Internal exhaust type parallel counter-rotating multi-screw extruder

A multi-screw extruder, exhaust type technology, applied in the field of plastic extrusion molding, can solve the problems of affecting product quality, extrusion capacity affecting output and cost, poor plasticizing performance, etc., to achieve large melting surface and energy saving effect Significant, increased eater and compressibility effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

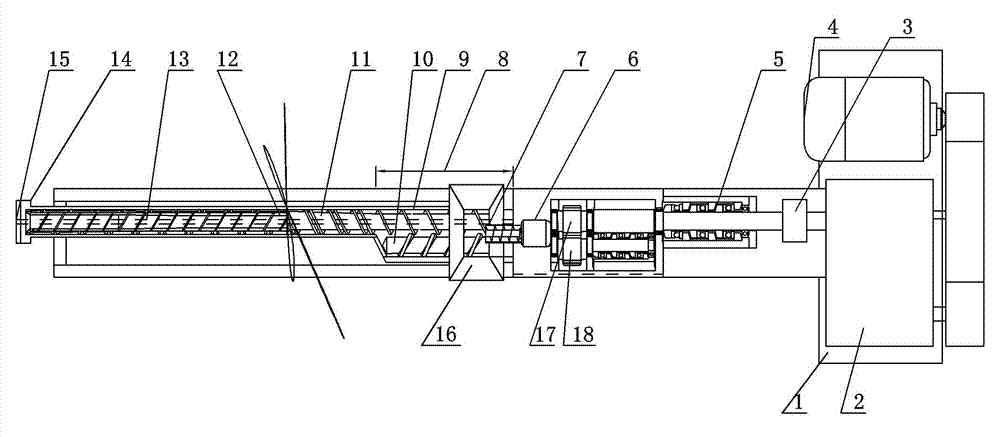

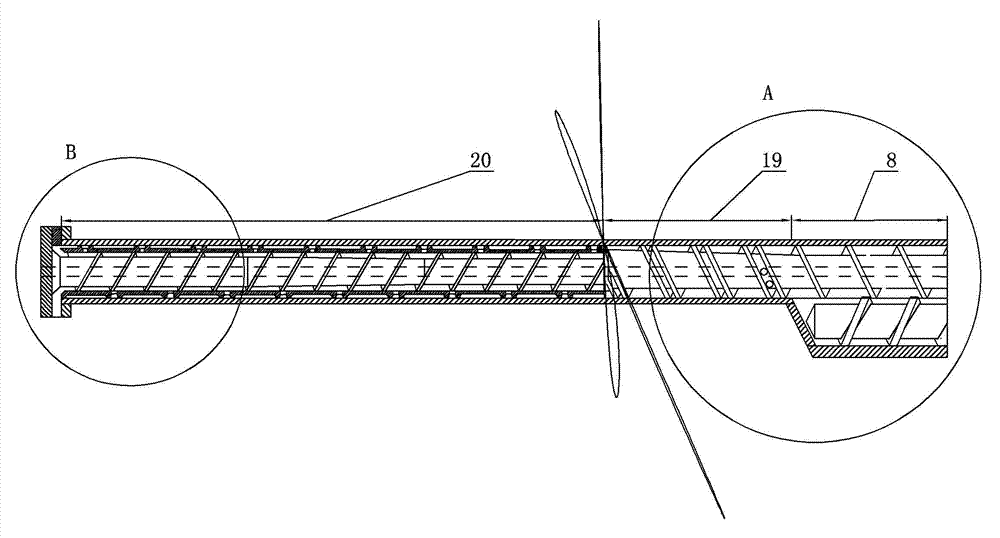

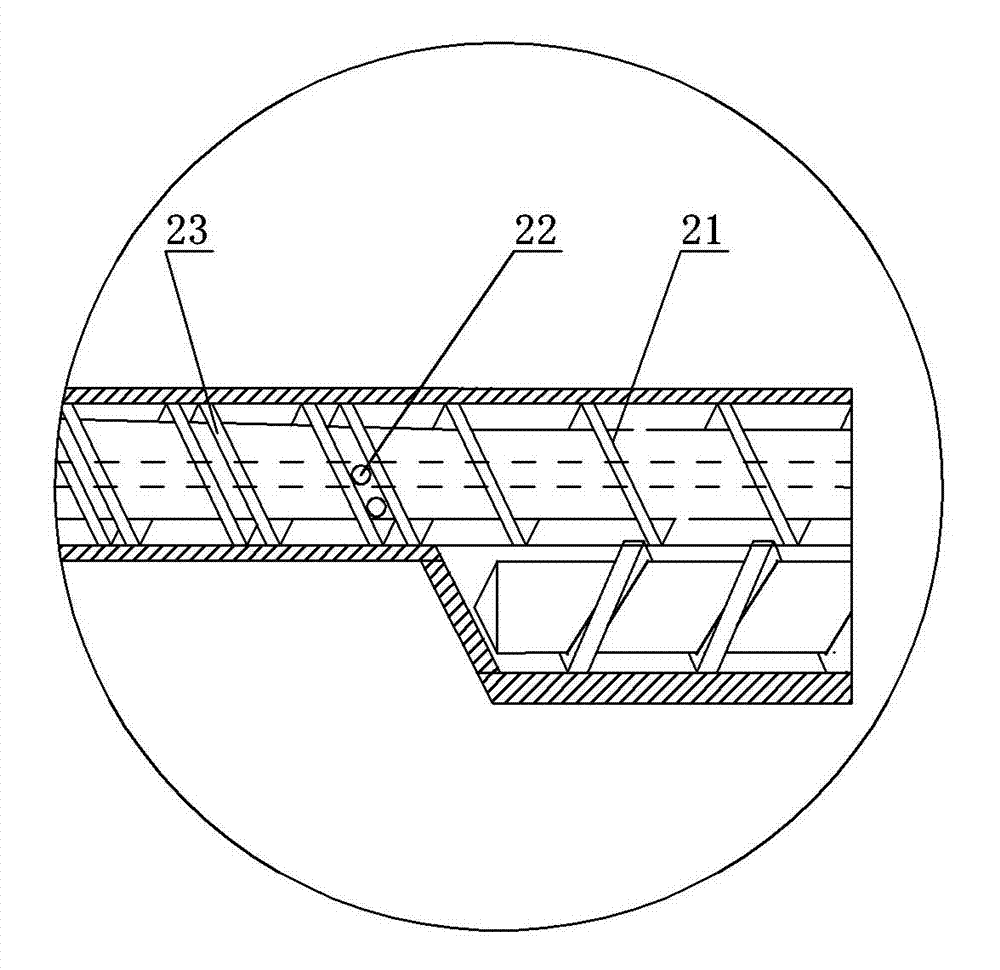

[0035] Such as figure 1 As shown, the extruder of the present invention includes a frame 1, a drive motor 4 and a reduction box 2 are arranged on the frame 1, and the reduction box 2 is connected to the distribution box 5 on its left side by a coupling 3, and the distribution box 5 on the distribution box 5 The feeding device 6 corresponds to the top of the hopper 16, the bottom of the hopper 16 corresponds to the feed end 7 of the barrel 9 on the left side of the distribution box 5, the discharge end 15 of the barrel 9 is provided with an end cover 14, and the barrel 9 has a built-in main The screw rod 11 and the auxiliary screw rod 10 opposite to the thread direction of the main screw rod 11 located at the feed end 7, the main screw rod 11 and the auxiliary screw rod 10 are respectively connected with the driving gear 17 and the driven gear 18 in the distribution box 5; the main screw rod 11 The left section is a hollow structure, and a built-in internal screw 12 whose le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com