Mould supporting method for trapezoid cross section base of shear wall

A technology of trapezoidal section and formwork support method, which is applied in basic structure engineering, construction, etc., and can solve problems such as difficult repair, large cross-sectional area, and difficult positioning of waist formwork

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

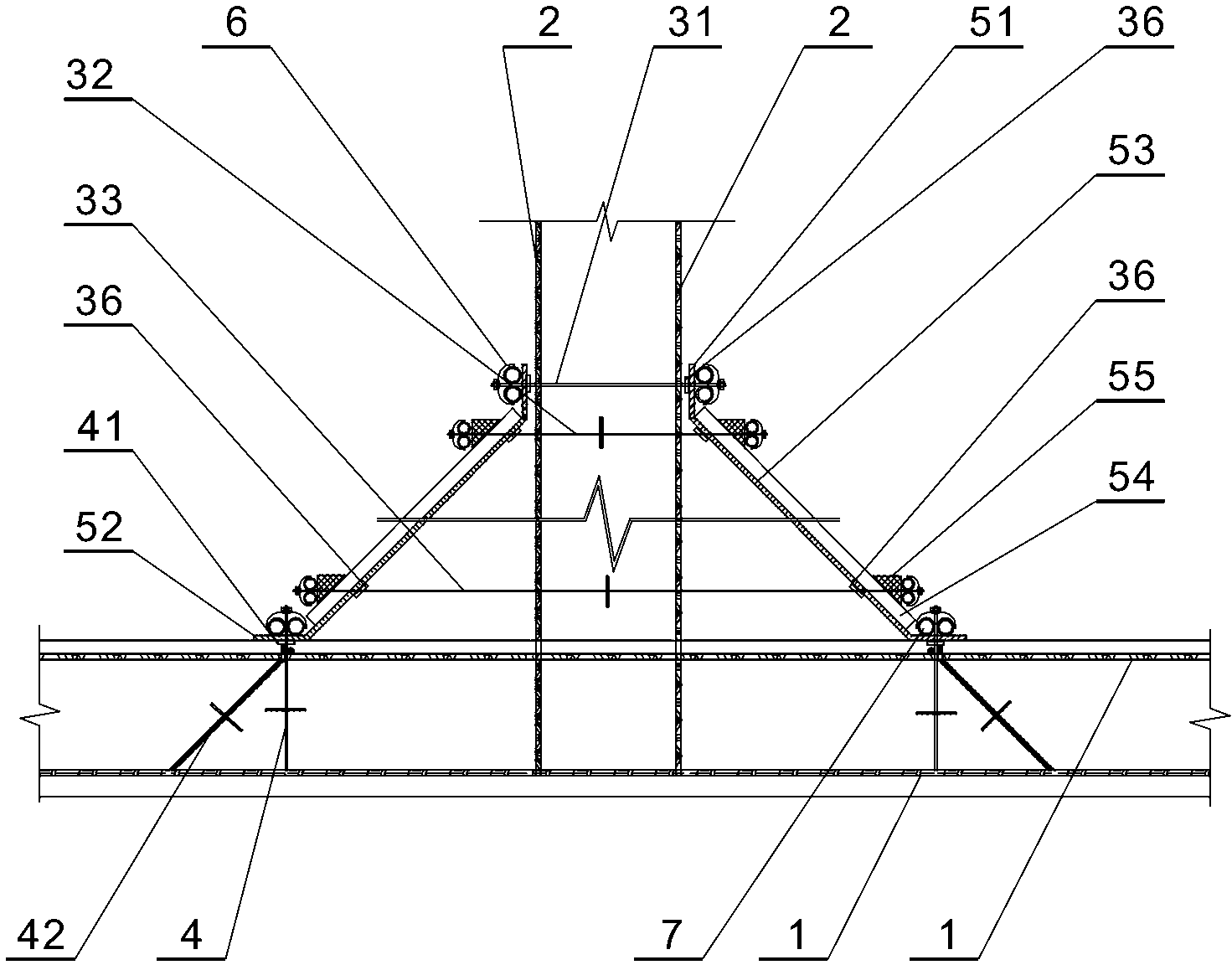

[0031] The thickness of the shear wall panel is 600mm, and the foundation formwork process of the trapezoidal section of the shear wall, the specific steps are as follows:

[0032] a), foundation excavation

[0033] According to the construction drawing, lay the foundation line and implement the foundation excavation;

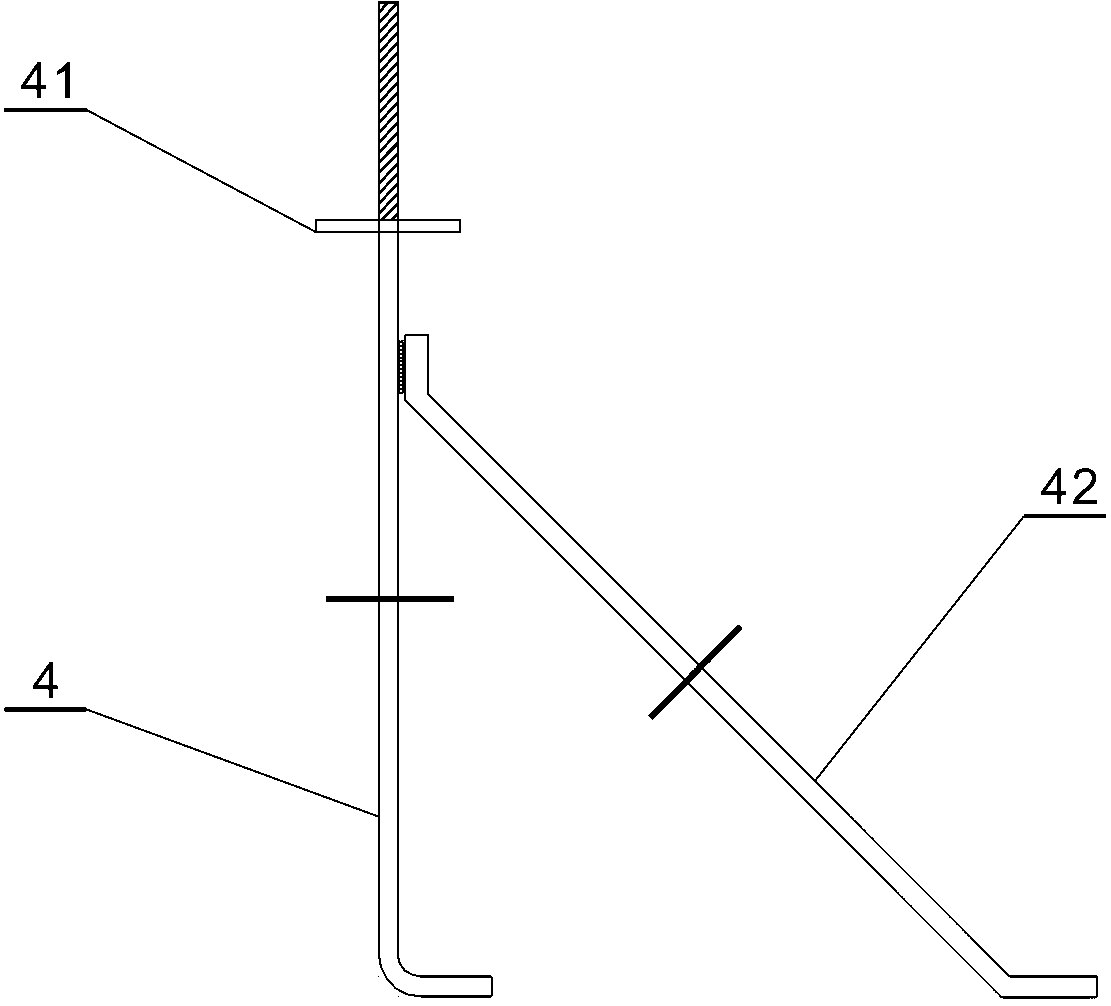

[0034] b), tie the bottom plate reinforcement and wall reinforcement

[0035] According to the construction drawing, tie the floor reinforcement 1 in the horizontal direction and the wall reinforcement 2 in the vertical direction. The height of the wall reinforcement 2 must be more than 500mm higher than the trapezoidal section foundation;

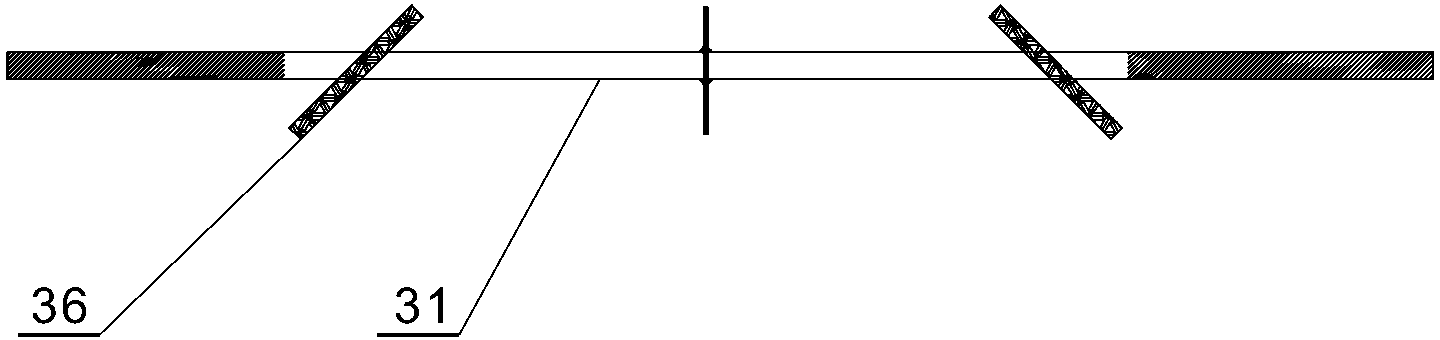

[0036] c), set the upper support mold point of the trapezoidal section foundation

[0037] Select several tension bolts 31, distribute the tension bolts 31 along the longitudinal contour of the wall panel reinforcement 2 according to 400-500 mm, and penetrate the wall panel reinforcement 2 horizontally to weld with it, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com