Dual-drive multi-screw extruder

A multi-screw extruder and dual-drive technology, applied in the field of multi-screw extruders, can solve the problems of high energy consumption for single-screw plasticization, wear of the screw and shell, troublesome production operations, etc., and achieve good vacuum exhaust effect, Energy saving and high versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

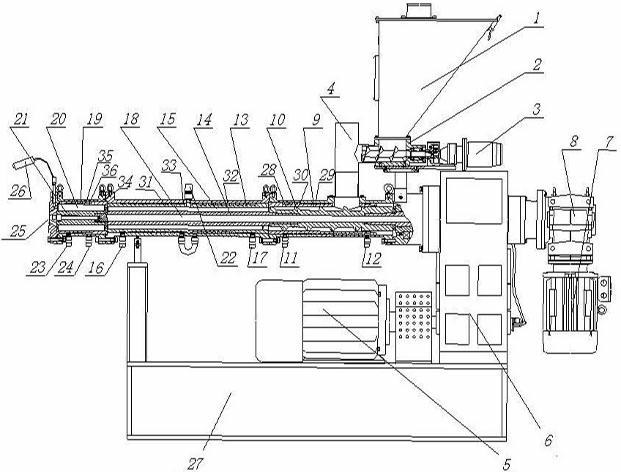

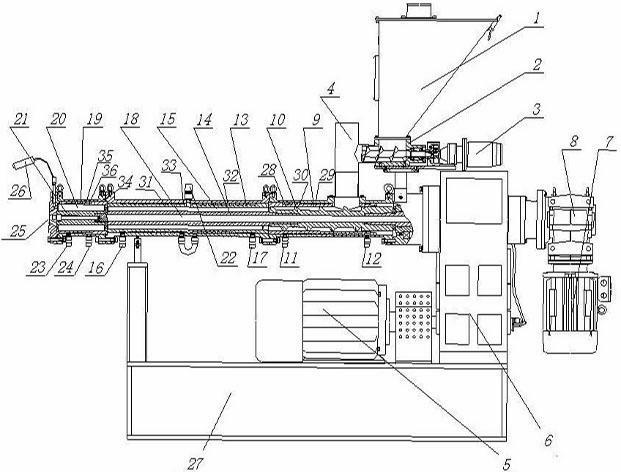

[0017] Attached below figure 1 One embodiment of the present invention is described.

[0018] The double-drive multi-screw extruder includes a base 27, a feeding device, a feeding device and a main plasticizing device sequentially arranged on the base 27, and a pressurized extrusion device is arranged at the rear end of the main plasticizing device.

[0019] The feeding device includes a hopper 1, a feeder 2, a variable frequency feeding motor 3 and a blanking sleeve 4. A hopper 1 is arranged above the feeder 2, and the feeder 2 is connected with the output shaft of the variable frequency feeding motor 3. The blanking sleeve 4 is placed at the outlet end of one side of the feeder 2; the feeding device includes a feeding casing 9, a feeding screw 10, a main drive frequency conversion motor 5 and a main drive transmission reduction box 6, and the feeding casing 9 is sleeved on the feeding screw 10. The output shaft of the main drive variable frequency motor 5 is fixedly connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com