Granulation die head device for increasing extrusion pressure

A granulation die head and extrusion pressure technology, applied in the field of granulation die head, can solve the problems of affecting production efficiency, long-term preheating, multi-energy, etc., and achieve the effects of improving efficiency, preventing material solidification, and reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

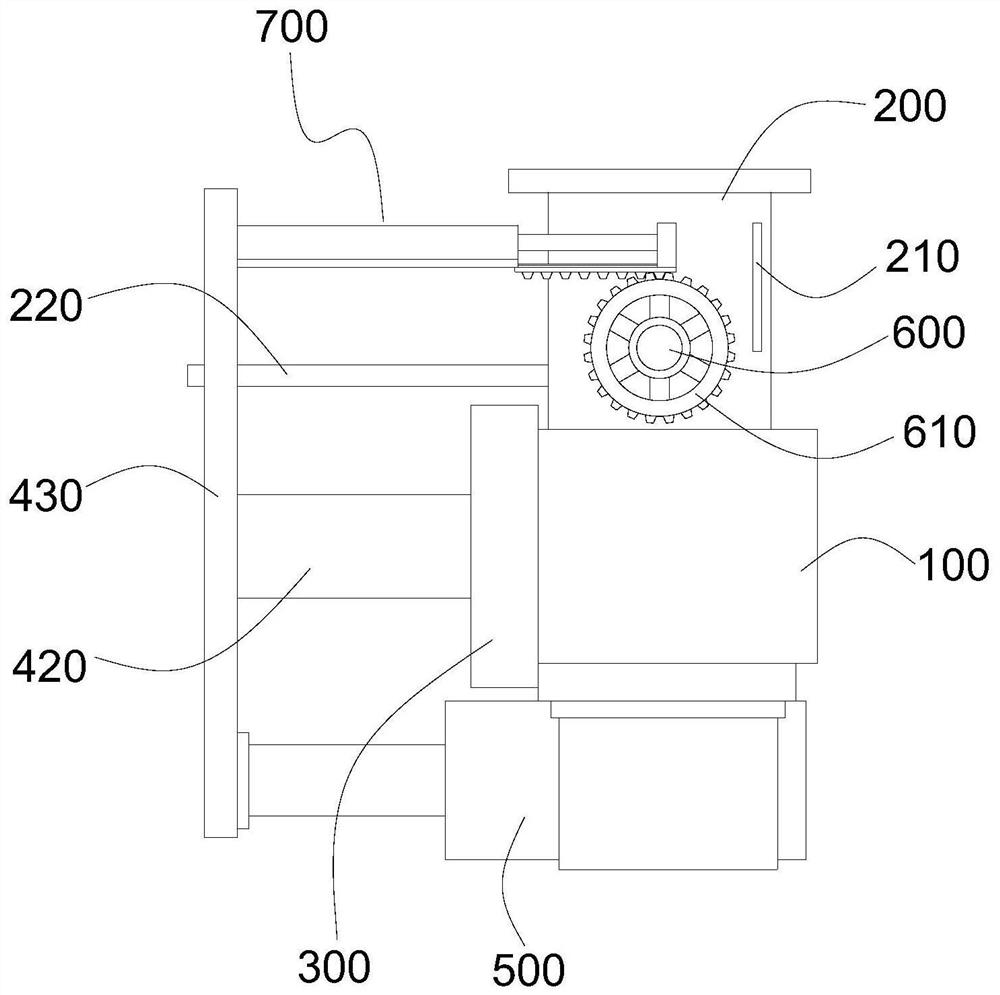

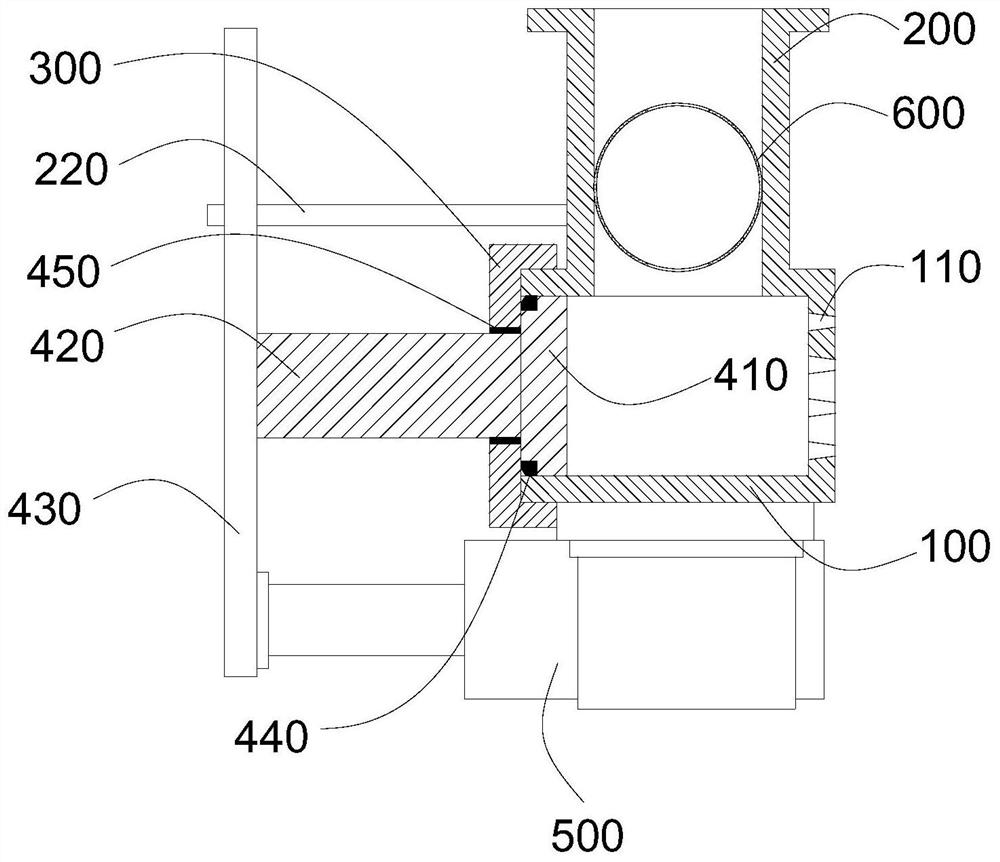

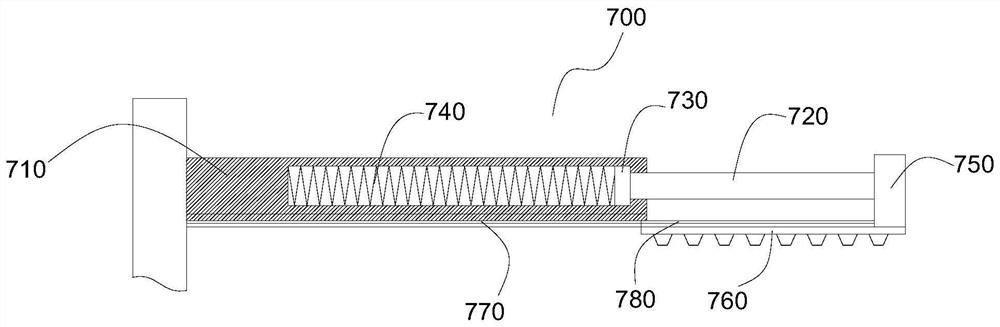

[0023] Such as Figure 1 to Figure 3 As shown, the granulation die head device for increasing the extrusion pressure provided by the specific embodiment of the present invention includes a first pipe body 100 arranged horizontally, and a second pipe body 200 is connected to the top of the first pipe body 100, One end of the first pipe body 100 is sealed, and the sealed end is provided with a plurality of discharge holes 110, the other end of the first pipe body 100 is provided with an end cap 300, and the middle part of the end cap 300 is provided with a through hole A piston block 410 is slid inside the first pipe body 100, and a pressure rod 420 is fixed in the middle of one end of the piston block 410 away from the discharge hole 110, and the shape of the pressure rod 420 is similar to that of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com