Processing Technology of Hyperbolic Bending and Torsional Components

A processing technology and bending technology, which is applied in the field of hyperbolic bending and torsion component processing technology, can solve the problems of high difficulty in processing hyperbolic bending and torsion components and low processing dimensional accuracy, so as to ensure processing quality, improve efficiency, and reduce welding deformation. easily controlled effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in further detail below by means of specific embodiments:

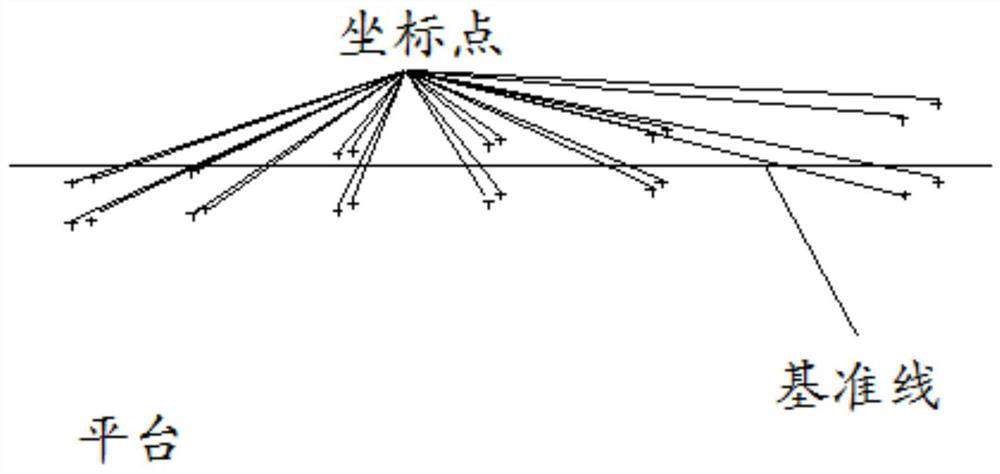

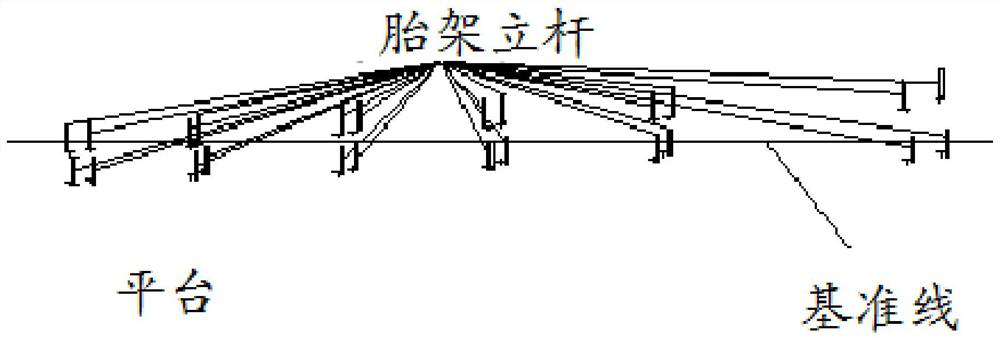

[0041] The processing technology of the hyperbolic bending and torsion member includes the following steps:

[0042] (1) Cutting of bending and torsion parts: making steel plates and profiles into individual parts for processing and manufacturing double bending and torsion components. When the wing web of the twisted member is bent and twisted, the numerical control programming is used for one-to-one comparison and material cutting to ensure the geometric dimension accuracy of the unfolded wing web.

[0043] Quality control and precautions in the blanking process of twisted parts:

[0044] A. When programming, according to the model, the size of the spare parts after expansion is one-to-one in the width direction, and the length direction is based on the 0.7mm allowance of each rib plate inside the box, and the welding correction shrinkage allowance of 4 main welds not l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com