Metal seamless pipe extrusion forming device and forming method

A seamless pipe, extrusion molding technology, applied in the direction of metal extrusion, metal extrusion dies, metal processing equipment, etc., can solve the problems of high maintenance costs, restrictions, high cost, etc., to achieve low operating costs and high extrusion pressure , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

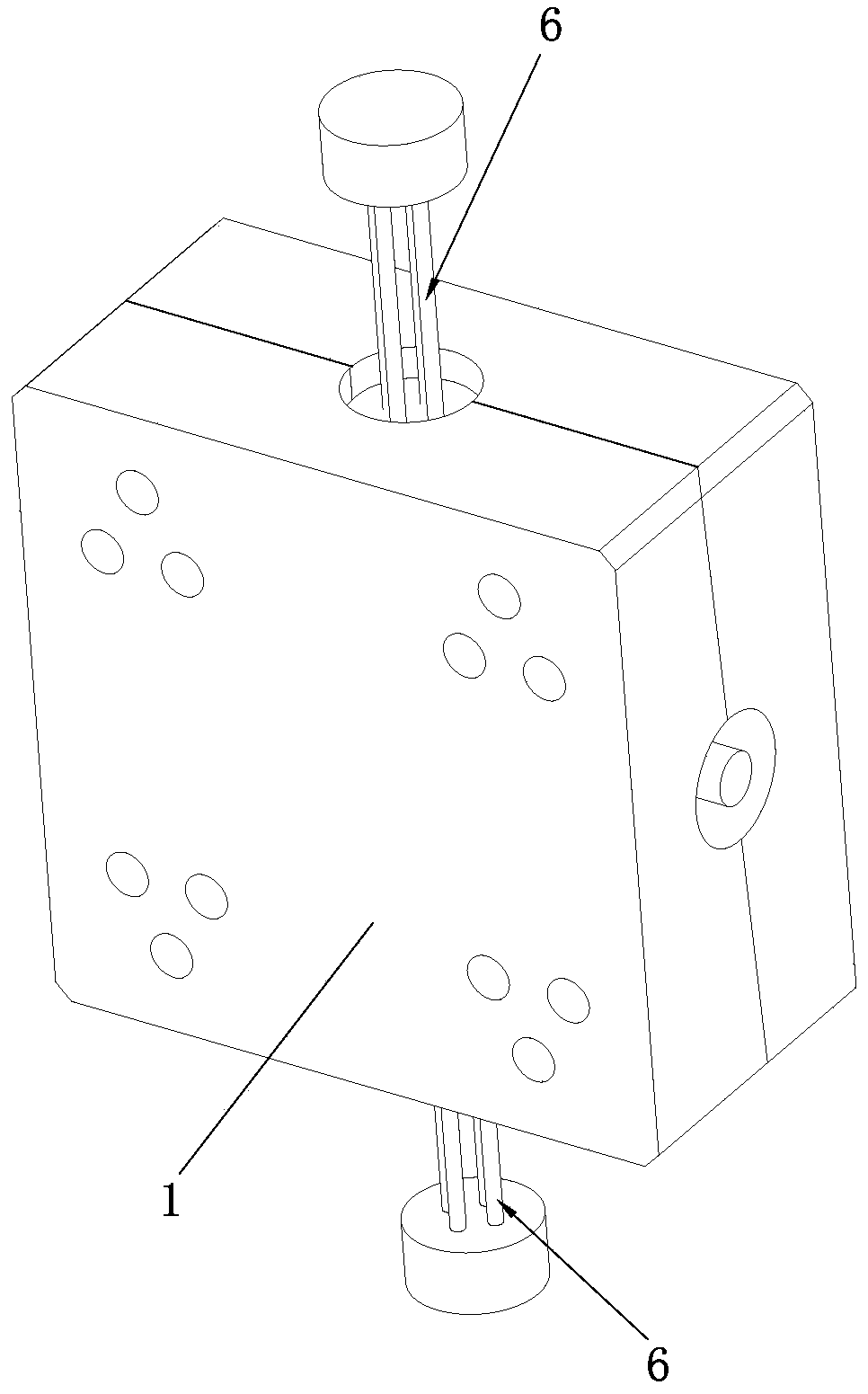

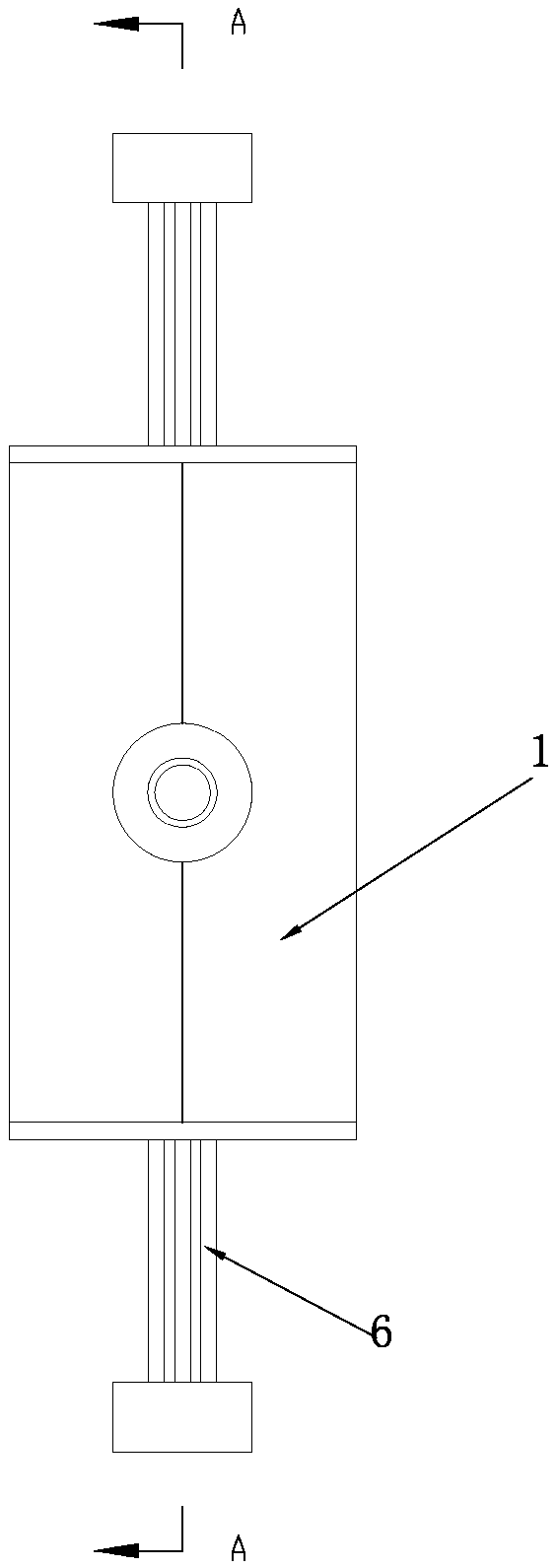

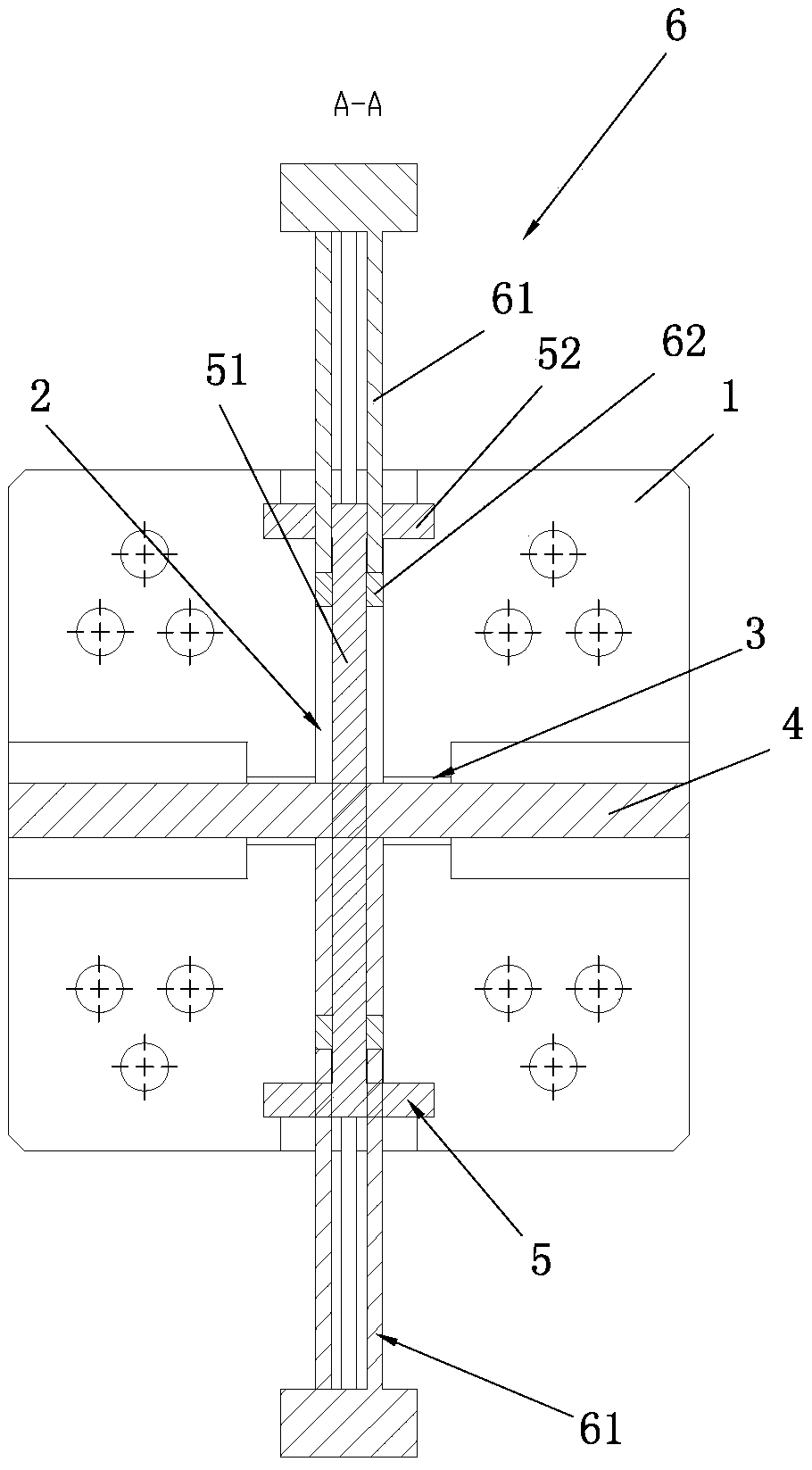

[0032] like Figure 1~4 As shown, a metal seamless pipe extrusion molding device in this embodiment includes a die 1, and the die 1 is provided with a blank cavity 2 and a pipe extrusion channel 3 that communicate with each other, and also includes a pipe core 4 , the support assembly 5 and the extrusion device 6 for extruding the material from the blank cavity 2 into the pipe extrusion channel 3, the support assembly 5 is arranged in the blank cavity 2, the extrusion device 6 is reciprocally slidably arranged on the support assembly 5, and the pipe core 4 is set in the pipe extrusion channel 3. A metal seamless pipe extrusion molding device of the present invention has simple structure and low operating cost, and can use the power provided by a hydraulic press, so that the extrusion device 6 can provide a higher extrusion pressure, thereby making the crystal grains of the product more compact. refinement, thereby improving the mechanical properties of the product.

[0033] ...

Embodiment 2

[0039] like Figure 1~5 As shown, a metal seamless pipe extrusion molding device in this embodiment also includes a feeding device 7, and the feeding device 7 is provided with a feeding port 71, a shut-off valve 72, a feeding push rod 73, and a blank cavity 2 The feeding chamber 74 is connected, the feeding push rod 73 is reciprocally slidably arranged in the feeding chamber 74 , and the shut-off valve 72 is arranged between the feeding chamber 74 and the blank chamber 2 . A metal seamless pipe extrusion molding device in this embodiment, when working, makes the melted material enter the feeding cavity 74, and the feeding push rod 73 squeezes the material into the blank cavity 2 and the pipe extrusion channel 3; close the shut-off Valve 72 returns the feeding push rod 73, and the external feeding mechanism makes the material enter the feeding chamber 74 from the feeding port 71. After the material is filled with the feeding chamber 74, the shut-off valve 72 is opened to contin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com