Stinging two-way stretching plastic protective screen and manufacturing method thereof

A technology of two-way stretching and manufacturing method, applied in the direction of fence, metal processing, building type, etc., can solve the problem of theft or vandalism, can only play a warning role, can only play a warning role, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Prepare polypropylene sheets; specifically, high-density polypropylene polymers are selected as raw materials, and additives such as carbon black, anti-ultraviolet agents, and antioxidants are added. The polymer is melted at 180-280°C at the outlet, and the sheet blank is extruded through a hanger-type head, cooled by a three-roll calender, calendered and shaped into a sheet, and the excess edge is cut off; the thickness of the sheet is 5mm;

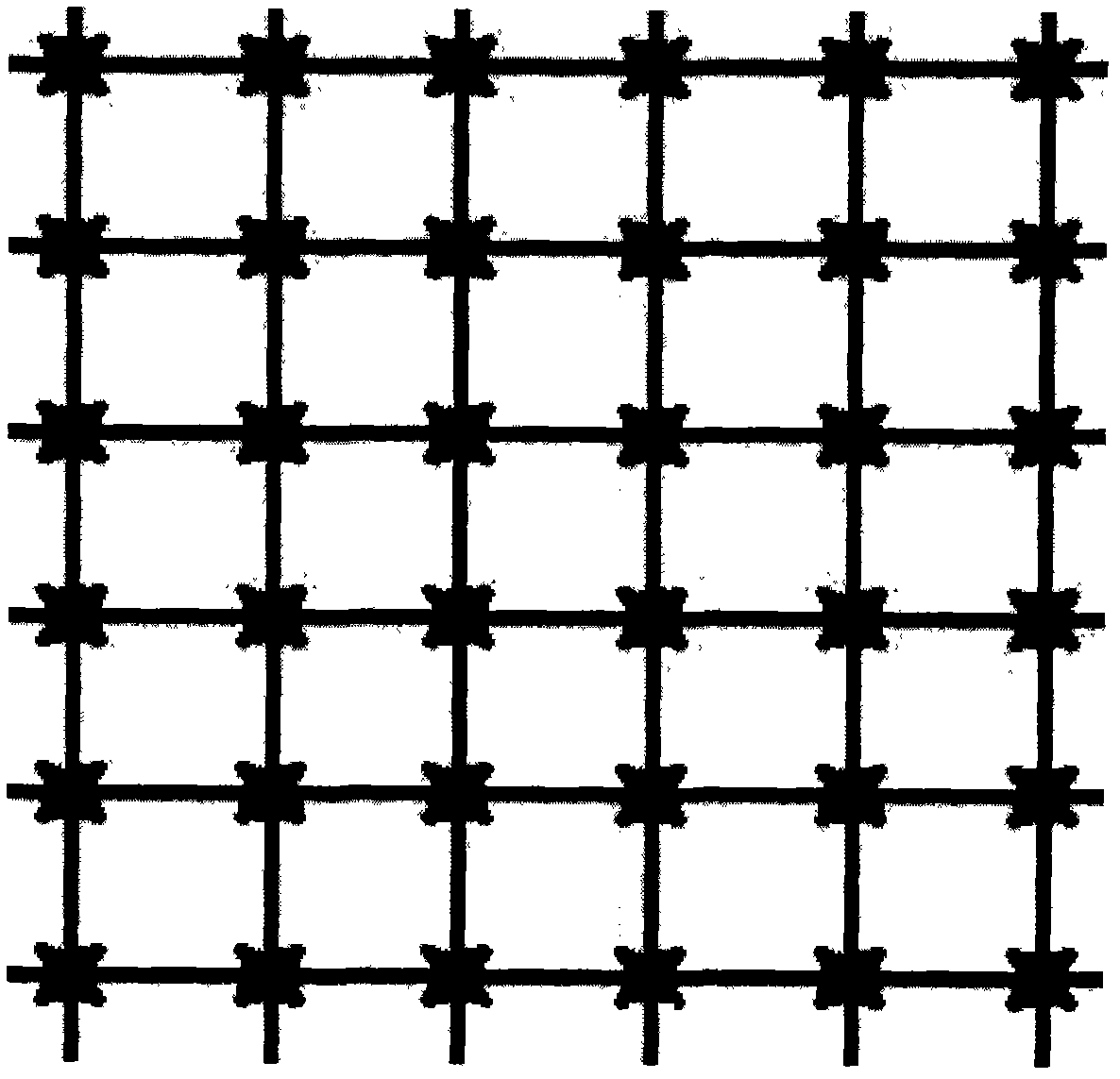

[0024] A punching machine is used to punch holes in the plastic sheet to form a regularly arranged hole array. Wherein, each hole is a cross hole, the diameter of each cross hole is 5mm, and the distance between holes is 10mm;

[0025] The plate is stretched longitudinally and transversely about 6-12 times at equal ratios successively to form a barbed biaxially stretched plastic protective net. Specifically, the above board is preheated to 100°C, and stretched longitudinally. Depending on the material, the stretching ratio is 6-1...

Embodiment 2

[0027] Prepare polyethylene sheet; its thickness is 8mm;

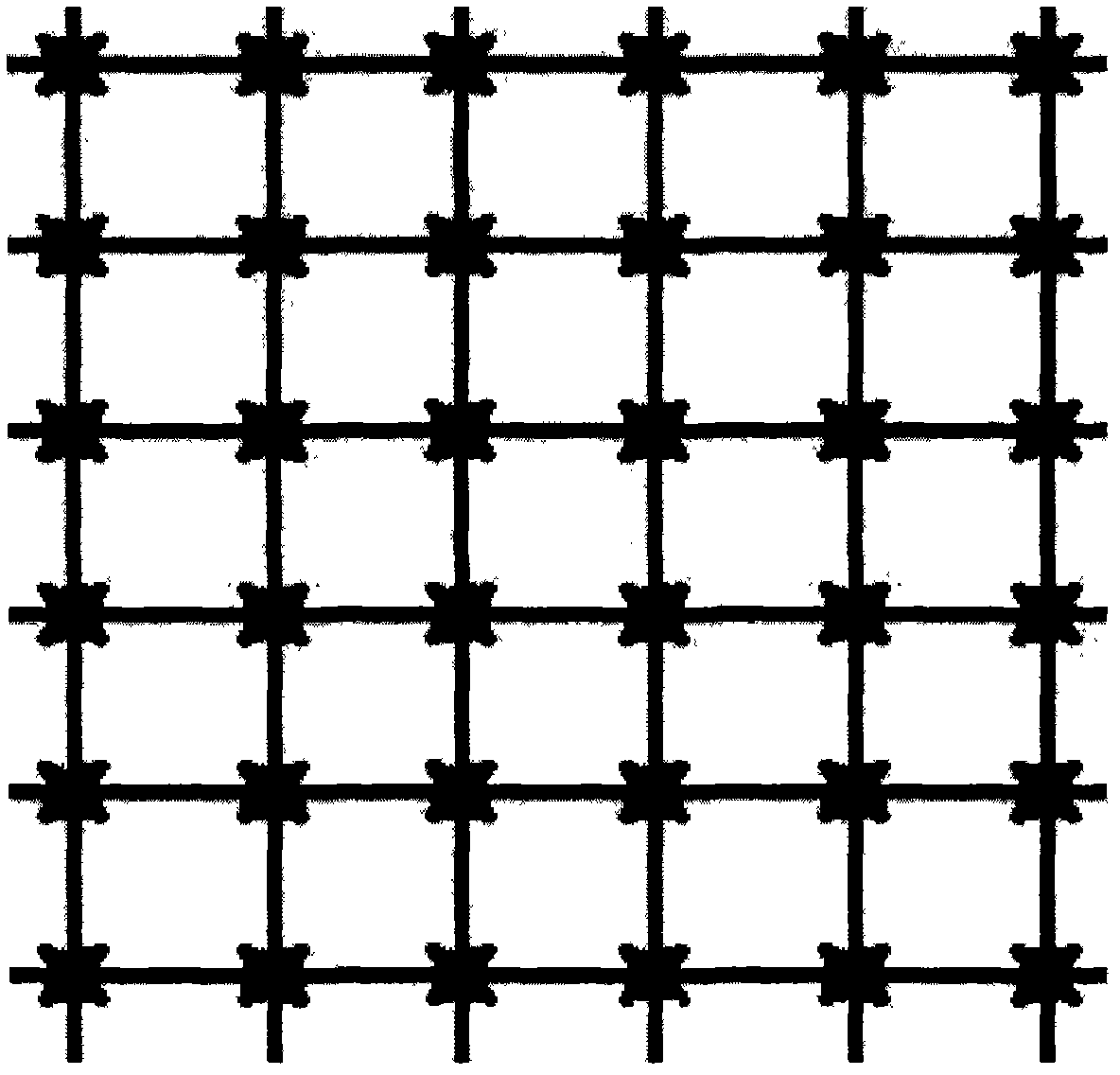

[0028] A regularly arranged hole array is formed on the plastic plate by punching holes. Wherein, each hole is a cross hole, the diameter of each cross hole is 20mm, and the distance between holes is 40mm;

[0029] The plate is stretched longitudinally and transversely by 4-10 times at the same time to form a barbed biaxially stretched plastic protective net. Specifically, the above board is preheated to 80°C, stretched longitudinally and transversely 4-10 times at the same time, and after heat setting, it becomes a barbed biaxially stretched plastic protective net, which is rolled after trimming.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com