Preparation method of silicon carbide ceramic heat-exchange tube and product prepared by method

A technology of silicon carbide ceramics and heat exchange tubes, applied in the field of engineering ceramics preparation, can solve the problems of unfavorable promotion of SiC heat exchangers, large equipment investment and energy consumption, high requirements for green body strength, etc., and achieves reduction in equipment and related configuration investment. Small size, improved yield and high green body density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

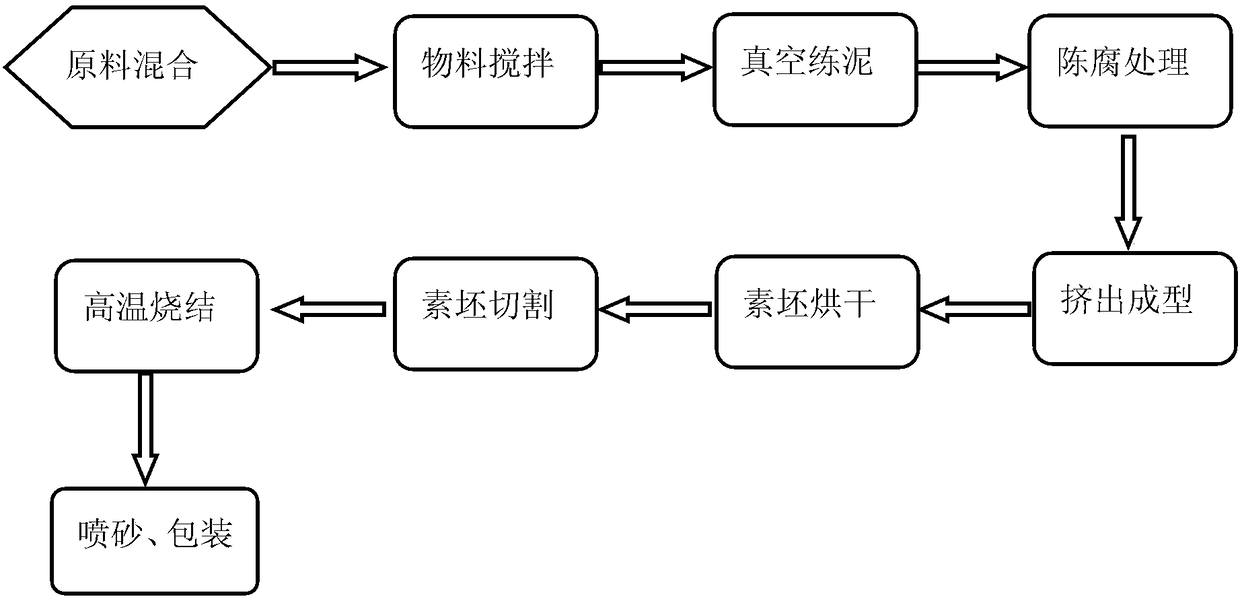

Method used

Image

Examples

Embodiment 1

[0067] Embodiment 1: Preparation of the silicon carbide ceramic heat exchange tube of the present invention

[0068] raw material

[0069] Silicon carbide powder: 65kg, of which, particle size 0.5μm: 7.6kg; particle size 10μm: 38.2kg; particle size 20μm: 19.2kg;

[0070] Carbon black: 25kg, particle size is 20μm;

[0071] Naphthalene sulfonate: 10kg;

[0072] Water: 30kg;

[0073] Yellow dextrin: 5kg;

[0074] Stearic acid: 0.4kg,

[0075] Oleic acid: 0.1kg;

[0076] Polyacrylic acid: 3kg;

[0077] Metal silicon powder: 97.5kg, particle size 10mm.

[0078] (1) Dry-mix silicon carbide micropowder, carbon black, and naphthalene-based sulfonate, put them into a V-type mixer and mix for 3 hours, and pour them into the kneader after mixing evenly; in addition, add water, yellow dextrin, hard Fatty acid, oleic acid, and polyacrylic acid are mixed and stirred evenly, then sprayed into the kneader, and stirred for 2 hours;

[0079] (2) The material that step (1) is obtained...

Embodiment 2

[0084] Embodiment 2: Preparation of the silicon carbide ceramic heat exchange tube of the present invention

[0085] raw material

[0086] Silicon carbide powder: 85kg, of which particle size 0.5μm: 21.25kg; particle size 10μm: 42.5kg; particle size 20μm: 21.25kg;

[0087] Carbon black: 8kg, particle size is 45μm;

[0088] Naphthalene sulfonate: 7kg;

[0089] Water: 15kg;

[0090] Cross-linked starch: 2kg;

[0091] Polyvinyl alcohol: 1kg;

[0092] Magnesium stearate: 0.2kg;

[0093] Tetramethylammonium hydroxide: 0.1kg;

[0094] Metal silicon powder: 70kg, particle size 6mm.

[0095] (1) Dry-mix silicon carbide micropowder, carbon black, and naphthalene-based sulfonate, put them into a V-type mixer and mix for 3 hours, and pour them into the kneader after mixing evenly; Vinyl alcohol, magnesium stearate, and tetramethylammonium hydroxide were mixed and stirred evenly, then sprayed into the kneader, and stirred for 4 hours;

[0096] (2) pack the material that step (1...

Embodiment 3

[0101] Embodiment 3: Preparation of the silicon carbide ceramic heat exchange tube of the present invention

[0102] raw material

[0103] Silicon carbide powder: 77kg, of which, particle size 0.5μm: 14kg; particle size 10μm: 42kg; particle size 20μm: 21kg;

[0104] Carbon black: 16kg, particle size is 15μm;

[0105] Naphthalene sulfonate: 7kg;

[0106] Water: 15kg;

[0107] Yellow dextrin: 3kg;

[0108] Polyvinyl alcohol: 2kg;

[0109] Stearic acid: 0.4kg;

[0110] Tetramethylammonium hydroxide: 0.15kg;

[0111] Metal silicon powder: 90kg, particle size 5mm.

[0112] (1) Dry-mix silicon carbide micropowder, carbon black, and naphthalene-based sulfonate, put them into a V-type mixer and mix them for 2 hours, and pour them into the kneader after mixing evenly; in addition, add water, yellow dextrin, poly Vinyl alcohol, stearic acid, and tetramethylammonium hydroxide were mixed and stirred evenly, then sprayed into the kneader, and stirred for 4 hours;

[0113] (2) Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com