Photoelectric composite cable

An optoelectronic integrated cable and cable core technology, which is applied to insulated cables, communication cables, bendable cables, etc., can solve the problems of loose optoelectronic integrated cable structure, low production efficiency, and blocked optical paths, so as to improve the strain screening strength, improve the use of The effect of improved reliability and excellent bending properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

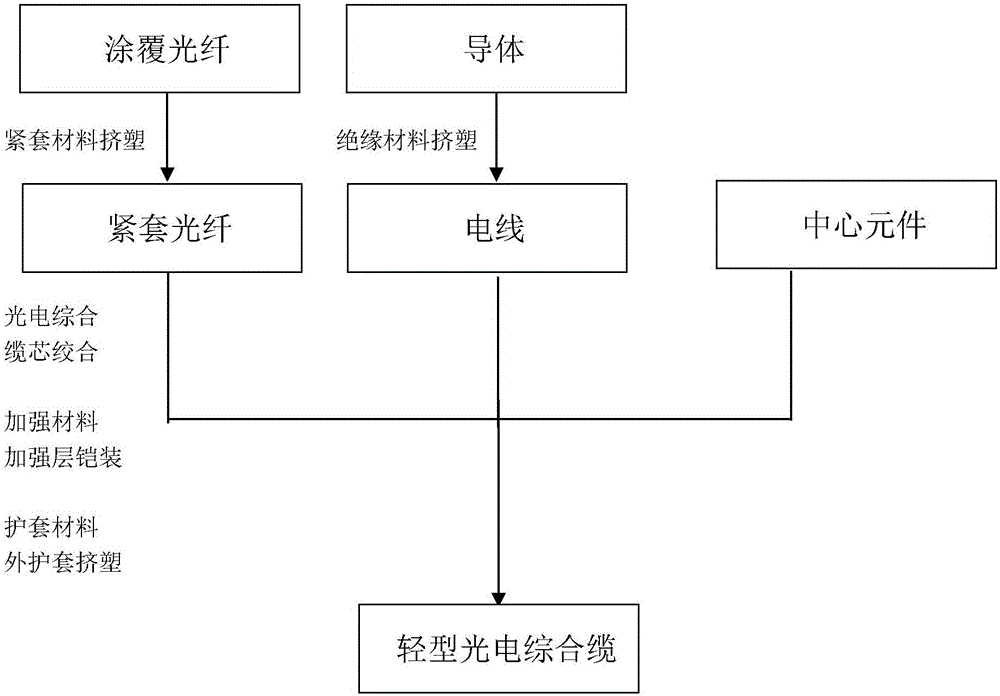

[0039] The optical fiber secondary coating extruder is selected, and a tight sleeve layer is uniformly coated on the outside of the optical fiber at a line speed of 40m / min at a tension of 0.5N and an extrusion temperature of 130°C to 200°C. When the optical fiber is a bending loss insensitive single-mode optical fiber with a carbon coating layer, the diameter of the optical fiber is 0.245mm, the strain screening of the optical fiber is 2%, the static fatigue resistance index N is 100, and the material of the tight sleeve layer is preferably flame-retardant polyurethane , the outer diameter of the tight sleeve layer is 0.4mm, and then cooled by a water tank, the cooling temperature of the water tank is between 30°C and 40°C, and the mold adopts a squeeze tube type to make a tight sleeve optical fiber with an outer diameter of 0.4mm;

[0040] Then choose a high-temperature extruder, under the condition that the take-up and take-off line tension is 1.0N, and the extrusion tempera...

Embodiment 2

[0043] The optical fiber secondary coating extruder is selected, and a tight sleeve layer is uniformly coated on the outside of the optical fiber at a line speed of 70m / min at a tension of 1.0N and an extrusion temperature of 180°C to 250°C. When the optical fiber is a multi-mode optical fiber, the diameter of the optical fiber is 0.3mm, and the strain of the optical fiber is 1%. The material of the tight jacket layer is preferably a thermoplastic polyester elastomer Hytrel, and the outer diameter of the tight jacket layer is 0.6mm, and then passes through the water tank Cooling, the cooling temperature of the water tank is between 40°C and 60°C, and the mold adopts extrusion type to make a tight-sleeved optical fiber with an outer diameter of 0.6mm;

[0044] Then choose a high-temperature extruder, under the condition that the winding tension is 5.0N and the extrusion temperature is between 280°C and 380°C, a layer of insulating layer is uniformly extruded outside the conducto...

Embodiment 3

[0047] The optical fiber secondary coating extruder is selected, and a tight sleeve layer is uniformly coated on the outside of the optical fiber at a line speed of 100m / min at a tension of 0.8N and an extrusion temperature of 180°C to 250°C. When the optical fiber is a bending loss insensitive single-mode optical fiber provided with a coating layer, the diameter of the optical fiber is 0.4mm, and the strain screening of the optical fiber is 1%. The material of the tight jacket layer is preferably nylon, and the outer diameter of the tight jacket layer is 0.8mm. Then it is cooled in a water tank, the cooling temperature of the water tank is between 30°C and 40°C, and the mold adopts a squeeze tube type to make a tight-sleeved optical fiber with an outer diameter of 0.8mm;

[0048] Then choose a high-temperature extruder, under the condition that the take-up and take-off line tension is 3.0N, and the extrusion temperature is between 130°C and 200°C, a layer of insulating layer i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com