High-frequency vibration 3D printing nozzle

A 3D printing, high-frequency vibration technology, applied in 3D object support structures, coating devices, manufacturing tools, etc., can solve the problems of low adhesion, low Z-axis strength, etc., to enhance the bonding force and improve the interlayer. Bonding force, the effect of reducing the workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

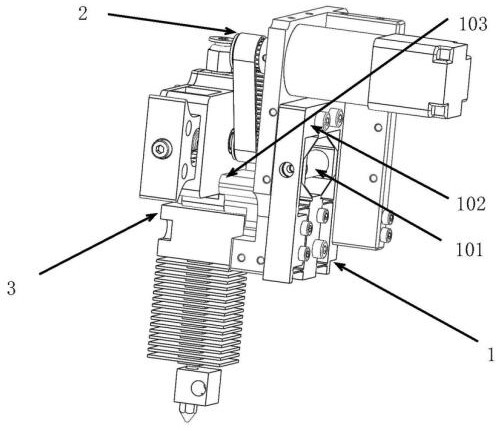

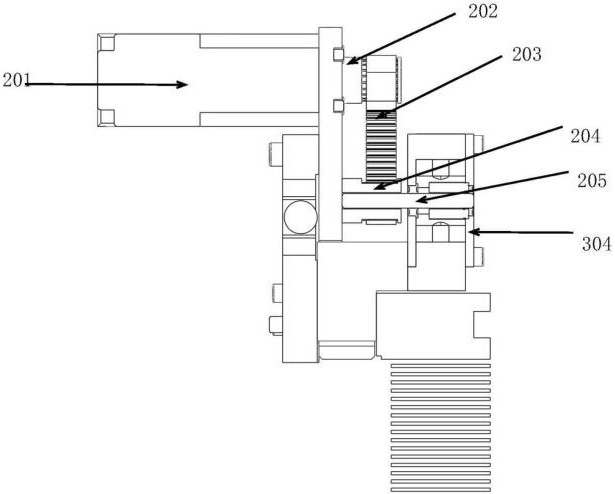

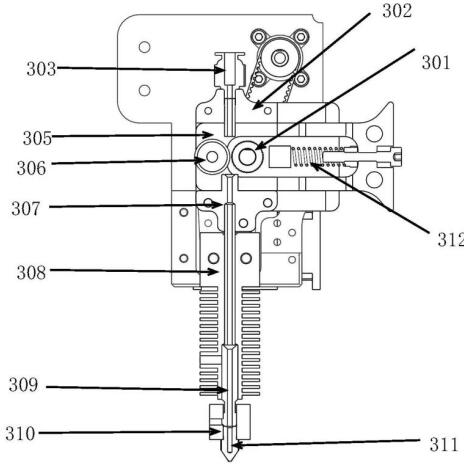

[0016] A high-frequency vibration 3D printing nozzle includes a vibration mechanism 1, a transmission mechanism 2, and a melting extrusion mechanism 3. The vibration mechanism 1 includes: a piezoelectric actuator 101 is connected and fixed to a micro-displacement amplification mechanism 102, and the micro-displacement The displacement amplifying mechanism 102 is fixed on the base block 4 through bolt connection, the piezoelectric actuator 101 is connected to the piezoelectric ceramic drive power supply, and the piezoelectric actuator 101 is driven by the piezoelectric ceramic drive power supply, so as to achieve the effect of nozzle vibration; The transmission mechanism 2 includes: the base block 4 is equipped with an extrusion motor 201, and the extrusion motor 201 is matched with the synchronous pulley driving wheel 202 and fixed with a set screw. The wheel driven wheel 204 is connected and driven by a synchronous belt 203. The synchronous pulley driving wheel 202 and the syn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com