Polymer melt calculus heat transfer enhancement and mixing plasticization extruder

A technology for enhancing heat transfer and polymer, applied in the field of plastic extrusion molding device, can solve the problem that the mixing effect is not very good, and achieve the effects of enhancing the mixing effect, strengthening heat transfer, and uniform plasticization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

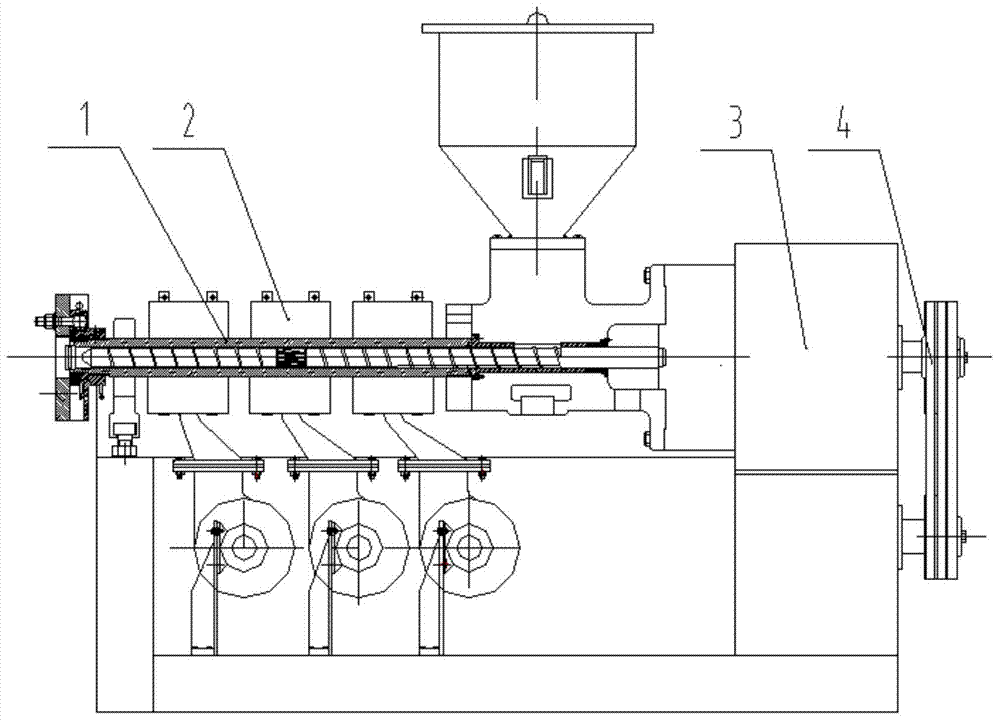

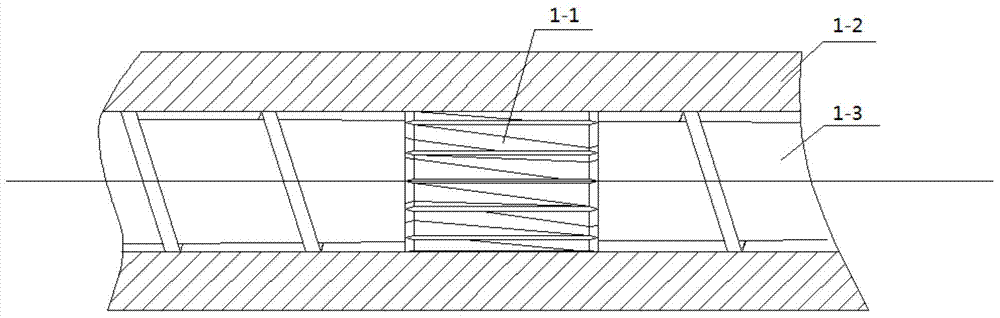

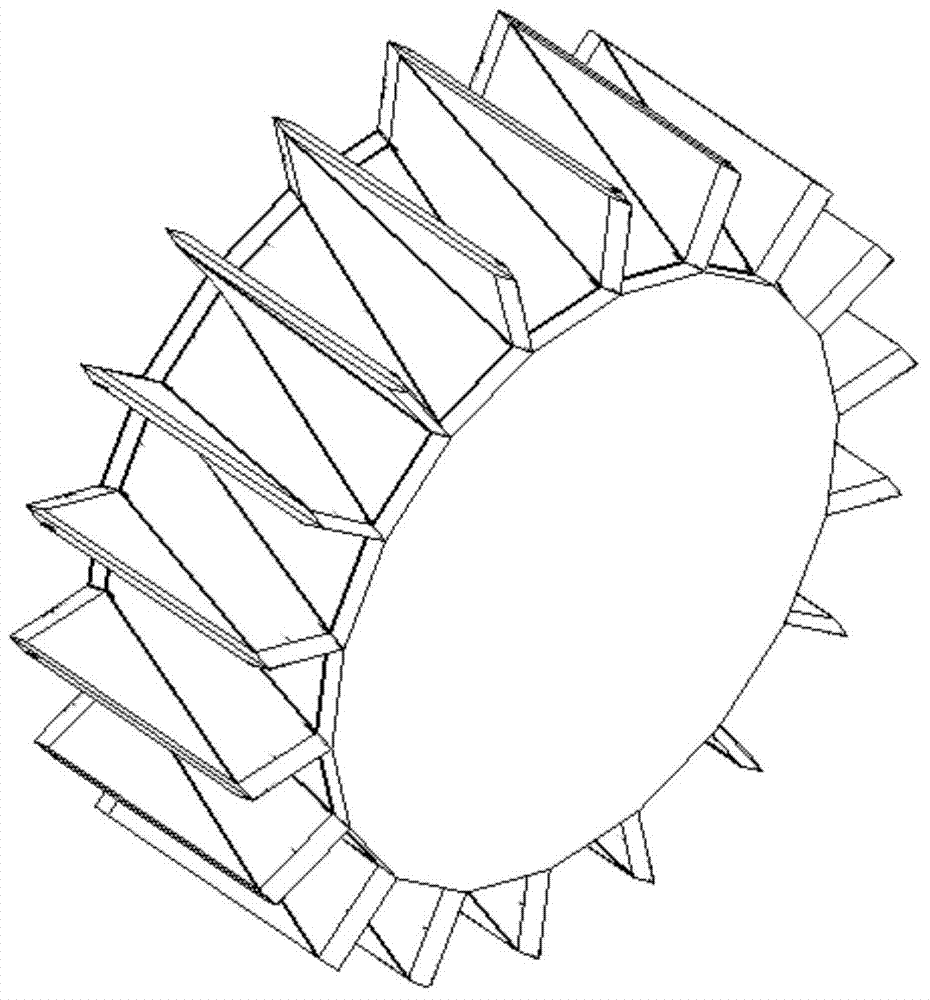

[0023] Polymer melt calculus of the present invention enhances heat transfer and mixing plasticizing extruder such as figure 1 As shown, it consists of heating and plasticizing part 1, heating and cooling part 2, control system 3 and transmission system 4. Wherein the screw rod 1-3 of the feeding plasticizing part 1 has a mixing section, that is, a diverging and twisting converging section 1-1, see figure 2 and image 3 .

[0024] Two mutually perpendicular 90° torsion curved surfaces are set in the dividing groove of the diversion torsion confluence section 1-1 to realize the torsion of the polymer melt, see Figure 4 . The bottom of the screw groove is divided into two areas, one area gradually becomes smaller along the direction of the splitting edge, and the depth of the groove gradually decreases until it is twisted 90 degrees at the exit; the other area gradually becomes larger along the direction of the splitting edge, and the groove The depth gradually increases u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com