Ethylene oligomerization modification additive and homogeneous catalysis system thereof

A technology for ethylene oligomerization and homogeneous catalysis, which is applied in physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, organic chemistry, etc., and can solve the problems of high cost, high cocatalyst ash content, and product economy Lowering and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

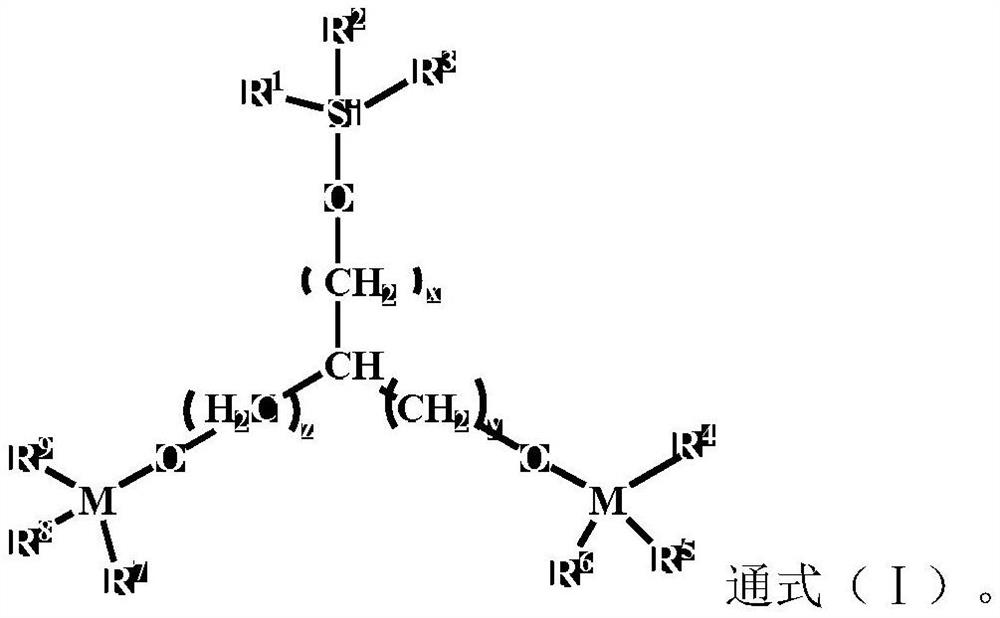

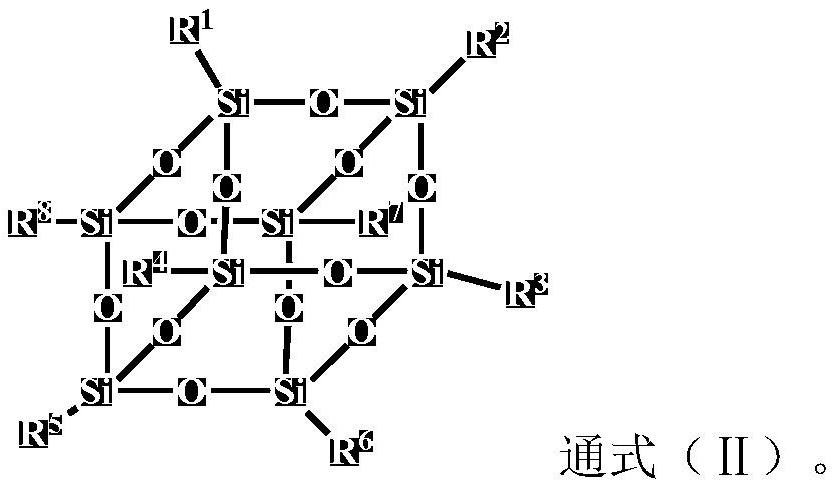

[0059] The oligomerization modifier component D is shown on the left of the figure below, where M is Si, X=Y=Z=5, R 1 , R 2 , R 3 , R 4 , R5 , R 6 is isopropyl, R 7 , R 8 , R 9 It is n-butyl group; the ligand structure of the main catalyst component A is shown on the right side of the figure below, the central metal atom is Co(II), R 1 , R 2 , R 3 is isopropyl.

[0060]

[0061] Homogeneous catalytic system S configuration: Add 0.1 mmol of oligomerization modification assistant component D shown in the figure above to 1 L of toluene solution to form a homogeneous solution, and the homogeneous solution is kept under continuous stirring for at least 30 minutes. Then 5 mmol of main catalyst component A was added and dissolved, and the stirring was continued for at least 120 min. The above configuration operations were all performed in an inert gas environment, and the obtained homogeneous catalytic system S was reserved for oligomerization.

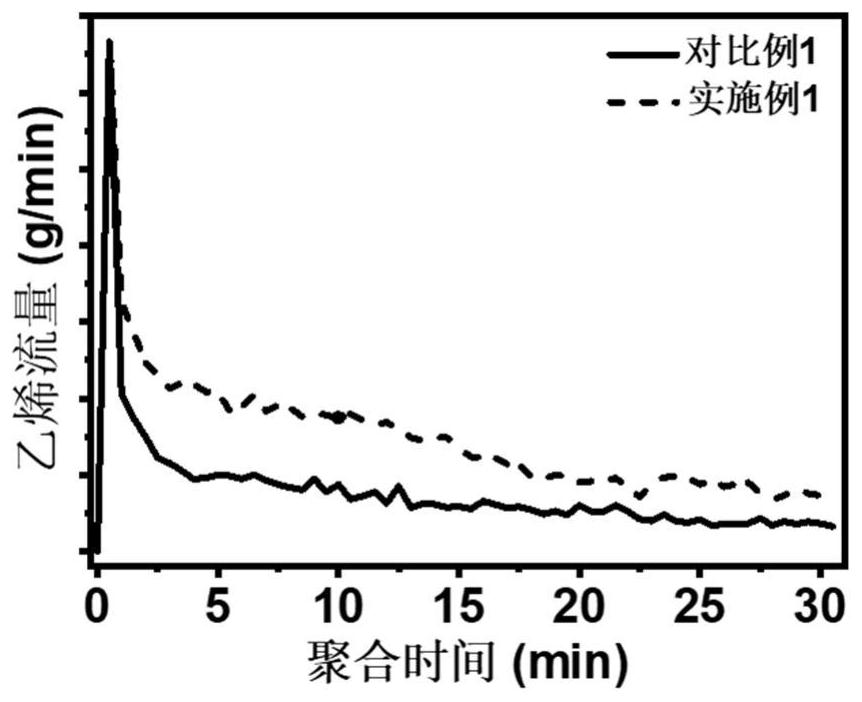

[0062] The 1L oligomeriz...

Embodiment 2

[0064] The oligomerization modifier component D is shown on the left of the figure below, where M is Si, X=Y=Z=12, R 1 , R 2 , R 3 , R 4 , R 5 , R 6 is isopropyl, R 7 , R 8 , R 9 is isobutyl group; the ligand structure of main catalyst component A is shown on the right side of the figure below, the central metal atom is Cr(VI), and R is isopropyl group.

[0065]

[0066] Homogeneous catalytic system S configuration: add 50 mmol of oligomerization modification assistant component D shown in the figure above into 1 L of n-hexane solution to form a homogeneous solution, and the homogeneous solution is kept under continuous stirring for at least 30 min. Then 5 mmol of main catalyst component A was added and dissolved, and the stirring was continued for at least 120 min. The above configuration operations were all performed in an inert gas environment, and the obtained homogeneous catalytic system S was reserved for oligomerization.

[0067] The 1L oligomerization reacto...

Embodiment 3

[0069] The oligomerization modifier component D is shown on the left of the figure below, where R 1 , R 2 , R 3 , R 4 is hydroxyl, R 5 , R 6 , R 7 , R 8 is n-butyl group; the ligand structure of main catalyst component A is shown on the right of the figure below, the central metal atom is Fe(III), and R is isobutyl group.

[0070]

[0071] Homogeneous catalytic system S configuration: Add 80 mmol of oligomerization modification assistant component D shown in the figure above into 1 L of toluene solution to form a homogeneous solution. The homogeneous solution is kept under continuous stirring for at least 30 minutes. 500 mmol of the main catalyst component A was added and dissolved, and the stirring was continued for at least 120 min. The above configuration operations were all performed in an inert gas environment, and the obtained homogeneous catalytic system S was reserved for oligomerization.

[0072] The 1L oligomerization reactor was baked for at least 120min u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com