Vacuum extruder of brick or tile

A vacuum extruder and extruder technology, which is applied in the field of brick and tile machinery and equipment, can solve the problems of unsatisfactory extrusion effect, inability to uniformly mix mud, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

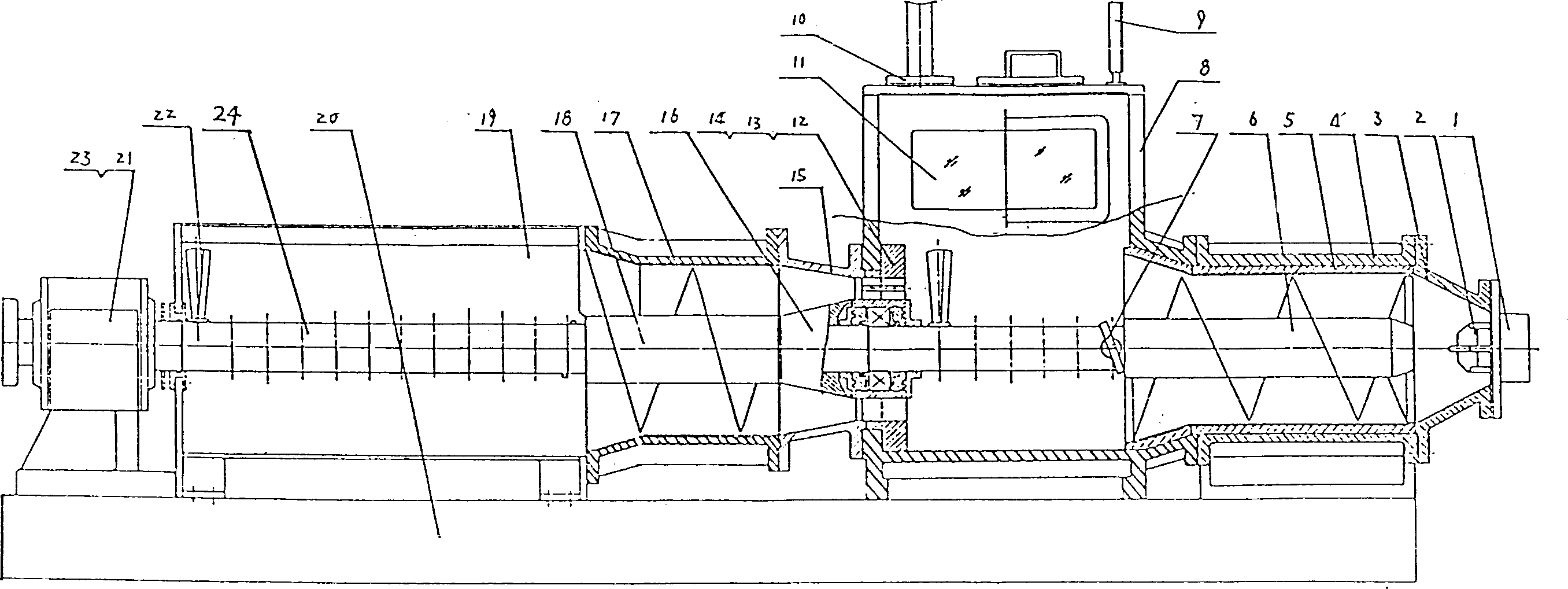

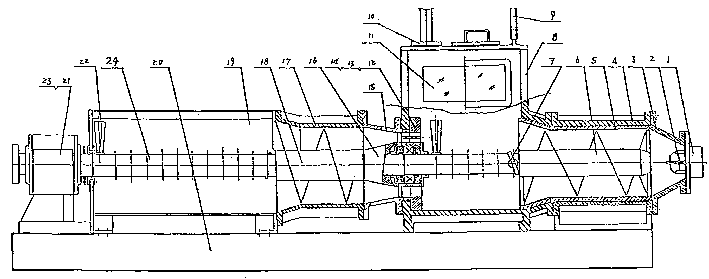

[0015] Referring to the accompanying drawings, the machine mouth 1, mandrel frame 2, and machine head 3 are fixed on the outlet of the mud cylinder 4 behind the vacuum chamber. There is a bushing 5 inside the mud cylinder 4, and the top of the vacuum chamber passes through the flange and the exhaust pipeline. 10 links to each other, and rear mud cylinder 4 is horizontally connected with taper mud cylinder 15, half mud cylinder 17, mixing box 19 through vacuum chamber 8. The reamer shaft 24 is sequentially equipped with a rear thrust bearing group 23, a stirring tooth 22, a Huff stirring knife 18, a taper sleeve 16, a bearing 13, a sealing assembly 14, a stirring knife 7, and an extrusion stirring knife 6 from back to front. Simultaneously, the middle part of the reamer shaft 24 is fixedly connected with the thrust seat 12, the bearing 13, the sealing assembly 14 and the vacuum chamber 8.

[0016] When working, the same as the operation of the upper and lower double-stage vacuu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com