Degradable sheet extrusion molding machine

A technology of extrusion molding machine and twin-screw extruder, which is applied in the field of sheet forming equipment, can solve problems such as increased labor intensity, labor costs, unfavorable production planning arrangements, and increased production costs, so as to ensure smoothness and stability, The effect of reducing manpower and reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the purpose, technical scheme and advantages of the present invention clearer, the following will be combined with the attached figure 1 -6 further describe the present invention in detail.

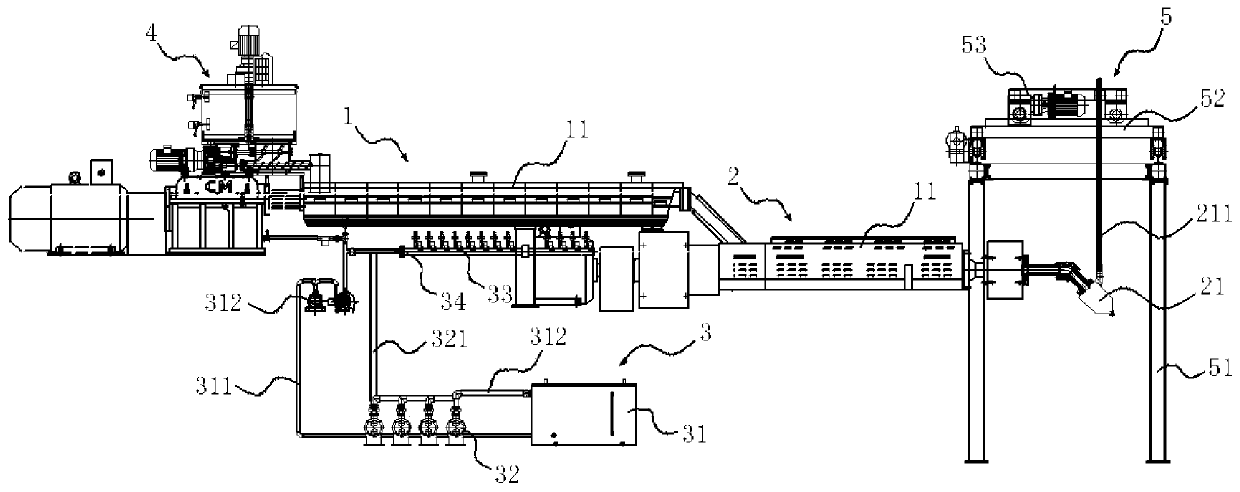

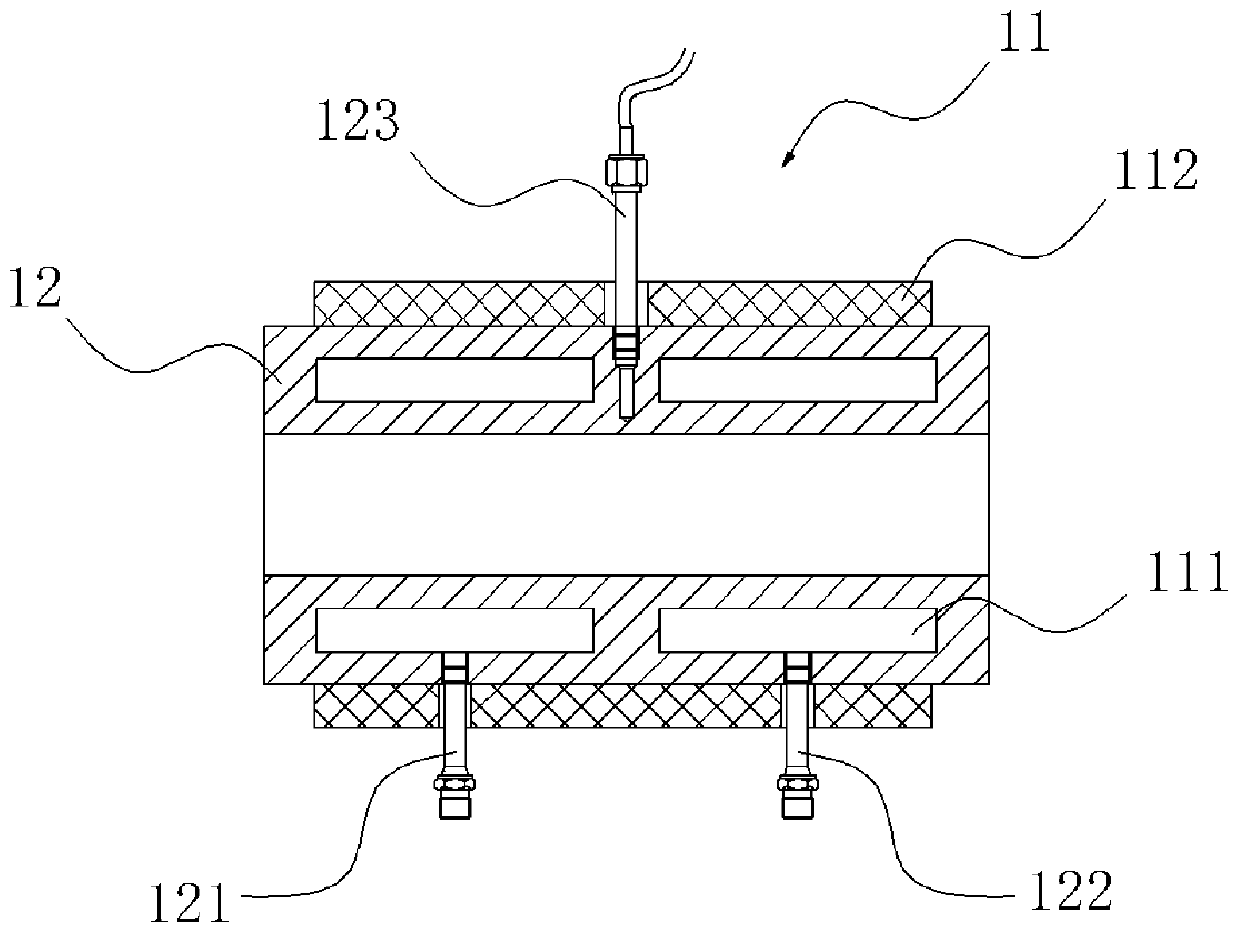

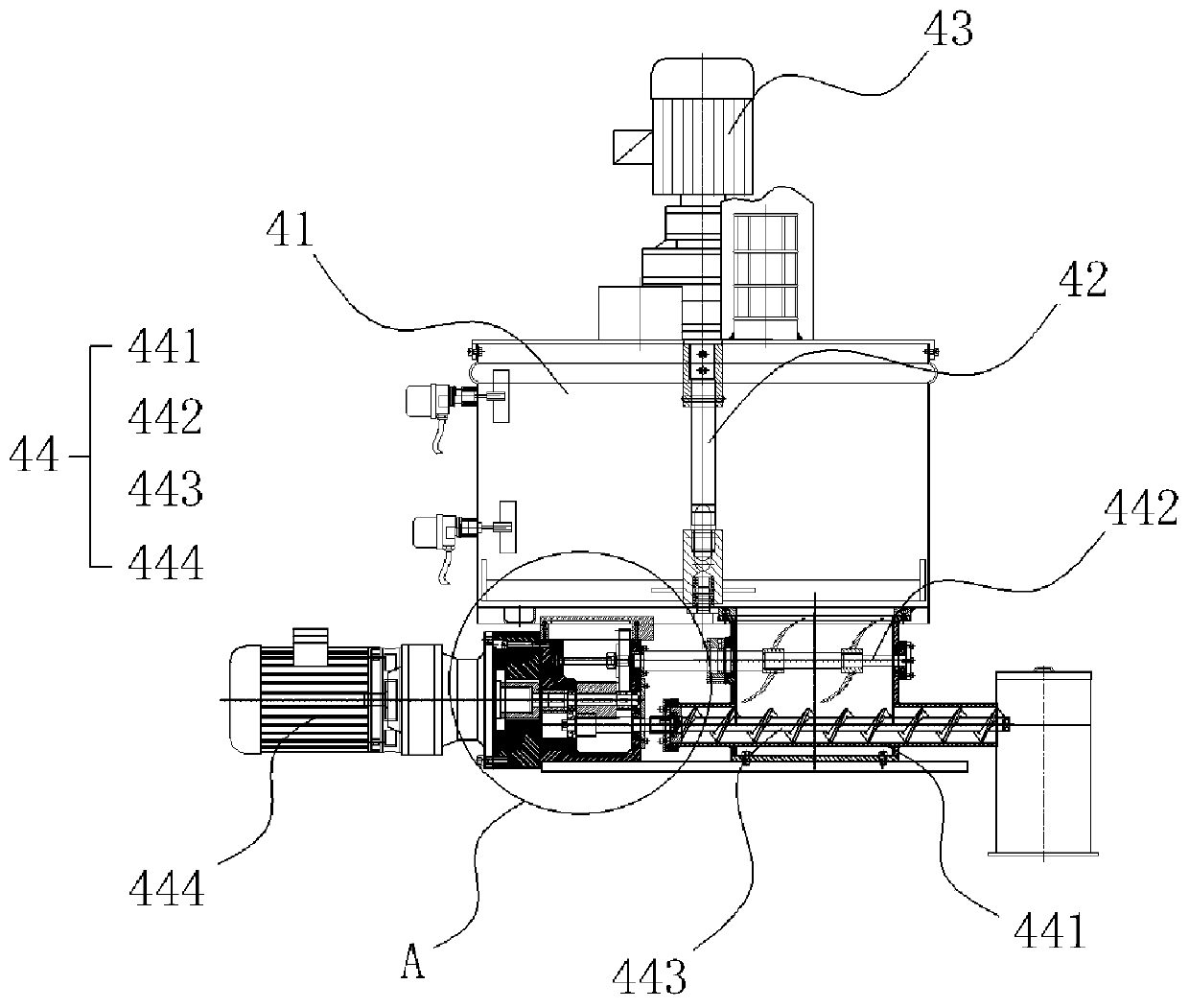

[0024] refer to figure 1 As shown, a degradable sheet extrusion molding machine includes a twin-screw extruder 1, a single-screw extruder 2, an automatic constant temperature device 3, a blanking control device 4, and a die head lifting device 5.

[0025] The blanking control device 4 is arranged on the feed port of the twin-screw extruder 1, the discharge port of the twin-screw extruder 1 communicates with the feed port of the single-screw extruder 2, and the feed port of the twin-screw extruder 1 The position is higher than the single-screw extruder 2. After the material enters the twin-screw extruder 1, it enters the single-screw extruder 2 through the discharge port of the twin-screw extruder 1, and the discharge port of the single-screw extruder 2 is fixed. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com