Reinforced fabricated beam-column connection joint

A beam-column connection and assembly technology, which is applied in the direction of building and building structure, can solve the problems of complex installation, long construction period, weak connection, etc., and achieve the effect of improved stability and high stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

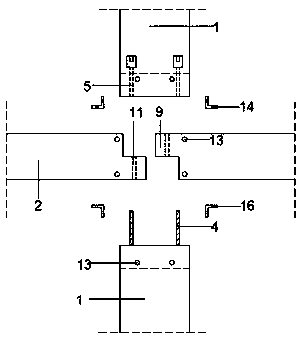

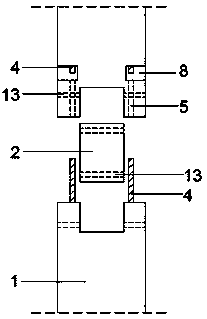

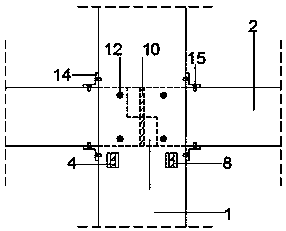

[0027] Such as figure 1 As shown in —9, a reinforced prefabricated beam-column connection node includes a prefabricated column 1, a prefabricated beam 2, an L-shaped connection reinforced steel plate 3, a main reinforcement extending inside and outside the column 4, a main reinforcement hole 5 reserved in the column, and a rectangular shape Groove 6, L-shaped groove 7, main reinforcement connection hole 8, beam upper rectangular connection rib 9, connecting beam threaded short reinforcement 10 high-strength node connection reinforcement 12; the prefabricated column 1 and prefabricated beam 2 are integral steel-concrete structures ; The prefabricated column 1 is arranged with a reserved rectangular groove 6 up and down, and its cross-sectional size is half the cross-sectional size of the end of the prefabricated beam 2, and the interior of the prefabricated column 1 is arranged with four main ribs 4 protruding from the inside and outside of the column , the length of the main r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com