Multiscrew pressurizing extruder

An extruder and multi-screw technology, which is applied in the field of plastic product processing equipment, can solve the problems of more water bubbles in plastics and small extrusion force, and achieve the effects of low maintenance cost, small wear amount and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following descriptions are only preferred embodiments of the present invention, and therefore do not limit the protection scope of the present invention.

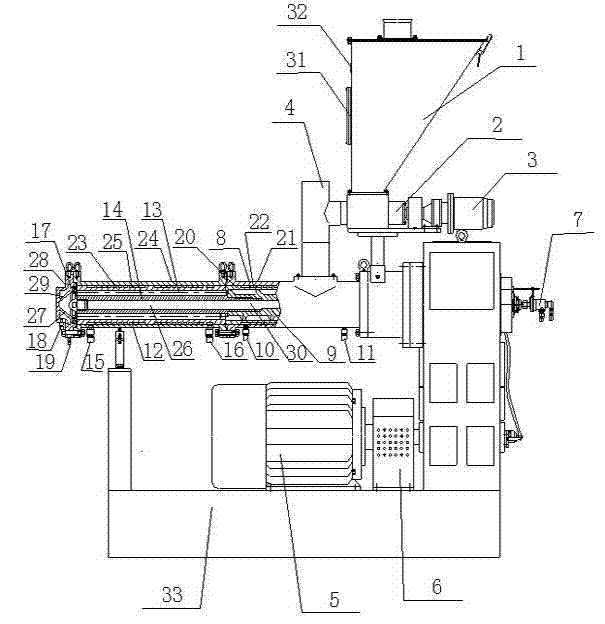

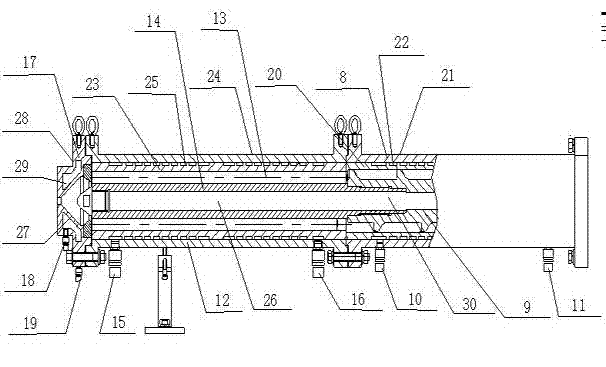

[0026] Examples, see Figure 1 to Figure 2 Shown:

[0027] The multi-screw supercharged extruder includes a base 33. The base 33 is a steel structure for the support of the main motor 5 with variable frequency speed regulation, the reducer 6 and the extrusion pressurized plasticizing section, etc., and the feeding materials arranged on the base 33 in turn section, a feeding section and a discharging section, the feeding section and the discharging section are provided with an extrusion pressurized plasticizing section, the output shaft of the frequency conversion speed regulating main motor 5 is fixedly connected with the input shaft of the reducer 6, and the decelerating The output shaft of the machine 6 directly drives the feeding section and the extrusion pressurized plasticizing section fixedly connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com