Supercharge mixed flow perforated plate for wood plastic profiled bar extrusion mold

A technology for extruding molds and profiles, applied in the field of transition devices, can solve the problems of affecting production efficiency, low material flow pressure, poor mixing uniformity of wood-plastic materials, etc., to enhance mixing uniformity, improve smoothness and wood The effect of grain shape simulation, improving physical performance and surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

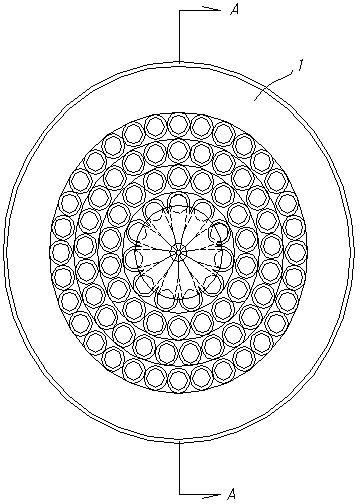

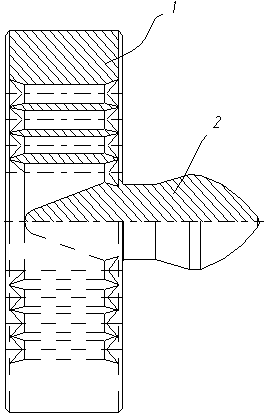

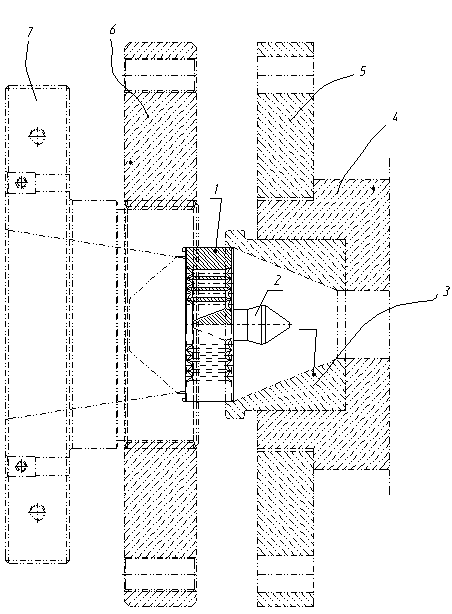

[0013] Such as figure 1 As shown, the pressurized mixed-flow perforated plate is used for the extrusion die of wood-plastic profiled materials. Conical hole with small inside and big outside, such as figure 2 As shown, the center of the circular plate 1 is fixedly connected to the center of the circular plate 1 with a spindle-shaped mixed flow hammer 2 perpendicular to the plate surface. This end inside the shaped plate pressurizes the material passing by. The middle part of the mixed flow hammer 2 is a cylinder, the diameter of which is smaller than the maximum diameter of the conical section at both ends, and the cylinder is connected with the two ends in an arc transition. The maximum cross-sectional diameter of the mixed flow hammer 2 away from the circular plate end is greater than the maximum cross-sectional diameter of the other end. The sideline of the vertical section of the mixed flow hammer 2 away from the circular plate end is an involute line, which makes the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com