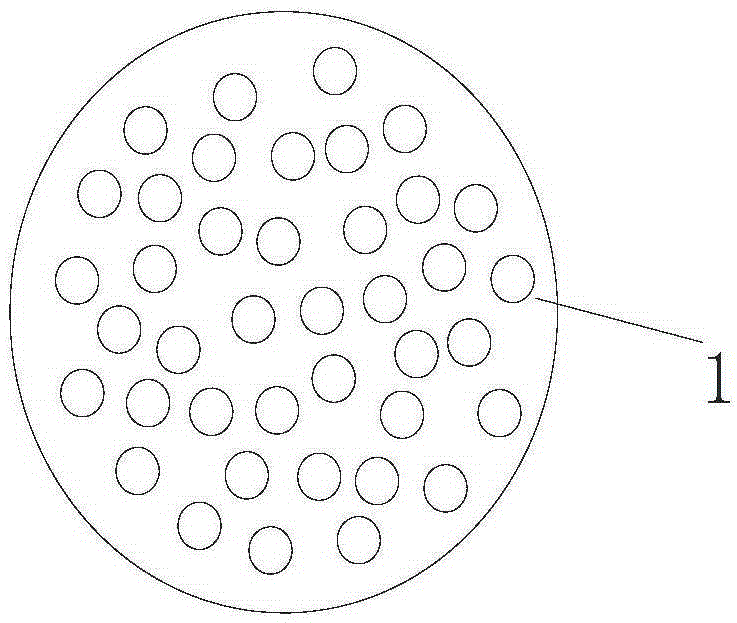

Forming machine with screw hole sieve

InactiveCN105235182AIncrease extrusion pressureImprove plasticizing effectMolding machineEngineering

The invention discloses a forming machine with a screw hole sieve. The forming machine comprises a material stirring extrusion mechanism which is connected with a machining shaping mechanism. The sieve used for allowing materials to pass is arranged in the material stirring extrusion mechanism and provided with a round hole. The inner wall of the round hole is in a screw shape. Or, the center line of the front end face of the round hole and the center line of the rear end face of the round hole are not located on the same straight line. Compared with the prior art, the sieve of the novel structure is adopted, and therefore the material extrusion pressure is improved, and the material plasticity effect can be improved through the sieve of the structure via tests.

Owner:天津市志强管业制造有限公司

An injection joint for injection molding machine with pressure supply design

ActiveCN111070608BFully filledIncrease extrusion pressureProcess engineeringInjection molding machine

The invention relates to the technical field of injection molding machine design, in particular to an injection joint for an injection molding machine that adopts a pressure supply design, including an injection tube, the injection tube includes a heating tube that is fixed and installed with a feeder through bolts, and the left side of the heating tube passes through The bolts are installed with a pressure supply pipe, the left side of the pressure supply pipe is welded and installed with a butt joint, and a telescopic tube is inserted into the butt joint. The beneficial effect is: the device can provide higher extrusion pressure by driving the push rod and the push plate, so that the material can be more fully filled into the mold, effectively avoiding product defects caused by insufficient extrusion pressure The problem is that the device is easy to use, can adapt to molds of different sizes, and only needs to set the extrusion pressure and extrusion cycle in the controller to complete the injection extrusion automatically, which effectively saves manpower and has a lot of advantages. High practical value.

Owner:东莞市锦洲塑胶制品有限公司

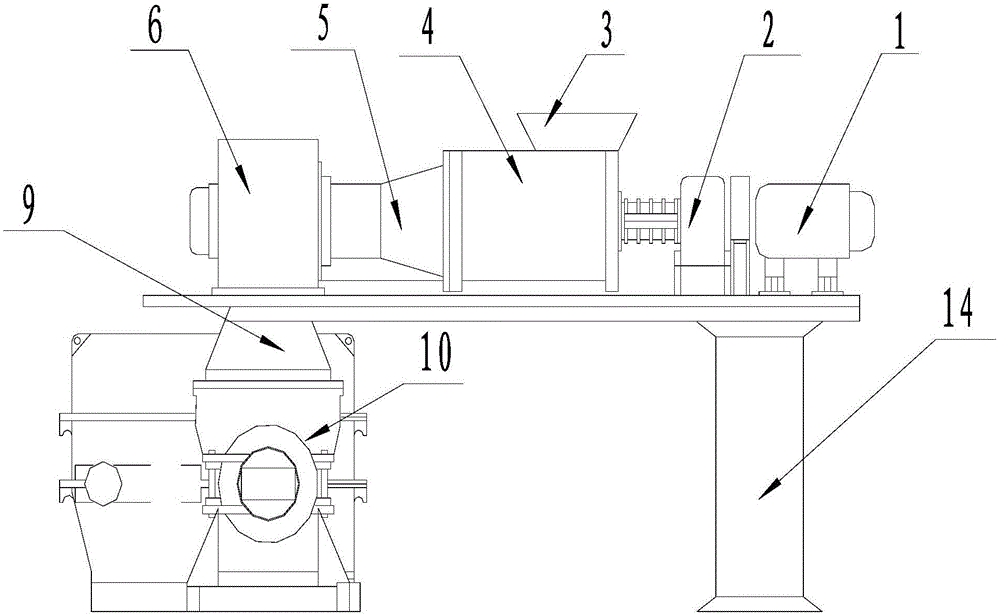

Integral structure of molded-coal vacuum hard-plastic extruding machine

InactiveCN105150582ATo stir and mixPlay the role of hard plastic extrusionShaping pressMachine partsPulp and paper industry

The invention discloses an integral structure of a molded-coal vacuum hard-plastic extruding machine. The integral structure comprises an upper machine part, a lower machine part and a supporting part. The upper machine part comprises a first motor, a first speed reducer, a hopper, an agitating tank, a screw propelling auger and a discharging box, wherein the first motor, the first speed reducer, the hopper, the agitating tank, the screw propelling auger and the discharging box are sequentially arranged from the right end to the left end. The lower machine part comprises a second motor, a second speed reducer, a connecting box, a vacuum chamber, a vacuumizing device, an extruding auger and a mold outlet device, wherein the second motor, the second speed reducer, the connecting box, the vacuum chamber, the vacuumizing device, the extruding auger and the mold outlet device are sequentially arranged from the front end to the back end. The vacuum chamber of the lower machine part is communicated with the discharging box of the upper machine part through the connecting box. Vacuumizing operation is carried out on the vacuum chamber through the vacuumizing device. The integral structure of the molded-coal vacuum hard-plastic extruding machine has the advantages that molding products are not prone to damage, the extruding pressure is large, the molding water content is low, drying is easy, and fire resistance is good; molded coal in multiple shapes can be produced, multiple requirements of users can be met, and production efficiency is high.

Owner:XINTAI HUATENG MACHINERY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com