Patents

Literature

37results about How to "Geometry is easy to control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

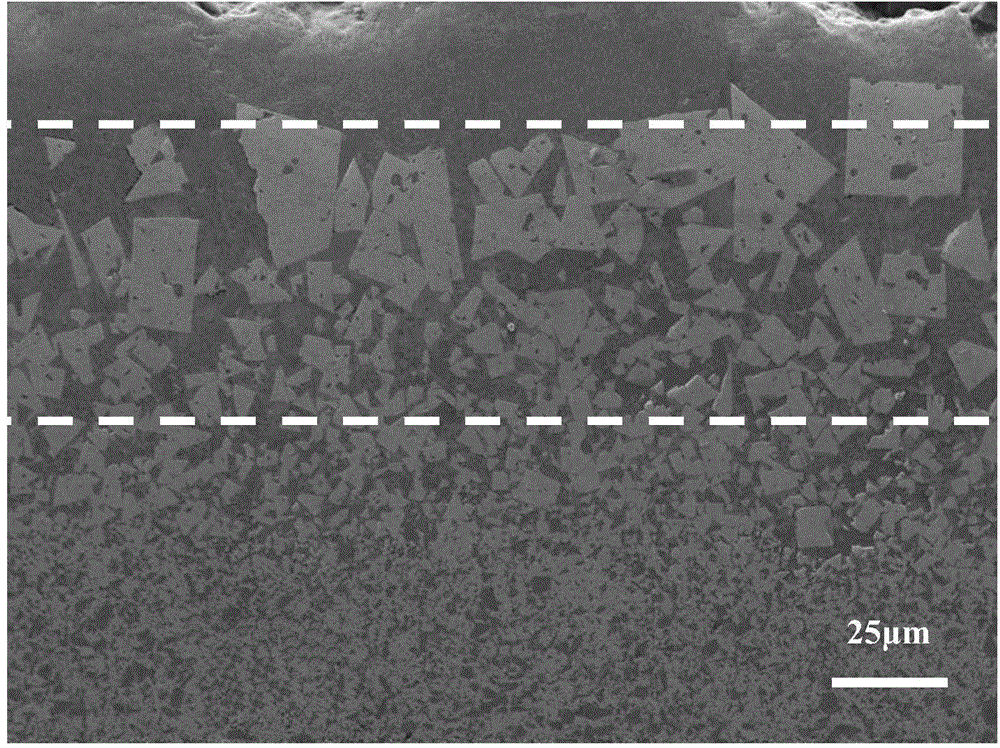

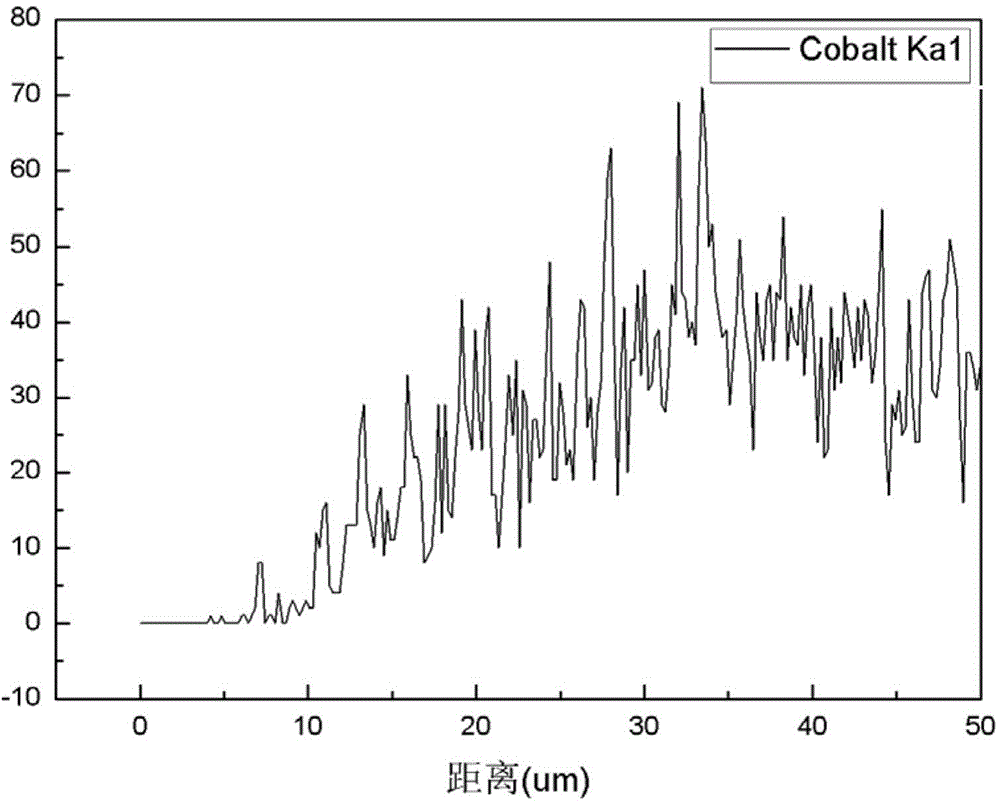

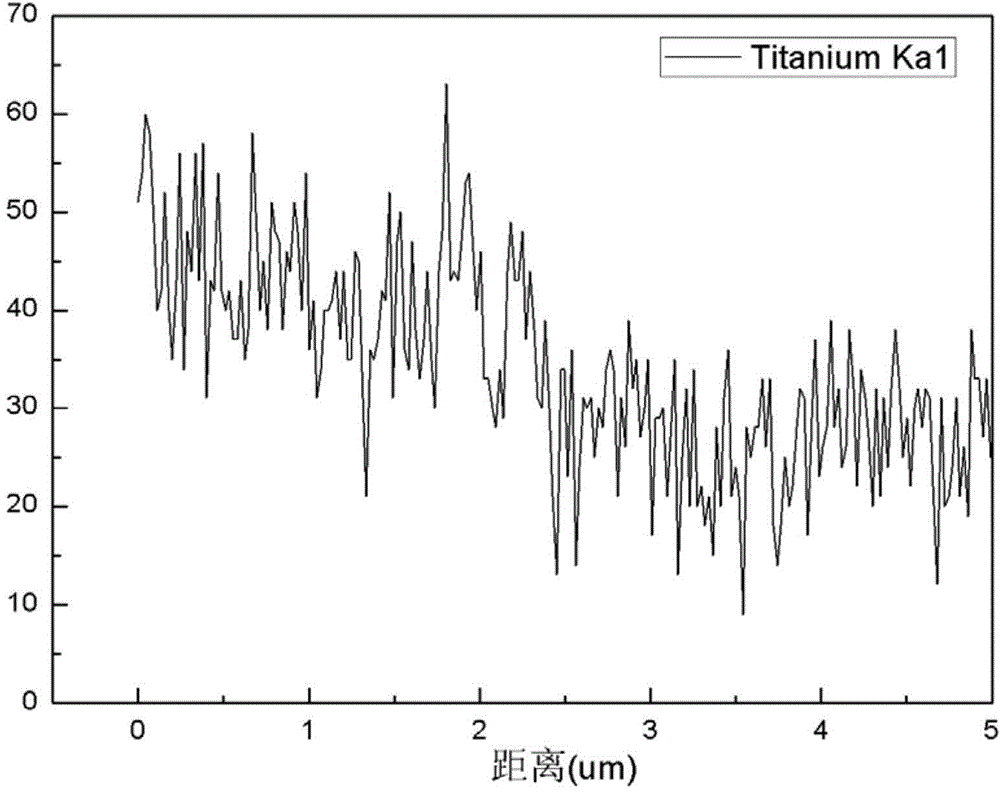

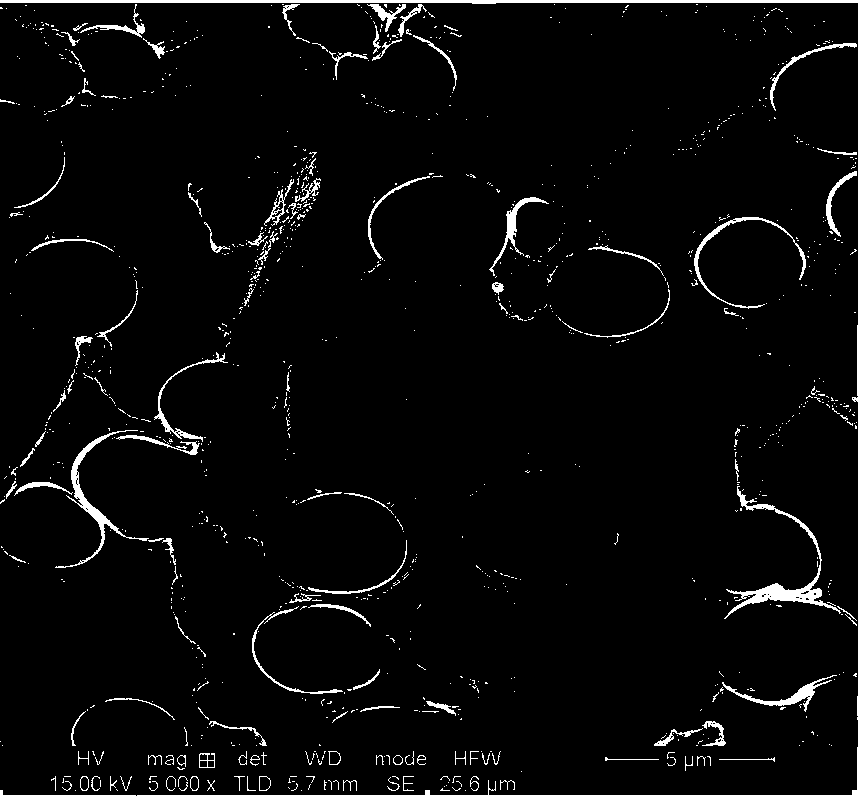

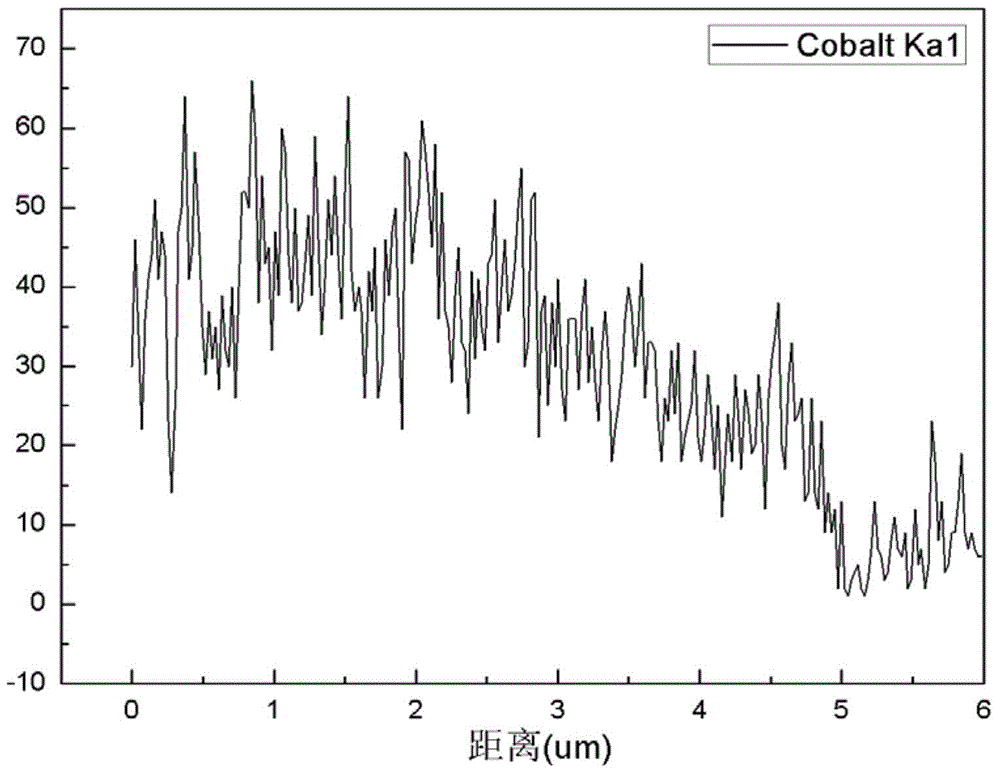

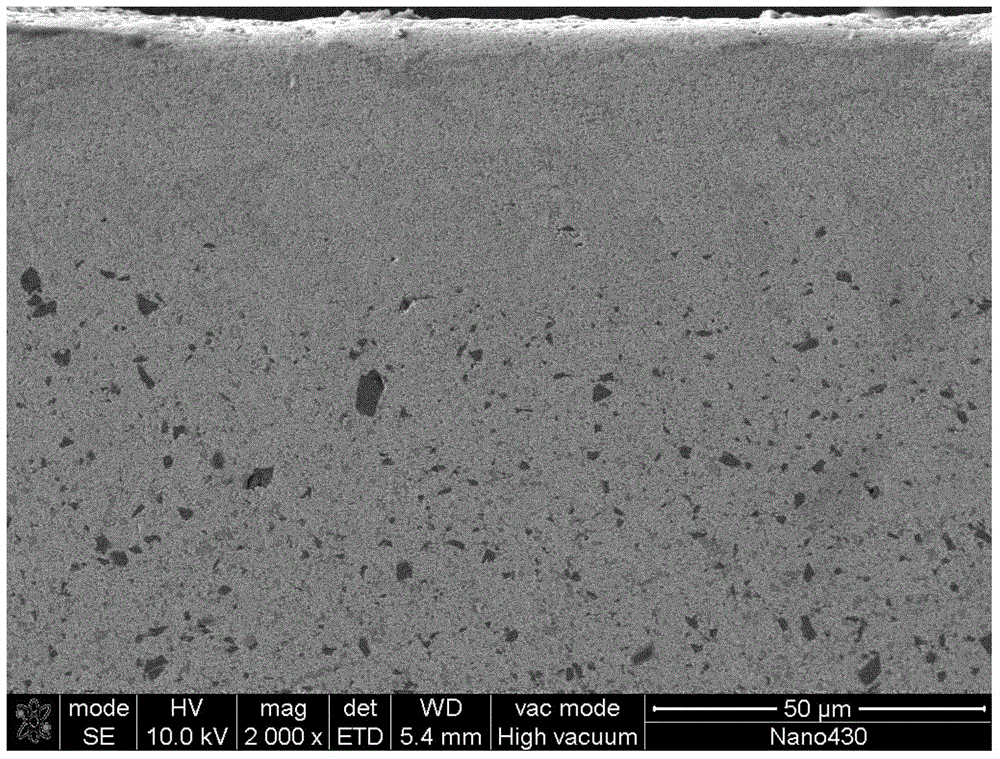

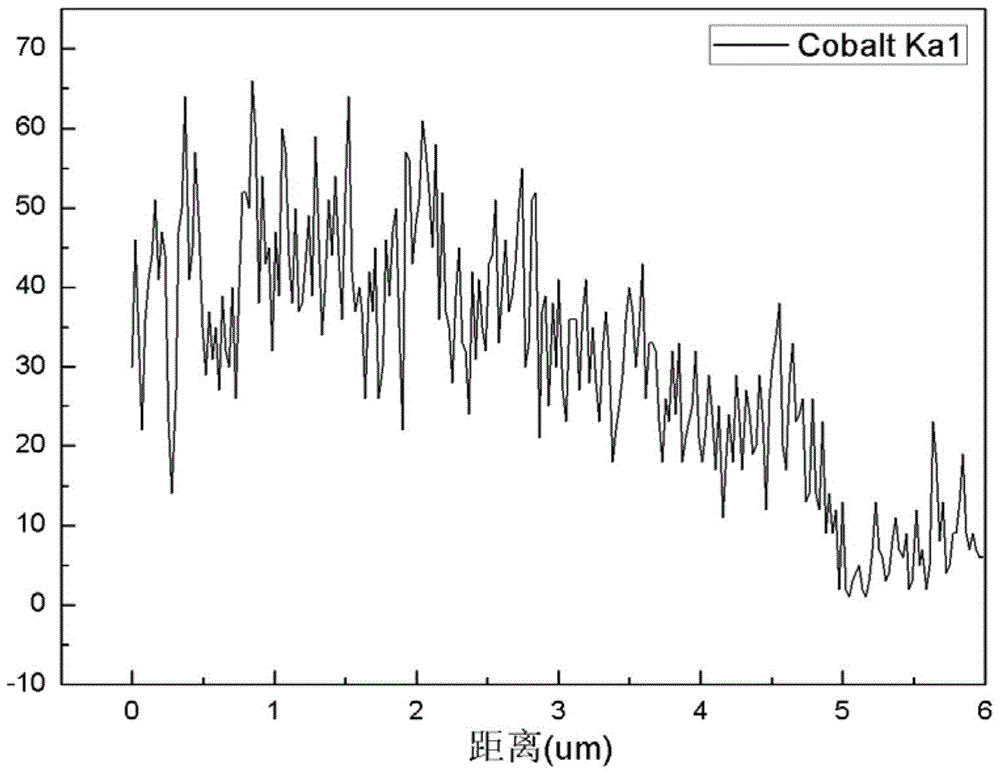

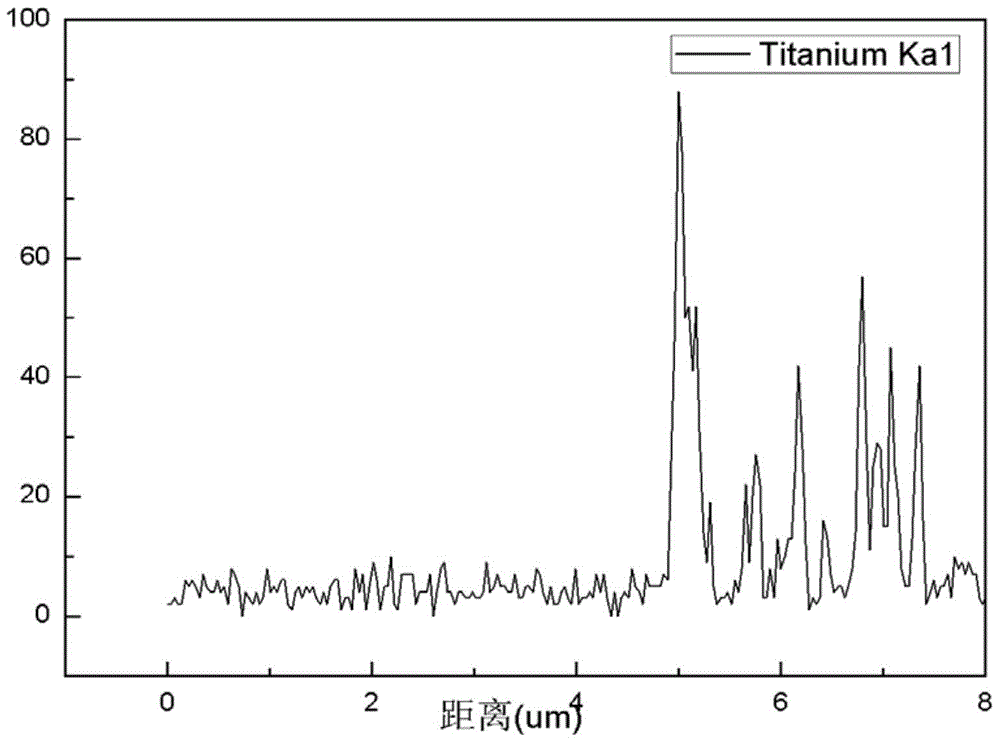

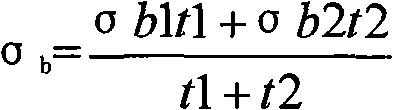

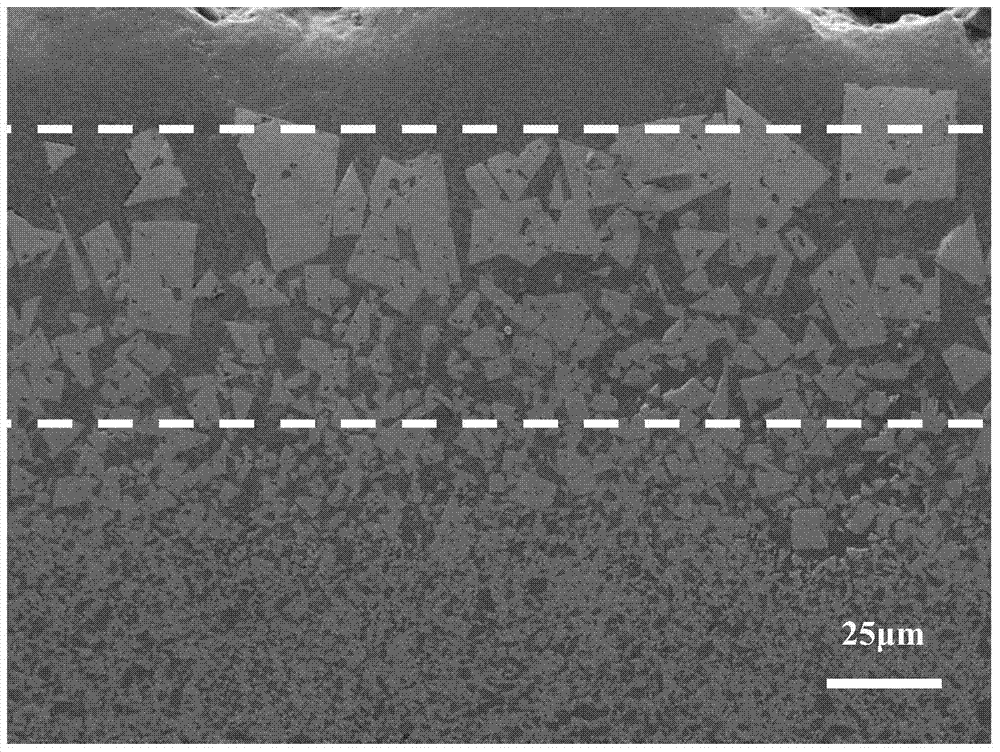

Surface-hardened gradient cemented carbide and preparation method thereof

The invention relates to the technical field of cemented carbide preparation, in particular to surface-hardened gradient cemented carbide and a preparation method thereof. By adjusting components of an alloy binding phase, the WC crystalline grains in the prepared cemented carbide are small, even in distribution, high in density and remarkable in gradient, the cemented carbide is made to have the more excellent mechanical property, and the red hardness of the cemented carbide is improved. The components and thickness of a gradient layer of the cemented carbide are controlled by adjusting blank formulas, sintering temperature, sintering time and other parameters, the surface layer of the cemented carbide is made to be rich in cubic phase and poor in binding phase, and due to the fact that a transition layer rich in alloying binding phase is arranged below the surface layer, the cemented carbide is excellent in hardness, wear resistance and roughness, and the cemented carbide can be used for metal machining. The cemented carbide prepared through the method has the excellent wear resistance, strength, hardness and toughness at the same time. According to the method, the functional gradient cemented carbide can be produced by slightly modifying existing equipment and processes, and is suitable for industrial production.

Owner:GUANGDONG UNIV OF TECH

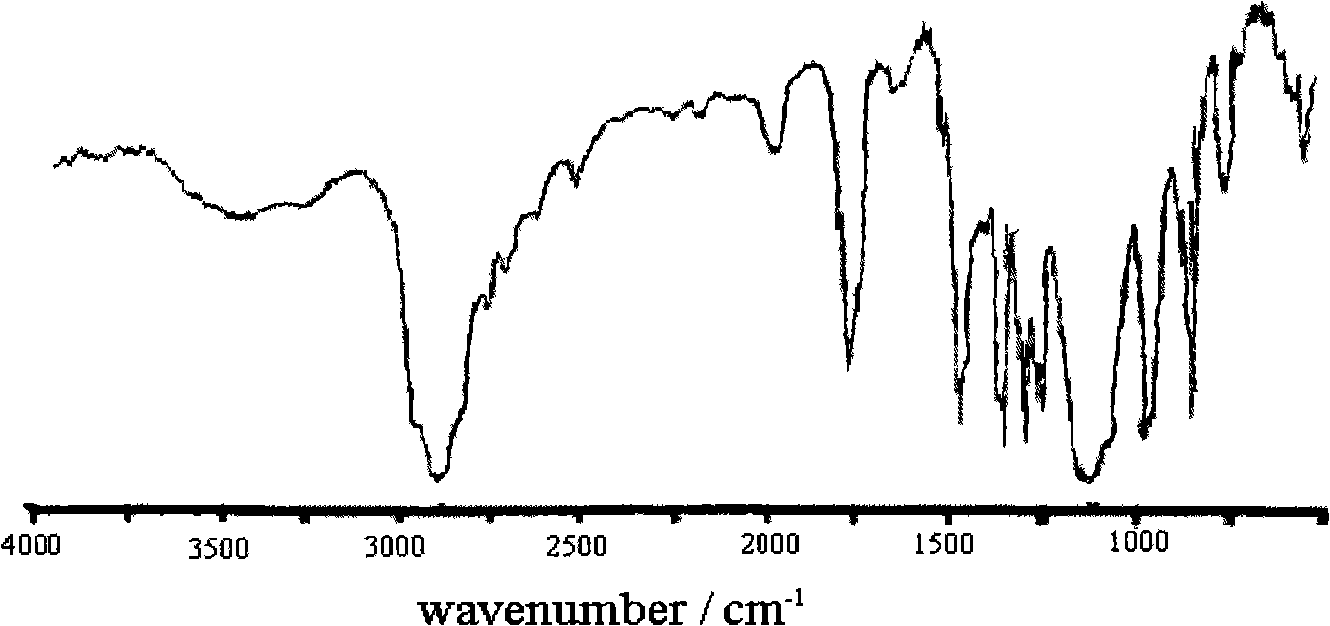

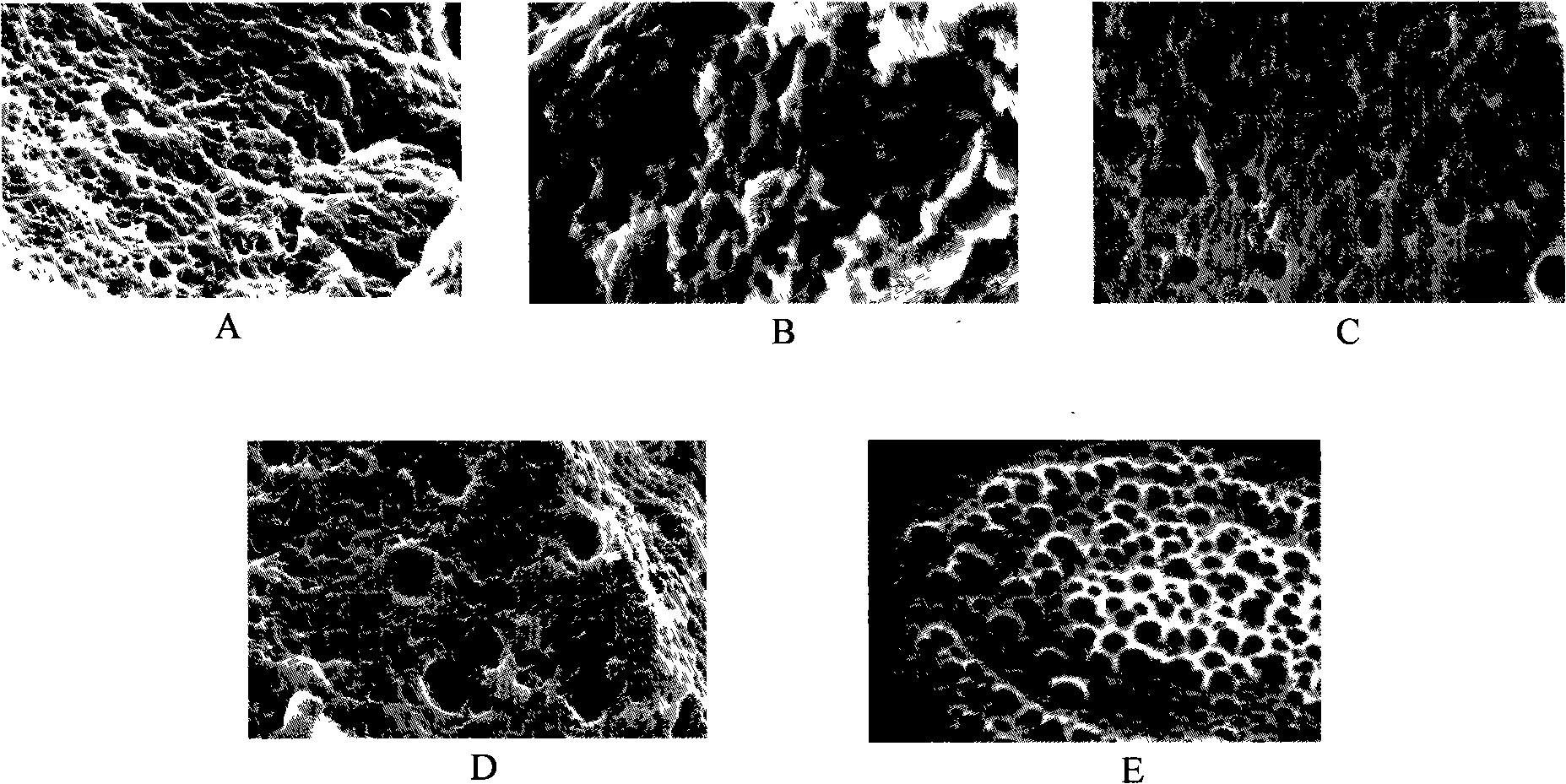

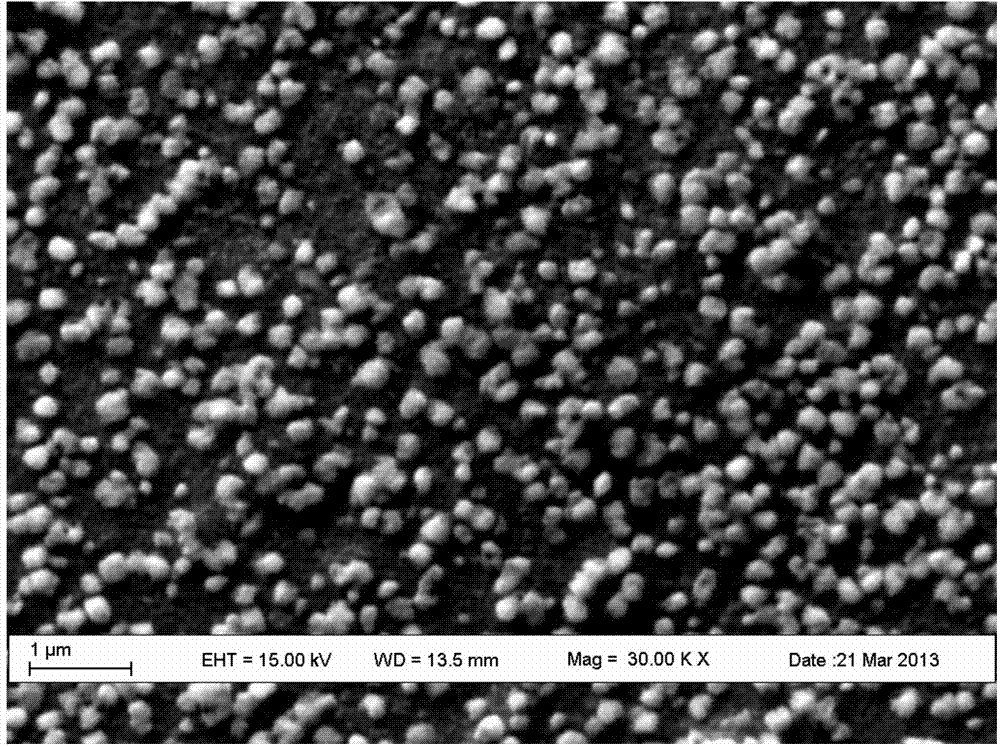

Bioactive aquagel-conductive polymer nanometer composite material and synthetic material thereof

InactiveCN101280094AGeometry is easy to controlShort curing timeNon-conductive material with dispersed conductive materialPyrroleAcrylic acid

A hydrogel-conductive polymer nano-composite material with biological activity and the synthesis method relate to a biological activity material; firstly, polyethylene glycol and hydroxy acid are synthesized to obtain glycol-hydroxy-acid block copolymer under the catalysis of tin octoate; the copolymer, acryloyl chloride and triethylamine are reacted to get glycol-hydroxy-acid block copolymer terminated with acrylic group; the copolymer is then dissolved in water to get gel through photoinitiated crosslinking or free radical crosslinking; finally, the gel is swelled with pyrrole or aniline monomer solution to get the nano-composite material of the glycol-hydroxy-acid block copolymer and the polypyrole or polyaniline through the polymerization under the effect of initiators. Through the copolymerization with hydroxy acid, PEG is endowed with gel system biodegradability; besides, the honeycomb holes of the hydrogel film material can provide composite spaces for conductive polymers; the biological activity of the polypyrole and polyaniline enables the hydrogel to be endowed with biological activity after combination and has nano-enhancing effects to the gel system.

Owner:XIAMEN UNIV

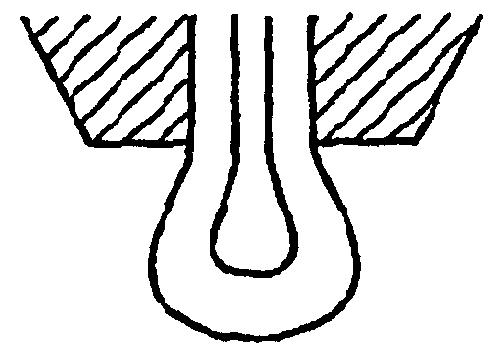

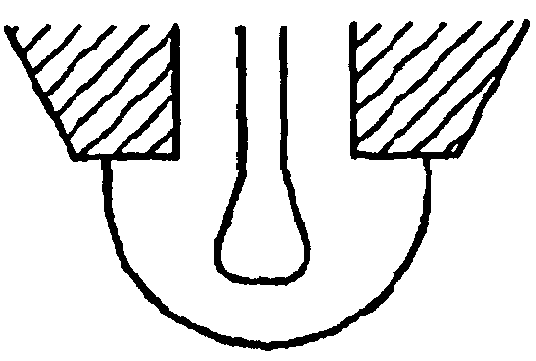

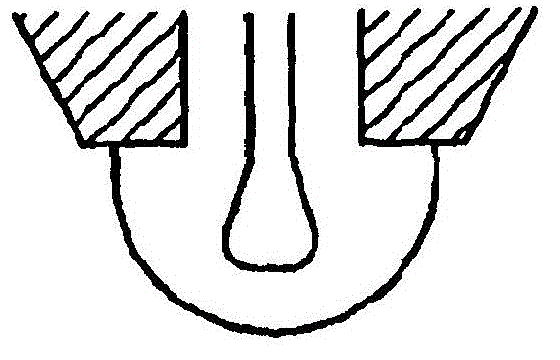

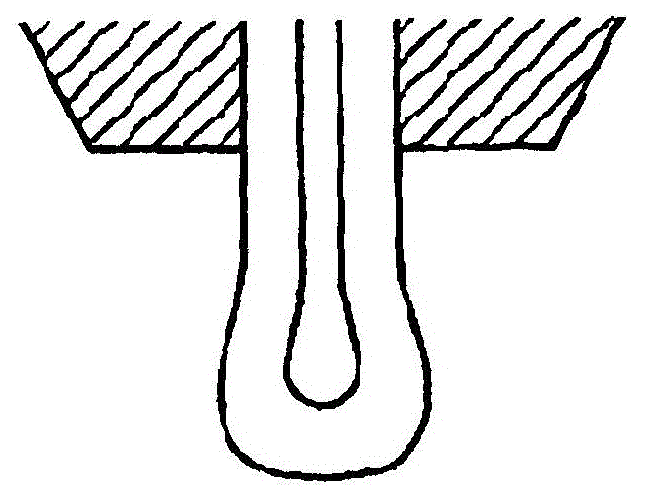

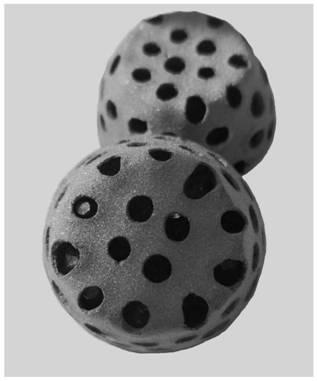

Fabrication of core/shell capsules of different geometries and treatment thereafter

ActiveCN102843918AImprove mechanical stabilityImprove consistencyTobacco treatmentTobacco smoke filtersMaterials scienceLiquid drop

Multi-shelled capsules are made by co-extruding a first liquid flavorant composition and a first shell-forming polymeric material to form droplets which are hardened to form an inner shell containing a first liquid flavorant composition, and then coated with a second shell-forming polymeric material which is hardened to form an outer shell. The result is a capsule where the inner surface of the outer shell is separate and / or separable from the outer surface of the inner shell to define a space, wherein a second liquid flavorant composition may be located.

Owner:PHILIP MORRIS PROD SA

Preparation method of polystyrene foam microsphere

The invention provides a preparation method of a polystyrene foam microsphere. The preparation method mainly comprises the steps of: by virtue of manners of introducing a pore-forming agent into a polystyrene solution and introducing microbubbles through ultrasonic oscillation, preparing water-in-polystyrene-solution composite emulsifiable particles or polystyrene solid emulsifiable particles by virtue of a microfluidic technology, removing an organic solvent for dissolving a polystyrene-based polymer by virtue of a spin evaporation method and drying to remove water and residual solvent, thereby obtaining the polystyrene foam microsphere with narrow particle size distribution. The foam microsphere can be widely applied in the fields such as chemical catalysis and high-energy physical experiments.

Owner:LASER FUSION RES CENT CHINA ACAD OF ENG PHYSICS

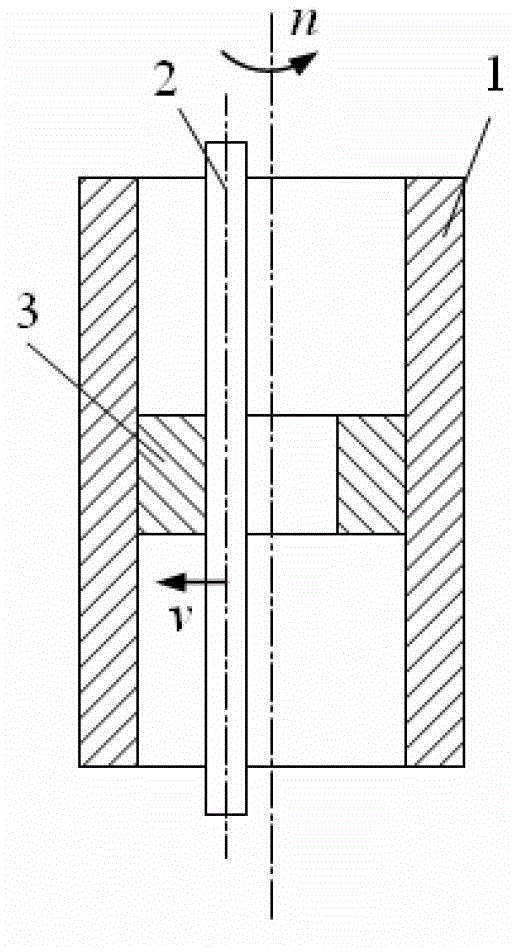

Internal deep groove annular piece precision rolling forming method and device

Owner:WUHAN UNIV OF TECH

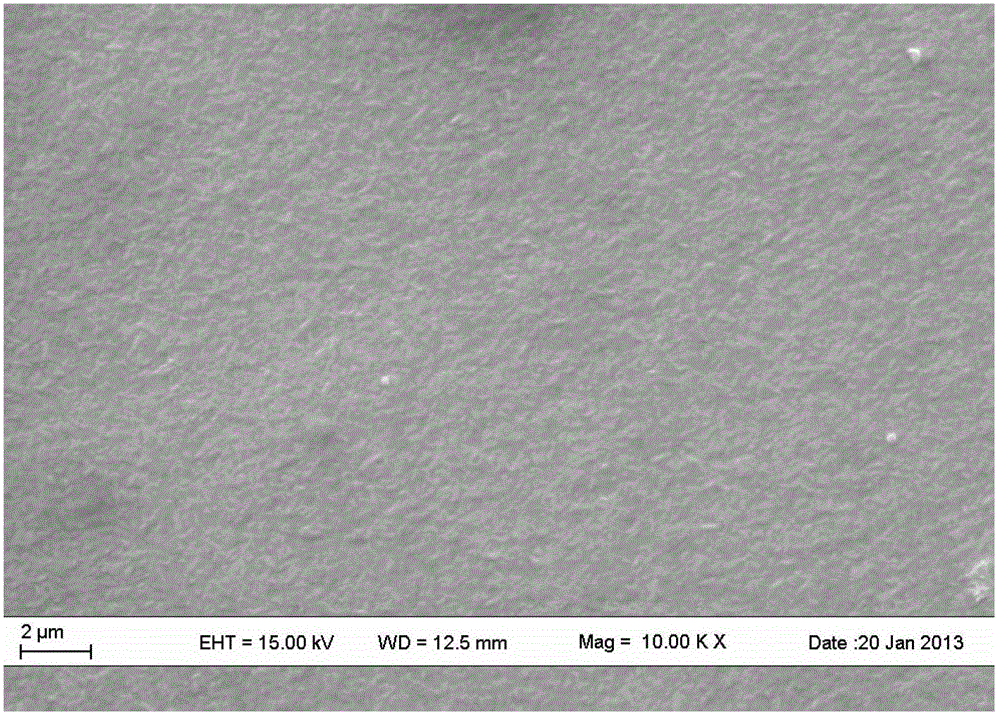

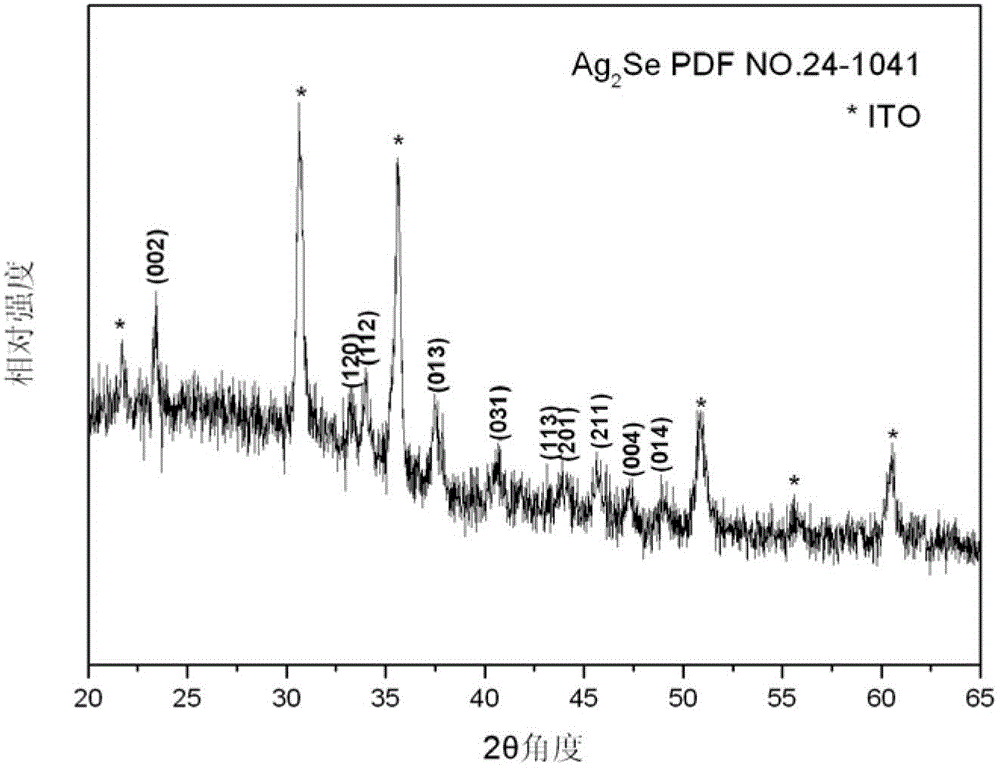

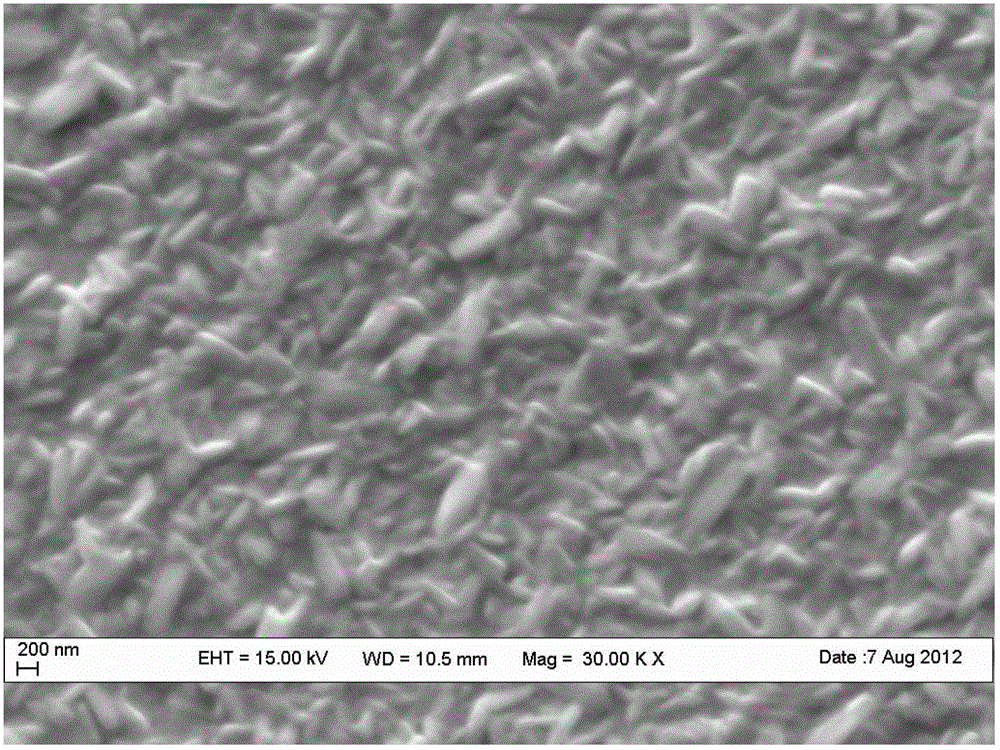

Chemical method for synthesising silver selenide semiconductor photoelectric film material in situ at room temperature

The invention provides a chemical method for synthesising a silver selenide semiconductor photoelectric film material in situ at a room temperature. The method comprises the following steps of: dissolving elementary-substance Se powder in Na2S aqueous solution to form orange-yellow solution; placing a substrate material sputtered with an elementary-substance silver film on the surface and the solution aforementioned in the same container; and growing the Ag2Se semiconductor photoelectric film material on the surface of the substrate in situ via a short-time reaction in a temperature range from 7 to 35 DEG C. The reactants are low in price, has no need of being further purified, green and environment-friendly, and any surfactant or other chemical additives are not required; room-temperature reaction conditions are moderate, energy consumption is little, and influence on a conducting substrate is avoided; and the chemical method is fast in reaction, convenient in operation, and controllable in process. The chemical method provided by the invention overcomes the defects of dependence on high vacuum, high energy consumption and high production cost, high reactant toxicity, complex film-forming process and the like of the existing preparation process for an Ag2Se semiconductor photoelectric film material, and is beneficial to large-scale production and industrial application.

Owner:XUCHANG UNIV

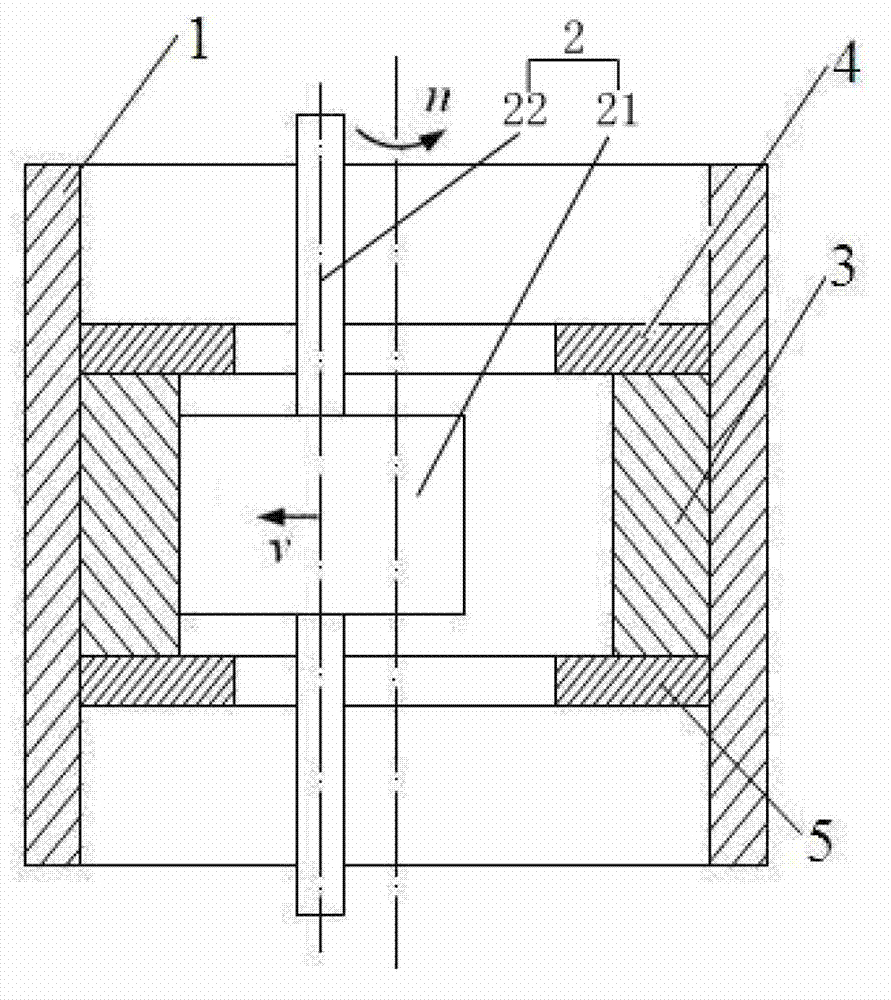

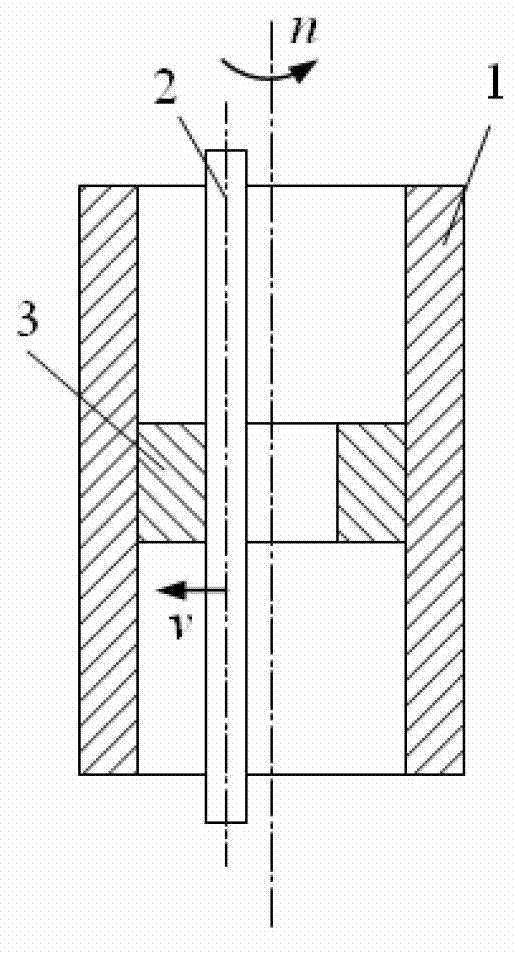

Method and device for precision-rolling and forming cylindrical part

ActiveCN102921847AGeometry is easy to controlImprove surface qualityCylindersProduction ratePlastic property

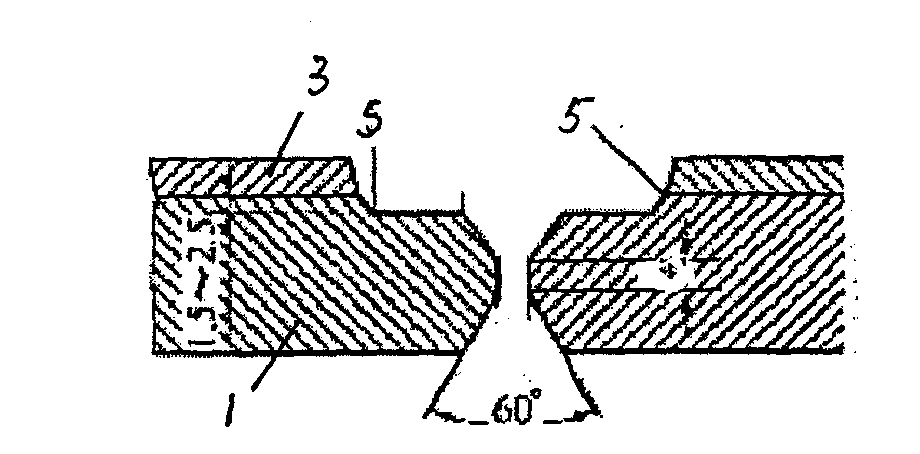

The invention relates to a method and a device for precision-rolling and forming a cylindrical part. The method comprises the following steps: S1, obtaining an annular blank, wherein the external diameter of the blank is equal to that of the cylindrical part; S2, putting the annular blank into an annular driving roller and enabling the outer wall of the blank to be closely attached onto the inner wall of the driving roller; S3, putting a core roller into the blank, wherein the diameter of the core roller is smaller than that of the blank; S4, enabling the driving roller and the blank to rotate around a central axis of the blank and enabling the core roller to do linear feed motion along the radial direction of the blank; and S5, when the axial height of the blank reaches a preset value, enabling the core roller to stop feeding and taking out the prepared cylindrical part. The device comprises the driving roller (1), the core roller (2), a rotating drive device and a linear drive device, wherein the driving roller (1) is annular; and the core roller (2) is cylindrical. The method and the device for precision-rolling and forming the cylindrical part have the beneficial effects that the cylindrical part is wholly formed at one time through continuous partial plastic deformation, and the effects of saving energy and materials, reducing the production cost and improving the production rate and the product performance effect are remarkable.

Owner:WUHAN UNIV OF TECH

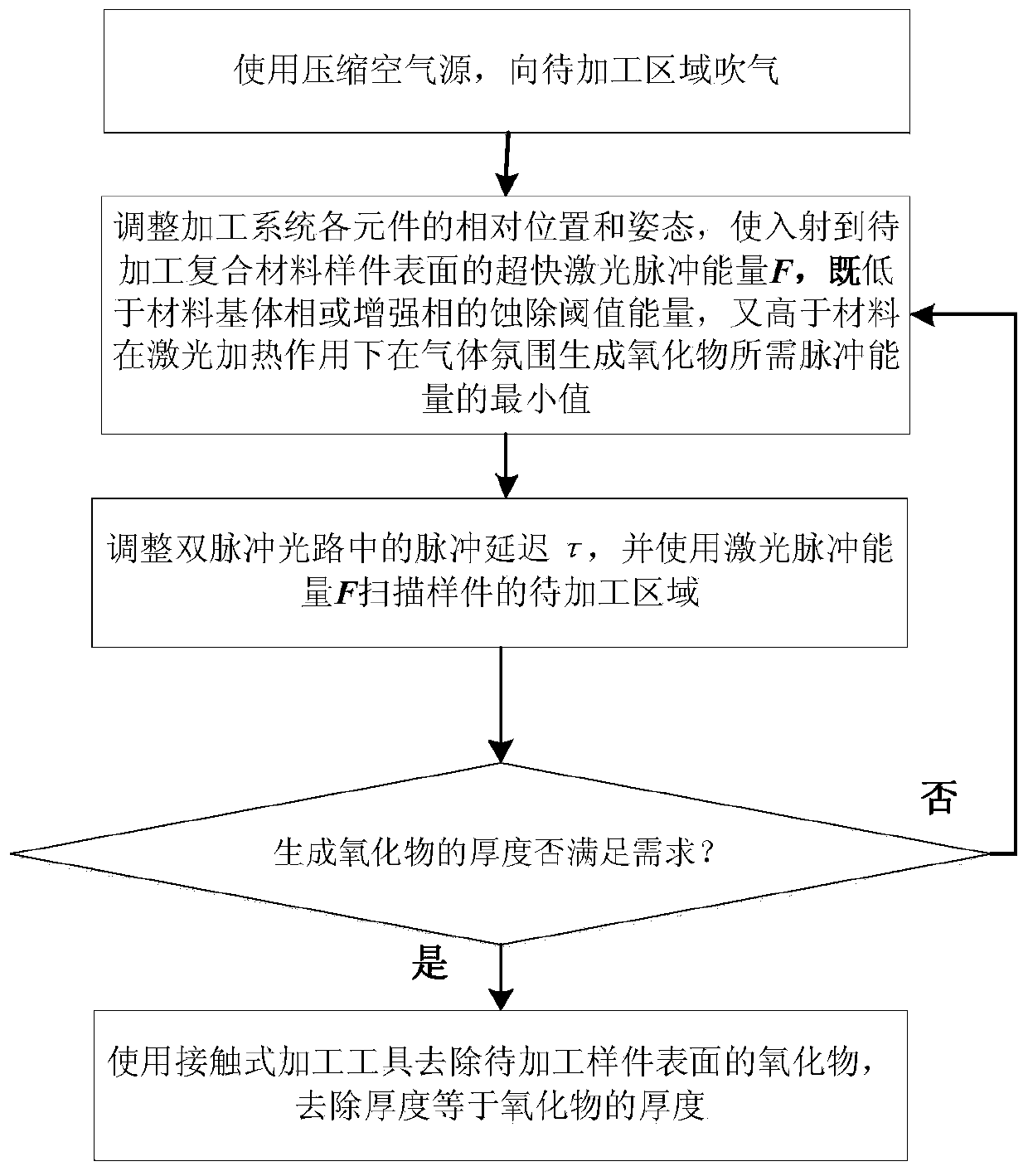

Efficient and precise machining method for composite material

ActiveCN111037101AReduce wearImprove continuous processing abilityOther manufacturing equipments/toolsLaser beam welding apparatusMachinabilityHeat effect

The invention discloses an efficient and precise machining method for a composite material. The thickness and the heated degree of a heated area of the composite material are regulated accurately through time domain shaping ultrafast lasers; the thickness of easily-machined loose oxide generated in the manner that a matrix phase and a reinforced phase of the material are subjected to a chemical reaction through gas assisting under the heat effect is controlled; conditions are created for achieving precise machining by directly removing a loose oxide layer subsequently through cutting / grindingmachining; and machinability of the material is greatly improved.

Owner:BEIJING SATELLITE MFG FACTORY

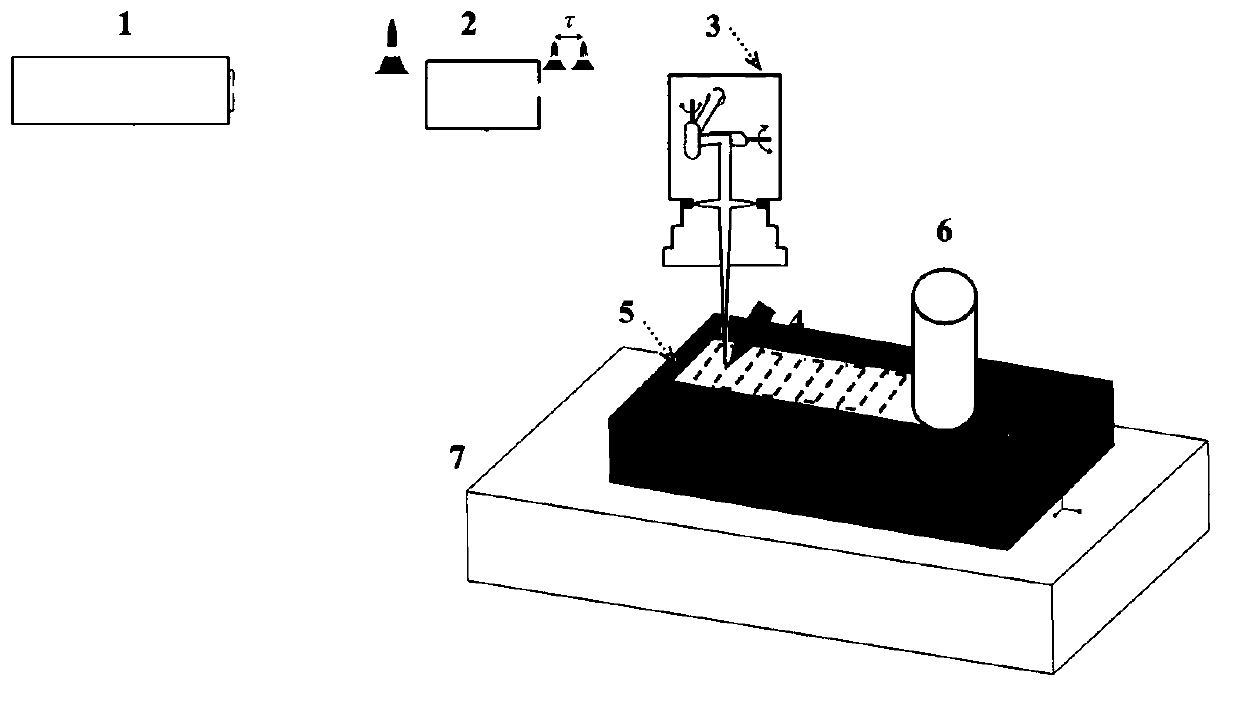

Measuring device for injection hole pressure of engine fuel oil injection system

ActiveCN108843476AGeometry is easy to controlObserve the flowEngine testingFuel injection apparatusEngine testingFuel oil

The invention disclose a measuring device for injection hole pressure of an engine fuel oil injection system, and belongs to the technical field of engine testing and measurement. The measuring devicecomprises a high pressure oil supply module, an oil injector, a visible plate, a pressure collection connection block and a pressure sensor. The high pressure oil supply module is used for pressurizing fuel oil and supplying fuel oil to the oil injector, and a cavity at the crossed position of a nozzle and an installation hole in the visible plate is a pressure chamber. The visible plate is further provided with a conical frustum hole and a pressure collection channel communicating with the pressure chamber. The oil inlet end of the oil injector is connected with the high pressure oil supplymodule, the oil outlet end of the oil injector is installed in the installation hole in the visible plate, one end of the pressure collection connection block is connected with the pressure sensor, aconical frustum at the other end is installed in the conical frustum hole in the visible plate, and a pressure transfer channel communicating with the pressure collection channel is machined in the conical frustum. The measuring device is applied to an internal combustion engine, and can measure the pressure of the nozzle and the pressure chamber in an injection hole of the internal combustion engine, thereby obtaining the flow flowing through the injection hole through calculation.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

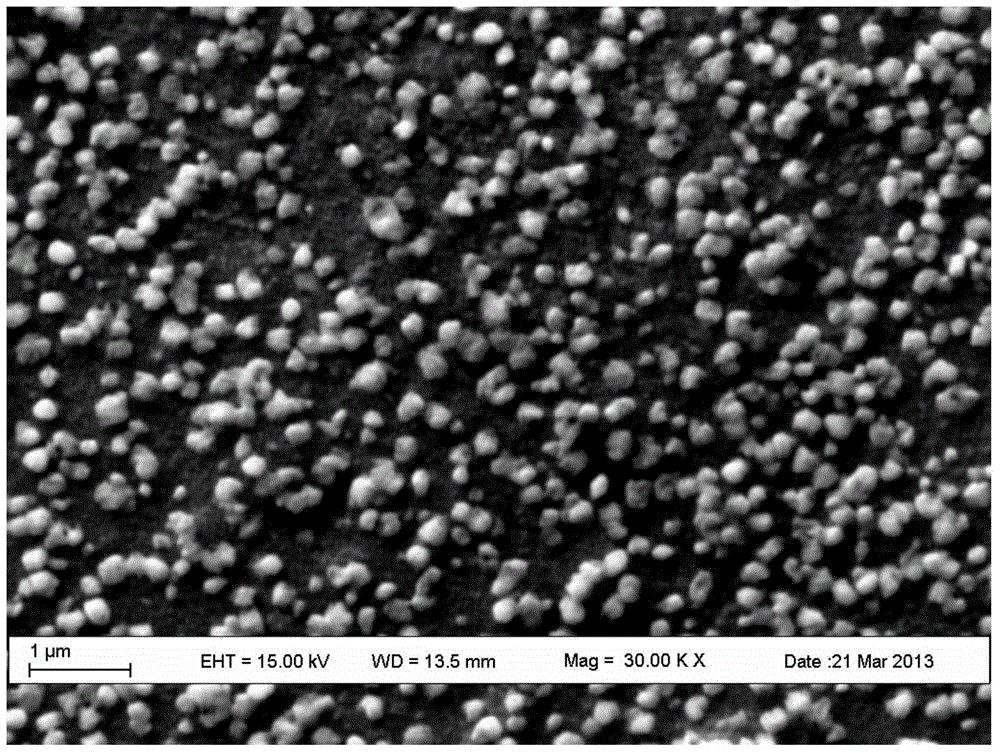

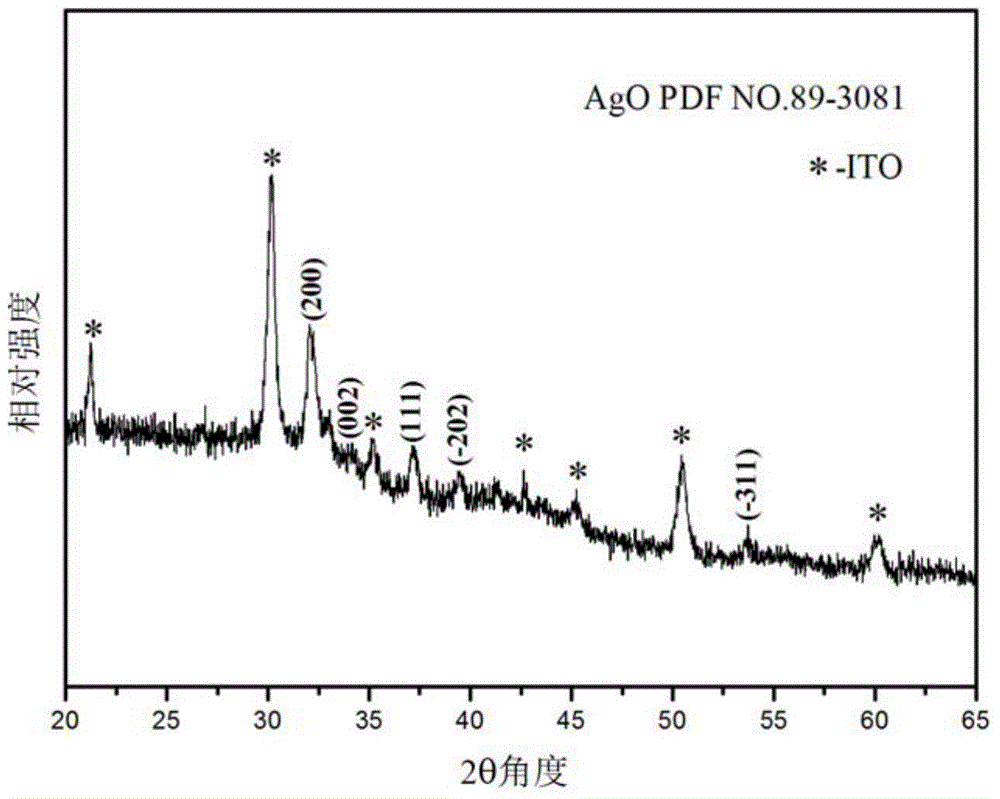

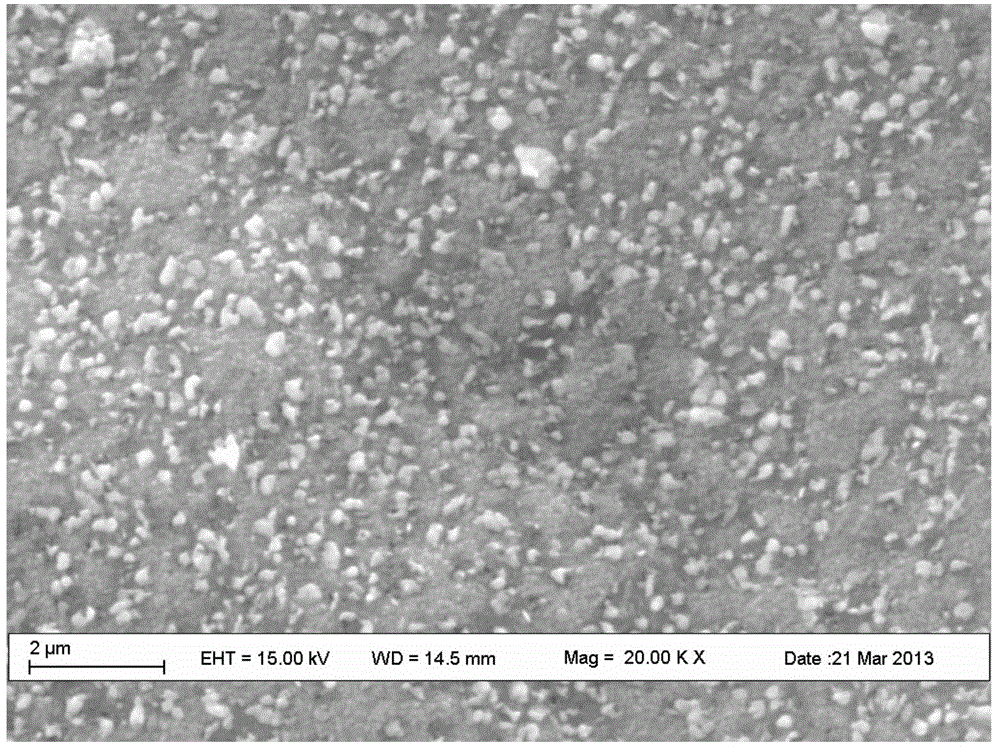

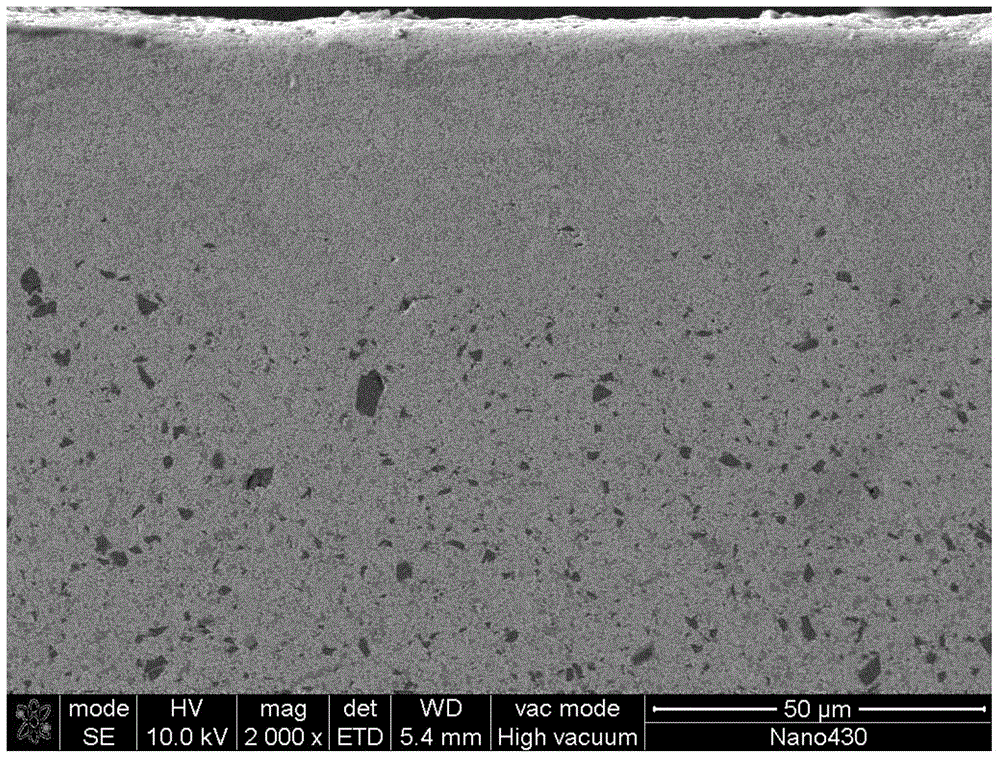

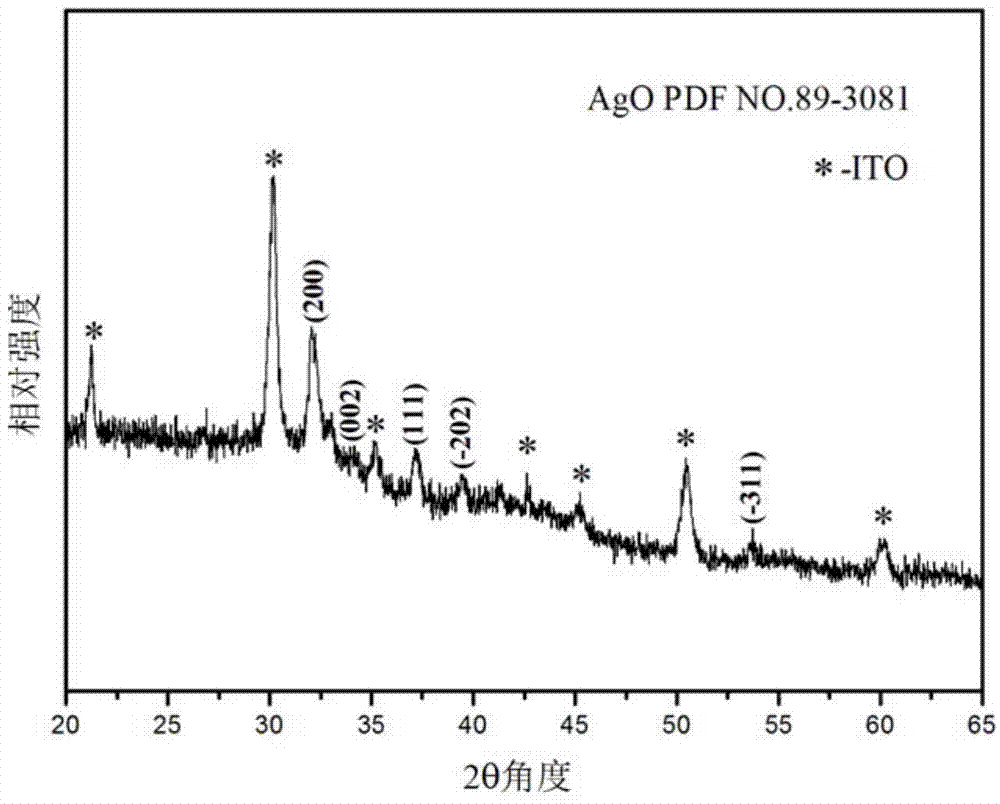

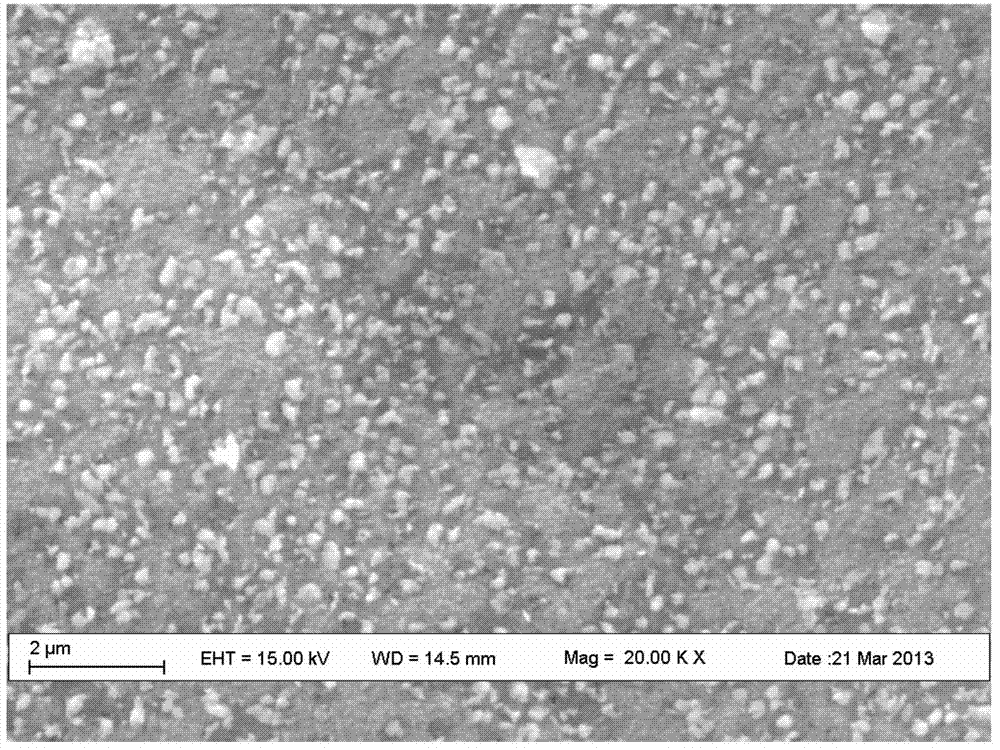

Method for synthesizing silver oxide semiconductor thin-film material through room temperature in-situ control

ActiveCN103602945AMild conditionsThe reaction process is easy to controlVacuum evaporation coatingSputtering coatingCompound (substance)Room temperature

The invention relates to a method for synthesizing a silver oxide semiconductor thin-film material through room temperature in-situ control. The method is characterized by comprising the following steps: putting a substrate material, the surface of which is covered by an elementary substance silver thin film, in a UV-03 reactor, maintaining the relative humidity of a system to 30-90%, and reacting for 1-2 hours at the temperature of 10-40 DEG C under the condition of oxygen or air existence so as to obtain the AgxO(AgO or Ag2O) semiconductor thin-film material on the surface of a substrate in situ, wherein the UV-03 reactor is a UV-03 cleaning machine. According to the method, solvents, surface active agents or other chemical additives are not needed in a reaction process. The method is simple to operate and low in energy consumption and preparation cost and has wide industrial application prospect.

Owner:XUCHANG UNIV

Surface-softened gradient cemented carbide and preparation method thereof

The invention relates to the technical field of cemented carbide preparation, in particular to surface-softened gradient cemented carbide and a preparation method thereof. The solubility of WC crystalline grains in a liquid phase Co is lowered by adjusting components of an alloy binding phase, so that the situation that the WC crystalline grains grow through a dissolution and reprecipitation mechanism is reduced, growth of the WC crystalline grains is restrained, then the WC crystalline grains in the prepared cemented carbide are small, even in distribution, high in density and remarkable in gradient, the gradient cemented carbide is made to have the more excellent mechanical property, and the red hardness of the gradient cemented carbide is improved. The cemented carbide prepared through the method is adopted as a base body of a coating cutter, the trend that coating cracks expand into the base body can be slowed down, and the service life of the coating tool can be prolonged. According to the method, the functional gradient cemented carbide can be produced by slightly modifying existing equipment and processes, and is suitable for industrial production.

Owner:GUANGDONG UNIV OF TECH

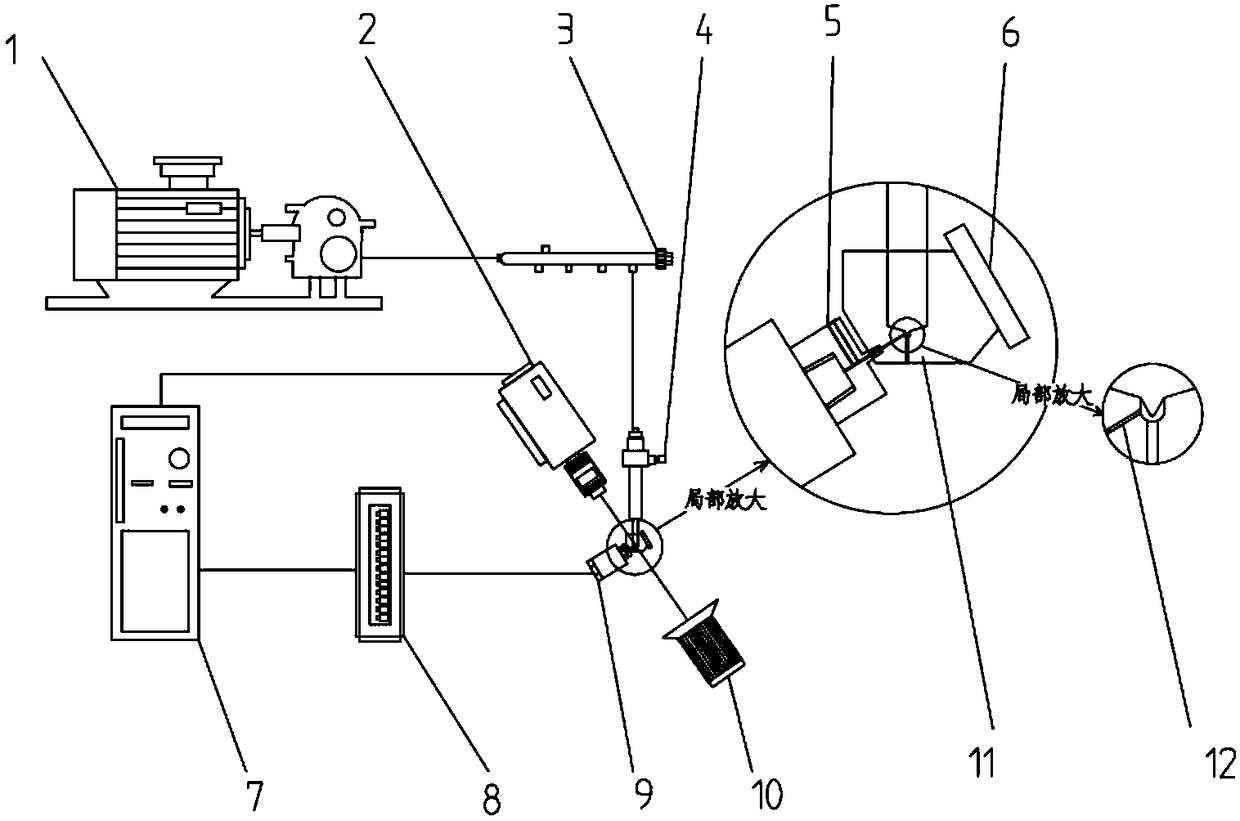

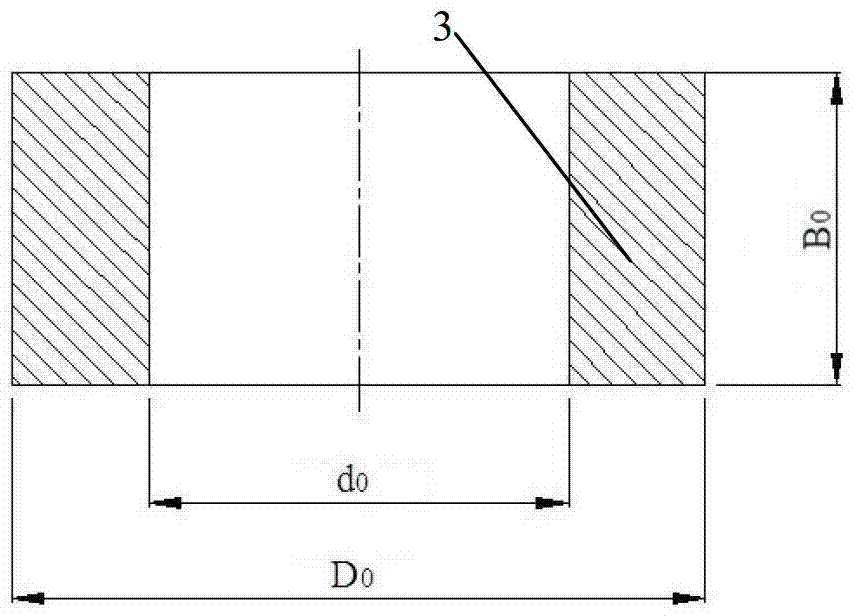

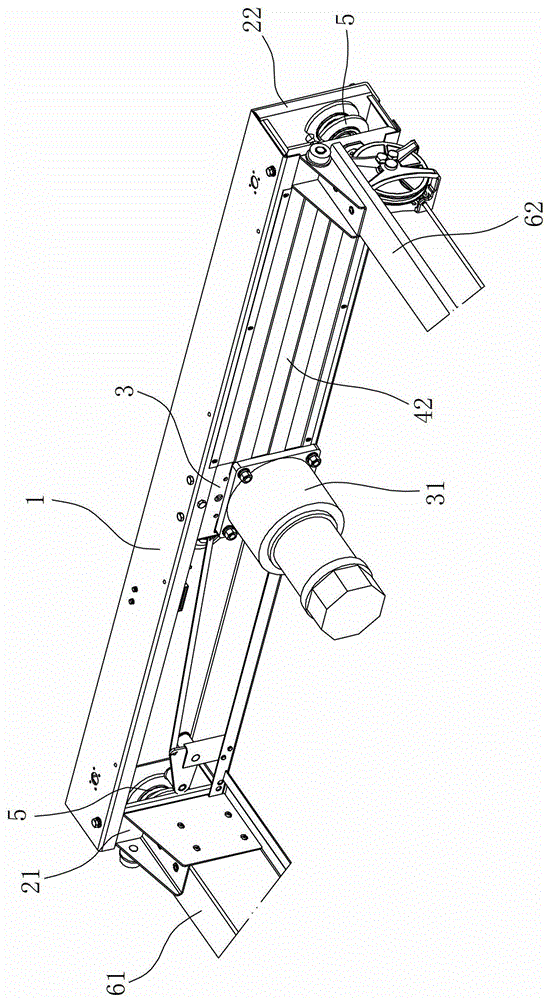

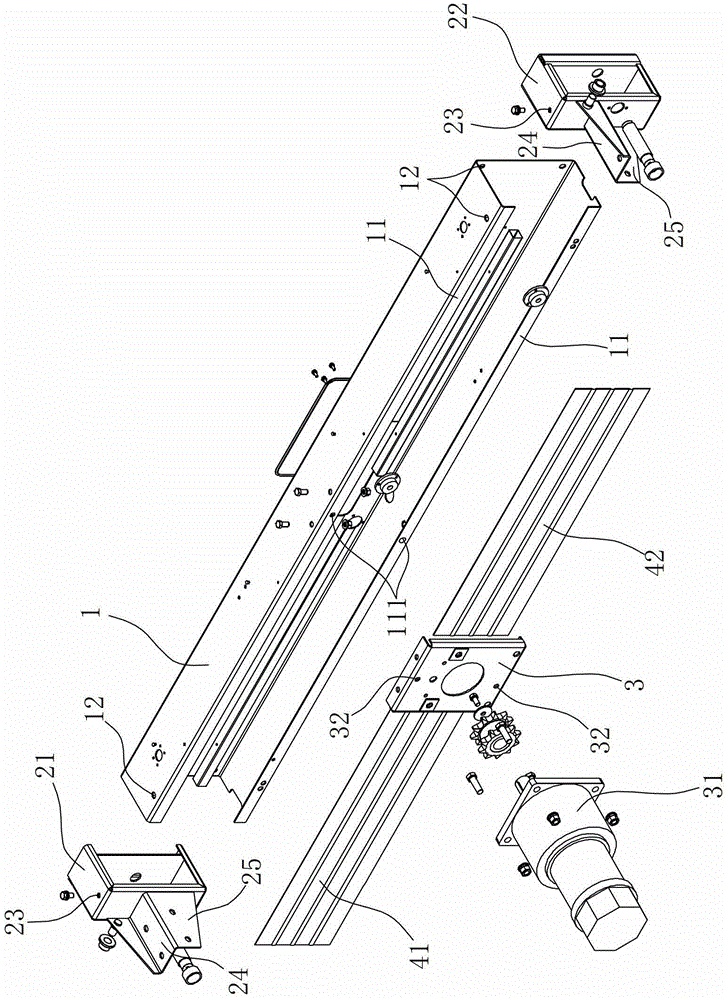

Method and device for hot-rolling forming of cylindrical gear with big modulus and large diameter

The invention provides a method and a device for hot-rolling forming of a cylindrical gear with the big modulus and the large diameter. The method comprises the following steps: S1, a blank is obtained; S2, the blank is arranged on a blank driving shaft and clamped by a clamping device; S3, the blank is heated by an induction heating device; S4, left and right baffle plates are mounted to two ends of a mold; S5, a driving device drives the mold and the blank to rotate in opposite directions at a certain speed ratio, and meanwhile, the mold is fed radially through a linear driving device; S6, when the center distance between the mold and the blank reaches a predetermined value, radial feeding of the mold is stopped, the mold is rotated continuously for two circles, and then the mold and the blank are rotated reversely for two circles simultaneously and stopped; S7, the clamping device loosens, and the blank is discharged. The device comprises a rack, the blank driving shaft, a mold driving shaft and an electromagnetic induction coil. According to the method and the device, the cylindrical gear is integrally formed by one step through continuous local plastic deformation, the production efficiency is improved, the materials are saved, and the product performance can be enhanced.

Owner:UNIV OF SCI & TECH BEIJING

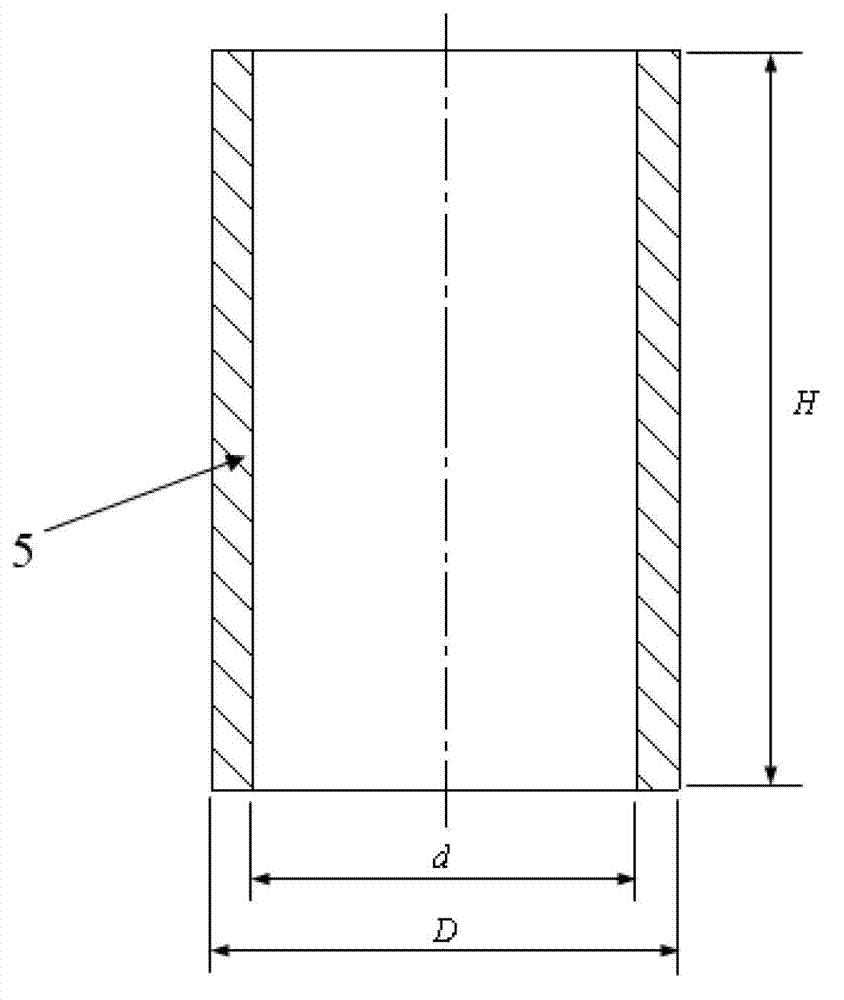

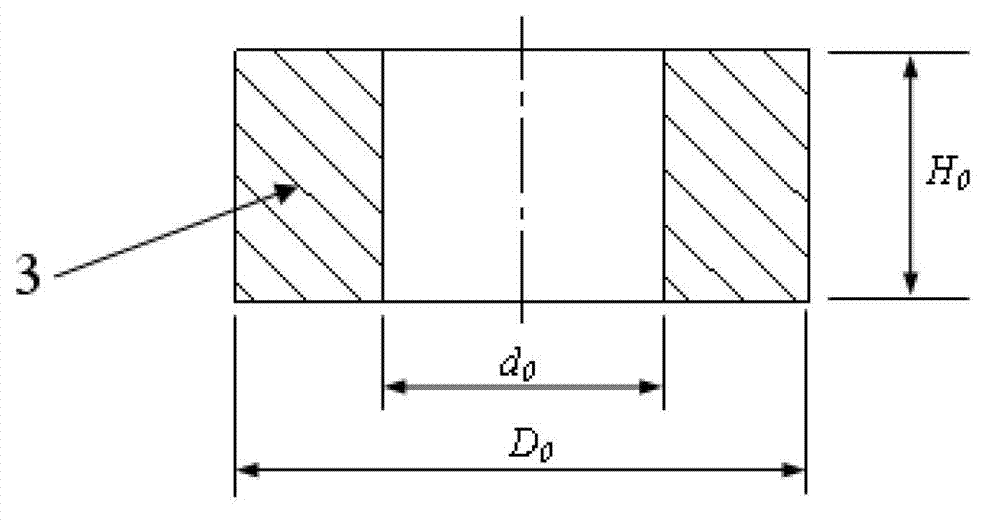

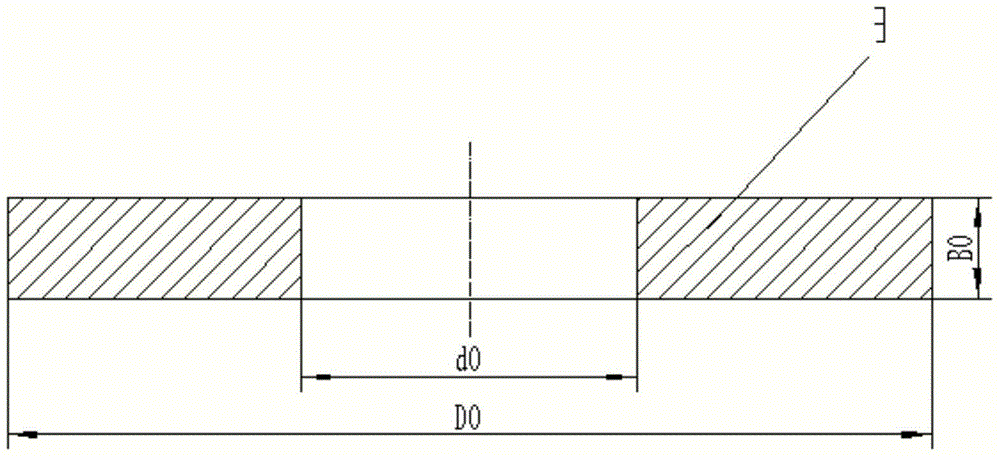

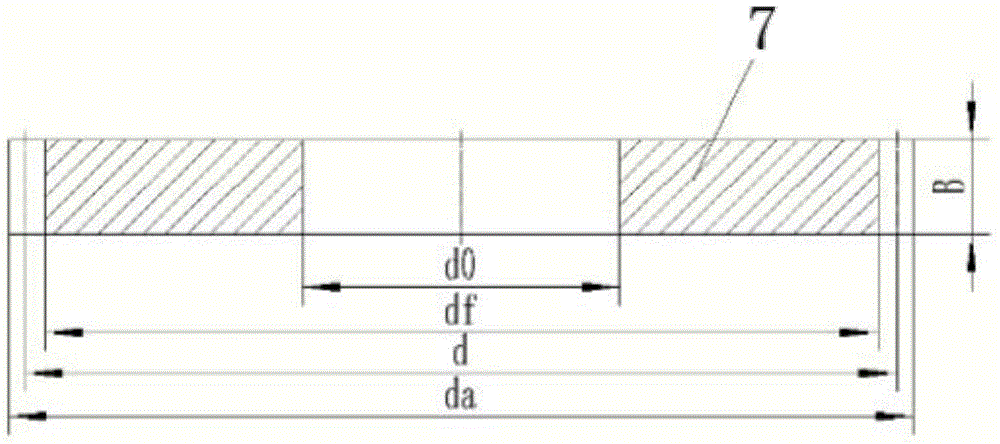

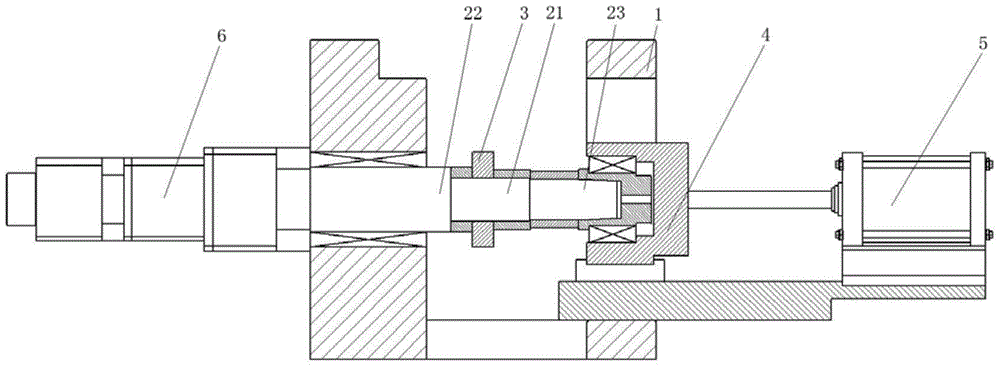

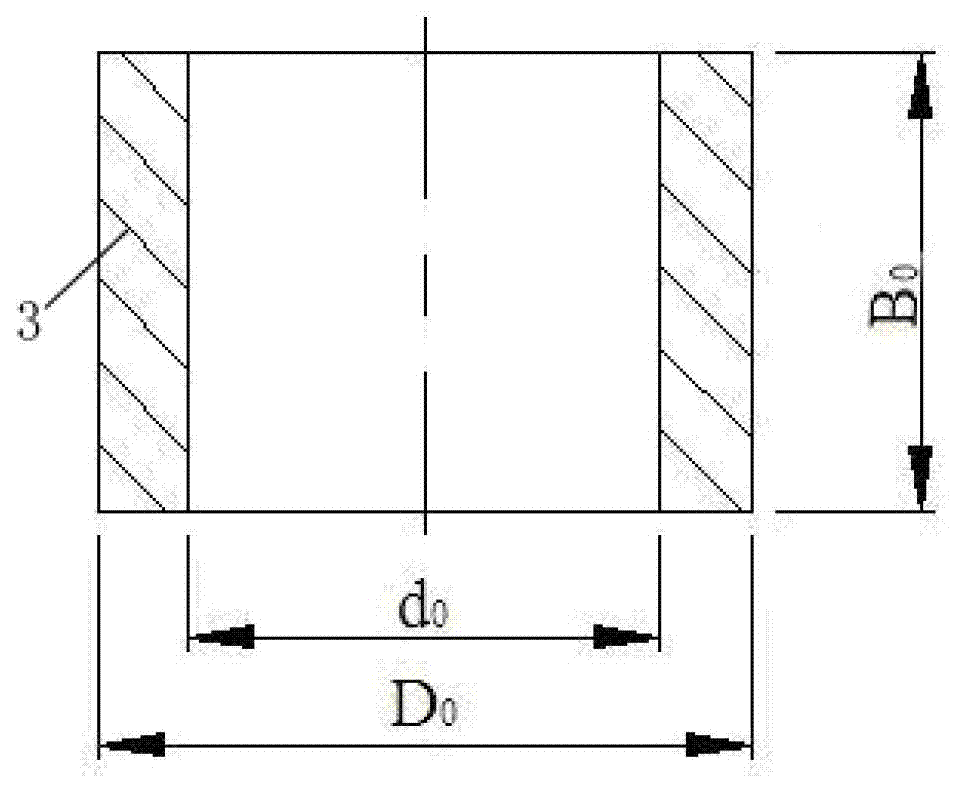

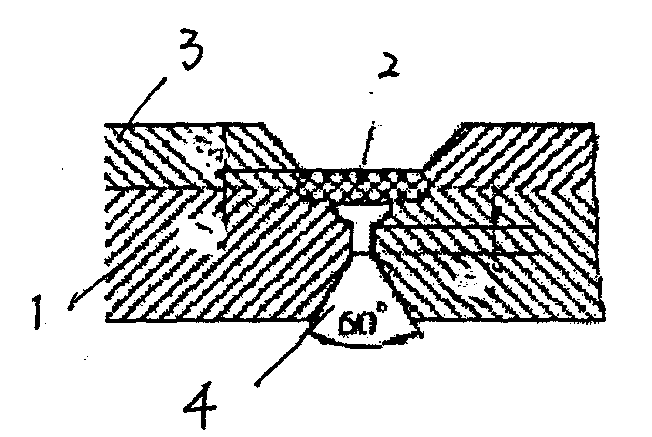

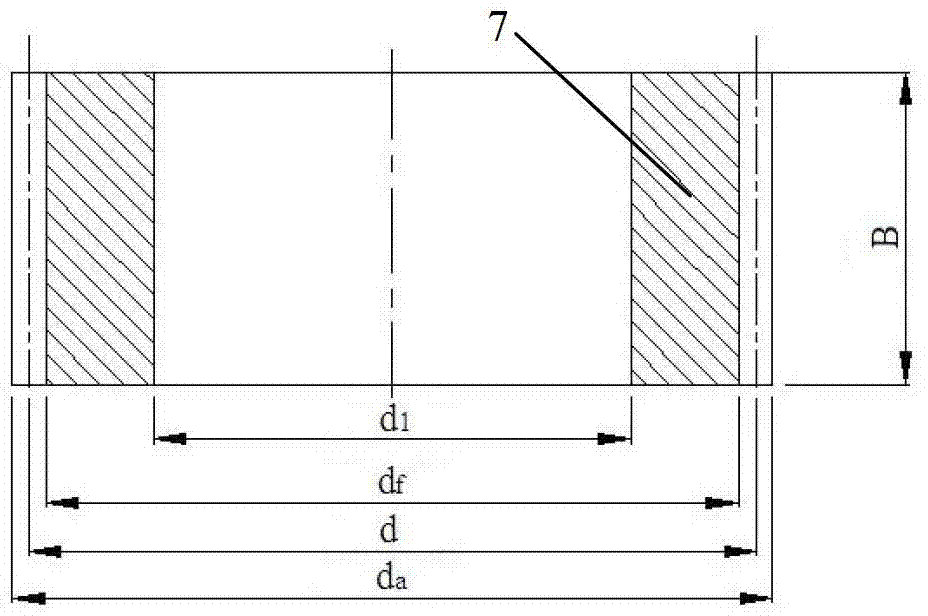

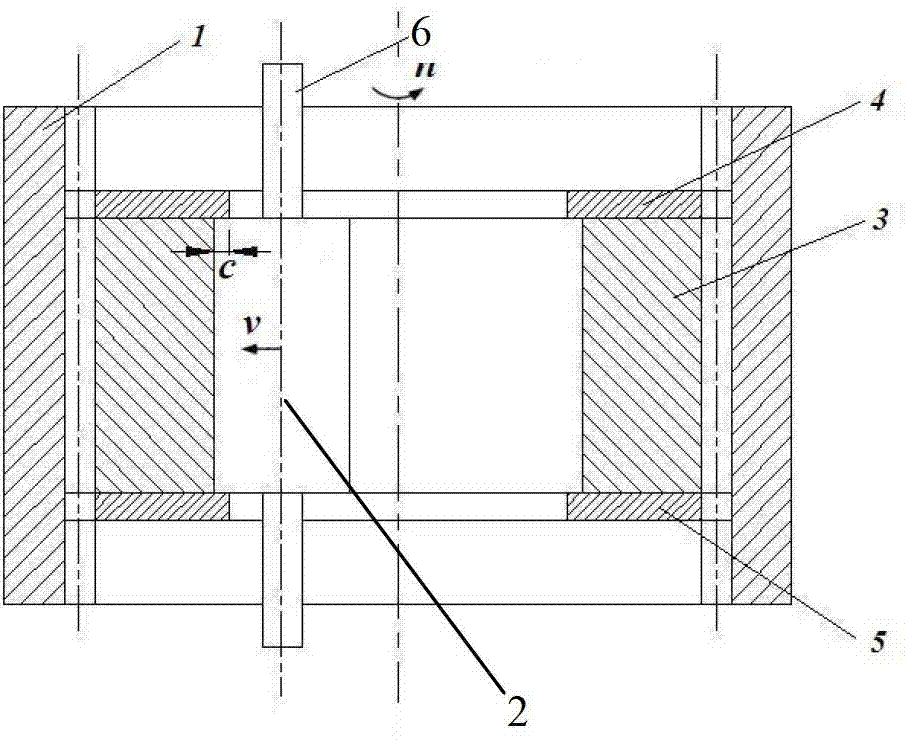

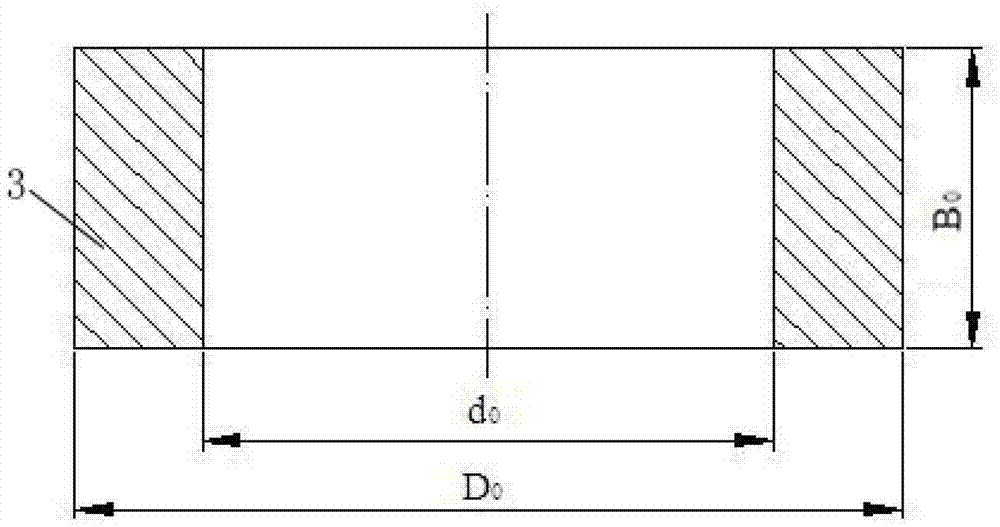

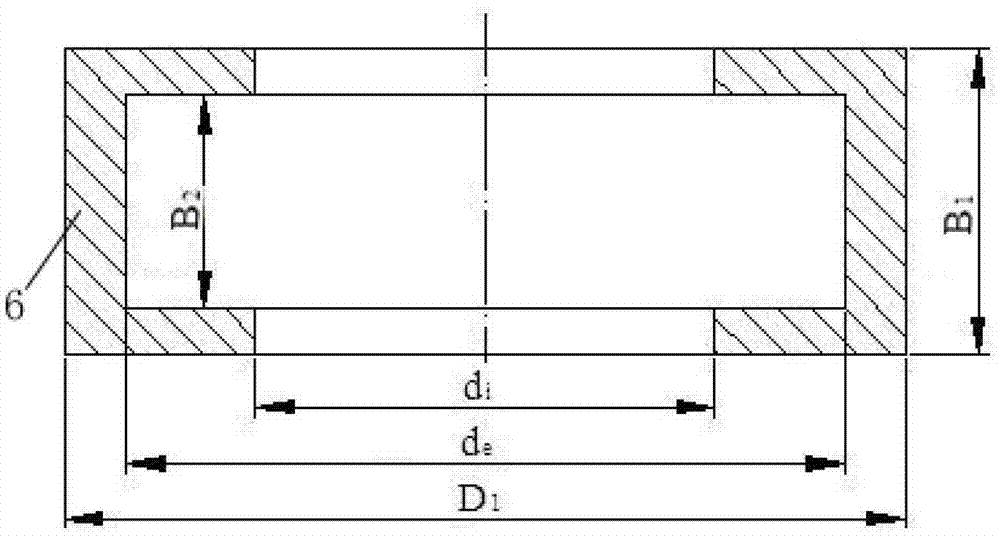

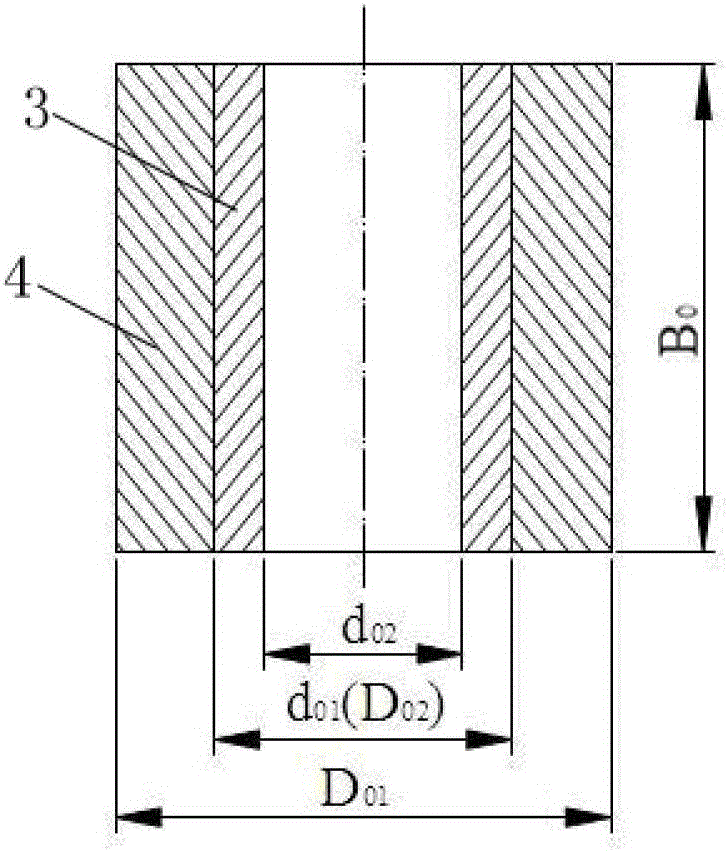

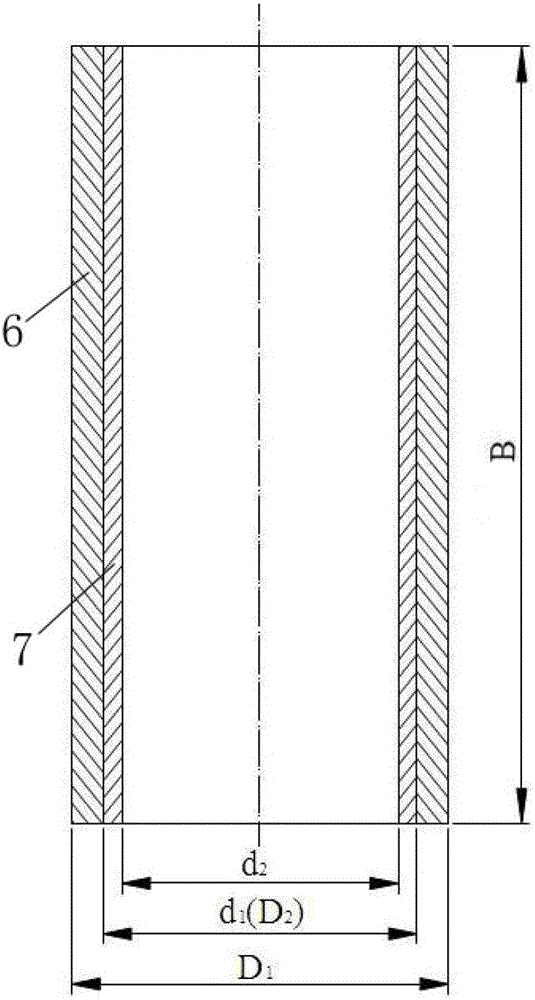

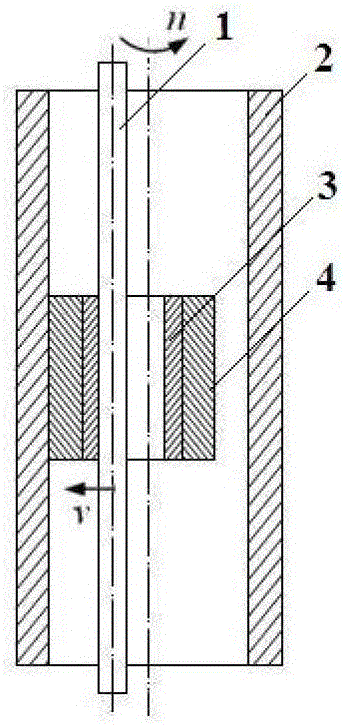

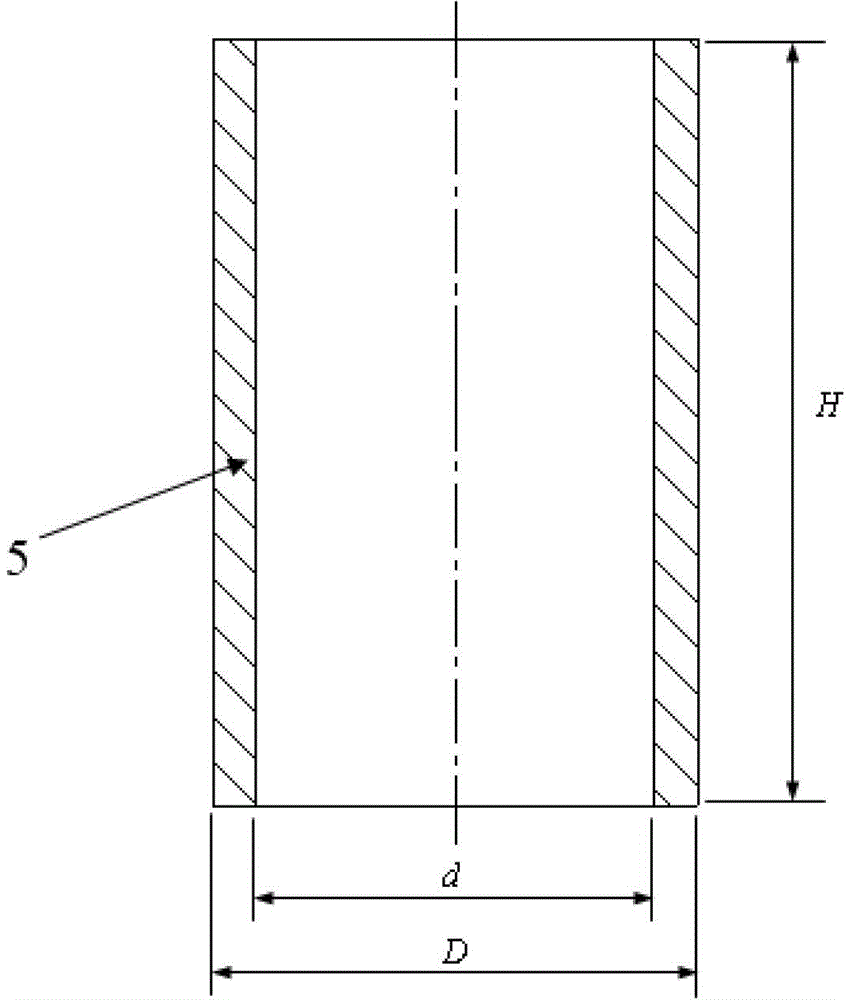

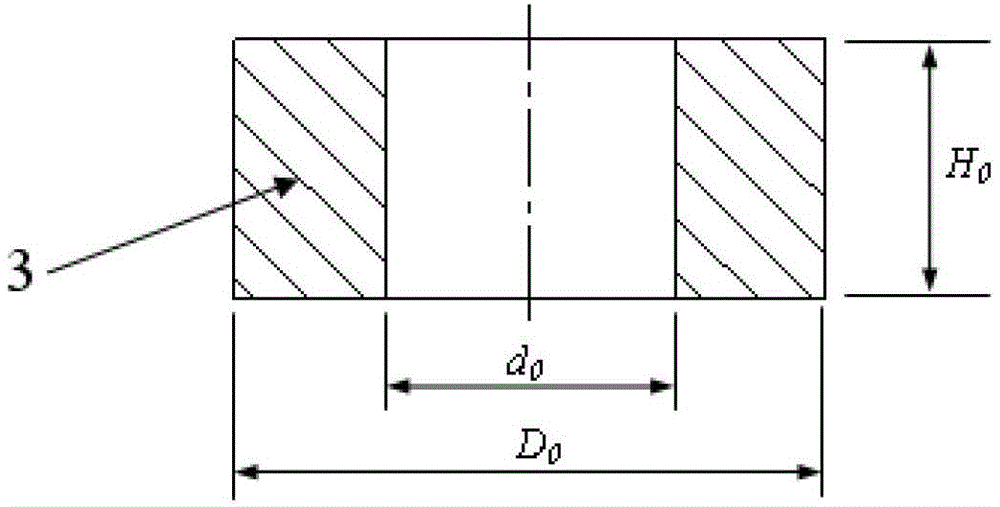

Accurate roll forming method and device of inner step cylindrical workpiece

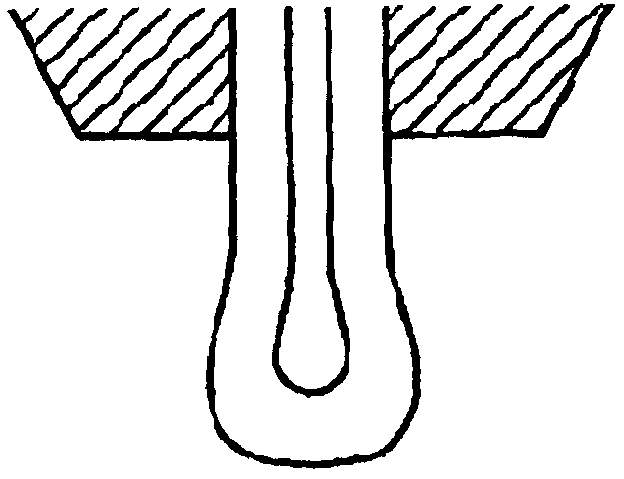

ActiveCN103084520AGeometry is easy to controlImprove surface qualityCylindersProduction rateRoll forming

The invention relates to an accurate roll forming method and a device of an inner step cylindrical workpiece, wherein the accurate roll forming method of the inner step cylindrical workpiece comprises the following steps: step (S) 1, acquiring annular blanks; S2, placing the annular blanks inside an annular driving roller, and the outer walls of the blanks closely clinging to the inner wall of the driving roller; S3, placing a core roller inside the blanks, and arranging a groove on the core roller; S4, rotating the driving roller and the blanks together, and the core roller conducting linear feed movement along the blank radial direction; S5, the core roller stopping feeding and acquiring produced inner step cylindrical workpieces when axial heights of the blanks achieve an index value. The accurate roll forming device of the inner step cylindrical workpiece comprises the driving roller (1), the core roller (2), a rotation driving device and a linear driving device, the driving roller (1) is annular, and the core roller is cylindrical. Continuous partial plastic deformation is used for achieving a one-step integral forming inner step cylindrical workpiece, and the accurate roll forming method and the device of the inner step cylindrical workpiece have the advantages of being prominent in energy and material conservation, and capable of reducing production cost and improving productivity and product performance effect.

Owner:WUHAN UNIV OF TECH

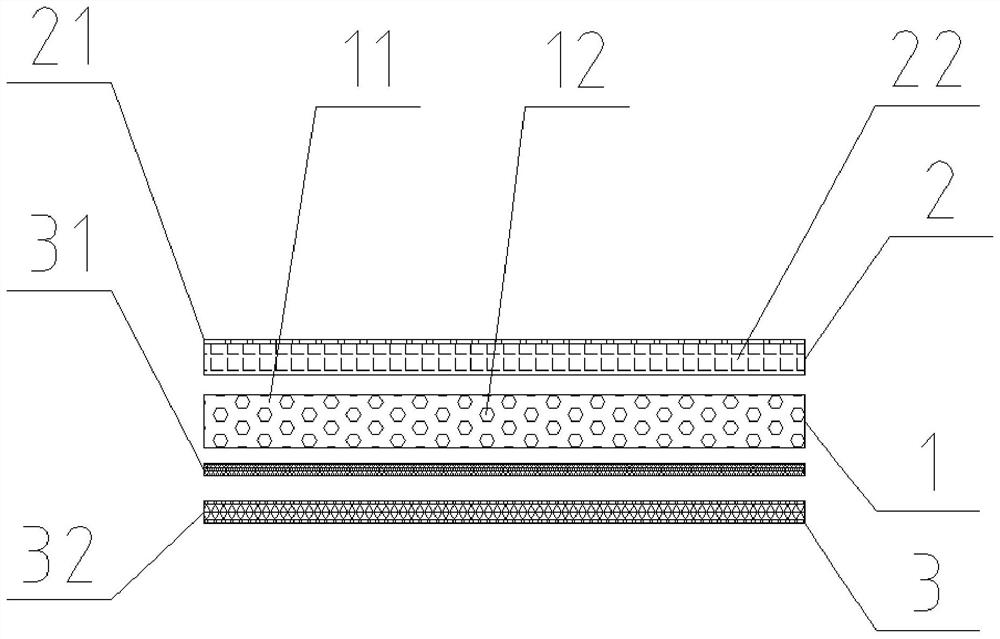

Stretchable microcapsule film for reflective display and preparation method thereof

ActiveCN113376914AShort operating timeGeometry is easy to controlNon-linear opticsPolymer scienceNanowire

The invention belongs to the technical field of displayer structures, solves the technical problems that in the prior art, a microcapsule film layer has no transformation possibility, and the stretchability of hydrogel is reduced after the hydrogel loses water, and provides a stretchable microcapsule film for reflective display and a preparation method thereof. The stretchable microcapsule film comprises a transparent electrode layer, a display film layer and a stretchable driving backboard which are tightly bonded from top to bottom in sequence, and the display film layer comprises hydrophilic light resin and microcapsules evenly distributed in the hydrophilic light resin; the transparent electrode layer comprises a first hydrophobic light resin layer and a nanowire film which is semi-embedded into the first hydrophobic light resin layer, the stretchable driving backboard comprises an elastic substrate made of a second hydrophobic light resin layer and a driving circuit, and the driving circuit is constructed on the elastic substrate and has a stretchable structure. The stretchable microcapsule film for reflective display and the preparation method have the advantages that the microcapsule film layer has the possibility of transformation, and the stretchability of the hydrogel is not affected after the hydrogel loses water.

Owner:SOUTHWEST MEDICAL UNIVERISTY

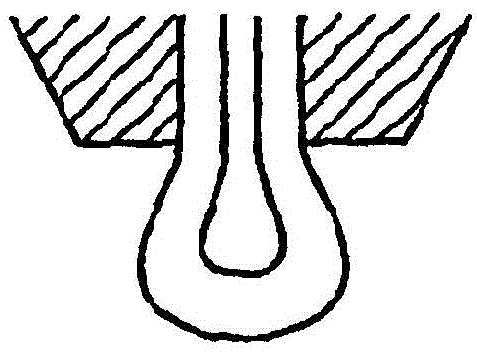

Fabrication of core/shell capsules of different geometries and treatment thereafter

ActiveCN102843918BImprove mechanical stabilityImprove consistencyTobacco treatmentTobacco smoke filtersMaterials science

Multi-shelled capsules are made by co-extruding a first liquid flavorant composition and a first shell-forming polymeric material to form droplets which are hardened to form an inner shell containing a first liquid flavorant composition, and then coated with a second shell-forming polymeric material which is hardened to form an outer shell. The result is a capsule where the inner surface of the outer shell is separate and / or separable from the outer surface of the inner shell to define a space, wherein a second liquid flavorant composition may be located.

Owner:PHILIP MORRIS PROD SA

Gradient cemented carbide with surface softening and preparation method thereof

The invention relates to the technical field of cemented carbide preparation, in particular to surface-softened gradient cemented carbide and a preparation method thereof. The solubility of WC crystalline grains in a liquid phase Co is lowered by adjusting components of an alloy binding phase, so that the situation that the WC crystalline grains grow through a dissolution and reprecipitation mechanism is reduced, growth of the WC crystalline grains is restrained, then the WC crystalline grains in the prepared cemented carbide are small, even in distribution, high in density and remarkable in gradient, the gradient cemented carbide is made to have the more excellent mechanical property, and the red hardness of the gradient cemented carbide is improved. The cemented carbide prepared through the method is adopted as a base body of a coating cutter, the trend that coating cracks expand into the base body can be slowed down, and the service life of the coating tool can be prolonged. According to the method, the functional gradient cemented carbide can be produced by slightly modifying existing equipment and processes, and is suitable for industrial production.

Owner:GUANGDONG UNIV OF TECH

Method for preparing butt-welding elbow through molding of stainless steel composite steel plate

InactiveCN101574775BGuaranteed weld heightNot easy to damageOther manufacturing equipments/toolsWelding/cutting media/materialsButt weldingRoom temperature

The invention discloses a method for preparing a butt welding elbow through the molding of a stainless steel composite steel plate, which comprises the steps of: (1) blanking, in which the stainless steel composite plate is selected to perform blanking to prepare into a blank of the elbow according to the size of the elbow; (2) pressing, in which the blank of the elbow is pressed for multiple times at room temperature or under the heating through a mold of the elbow to achieve the molding shape and size of the elbow, and conditions of heated pressing is that the blank is placed into a heatingfurnace for heating and is pressed when heated to the range of 930+ / -20 DEG C; (3) welding, in which different welding technology is selected for welding according to different materials, and weldinglayers of butt welding has three layers, namely a transition layer is added between a basic layer and a compound layer, namely the welding of the stainless steel composite steel plate is performed bythree parts: the welding of the basic layer, the welding of the compound layer, and the welding of the transition layer; and (4) heat treatment, in which the hot-pressed elbow is subjected to normalizing heat treatment with a temperature of 910+ / -10 DEG C, or the cold-pressed elbow is subjected to annealing heat treatment with a temperature of 610+ / -10 DEG C.

Owner:江阴市东发机械设备制造有限公司

A kind of surface-hardened gradient cemented carbide and its preparation method

The invention relates to the technical field of cemented carbide preparation, in particular to a surface-hardened gradient cemented carbide and a preparation method thereof. The invention adjusts the composition of the alloy binder phase to make the WC crystal grains in the prepared cemented carbide fine, evenly distributed, high in density and obvious in gradient, so that the cemented carbide exhibits more excellent mechanical properties and improves the performance of the cemented carbide. of red hardness. The composition and thickness of the cemented carbide gradient layer are controlled by adjusting parameters such as blank formula, sintering temperature and sintering time, so that the surface layer of the cemented carbide is rich in cubic phase and poor in binder phase, and there is a rich alloyed binder phase under the surface The excessive layer, so that the cemented carbide has excellent hardness, wear resistance and toughness, and can be used for machining of metals. The cemented carbide prepared by the method of the invention has excellent wear resistance, strength, hardness and toughness at the same time. The method of the invention can produce functionally graded cemented carbide with little modification to existing equipment and processes, and is suitable for industrialized production.

Owner:GUANGDONG UNIV OF TECH

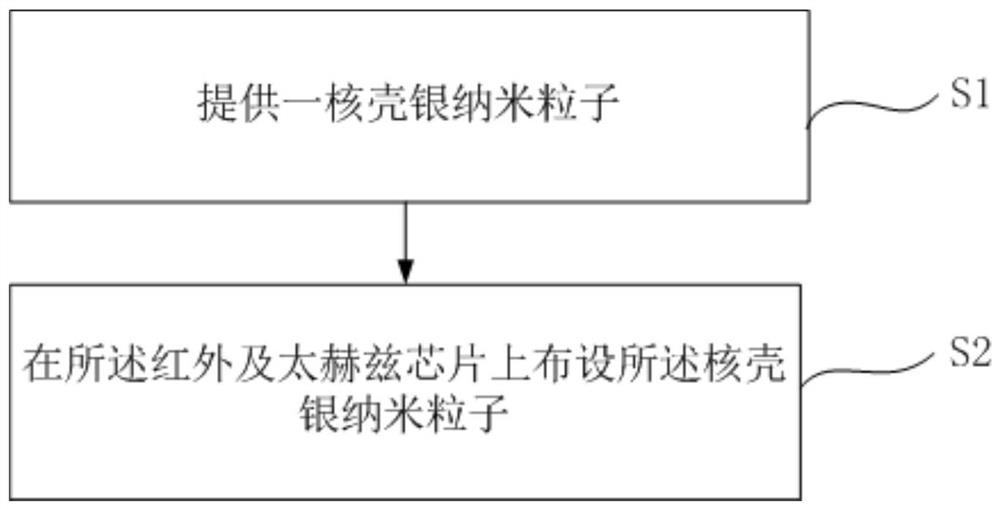

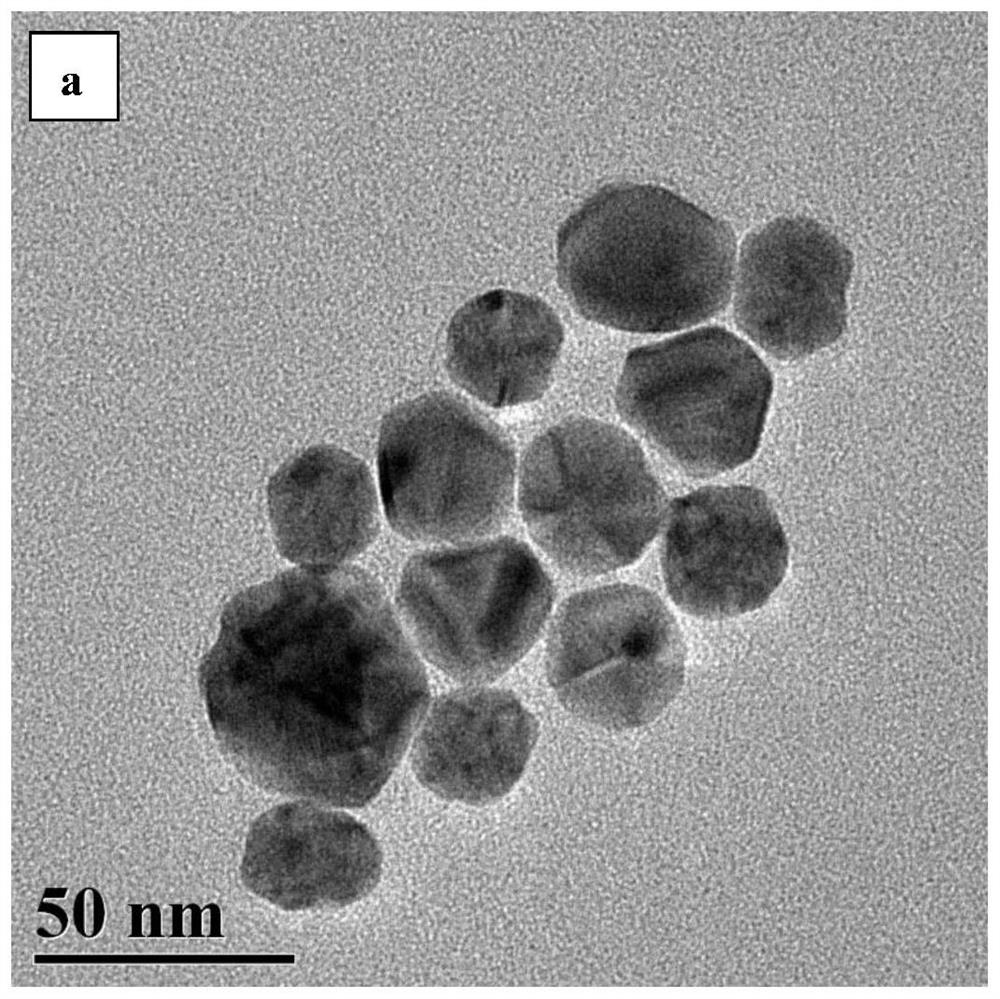

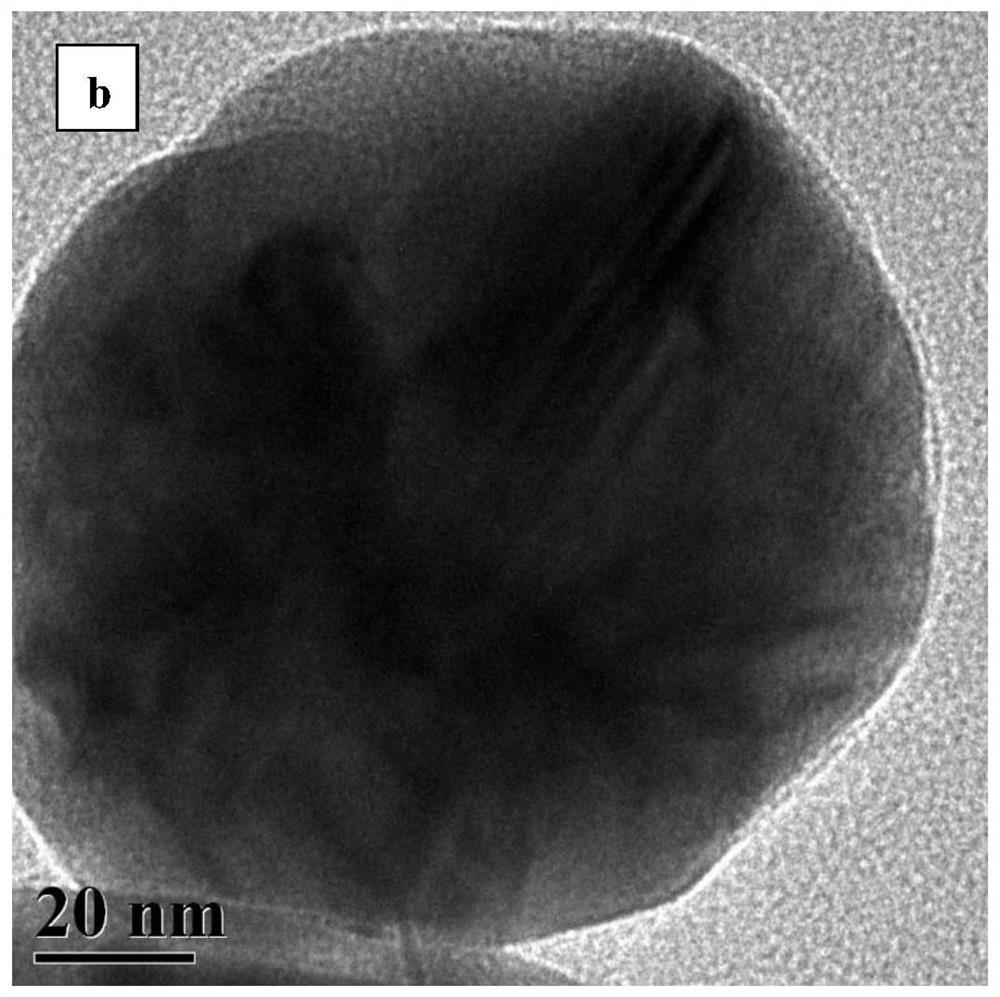

A method for improving the performance of infrared and terahertz chips and infrared and terahertz chips

ActiveCN111900231BImprove performancePerformance does not breakMaterial nanotechnologyFinal product manufactureReduction treatmentPhysical chemistry

The invention provides a method for improving the performance of infrared and terahertz chips and the infrared and terahertz chips. The method for improving the performance of infrared and terahertz chips includes the following steps: providing a core-shell silver nanoparticle; disposing the core-shell silver nanoparticle on the infrared and terahertz chip; wherein, the core-shell silver nanoparticle In a reaction medium with a boiling point of 100-170°C, in the presence of a protective agent, the precursor of the core structure is reduced at least once at a temperature of 100-170°C to obtain nano-seed particles of the core structure; and at 25-100°C At a reaction temperature of ℃, it is obtained by adding a shell-structured precursor and performing at least one reduction treatment. The infrared and terahertz chip obtained based on the manufacturing method of the invention has high modulation depth, response speed and wide working bandwidth, thereby ensuring ideal performance of the terahertz system.

Owner:HEFEI UNIV OF TECH

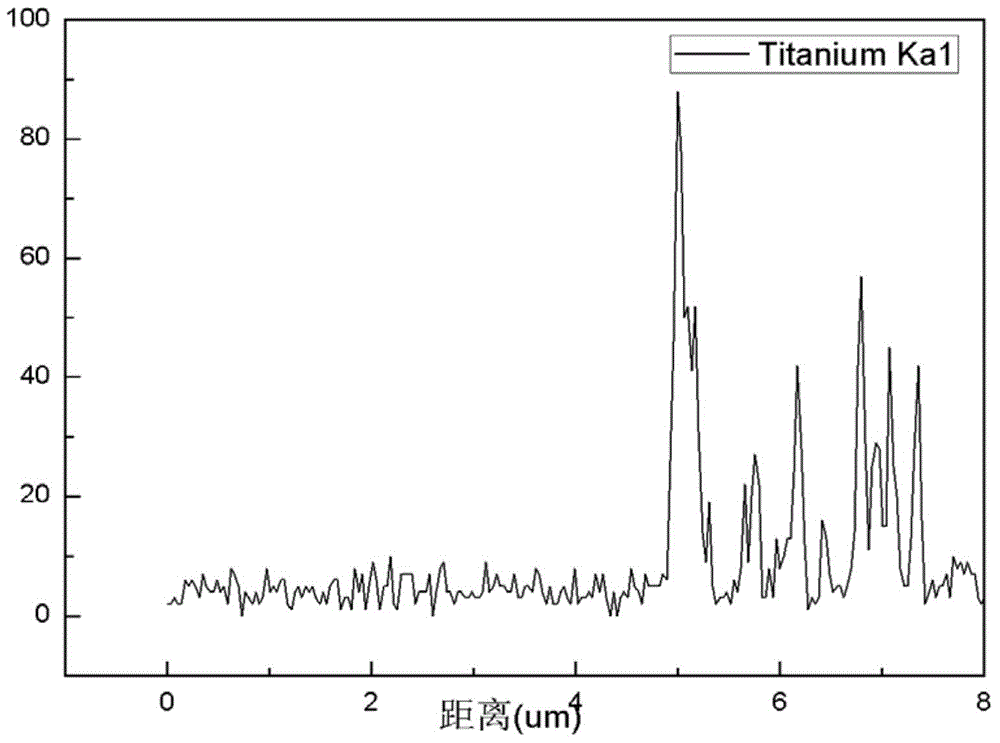

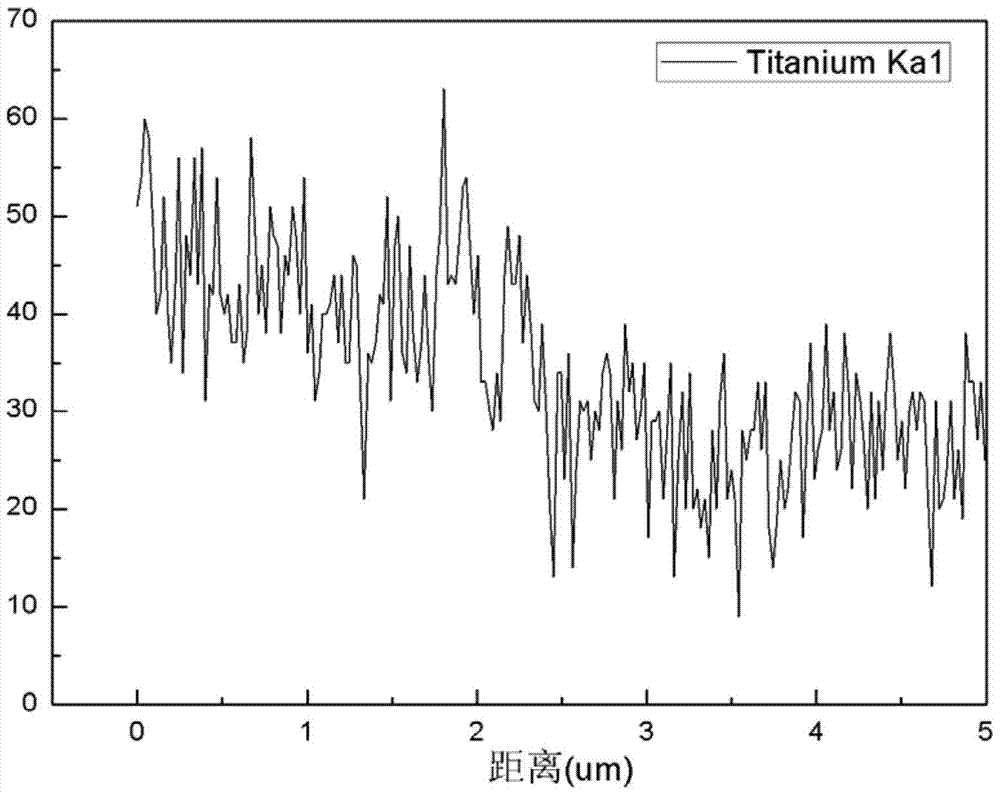

Preparation method of titanium foam

ActiveCN111230119AWide variety of sourcesNot easy to absorb waterWater contaminantsWater/sewage treatmentFixed bedCoking wastewater

The invention belongs to the technical field of electrode base materials, and provides a preparation method of titanium foam. The method comprises the steps that coke is adopted as a pore forming agent and mixed with titanium powder to be sintered, the pore forming agent is removed, and the titanium foam is obtained, wherein the volume ratio of the coke to the titanium powder is (0.5-2):1, the grain size of the coke is 1-6 mm, the sintering temperature is 1,400-1,600 DEG C, and the grain size of the titanium powder is 400 meshes. The preparation method specifically comprises the following steps that S1, the coke and the titanium powder are compacted after being mixed to obtain a mixed sample; S2, the mixed sample is sealed, vacuumizing is performed repeatedly, argon is introduced till foreign gas is exhausted; S3, the temperature is increased to 1,400-1,600 DEG C, and sintering is performed; and cooling is performed to the room temperature to obtain a titanium foam midbody; S4, the midbody is placed into a coke gasification small fixed bed reaction device, the temperature is increased to 1,100 DEG C, CO2 is introduced with the flow being 400-600 ml / min, the reaction is performed for a period of time, heating is stopped, cooling is performed to reach the room temperature. According to the technical scheme, the prepared titanium foam is adopted as an anode, electro-catalysis treatment is performed on the coked wastewater, the number of active loci is large, and the degradation efficiency is high.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

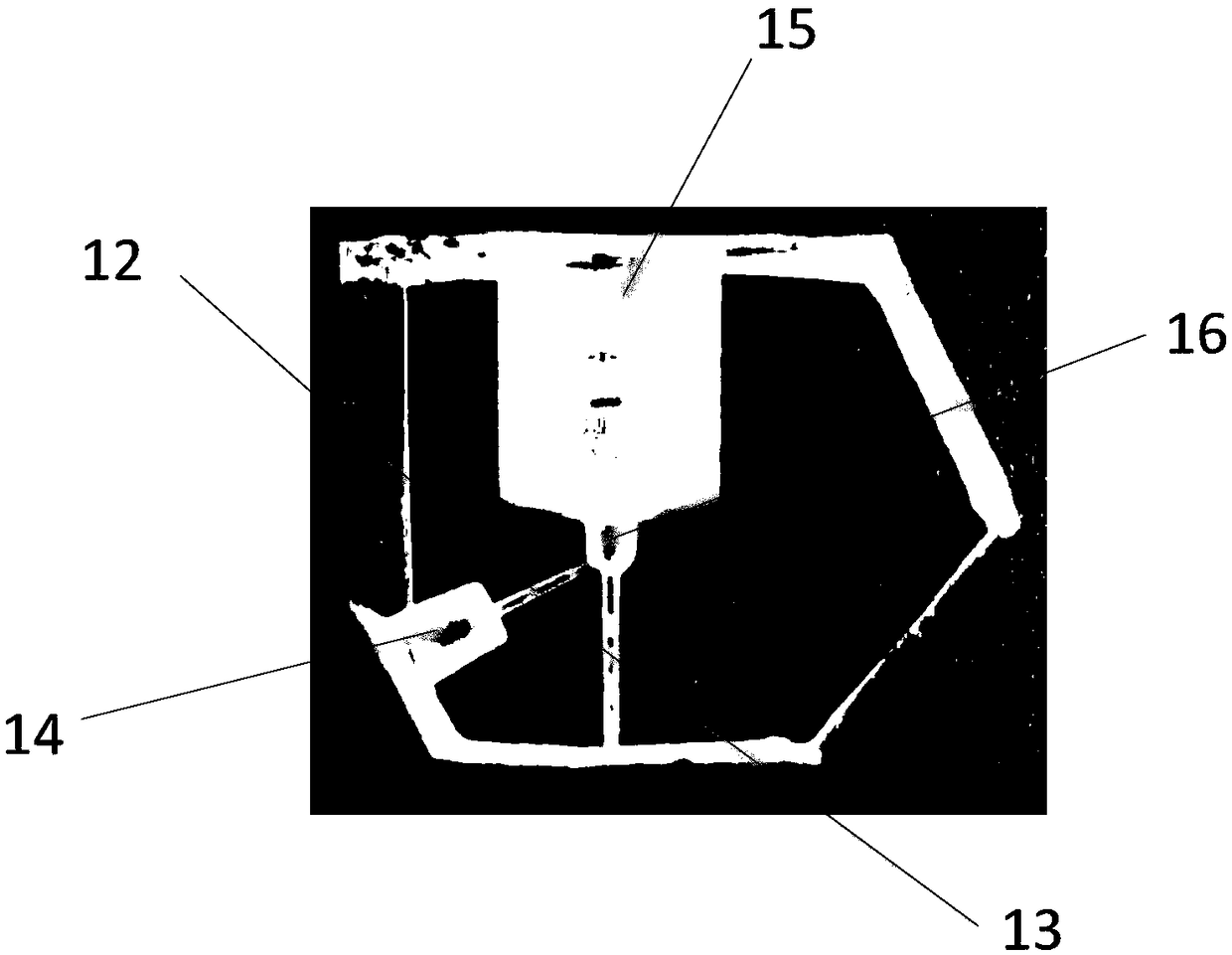

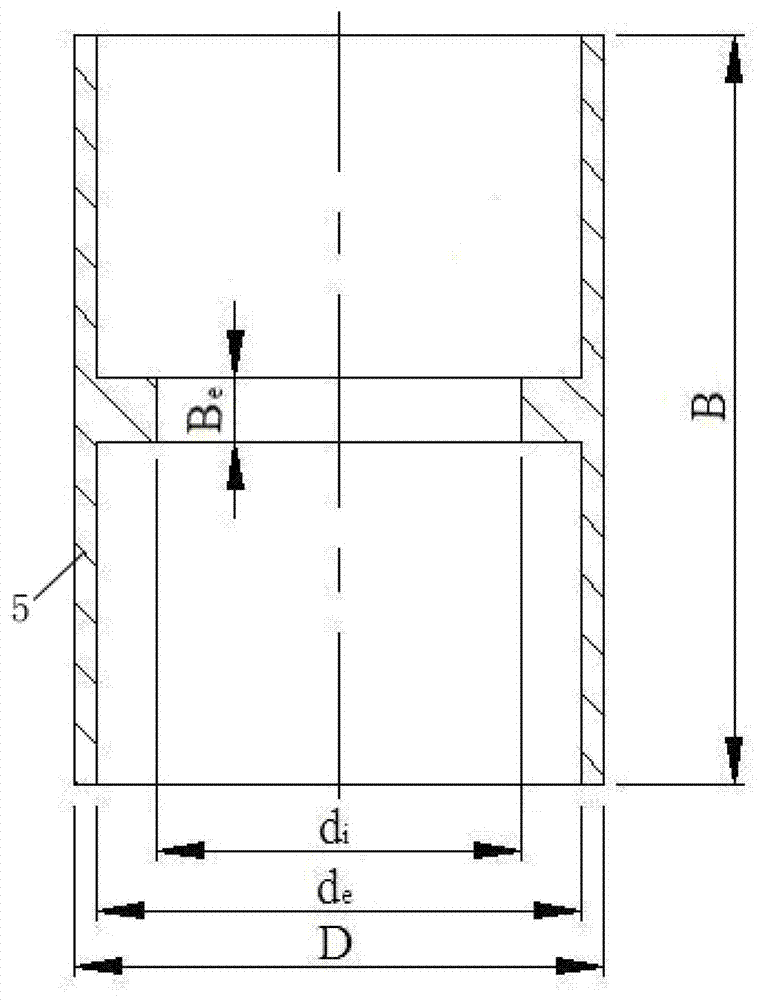

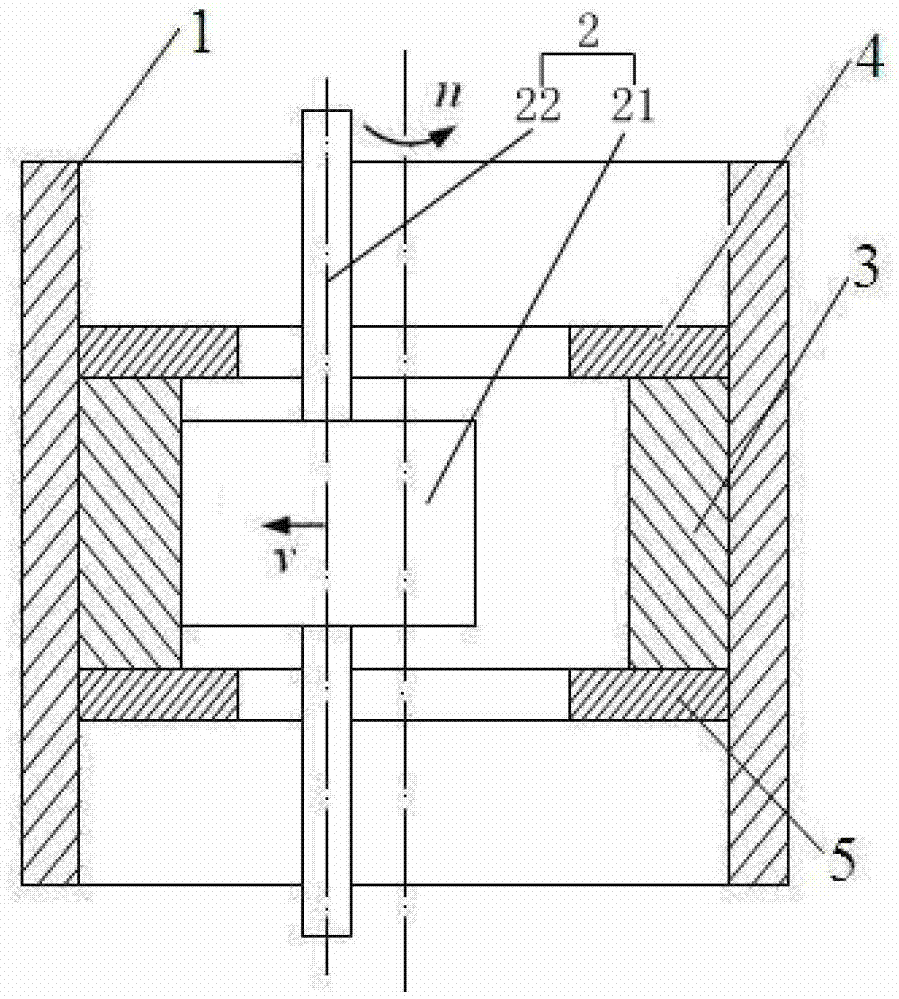

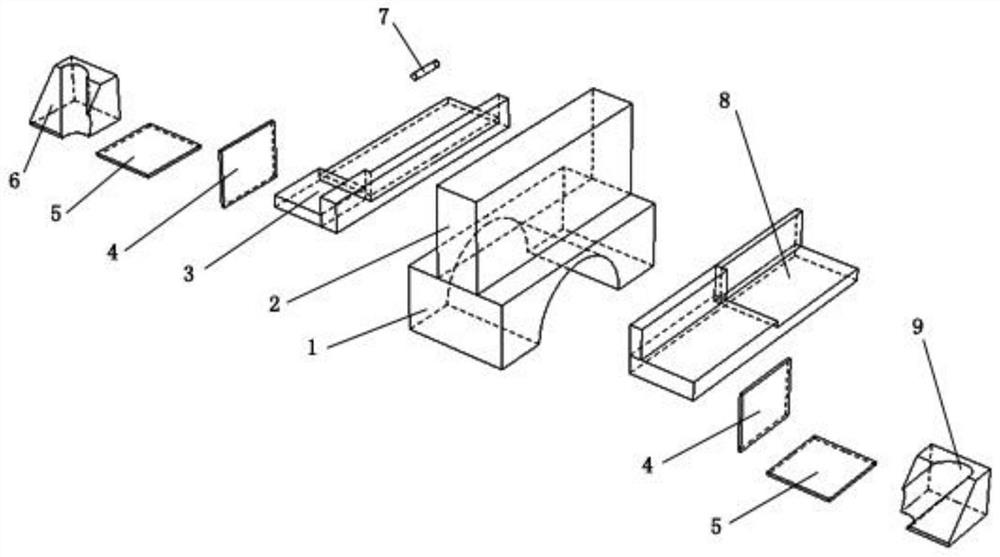

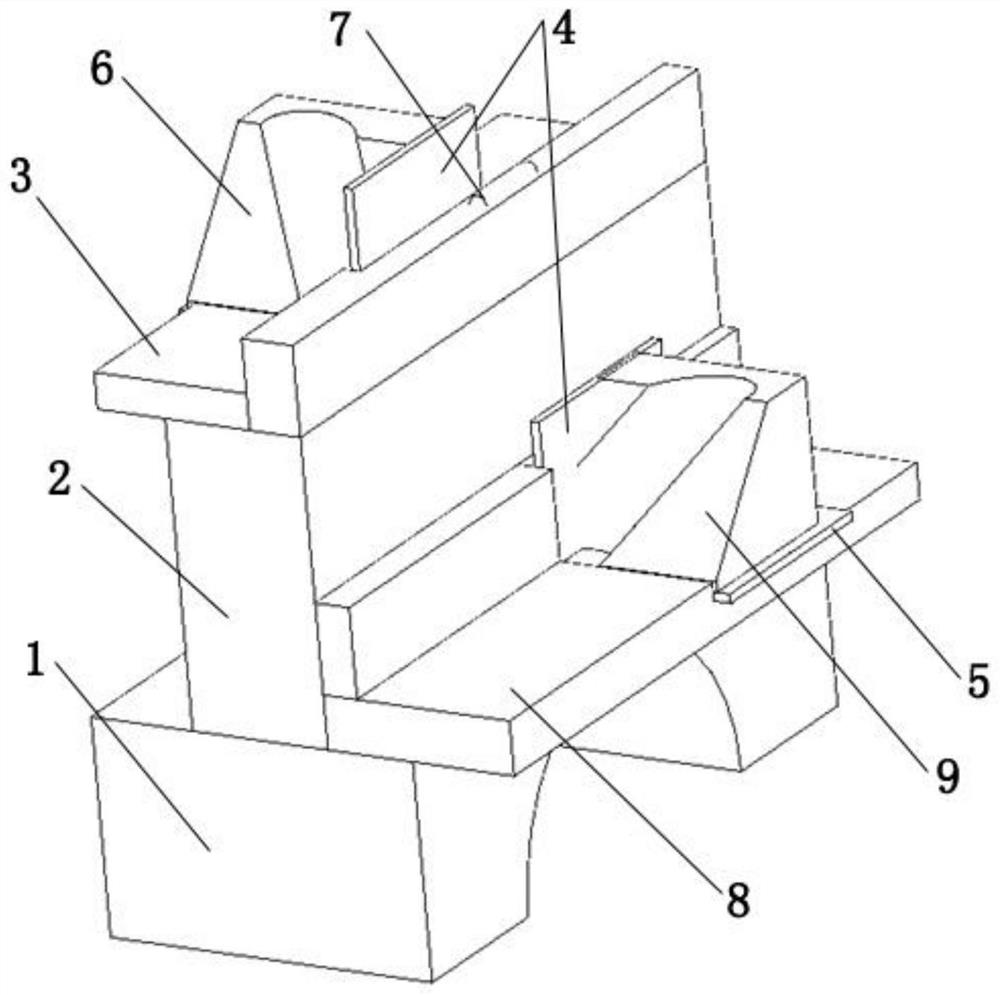

Method and device for precisely rolling and forming cylindrical gear

ActiveCN103056259BGeometry is easy to controlHigh geometric accuracyGear wheelsProduction rateEngineering

The invention provides a method and a device for precisely rolling and forming a cylindrical gear. The method includes steps of S1, obtaining an annular blank; S2, disposing the annular blank in a driving roll; S3, setting an upper retaining plate and a lower retaining plate at the upper end and the lower end of the blank; S4, disposing a core roll in the blank; S5, enabling the driving roll and the blank to rotate around the central axis of the blank, and enabling the core roll to do linear feed motion along the radial direction of the blank; and S6, stopping feeding of the core roll and taking out of the formed cylindrical gear when the inner diameter of the blank of the gear reaches the preset value; wherein the diameter of the core roll is smaller than the inner diameter of the upper retaining plate and the lower retaining plate. The device comprises the driving roll (1), the core roll, the upper retaining plate (4), the lower retaining plate (5), a rotary driving device and a linear driving device. The cylindrical gear is integrally formed at one step by continuous local plastic deformation, and has the advantages that energy and materials are remarkably saved, production cost is reduced, and productivity and product performance effect are improved.

Owner:WUHAN UNIV OF TECH

A precision rolling forming method and device for an inner deep groove ring

Owner:WUHAN UNIV OF TECH

A precision rolling forming method for bimetallic cylindrical parts

ActiveCN103111564BSignificant energy saving and material savingReduce manufacturing costCylindersProduction rateEngineering

The invention relates to a precise roll forming method of a bimetal tubular part. The precise roll forming method of the bimetal tubular part comprises a first step of obtaining an outer ring part blank and an inner ring part blank, a second step of assembling the outer ring part blank and the inner ring part blank, a third step of placing a core roller in the inner ring part blank, a fourth step of placing a drive roller outside the outer ring part blank, a sixth step of driving the drive roller to rotate through a drive device, wherein the core roller is driven to conduct linear feed movement along the radial direction, the outer ring part blank and the inner ring part blank are closely attached to each other all the time, continuous partial plastic deformation with small wall thickness, expanded inner and outer diameter and axial tension is generated, and a sixth step of stopping the core roller from feeding and enabling the core roller to return. By means of the continuous partial plastic deformation, the bimetal tubular part is formed integrally at a time. The geometric dimensioning of the bimetal tubular part is easy to control. Therefore, the precise roll forming method of the bimetal tubular part has the obvious advantages of saving energy and materials, reducing production cost, and improving the production efficiency. The bimetal tubular part is good in interface contact quality, high in connection intensity, and capable of meeting requirements of the service performance and the service life of the bimetal tubular part.

Owner:WUHAN UNIV OF TECH

Method for in-situ controlled synthesis of silver oxide semiconductor thin film materials at room temperature

ActiveCN103602945BMild conditionsReaction is easy to controlVacuum evaporation coatingSputtering coatingRoom temperatureSurface-active agents

The invention relates to a method for synthesizing a silver oxide semiconductor thin-film material through room temperature in-situ control. The method is characterized by comprising the following steps: putting a substrate material, the surface of which is covered by an elementary substance silver thin film, in a UV-03 reactor, maintaining the relative humidity of a system to 30-90%, and reacting for 1-2 hours at the temperature of 10-40 DEG C under the condition of oxygen or air existence so as to obtain the AgxO(AgO or Ag2O) semiconductor thin-film material on the surface of a substrate in situ, wherein the UV-03 reactor is a UV-03 cleaning machine. According to the method, solvents, surface active agents or other chemical additives are not needed in a reaction process. The method is simple to operate and low in energy consumption and preparation cost and has wide industrial application prospect.

Owner:XUCHANG UNIV

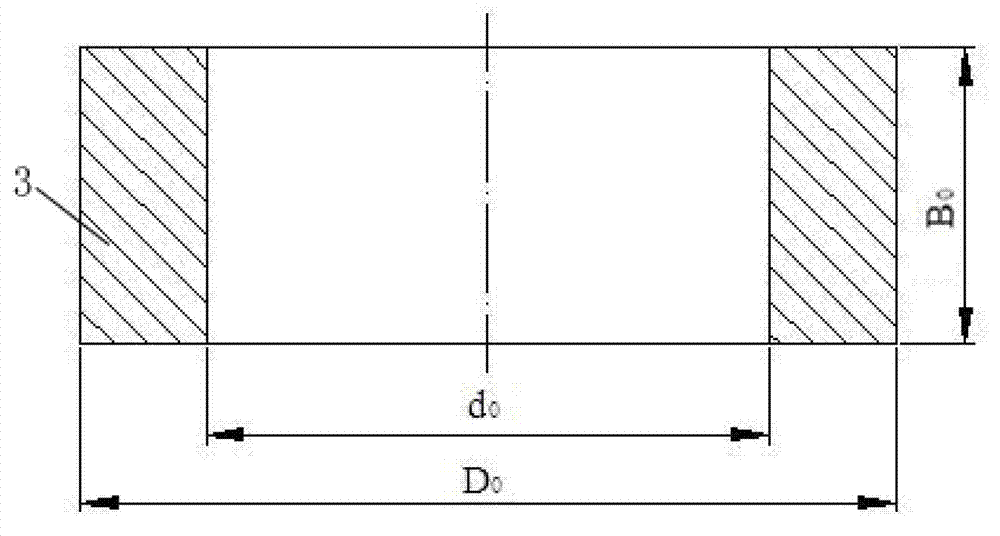

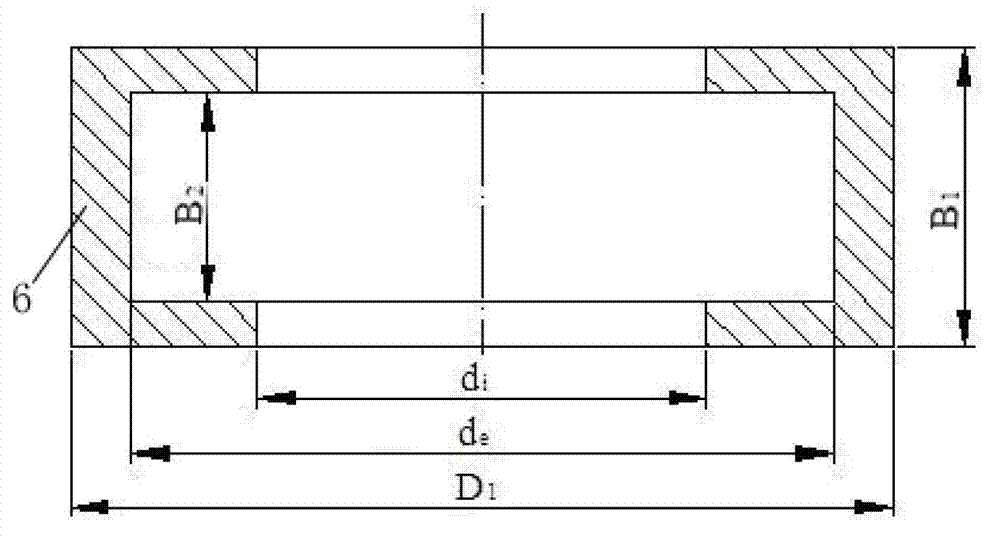

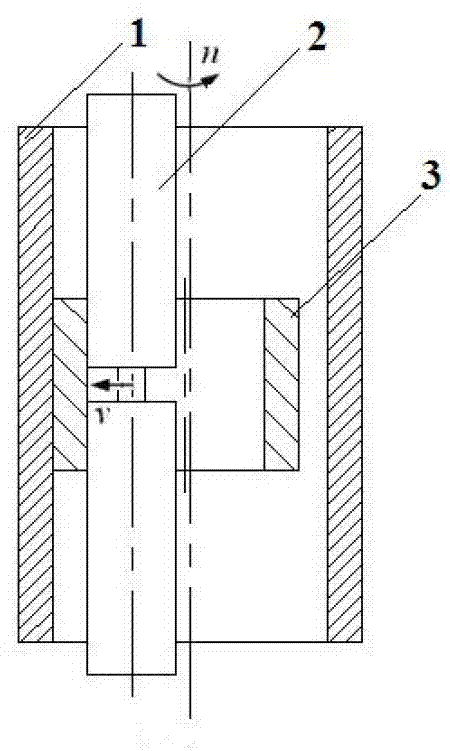

A precision rolling forming method and device for cylindrical parts

ActiveCN102921847BGeometry is easy to controlImprove surface qualityCylindersProduction rateEngineering

The invention relates to a method and a device for precision-rolling and forming a cylindrical part. The method comprises the following steps: S1, obtaining an annular blank, wherein the external diameter of the blank is equal to that of the cylindrical part; S2, putting the annular blank into an annular driving roller and enabling the outer wall of the blank to be closely attached onto the inner wall of the driving roller; S3, putting a core roller into the blank, wherein the diameter of the core roller is smaller than that of the blank; S4, enabling the driving roller and the blank to rotate around a central axis of the blank and enabling the core roller to do linear feed motion along the radial direction of the blank; and S5, when the axial height of the blank reaches a preset value, enabling the core roller to stop feeding and taking out the prepared cylindrical part. The device comprises the driving roller (1), the core roller (2), a rotating drive device and a linear drive device, wherein the driving roller (1) is annular; and the core roller (2) is cylindrical. The method and the device for precision-rolling and forming the cylindrical part have the beneficial effects that the cylindrical part is wholly formed at one time through continuous partial plastic deformation, and the effects of saving energy and materials, reducing the production cost and improving the production rate and the product performance effect are remarkable.

Owner:WUHAN UNIV OF TECH

A frame structure of a car-carrying disc lifting device

A frame body structure of a car loading disc lifting device comprises a main beam, a left box frame and a right box frame, wherein the left box frame and the right box frame are arranged on the two sides of the main beam. The frame body structure is characterized in that the main beam is an integrated piece with the U-shaped cross section, the left box frame and the right box frame are respectively provided with a set of connecting face plates on the side face which is located on the same side as a U-shaped opening of the main beam, each set of connecting face plates comprise a first connecting face plate and a second connecting face plate, the first connecting face plates can be connected with the horizontal side face of a left side beam of a car loading disc and the horizontal side face of a right side beam of the car loading disc in an attaching mode, and the second connecting face plates can be connected with the perpendicular side face of the left side beam of the car loading disc and the perpendicular side face of the right side beam of the car loading disc in the attaching mode. The main beam is of a U-shaped structure which is integrally formed by a top support and a bottom support, so that the overall rigidity and assembly accuracy of the lifting frame body are greatly improved. The left box frame and the right box frame are of a frame type structure formed by welding thin steel plates, therefore, self weight is reduced, the geometric dimension and the form and location tolerance are easy to control, and accuracy of the overall geometric dimension and the form and location tolerance of the lifting frame body is remarkably improved.

Owner:NINGBO BANGDA INTELLIGENT PARKING SYST

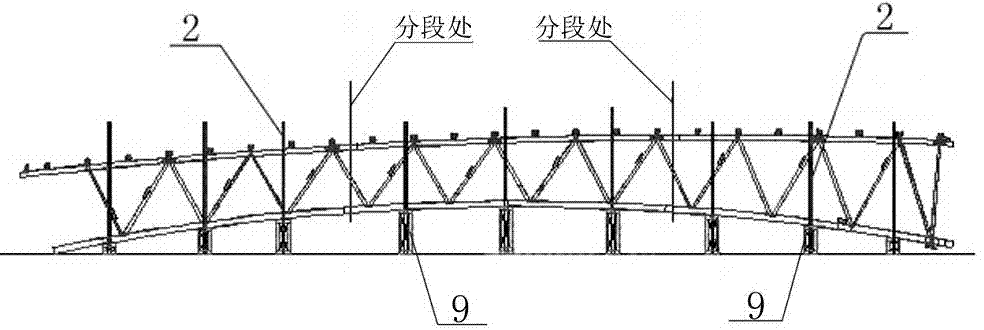

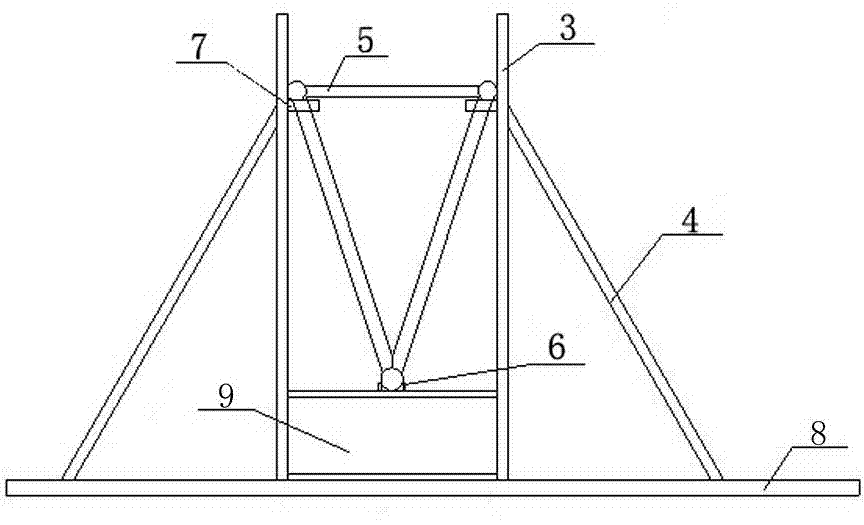

Assembling and splicing installation method of large-span tube-truss roof beam

InactiveCN102777047BEasy to installGeometry is easy to controlBuilding material handlingEngineeringSpandrel

The invention relates to an assembling and splicing installation method of a large-span tube-truss roof beam. The assembling and splicing installation method comprises the following steps of: dividing a tube-truss roof beam into a roof beam middle span section, a roof beam left span section and a roof beam right span section; dividing the roof beam left span section and the roof beam right span section into a plurality of sub sections, welding respectively, and transporting to an installation field; manufacturing an assembling and splicing jig frame, sequentially arranging each sub section of the roof beam left span sections on the assembling and splicing jig frame, assembling, splicing and welding into the roof beam left span section; manufacturing the roof beam right span section in the same way; and respectively lifting the roof beam left span section and the roof beam right span section in place, welding and fixing, splicing, installing and fixing the roof beam middle span section, respectively abutting the roof beam middle section with the roof beam left span section and the roof beam right span section, leveling by a web member, welding, so as to form an integrative tube-truss roof beam. With the adoption of the assembling and splicing installation method, the geometric dimension of the whole tube-truss construction member is controllable; and due to the assembling and splicing process on the ground, the working efficiency is improved, the cost of large machineries is saved, the safety risk during the lifting process is avoided, in this way, the construction method is especially suitable for the installation of each large-span tube-truss roof beam.

Owner:河北二十冶建设有限公司

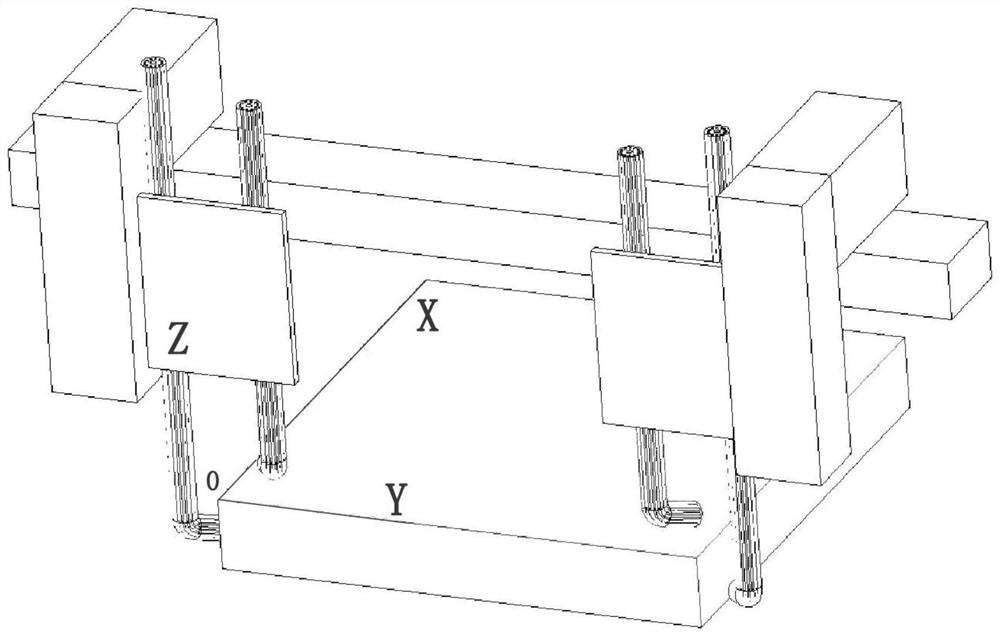

A positioning device and method for cleaning billet corners

ActiveCN109909468BRealize three-dimensional adjustmentGeometry is easy to controlThree-dimensional spaceStructural engineering

The invention relates to a positioning method and device for casting blank corner cleaning. The device comprises a magnetic base, a hot blank profile block, a level gauge, an inner arc gun positioningbase, an outer arc gun positioning base, an X-axis adjustment block, a Y-axis adjustment block, an inner arc gun angle adjustment block, an outer arc gun angle adjustment block. The bottom of the magnetic base is in a circular arc shape and cooperates with a roller table, the top of the magnetic base is fixedly connected with the hot blank profile block, the top of the hot blank profile block isprovided with the inner arc gun positioning base, the level gauge is embedded to the inner arc gun positioning base, the outer arc gun positioning base is fixed to the magnetic base and abuts againstthe side of the hot blank profile block, and the inner arc gun angle adjusting block and the outer arc gun angle adjusting block are provided with angle grooves correspondingly. The device has the advantages that the device structure is reasonable, the device is arranged on both sides of a casting blank, a cleaning gun is positioned, the cleaning gun and other equipment are accurately positioned in the three-dimensional space, the geometric shape is controllable after the casting blank corner is cleaned, and the slag hanging condition is controllable after the casting blank is cleaned.

Owner:ANGANG STEEL CO LTD

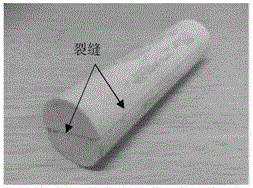

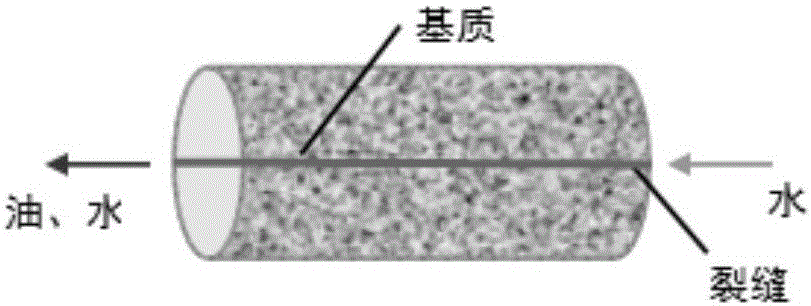

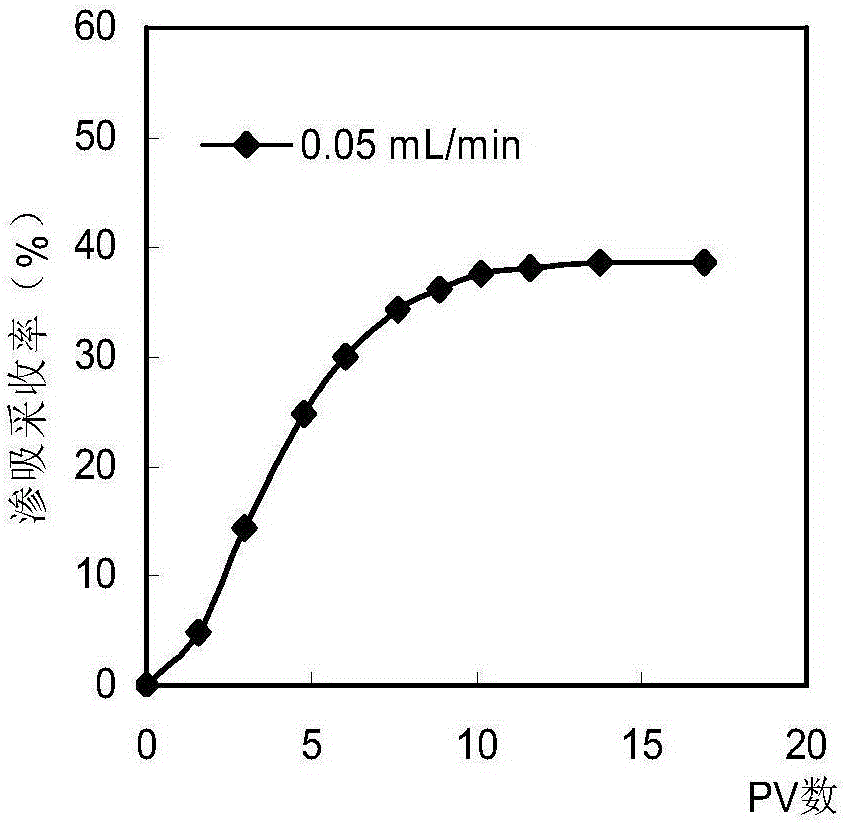

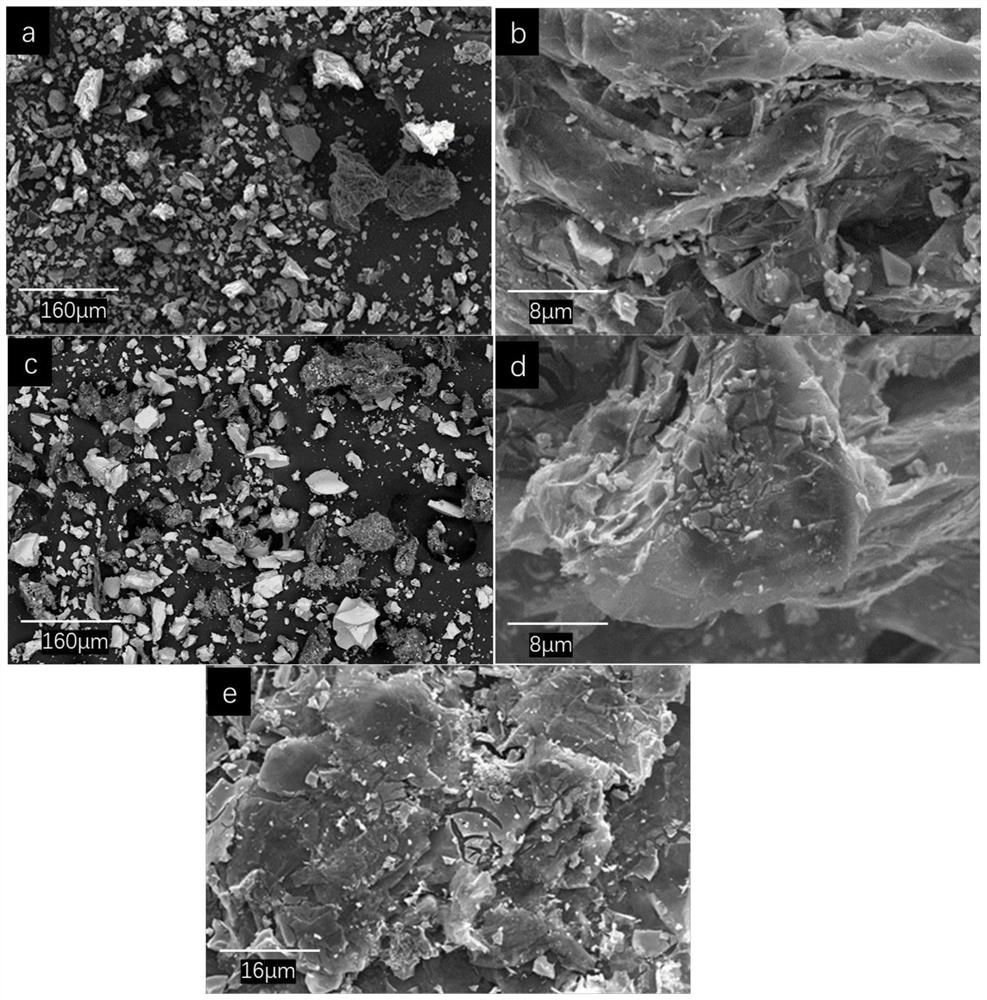

An experimental method for imbibition recovery in low-permeability fractured reservoirs

InactiveCN104655808BGood position repeatabilitySaturation accurately reflectsMaterial analysisRock coreExperimental methods

Owner:NORTHEAST GASOLINEEUM UNIV

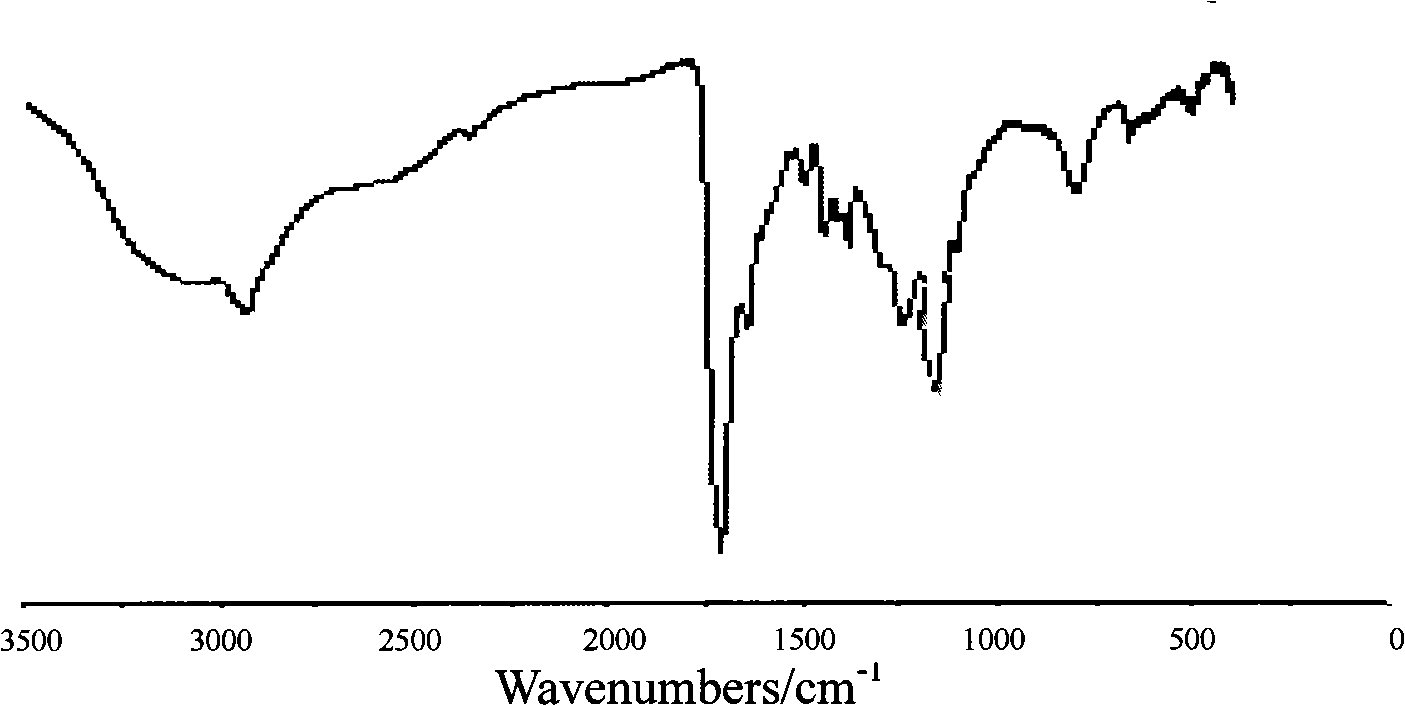

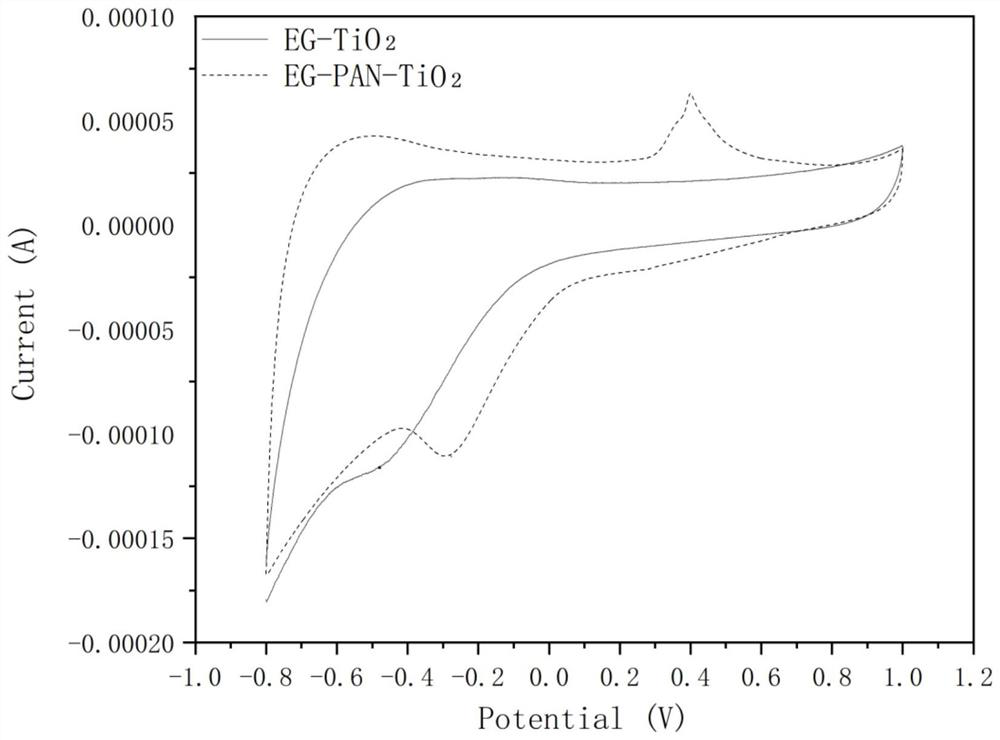

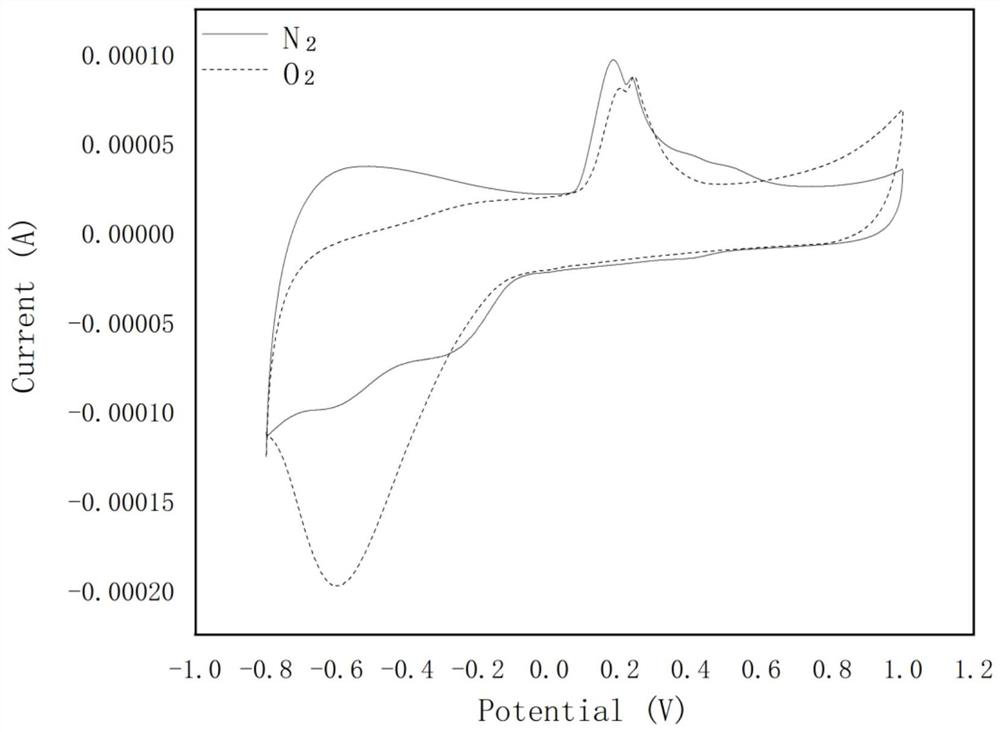

Self-supporting carbon-based TiO2 electro-catalytic material as well as preparation method and application thereof

ActiveCN114308002ASimple processReduce manufacturing costPhysical/chemical process catalystsWater/sewage treatment by oxidationPhysical chemistryAniline

The invention discloses a self-supporting carbon-based TiO2 electro-catalytic material as well as a preparation method and application thereof. The preparation method comprises the following steps: carrying out ultrasonic cleaning and drying on expanded graphite powder; putting into an aniline-ethanol solution, and carrying out ultrasonic treatment; adding the EG-PAN into a hydrochloric acid-sulfuric acid mixed acid solution, adding ammonium persulfate while stirring, stirring at low temperature, filtering and drying to obtain EG-PAN powder; the preparation method comprises the following steps: weighing EG-PAN powder, and mixing the EG-PAN powder with tetrabutyl titanate and absolute ethyl alcohol to obtain a mixed solution A; mixing absolute ethyl alcohol, deionized water and concentrated nitric acid according to a certain volume ratio to obtain a mixed solution B; dropwise adding the mixed solution B into the mixed solution A, and standing until a non-flowing gel system is formed; drying in a drying oven to obtain black gray particles; and grinding the mixture into powder, and calcining the powder to obtain EG-PAN-TiO2 powder. The prepared self-supporting carbon-based TiO2 electro-catalytic material can be formed at a time, and the electro-catalytic oxygen reduction reaction efficiency is effectively improved.

Owner:SHANDONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com