Chemical method for synthesising silver selenide semiconductor photoelectric film material in situ at room temperature

A photoelectric thin film, in-situ synthesis technology, applied in the field of material chemistry, can solve the problems of high toxicity of reactants, complicated film formation process, high production cost, etc., and achieve the effects of controllable reaction process, simple reaction device and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Ag 2 Preparation of Se Binary Compound Semiconductor Photoelectric Thin Film Materials

[0039] 1. Preparation: Clean the ITO conductive glass with detergent and deionized water for 20 minutes, and then use concentrated ammonia water (25% by mass) / hydrogen peroxide (30% by mass) / deionized water (volume ratio: 1: The mixed solution of 2:5) was treated at 80°C for 30 minutes, and finally ultrasonically cleaned with deionized water for 20 minutes. The treated ITO conductive glass was dried at 80°C and stored in a clean desiccator for later use. Use magnetron sputtering technology to sputter a single silver layer with a thickness of 100nm on the ITO conductive glass substrate, and use film thickness monitoring (FTM) to control the thickness of the silver layer. The obtained ITO conductive glass with a simple silver layer is stored in a desiccator for use .

[0040] 2. Reaction steps: Take 0.6g Na 2 S·9H 2 O was dissolved in 30 ml of deionized water, and then 0.01 g of S...

Embodiment 2

[0042] Ag 2 Preparation of Se Binary Compound Semiconductor Photoelectric Thin Film Materials

[0043] 1. Preparatory work: Same as in Example 1, sputtering a single silver layer with a thickness of 250nm on the ITO conductive glass substrate.

[0044] 2. Reaction steps: weigh 0.6g Na 2 S·9H 2 O was dissolved in 30 ml of deionized water, and then 0.01 g of Se powder was dissolved in the Na 2 In the S aqueous solution, the temperature was kept at 25° C. for 30 min to obtain an orange-yellow solution. Place the ITO conductive glass sputtered with 250nm Ag into the above orange solution, react at 25°C for 7min, and take out the sample.

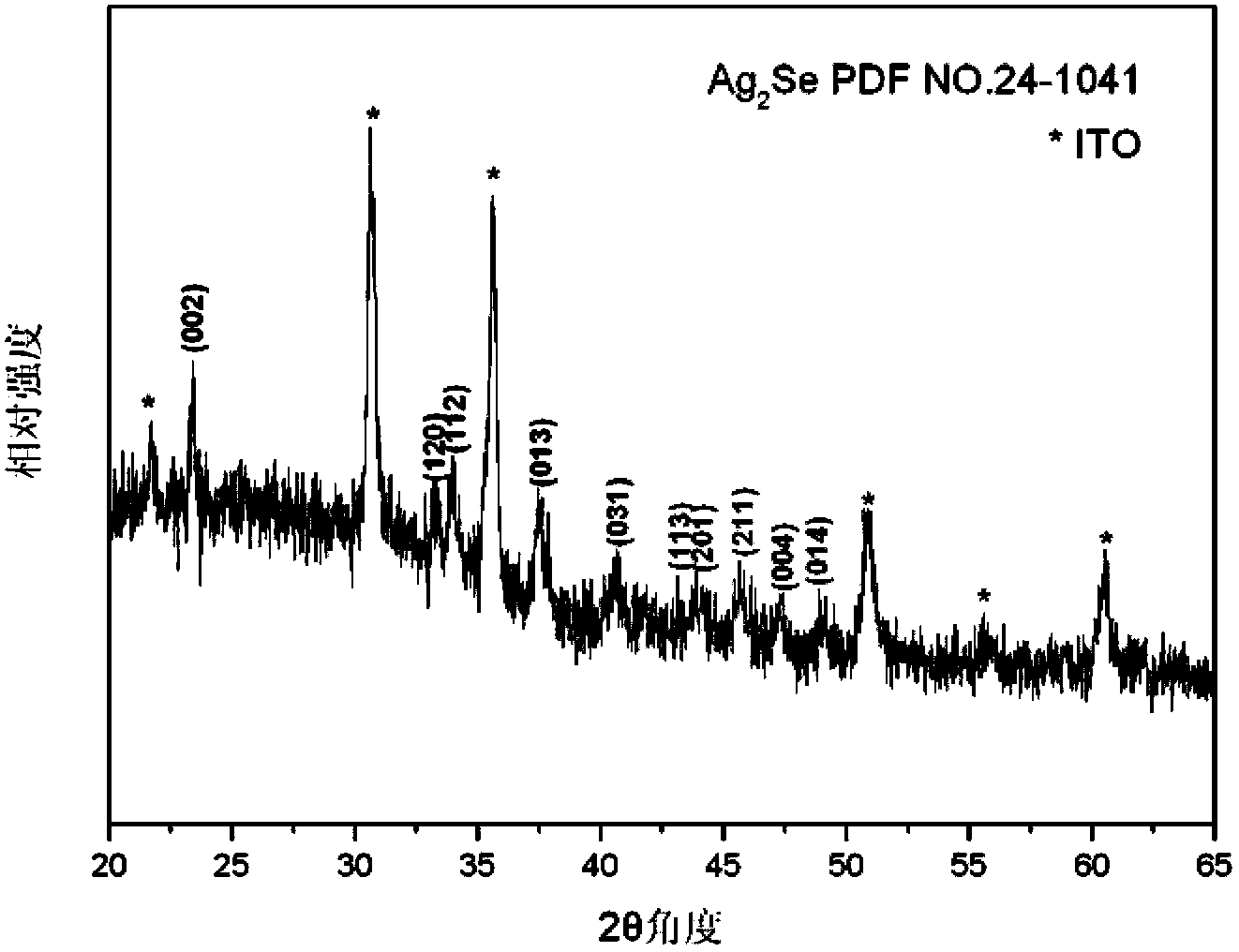

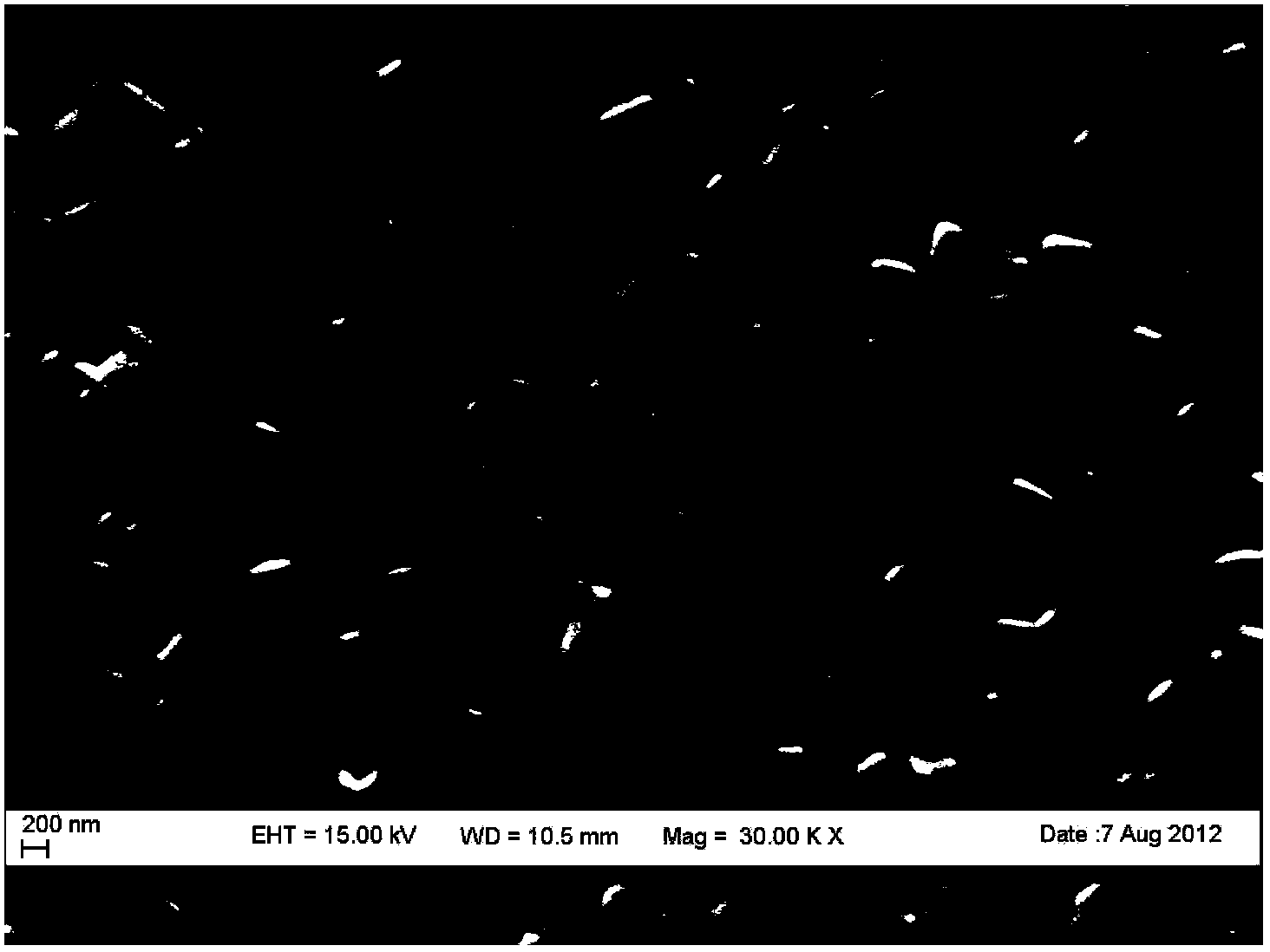

[0045] 3, aftertreatment: with embodiment 1. The product obtained was a silver gray film. diagram 2-1 SEM photographs of the obtained samples, Figure 2-2 It is the XRD figure of the obtained sample, and its PDF card number is: 24-1041, which proves that the obtained product is a pure silver selenide material. Example 3:

Embodiment 3

[0046] Ag 2 Preparation of Se Binary Compound Semiconductor Photoelectric Thin Film Materials

[0047] 1. Preparatory work: Same as in Example 1, sputtering a single silver layer with a thickness of 250nm on the ITO conductive glass substrate.

[0048] 2. Reaction steps: weigh 0.6g Na 2 S·9H 2 O was dissolved in 30 ml of deionized water, and then 0.01 g of Se powder was dissolved in the Na 2 In S aqueous solution, keep the temperature at 7° C. for 30 min to obtain an orange-yellow solution, and dilute the solution to 125 ml. Place the ITO conductive glass sputtered with 250nm Ag into the above orange solution, react at 7°C for 51min, and take out the sample.

[0049] 3, aftertreatment: with embodiment 1. The product obtained was a silver gray film. Figure 3-1 SEM photographs of the obtained samples, Figure 3-2 It is the XRD figure of the obtained sample, and its PDF card number is: 24-1041, which proves that the obtained product is a pure silver selenide material. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com