Double-cylinder multi-strip semi-hard plastic vacuum extruder

A vacuum extruder and hard plastic technology, applied in the field of brick and tile machinery manufacturing, can solve the problems of energy consumption, time-consuming, and affecting processing efficiency, and achieve the effects of reduced energy consumption, high extrusion pressure, and high output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Accompanying drawing has provided the specific embodiment of the present invention.

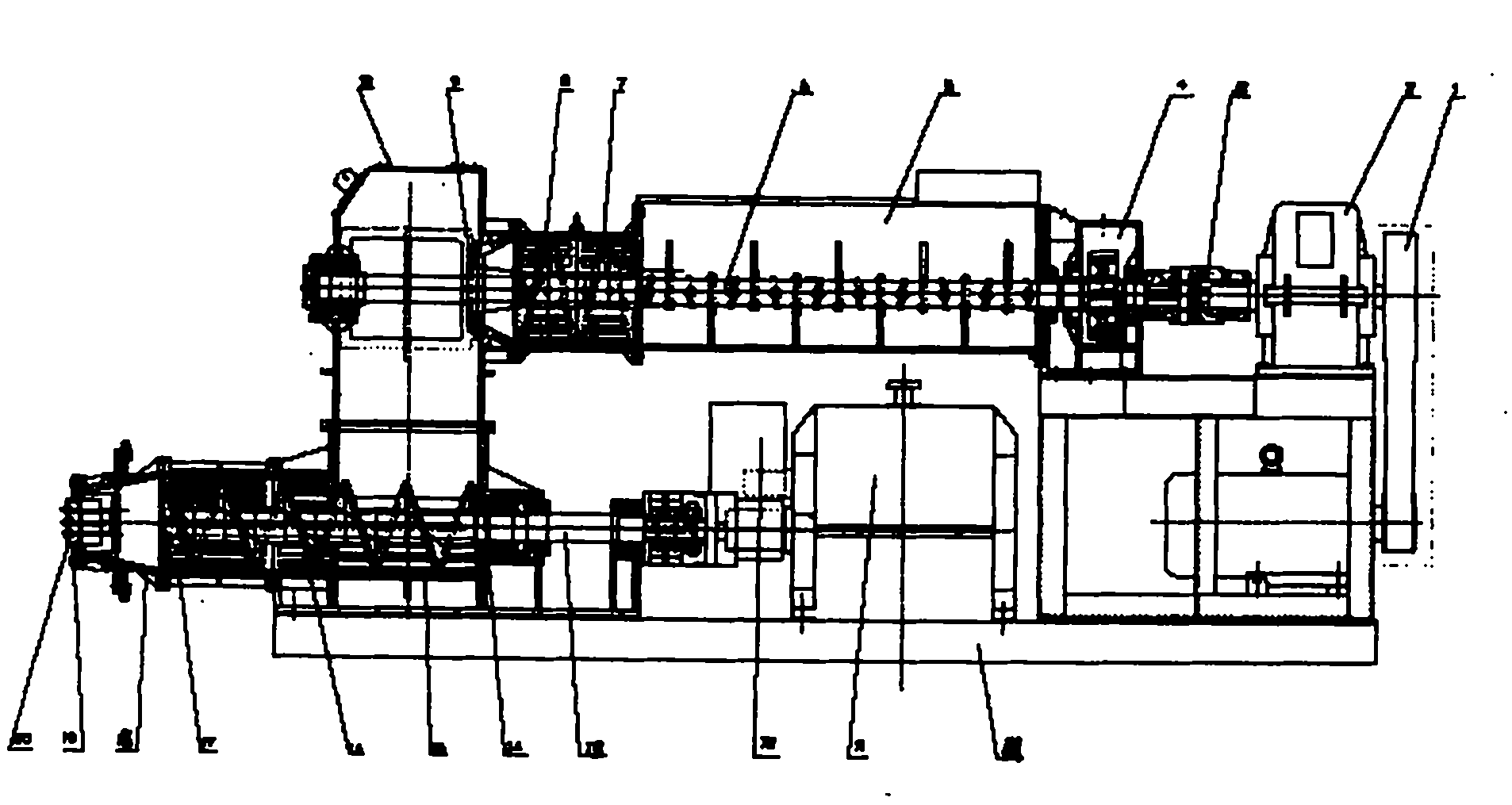

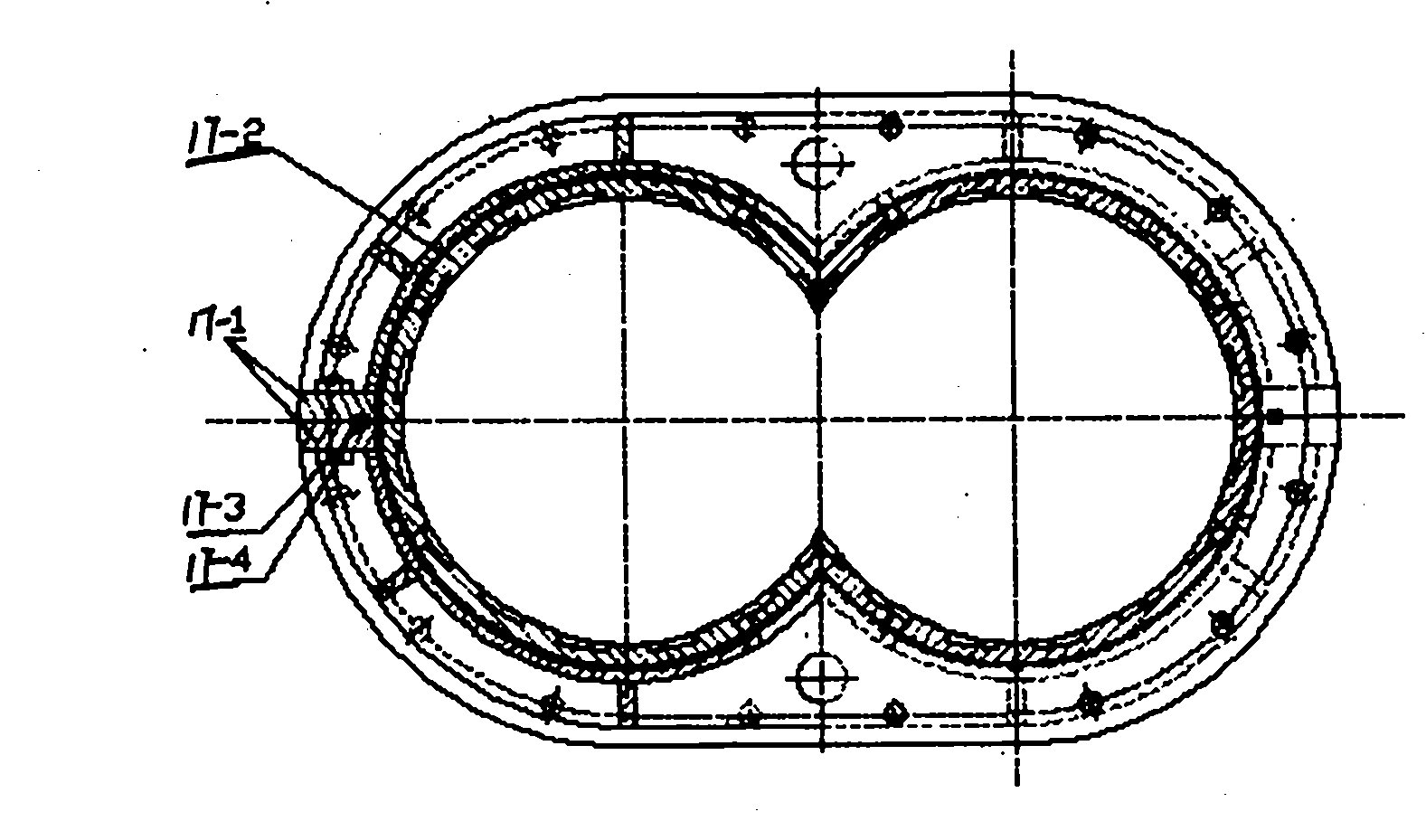

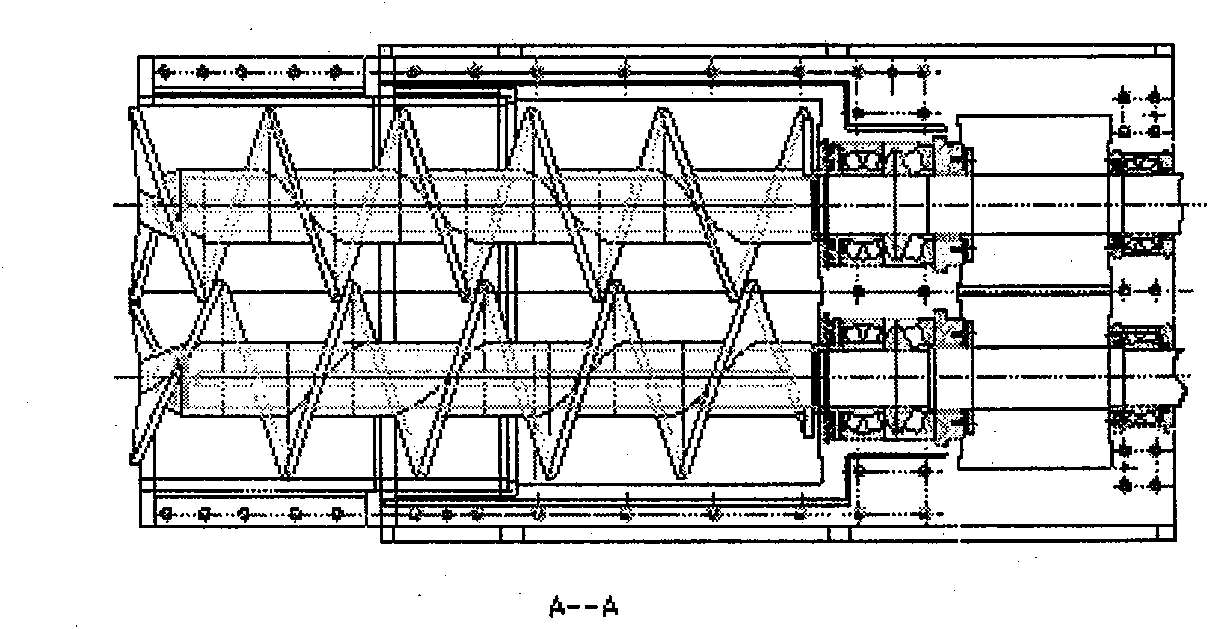

[0022] Such as figure 1 As shown, a double-cylinder multi-strip semi-rigid plastic vacuum extruder includes an upper-level mechanism for mixing and stirring the materials and a lower-level mechanism for continuing to extrude the materials and extrude them. The room is connected through the vacuum chamber 10, and its upper mechanism and lower mechanism are independently driven by driving motors. The upper mechanism consists of a pneumatic clutch 1, a reducer 2, a coupling 3, a gear box 4, a stirring box 5, a strong stirring shaft 6, a conveying reamer 7, a half mud cylinder 8, a mud cutter 9, and a vacuum chamber 10. The pneumatic clutch 1 connects the reducer 2 and the drive motor of the upper mechanism, the output shaft of the reducer 2 is connected with the power input shaft of the gear box 4 through the coupling 3, the power output shaft of the gear box 4 is connected with the powe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com