Preparation method of titanium foam

A technology of titanium foam and titanium powder, which is applied in chemical instruments and methods, water/sludge/sewage treatment, water pollutants, etc., can solve the problems of low catalytic activity, unsuitable electrode matrix, and small porosity of titanium foam. Achieve the effect of simple preparation method, low price and stable decomposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

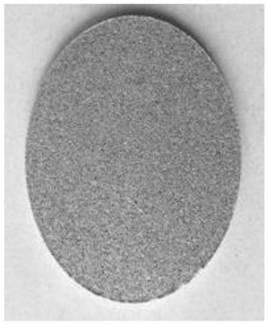

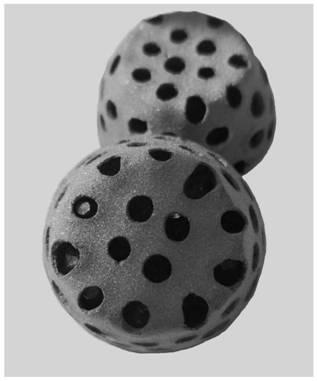

Image

Examples

Embodiment 1

[0032] A preparation method of titanium foam, comprising the following steps:

[0033] S1. Spread a layer of dense plastic film on the bottom of the metal container, and then evenly place coke particles with a particle size of 6mm in the metal container, and then evenly sprinkle in titanium powder with a particle size of 400 mesh, the mixture of coke and titanium powder The volume ratio is 1:1, cover with a press tablet, shake properly to mix well, and compact to obtain a mixed sample;

[0034] S2. Use the cut tube plug of the high temperature tube furnace as the carrier, take the mixed sample out of the plastic film, put it on the carrier, put it into the high temperature furnace together, seal the high temperature furnace, repeatedly evacuate the argon to the furnace The internal impurity gas is exhausted;

[0035] S3. Place the sample in a high-temperature tube furnace, first raise the temperature to 600°C at a rate of 10°C / min, hold for 10 minutes, then raise the temperat...

Embodiment 2

[0037] A preparation method of titanium foam, comprising the following steps:

[0038]S1. Spread a layer of dense plastic film on the bottom of the metal container, and then evenly place coke particles with a particle size of 6mm in the metal container, and then evenly sprinkle in titanium powder with a particle size of 400 mesh, the mixture of coke and titanium powder The volume ratio is 1:1, cover the pressing tablet, and shake it properly to fully mix and compact to obtain a mixed sample;

[0039] S2. Use the cut tube plug of the high temperature tube furnace as the carrier, take the mixed sample out of the plastic film, put it on the carrier, put it into the high temperature furnace together, seal the high temperature furnace, repeatedly evacuate the argon to the furnace The internal impurity gas is exhausted;

[0040] S3. Place the sample in a high-temperature tube furnace, first raise the temperature to 600°C at a rate of 10°C / min, hold for 10 minutes, then raise the te...

Embodiment 3

[0042] A preparation method of titanium foam, comprising the following steps:

[0043] S1. Spread a layer of dense plastic film on the bottom of the metal container, and then evenly place coke particles with a particle size of 6mm in the metal container, and then evenly sprinkle in titanium powder with a particle size of 400 mesh, the mixture of coke and titanium powder The volume ratio is 1:1, cover the pressing tablet, and shake it properly to fully mix and compact to obtain a mixed sample;

[0044] S2. Use the cut tube plug of the high temperature tube furnace as the carrier, take the mixed sample out of the plastic film, put it on the carrier, put it into the high temperature furnace together, seal the high temperature furnace, repeatedly evacuate the argon to the furnace The internal impurity gas is exhausted;

[0045] S3. Place the sample in a high-temperature tube furnace, first raise the temperature to 600°C at a rate of 10°C / min, hold for 10 minutes, then raise the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com