A Control System of a Compact Vacuum Brick Extruder

A technology of vacuum brick extruder and control system, which is applied in the direction of ceramic forming machine, comprehensive factory control, comprehensive factory control, etc. It can solve the problems of unguaranteed quality of hollow brick semi-finished products, lagging adjustment and control process, poor operation stability of brick extruder, etc. problems, to achieve the effect of improving equipment operation rate, semi-finished product quality assurance, output and quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

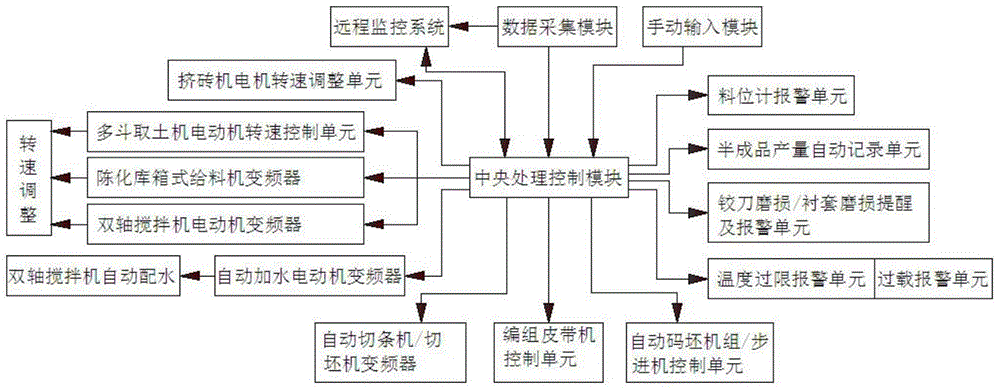

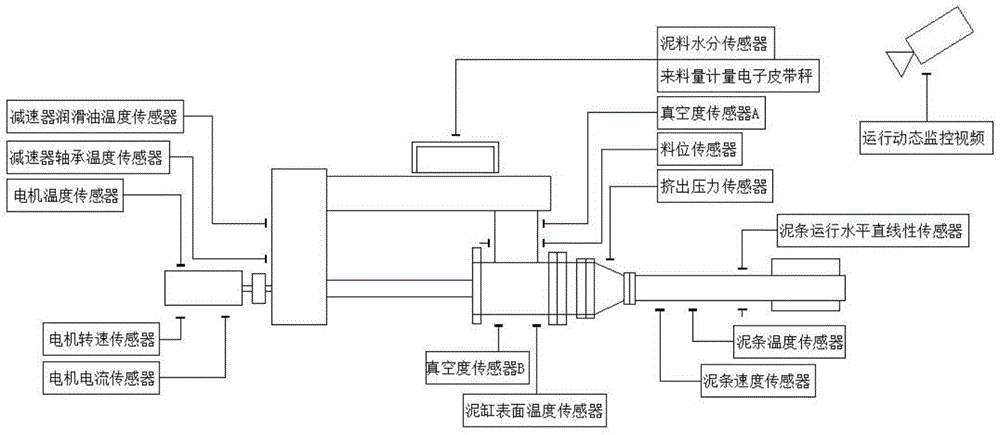

[0020] Such as figure 1 and figure 2 The control system of a compact vacuum brick extruder shown includes a data acquisition module, a manual input module, a central processing control module and an execution module; the signal output terminals of the data acquisition module and the manual input module are respectively connected with the central processing control module The signal input terminal is connected, and the central processing control module outputs the control signal through the signal output terminal to control the motor speed control unit of the brick extruder, the motor speed control unit of the multi-bucket excavator, and the box-type feeding of the aging warehouse in the execution module. Machine frequency converter, double-shaft mixer motor frequency converter and automatic water-adding motor frequency converter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com