Double-screw extruder

A twin-screw extruder and screw technology, applied in the field of plastic machinery manufacturing, can solve problems such as limiting the scope of use, and achieve the effects of wide application range, important economic value and market promotion value, and stable pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

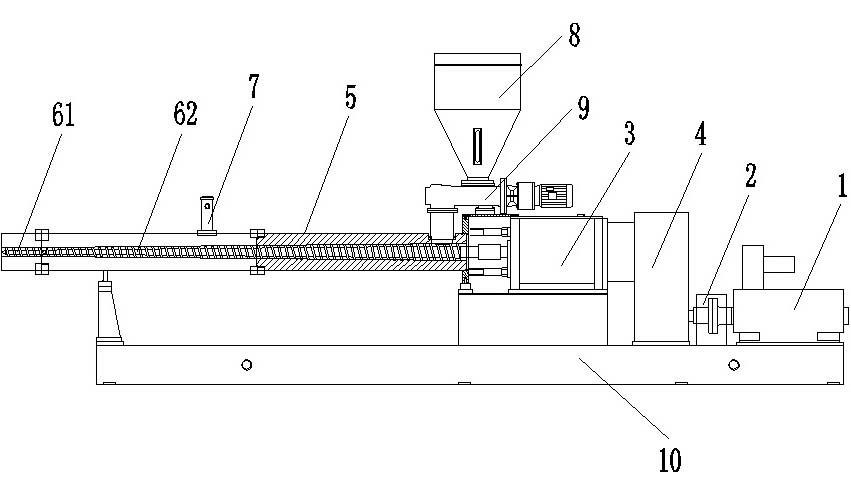

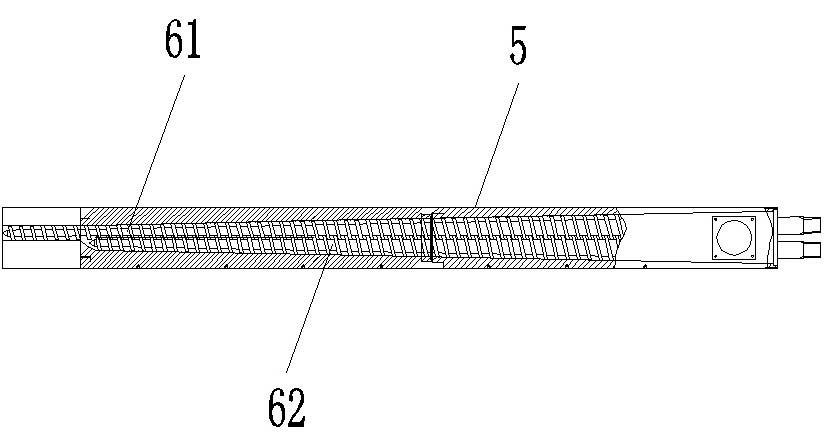

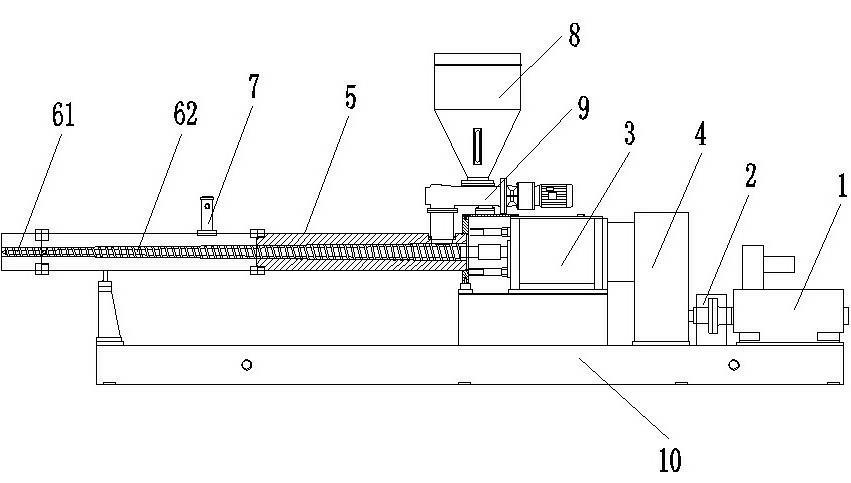

[0022] see Figure 1 to Figure 2 , the twin-screw extruder in this embodiment includes a drive motor 1, a coupling 2, a distribution box 3, a reduction box 4, a barrel 5, a long screw 61, a short screw 62, an exhaust system 7, a hopper 8, a feeding The material system 9 and the frame 10, wherein, the distribution box 3 is provided with a driving gear, an intermediate gear, and a driven gear, the intermediate gear meshes with the driving gear, and the driven gear meshes with the intermediate gear, that is, the driving gear and the driven gear Matched, the driven gear can be driven to rotate by the driving gear. In the present invention, the distribution box 3 may only be provided with a driving gear and a driven gear, and the driving gear and the driven gear are engaged, that is, the driving gear and the driven gear are matched.

[0023] The drive motor 1, distribution box 3, reduction box 4 and machine barrel 5 in this embodiment are all installed on the frame 10, the reducti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com