Hot melt rubber stick extrusion machine

An extruder and glue stick technology, applied in the field of special equipment for manufacturing hot melt glue sticks, can solve the problems of high cost, cumbersome operation, large equipment footprint, etc., to prevent mutual adhesion, increase extrusion pressure, improve The effect of quality and productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

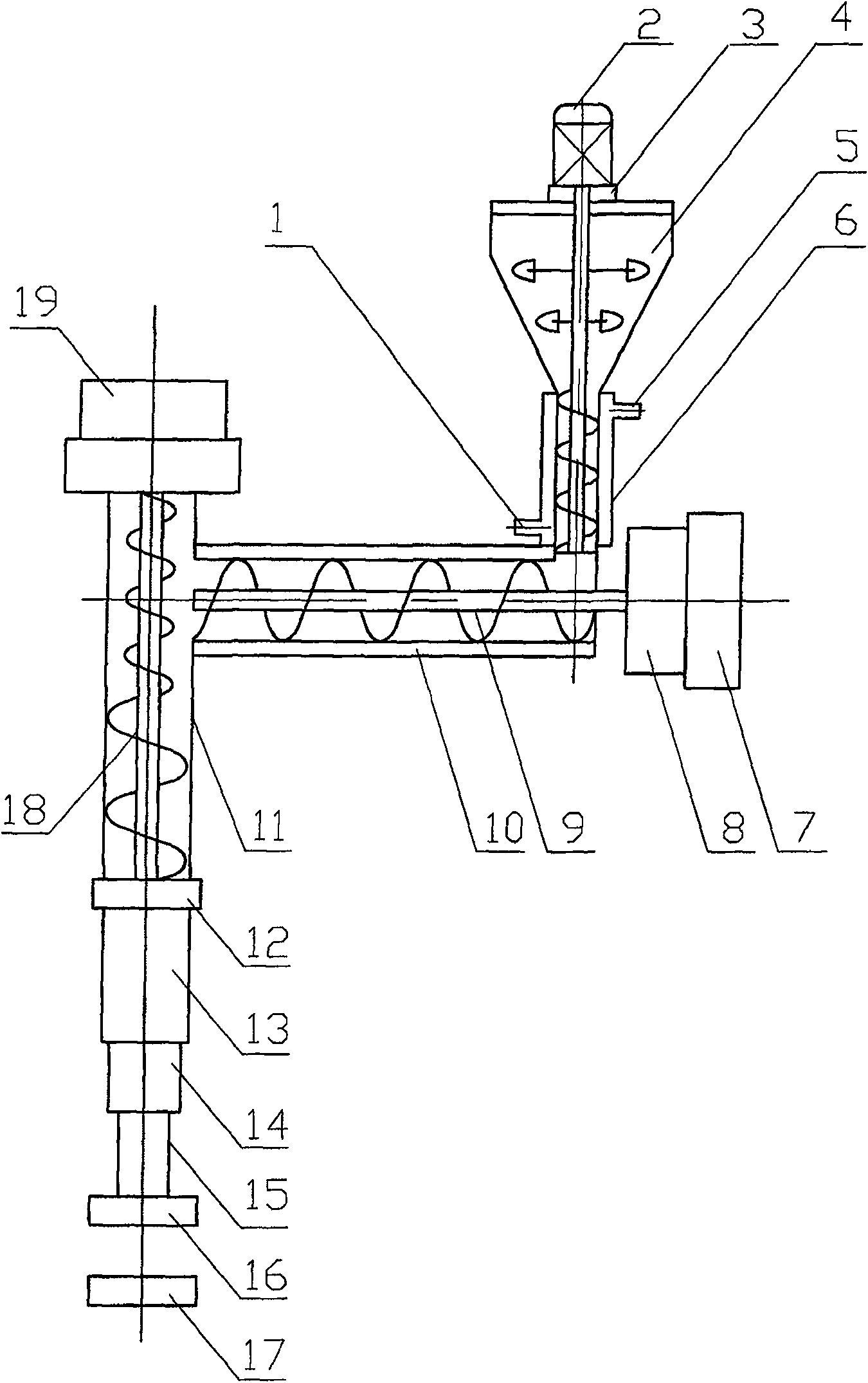

[0018] Such as figure 1 As shown, this embodiment includes a hopper 4 with a feed opening. Above the hopper 4, a feeding motor 2 and a speed reducer 3 connected with the feeding motor 2 are installed. The output shaft of the reduction motor 3 is connected with the stirring shaft in the hopper 4 through transmission. A screw-propelled feeding mechanism 6 is installed below the hopper 4, and the propulsive screw in the screw-driven discharging mechanism 6 is connected with the aforesaid stirring shaft through transmission. A cooling water circulation jacket with a water inlet 1 and a water outlet 5 is provided around the screw feeding mechanism 6 .

[0019] An extruder 10 with a heating device is connected below the screw feeding mechanism 6 . The extruder 10 is a screw extrusion type, wherein the power end of the extrusion screw 9 is connected to the extrusion power device 7 through an extrusion reducer 8 . The output end of the extruder 10 is connected to the extruder head...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com