Patents

Literature

42results about How to "Rich in active sites" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Honeycomb wire mesh catalyst for stationary source tail gas denitration and preparation thereof

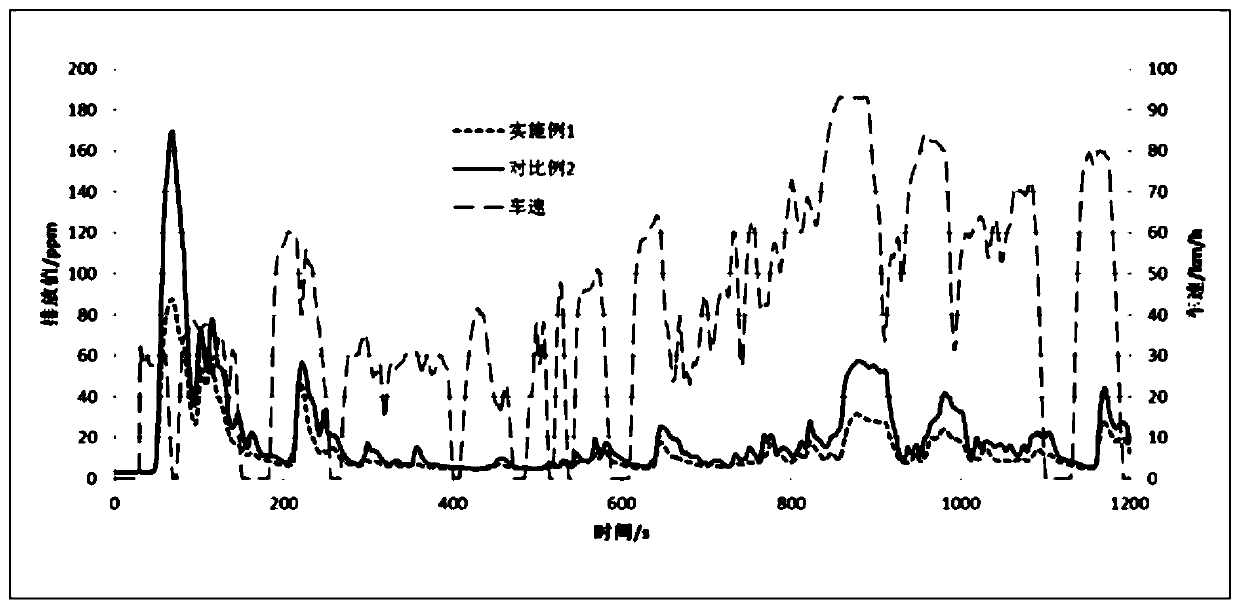

ActiveCN102166515AGood low temperature denitrification activityGood anti-sulfur at low temperatureDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsMoistureSmoke

The invention belongs to the field of the preparation of catalysts for stationary source tail gas denitration, and relates to the preparation of a catalyst by using a honeycomb metal carrier. Tabular and corrugated wire meshes attached with aluminum oxide coatings are stacked alternately and fixedly molded to form a catalyst carrier; a passage inside the carrier has a three-dimensional transparent structure. The preparation is characterized in that: the catalyst is prepared by loading the active components V2O5, WO3 and TiO2 on the surface of the catalyst carrier by a stepwise loading method; the mass sum of the V2O5, the WO3 and the TiO2 is 10-70 percent of the total weight of the aluminum oxide coatings and the V2O5, the WO3 and the TiO2; and the mass of V elements is 0.2-5.6 percent of the mass sum of the V2O5, the WO3 and the TiO2. The catalyst of the invention has low-temperature denitration activity and low-temperature sulfur and water resistant performance; and when the smoke temperature is 250 DEG C, the SO2 concentration is 600 ppm and the moisture content is 10%, the denitration efficiency of the catalyst is above 90%.

Owner:DALIAN UNIV OF TECH

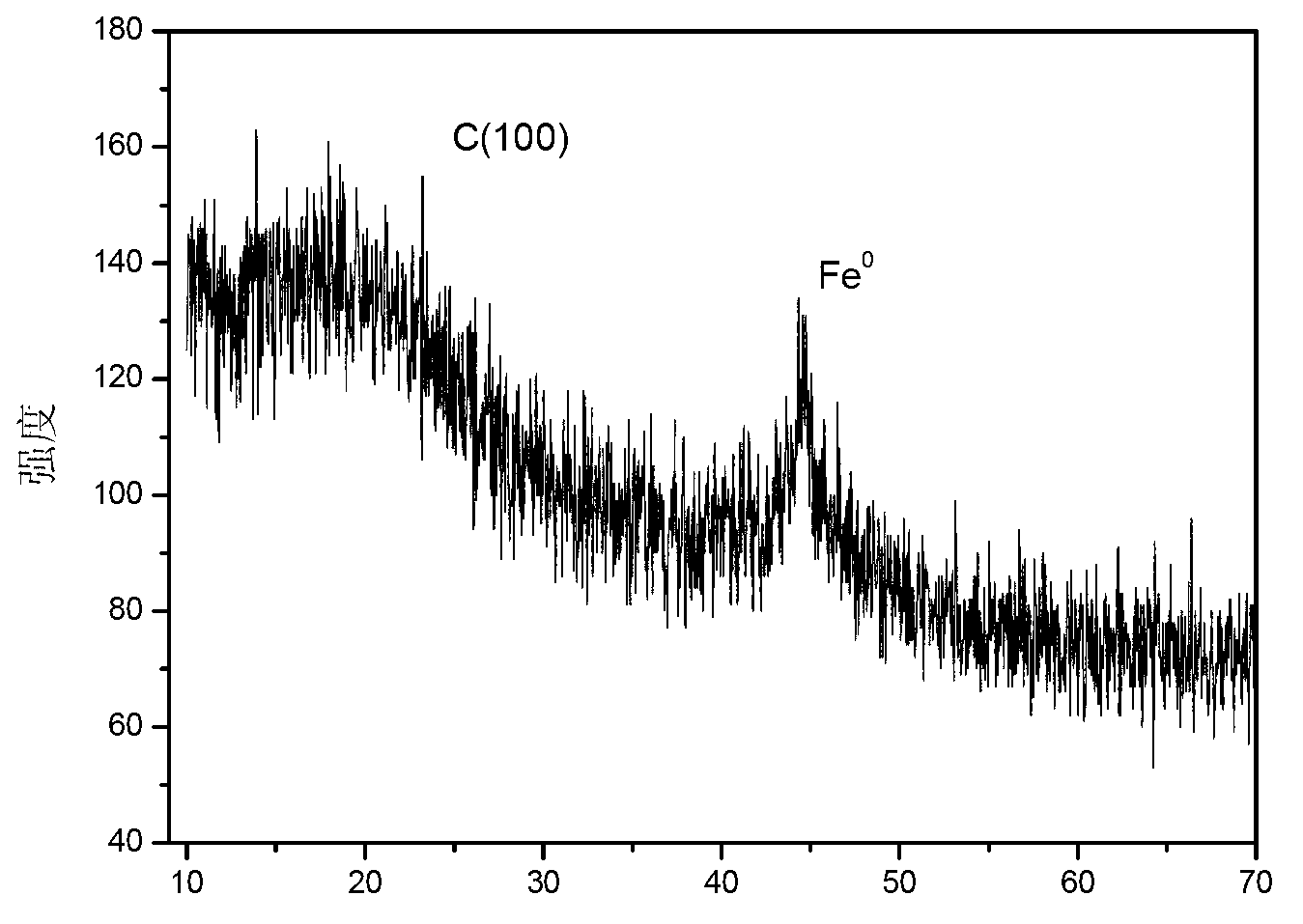

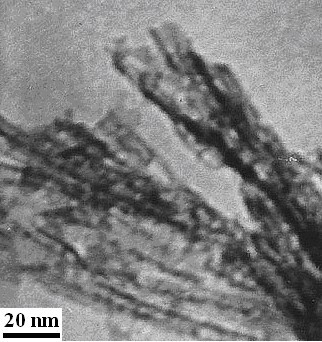

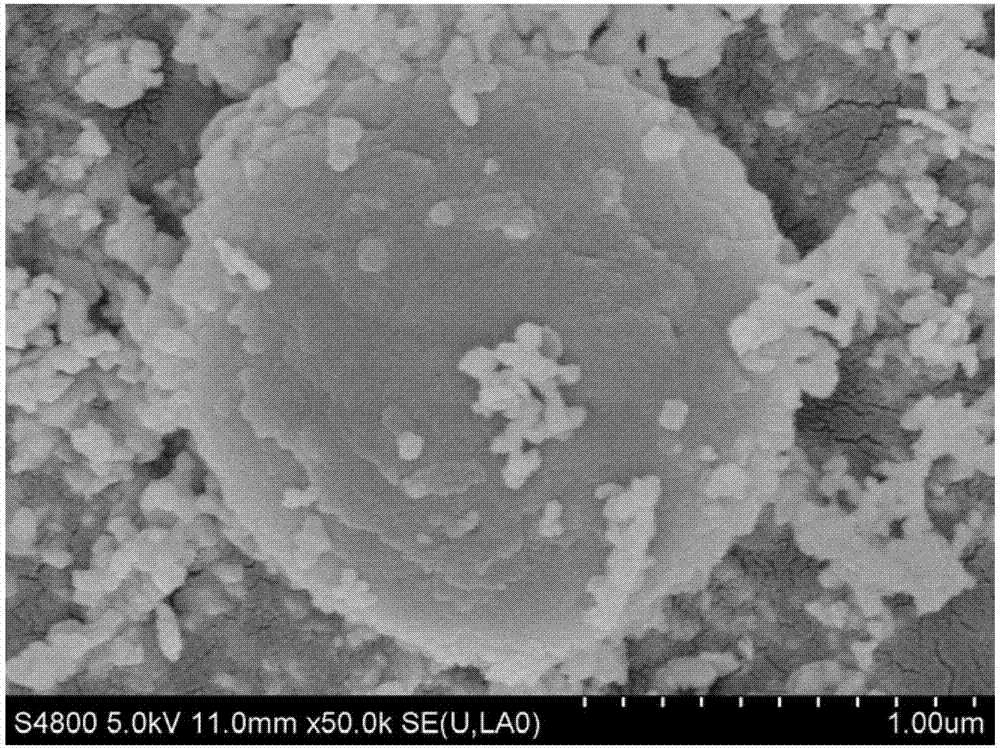

Method for preparing ordered mesoporous carbon loaded nano zero-valent iron composite material

Disclosed is a method for preparing an ordered mesoporous carbon loaded nano zero-valent iron composite material. The whole process of the method is performed under the protection of nitrogen. The method comprises the steps of (1) dissolving ferric salts and ordered mesoporous carbon in an aqueous ethanol solution to prepare a mixed solution; (2) adding a dispersing agent in the prepared mixed solution, and adjusting the pH to 6.0-6.8; (3) adding dropwise a NaBH4 or KBH4 solution in the mixed solution, and stirring continuously for reaction after adding dropwise; and (4) separating and drying the composite material in the mixed solution to obtain the ordered mesoporous carbon loaded nano zero-valent iron composite material of the required load rate. The method is simple in process, low in cost, simple in required equipment and easy to implement. The prepared material has the advantages of small particle sizes and high surface activity and reducibility of nano zero-valent iron as well as ordered hole ways, large specific surface area and high adsorbability of ordered mesoporous carbon simultaneously. The method can be widely applied to treatment and restoration of water environments.

Owner:SHANDONG UNIV

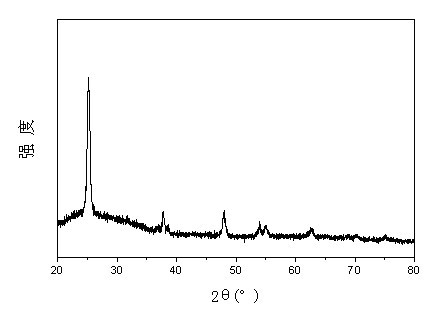

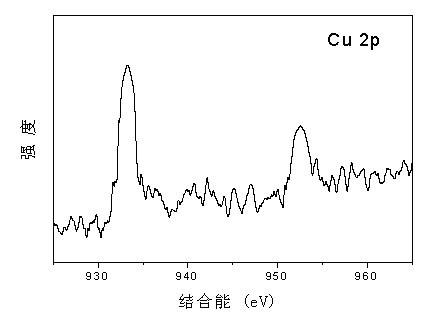

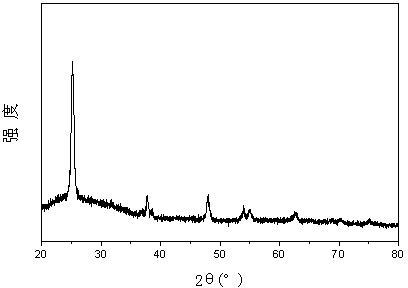

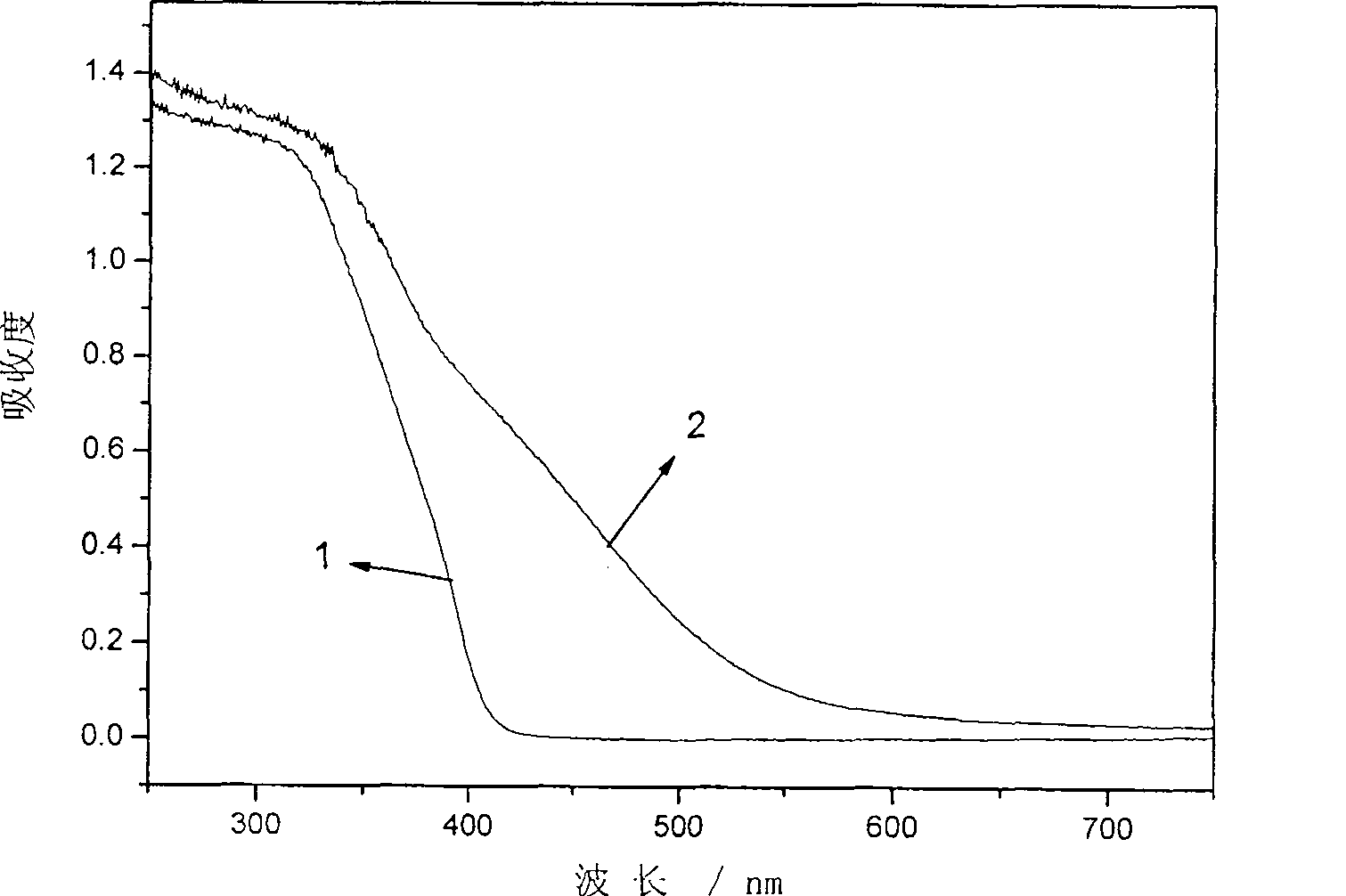

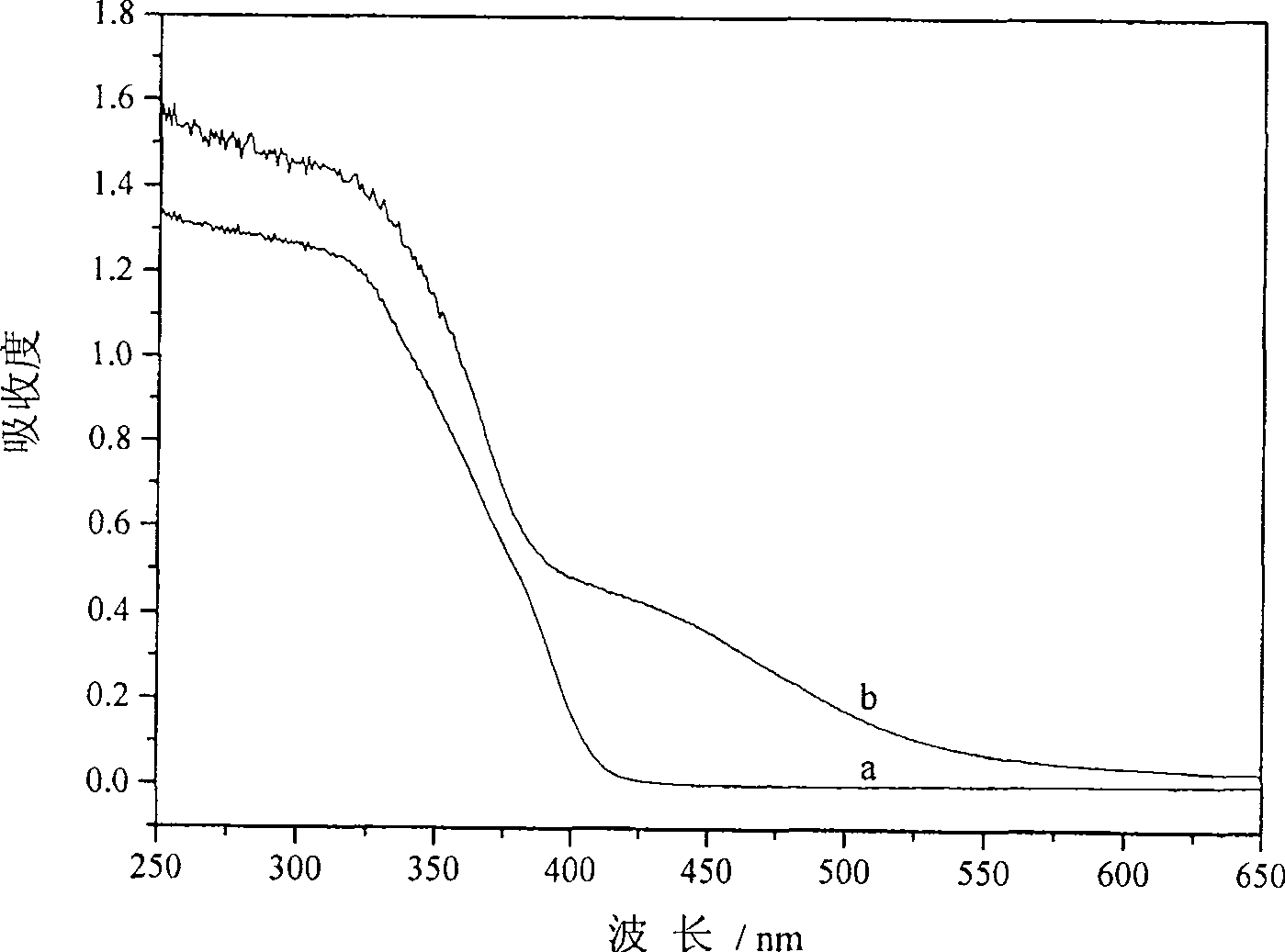

Copper and bismuth co-doped nano titanium dioxide photocatalyst and preparation and application thereof

ActiveCN102500388AIncrease profitExcellent visible light catalytic activityHydrocarbon from carbon oxidesOrganic compound preparationTitaniumCopper

The invention belongs to the technical field of a nano titanium dioxide photocatalyst, and particularly relates to a copper and bismuth co-doped nano titanium dioxide photocatalyst and preparation and application thereof. In the photocatalyst, in molar fraction, the doping amount of copper is 0.2-3.0%, and the doping amount of titanium is 0.5-5.0%. The copper and bismuth co-doped nano titanium dioxide photocatalyst disclosed by the invention is in an anatase type, is used for the reaction for preparing methane, methanol, and the like by photocatalytic reduction CO2, has the advantages that the photon efficiency is high, specific surface area is large, and CO2 adsorption ability is strong, and simultaneously, has visual photocatalytic activity and high sunlight utilization rate.

Owner:HENAN POLYTECHNIC UNIV

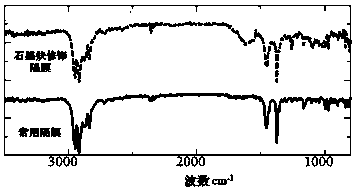

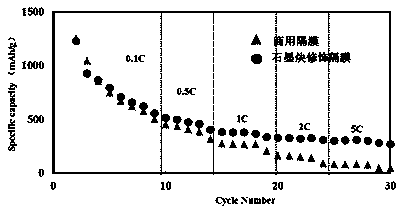

Preparation and application of graphdiyne material modified diaphragm

InactiveCN108963149ATightly boundImprove insulation defectsLi-accumulatorsCell component detailsChemistryIn situ polymerization

Belonging to the technical field of energy materials, the invention in particular relates to preparation and application of a graphdiyne material modified diaphragm. Directed at the problems of low electron conductivity, poor cyclic stability, the shuttle effect of lithium polysulfide and the like in existing lithium-sulfur battery diaphragms, solution in-situ polymerization is applied for deposition of a graphdiyne carbon nanomaterial on a commercial diaphragm. Preparation of the diaphragm mainly includes the steps of: preparation of a graphdiyne monomer serving as a carbon protective layer and deposition of a graphdiyne material in a solution on the surface of a commercial diaphragm. The graphdiyne material modified diaphragm prepared by the method has the characteristics of simple and controllable preparation process, easy large-scale preparation, stable material structure, etc. The prepared diaphragm can reduce the shuttle effect of polysulfides in the electrochemical reaction process, and improves the capacity and cycle performance of energy storage devices.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

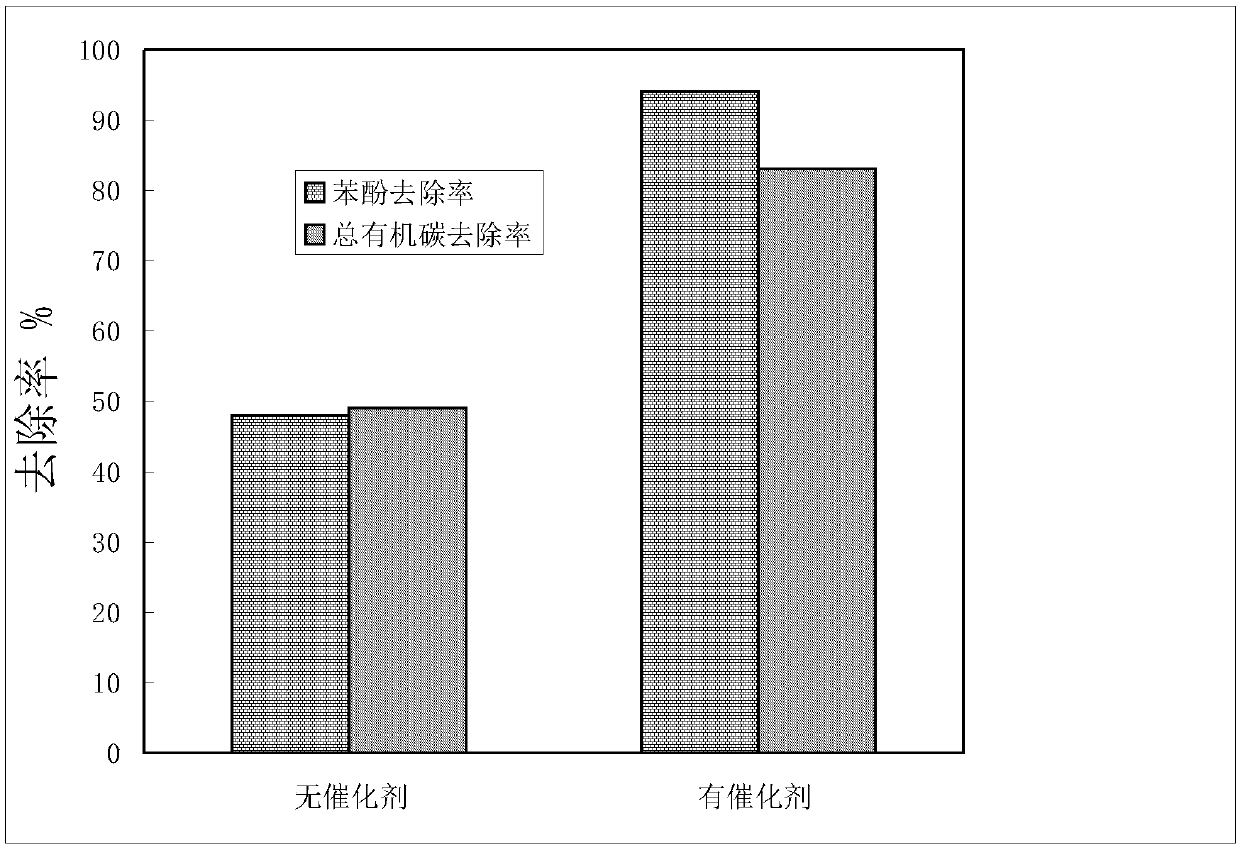

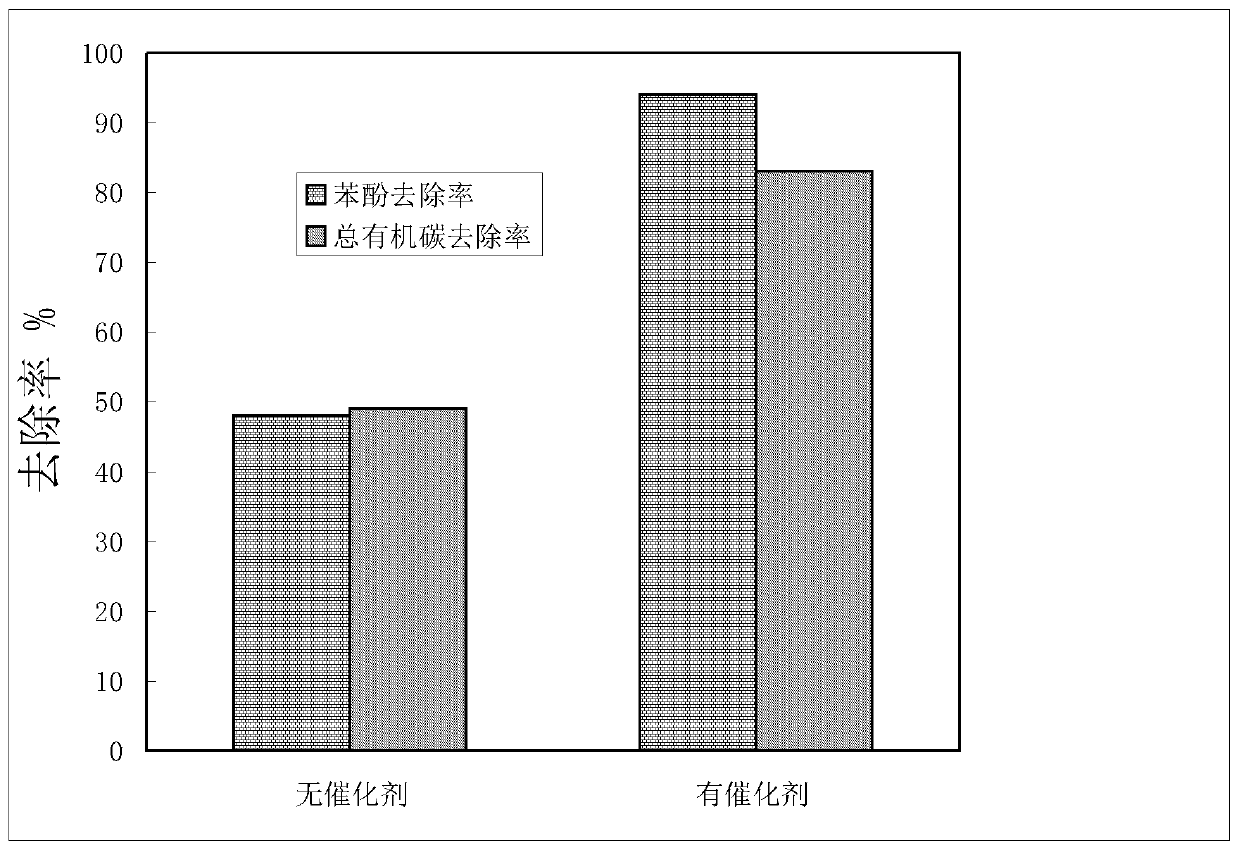

Preparation method of ozone catalytic decomposition catalyst using expandable graphite as carrier

ActiveCN107744806ASimple processLow costWater treatment compoundsCatalyst activation/preparationDiethylenetriamineCerium

The invention provides a preparation method of an ozone catalytic decomposition catalyst using expandable graphite as a carrier. The method comprises the following steps: sequentially carrying out ozone oxidation, chemical oxidation intercalation, diethylenetriamine amination and cerium ion impregnation loading treatment on flake graphite, and then carrying out microwave expanding treatment to obtain active component cerium supported expanded graphite; and carrying out impregnating treatment, manganese ion loading treatment and high temperature sintering treatment on the prepared expanded graphite to prepare the catalyst adopting the expanded graphite as the carrier and loaded with active components cerium and manganese. The prepared catalyst can highly-efficiently catalyze ozone to generate hydroxy free radicals in order to realize excellent removal of non-degradable highly-toxic organic pollutants in the water environment, so the catalyst has an expected application prospect in the field of wastewater pollution treatment.

Owner:秦皇岛晟创科技有限公司

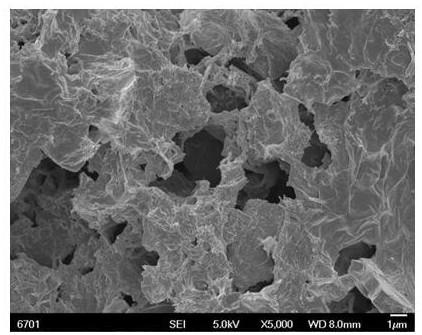

Ferric oxide/attapulgite/three-dimensional graphene oxide heterogeneous catalyst and preparation method thereof

InactiveCN109759045AImprove catalytic performanceIncrease the areaCatalyst carriersWater contaminantsActivated attapulgiteWastewater

The invention discloses a preparation method of a ferric oxide / attapulgite / three-dimensional graphene oxide heterogeneous catalyst. According to the catalyst, a carrier prepared from attapulgite and three-dimensional graphene oxide through compounding is adopted, the carrier is loaded with ferric oxide nanoparticles, and the catalyst can be applied to catalyzed degradation treatment of refractoryorganic wastewater. The preparation method comprises the steps of firstly, purifying and activating the attapulgite, mixing the activated attapulgite with home-made graphene oxide, carrying out molding, carrying out drying, and then, loading the surface of the attapulgite / three-dimensional graphene composite carrier with the ferric oxide nanoparticles, thereby obtaining the ferric oxide / attapulgite / three-dimensional graphene oxide heterogeneous catalyst. The preparation method of the catalyst is relatively simple, does not need special equipment and is low in cost and good in repeatability; the prepared catalyst is good in catalysis performance and wide in pH range, can be reused and can be used at the temperature of 20 DEG C to 80 DEG C. Secondary pollution is not caused, and the catalystcan be extensively applied to the fields of treatment of the refractory organic wastewater.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

Production method for preparing sorbic acid by catalyzing depolymerization of sorbic acid polyester with solid base catalyst

InactiveCN111454142ANo wasteWith green cleaningOxygen-containing compound preparationMolecular sieve catalystsPolyesterMolecular sieve

The invention belongs to the technical field of preparation of sorbic acid and relates to a production method for preparing sorbic acid by catalyzing depolymerization of sorbic acid polyester with a solid base catalyst. The production method comprises the following steps: (1) putting sorbic acid polyester into a reaction kettle, then adding deionized water and the solid base catalyst, stirring, heating to a catalytic temperature of 30-60 DEG C, and carrying out a base catalytic reaction for 10-20 min, (2) after the reaction is finished, raising the temperature to 100-150 DEG C for sublimation,and condensing and collecting sorbic acid to obtain a crude sorbic acid product, and (3) washing the crude sorbic acid with hot water at 80-100 DEG C, cooling, crystallizing and drying to obtain sorbic acid, wherein the solid base catalyst is a catalyst which takes a molecular sieve as a carrier and is loaded with an alkali metal compound. The method does not generate a waste liquid, has the advantages of environment friendliness, cleanness, high atom economy and no three wastes, is mild in reaction and low in energy consumption, and can increase the yield of sorbic acid and reduce tar byproducts.

Owner:江苏润普食品科技股份有限公司

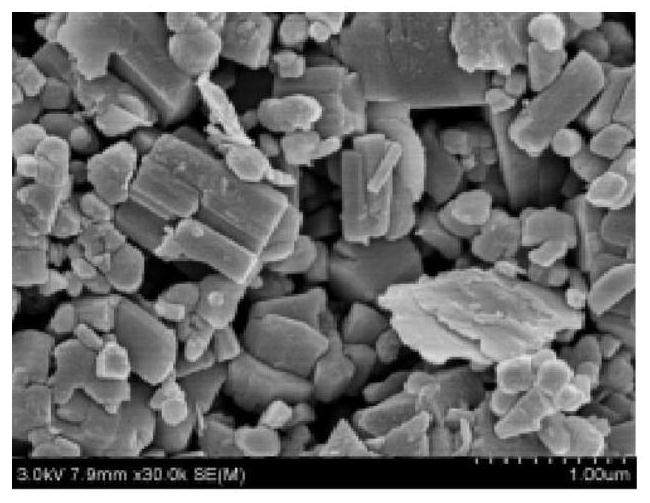

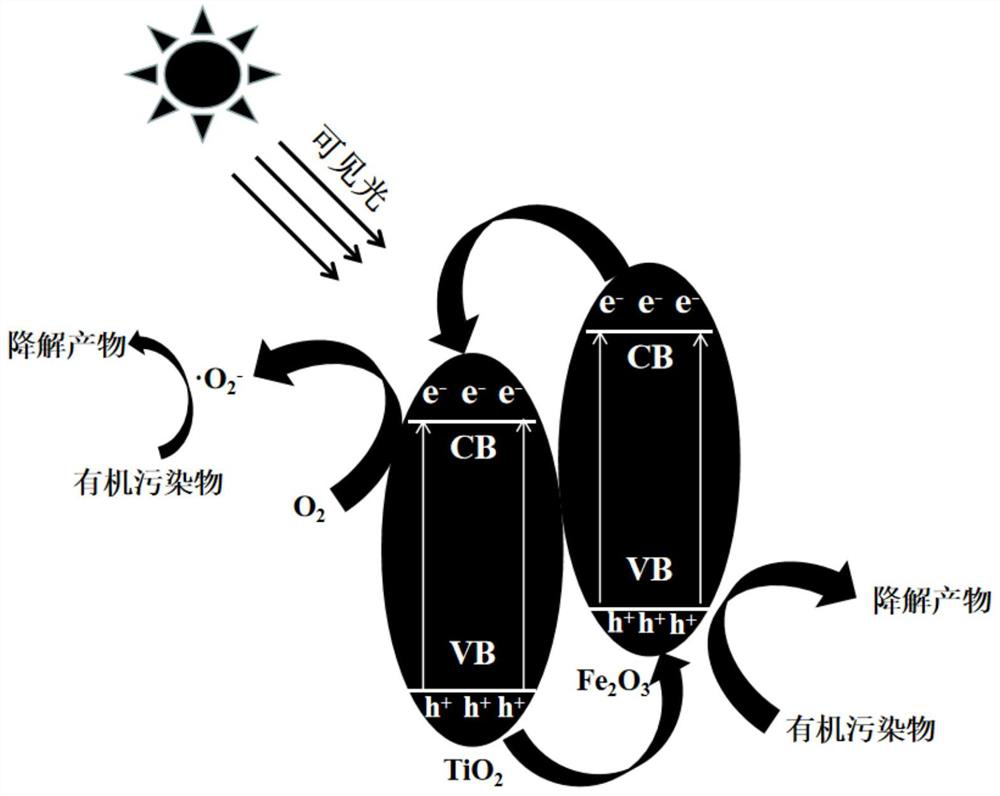

Preparation method of composite heterojunction photocatalyst and application thereof

ActiveCN111992216AImprove photocatalytic activitySimple and efficient operationWater/sewage treatment by irradiationWater contaminantsPhoto catalysisAluminium

The invention discloses a preparation method of a composite heterojunction photocatalyst and an application thereof, and belongs to the field of resource utilization and environment purification. Thecomposite heterojunction photocatalyst comprises 5-30 parts of high-iron red mud and 5-30 parts of a reducing agent. The preparation method comprises the following steps: uniformly mixing the high-iron red mud and the reducing agent, and molding under the pressure of 0.5-3MPa; calcining the obtained mixture at the temperature of 200 to 400 DEG C; and finally, taking out the mixture, grinding and sieving to obtain the photocatalyst. According to the method, Fe2O3 in the high-iron red mud is partially converted into magnetic Fe3O4 in a biomass pyrolysis mode, so that the catalyst has magnetism and is convenient to recycle; in the calcining process, silicon-aluminum minerals of the high-iron red mud are combined with Fe2O3 and TiO2, so that Fe2O3 and TiO2 generate heterojunctions; the pyrolysis product carbon is combined with catalyst particles, so that the adsorption and conductivity of the catalyst are improved; the degradation efficiency of the catalyst is favorably improved; accordingto the method, the low-molecular pollutants which are not thoroughly degraded can be adsorbed to the surface of the catalyst to be degraded again, secondary pollution is prevented, the whole degradation process is easy to operate, and the self-cleaning purpose is effectively achieved. The adopted raw materials are easily available and economically feasible.

Owner:UNIV OF SCI & TECH BEIJING

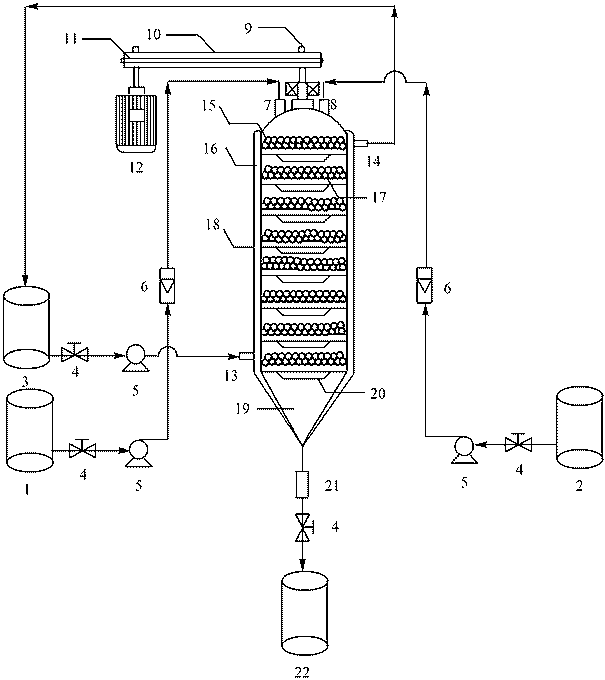

Device and method for preparing biodiesel through rotary fixed bed fast reaction

ActiveCN105713734AAvoid the uneven distribution of rotation and centrifugal forceAvoid uneven distributionFatty acid esterificationBiofuelsAlcoholCentrifugation

The invention provides a device and method for preparing biodiesel through a rotary fixed bed fast reaction. The device is mainly composed of a fixed bed reactor with a rotary shaft (9). Firstly, the fixed bed reactor filled with a solid catalyst is added to reactant methyl alcohol, and meanwhile a motor (12) is started to enable a reaction still to rotate. The dropping speed of raw material oil is controlled, and the oil and excessive methyl alcohol are subjected to the fast reaction. The contact chance of the reactant and the catalyst can be increased through rotating, more active point locations can be occupied, and sinking and separation of fatty acid methyl ester can be promoted. By means of a liquid redistributor, the phenomenon that liquid is unevenly distributed due to rotary centrifugation is avoided. The layering condition of sight glass (21) is observed, and products are removed in time. A forward reversible reaction can be accelerated through excessive methyl alcohol, timely removal of the products and the rotary reaction still. The advantages of being easy to operate, high in raw material utilization rate, high in esterification efficiency and the like are achieved, and the device and method can be used for fast and continuous preparation of the biodiesel.

Owner:SHANDONG UNIV OF TECH

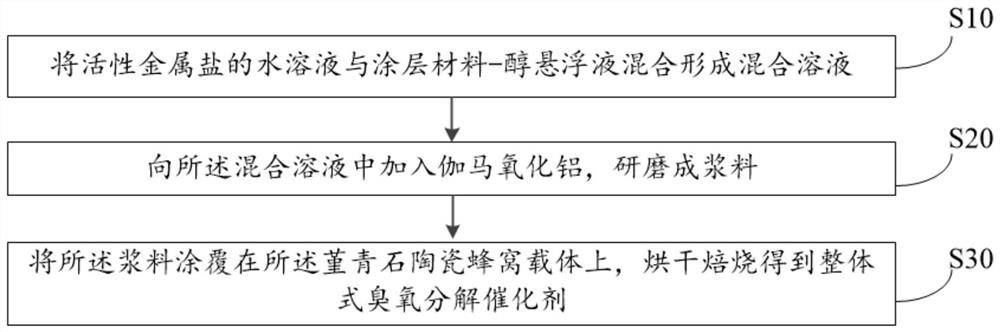

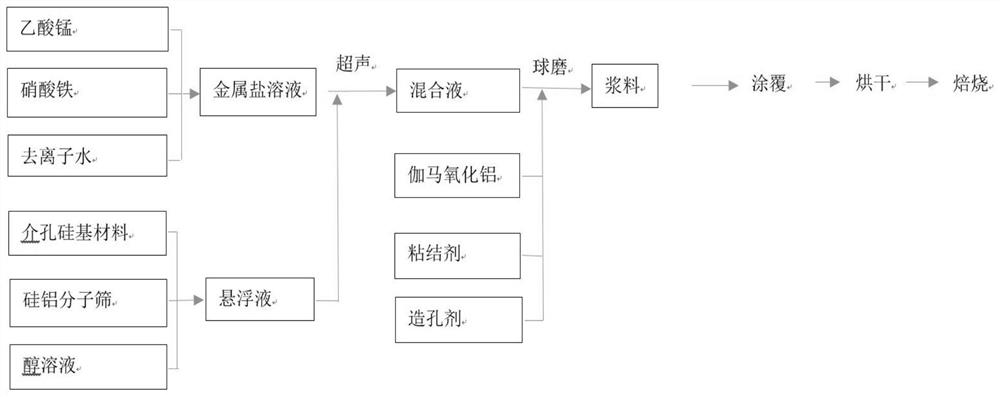

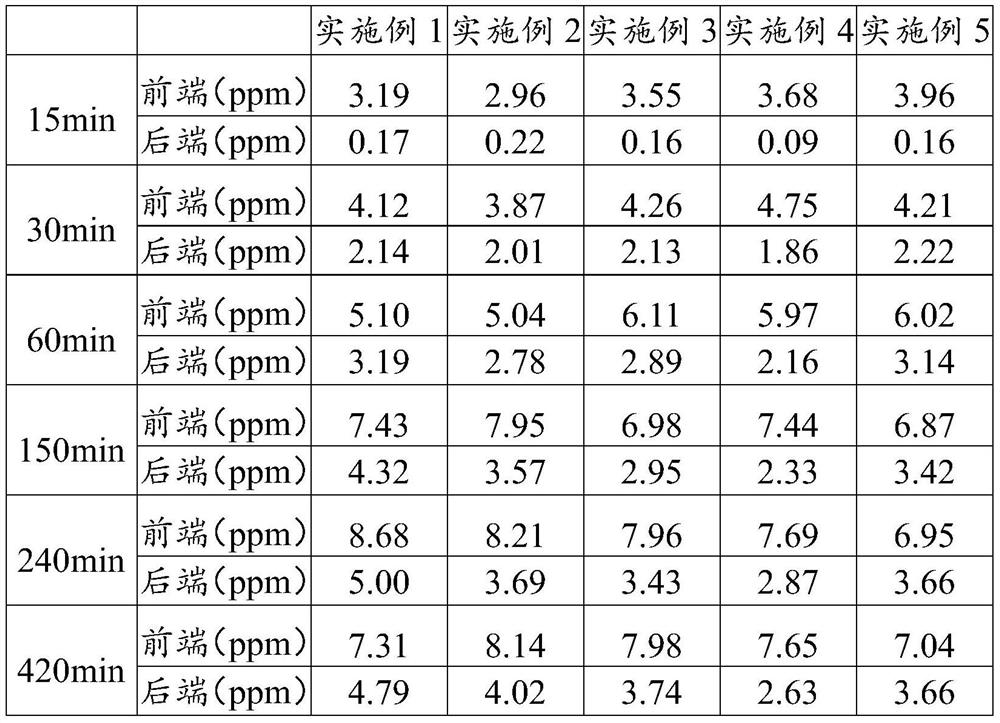

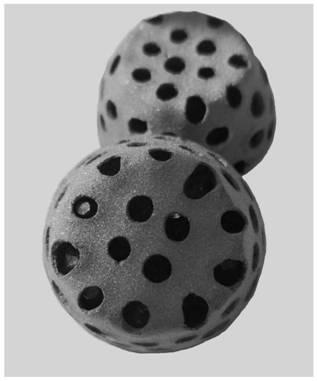

Integral ozonolysis catalyst and preparation method thereof

PendingCN112705217ARich microscopic surface structureRich in active sitesGas treatmentMolecular sieve catalystsComposite materialMolecular sieve

The invention discloses an integral ozonolysis catalyst and a preparation method thereof. The integral ozonolysis catalyst comprises a cordierite ceramic honeycomb carrier and a coating applied to the surface of the cordierite ceramic honeycomb carrier, and the coating comprises active metal oxide, gamma aluminum oxide and a coating material; wherein the coating material comprises at least one of a silicon-based mesoporous material and a silicon-aluminum molecular sieve. According to the invention, the cordierite ceramic honeycomb is selected as a carrier, and the cordierite ceramic honeycomb has a regular pore structure and a large specific surface area, so the wind resistance of the catalyst is well reduced, and the decomposition efficiency is improved; at least one of a silicon-based mesoporous material and a silicon-aluminum molecular sieve is selected as a coating material, and the surface of a carrier is coated with the coating material, so that the catalyst has a rich microcosmic surface structure, the catalyst has rich active sites, water vapor is more easily separated from the active sites under high humidity, and the catalyst is ensured to still have considerable decomposition efficiency under high humidity.

Owner:SHENZHEN TIANDEYI ENVIRONMENT TECH

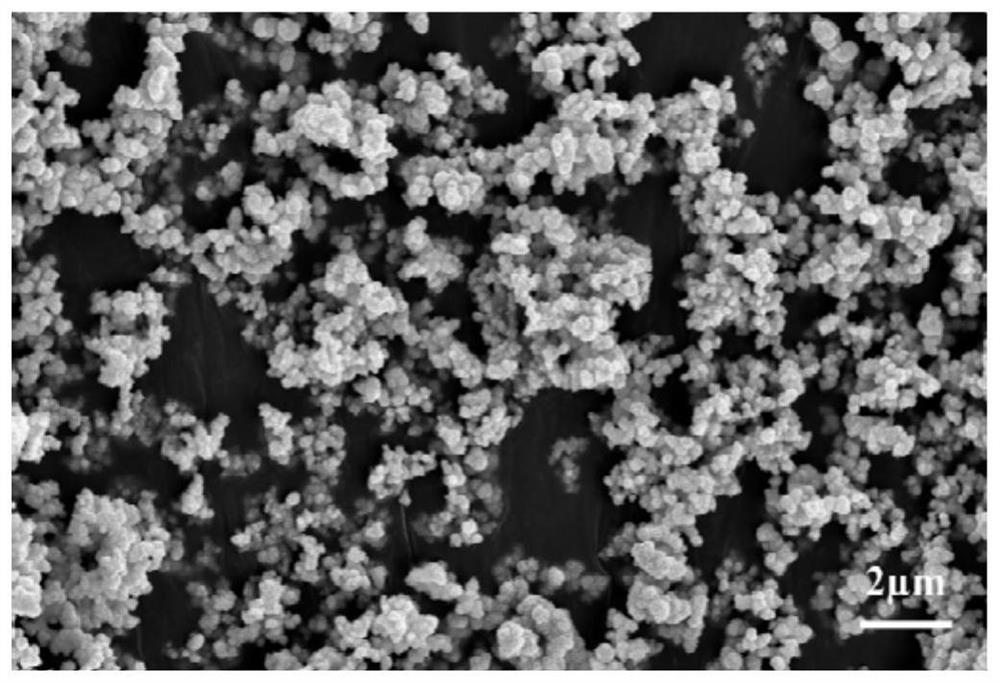

Flower cluster shaped calcium vanadate microsphere and preparation method thereof

The invention discloses a flower cluster shaped calcium vanadate microsphere and a preparation method thereof. The method has the advantages of easy availability of raw materials, simple process, lowenergy consumption, less agglomeration and easy implementation, wherein ethylene glycol and water are used as double solvents, the flower cluster shaped calcium vanadate microsphere can be formed, andthe clusters in each flower cluster shaped calcium vanadate microsphere are more dense; by using double solvents, the overall reaction time is shortened; at that same time, a high-pressure reaction kettle is adopted, the temperature and pressure can be controlled, and the close reaction environment makes the size of the prepared flower cluster shaped calcium vanadate more uniform, and the qualification rate of the shape of the flower cluster shaped calcium vanadate microsphere is higher, and the prepared flower cluster shaped calcium vanadate microsphere are in the flower cluster shape, and the clusters are dense, so that the active sites in the microspheres are more and the specific surface area is larger; when the microspheres are applied to the conductive thin film materials, the ion transport rate of the microspheres is high, the electron transport ability is strong, and the conductive ability is strong because of the large number of active sites.

Owner:SHAANXI UNIV OF SCI & TECH

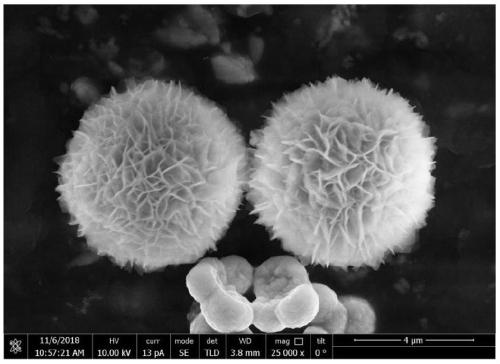

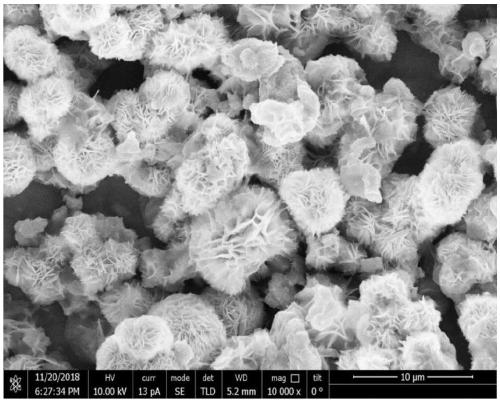

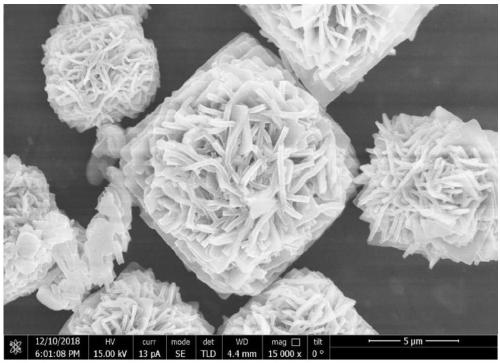

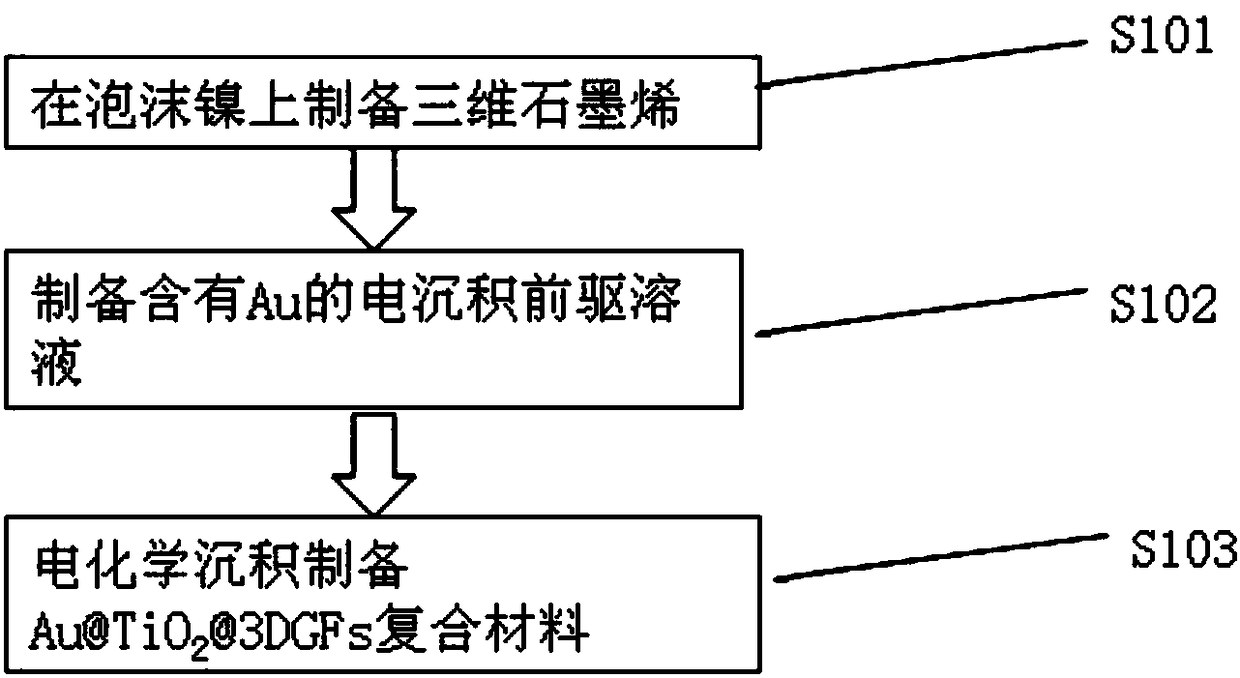

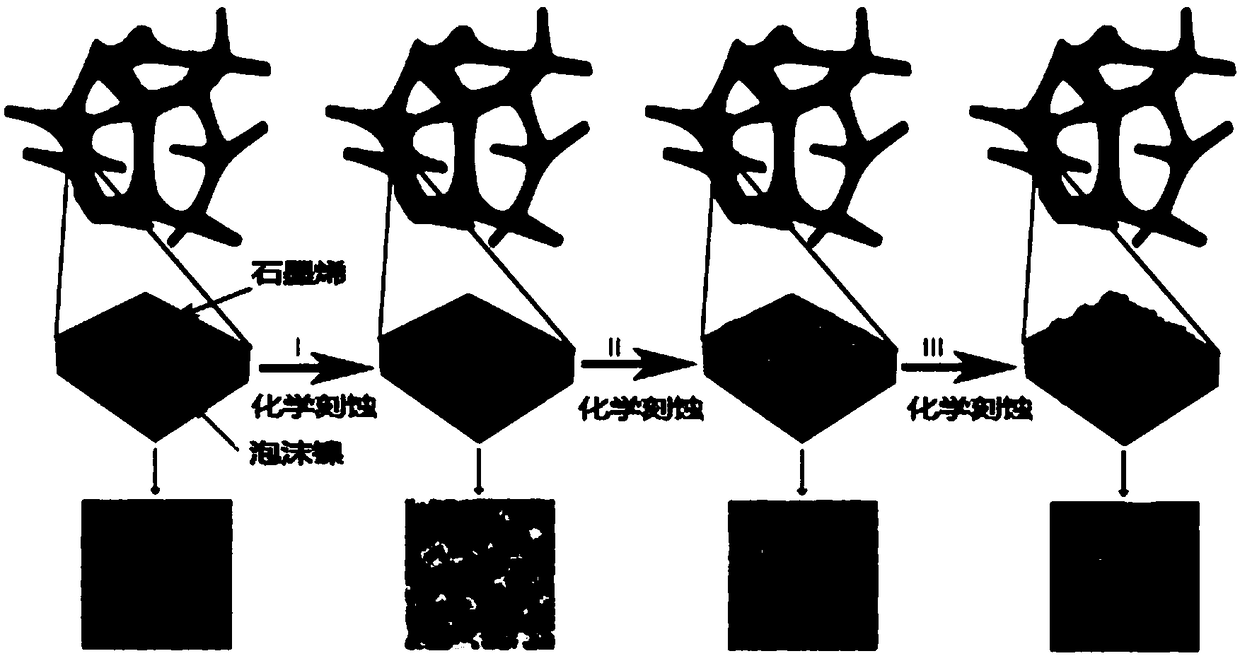

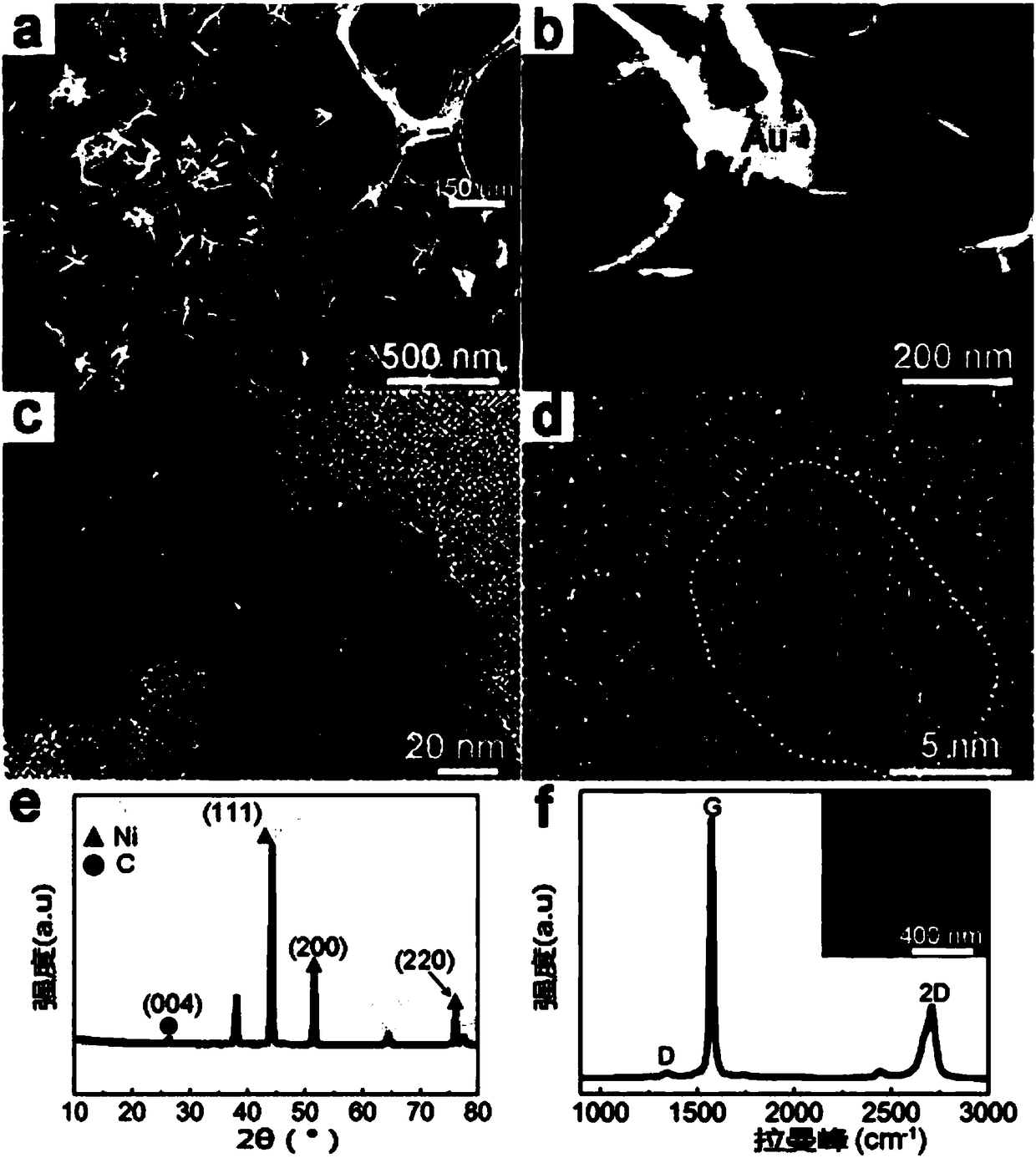

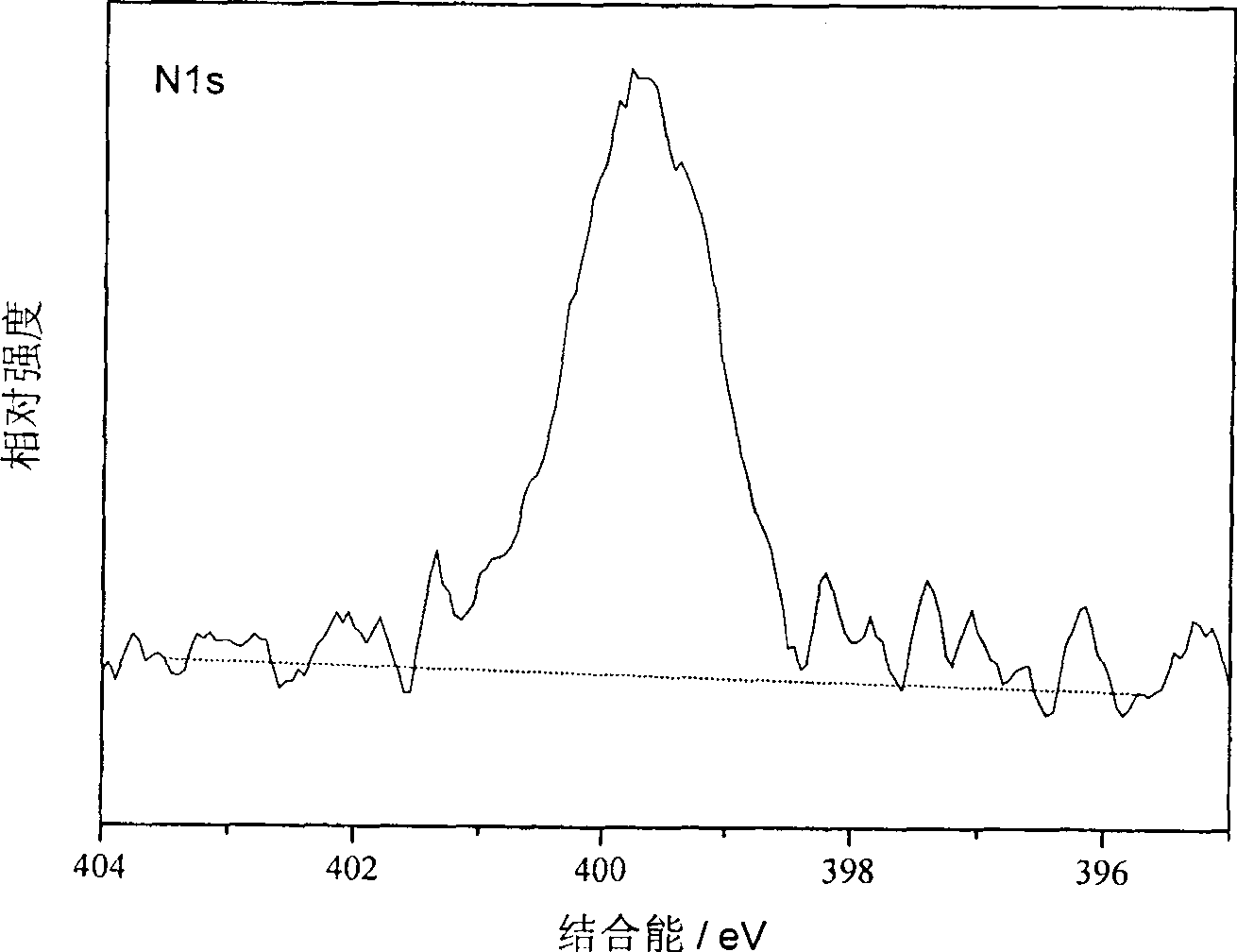

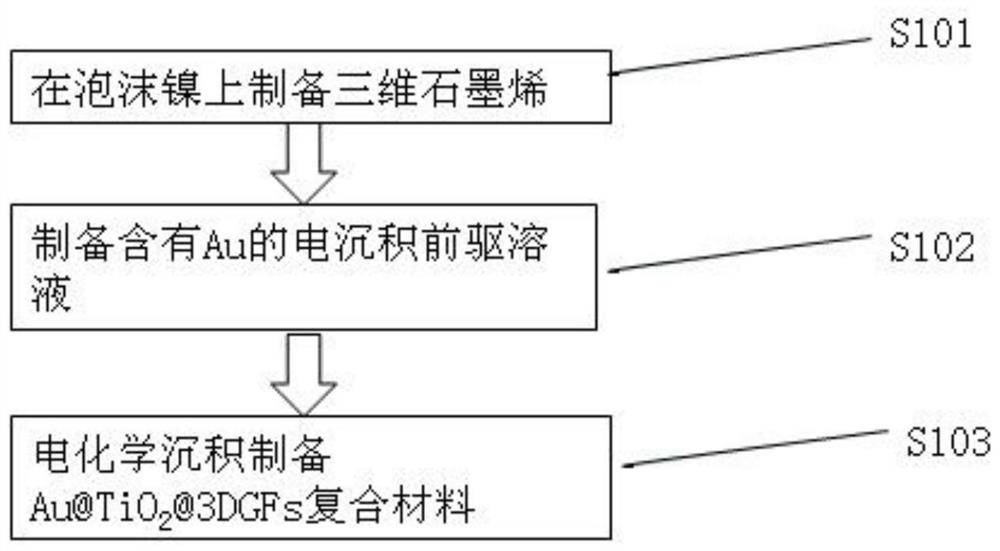

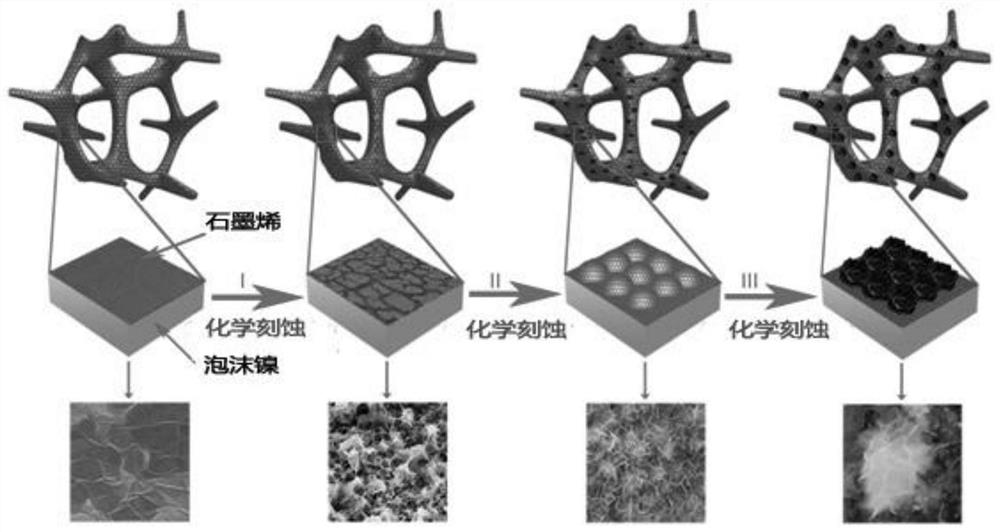

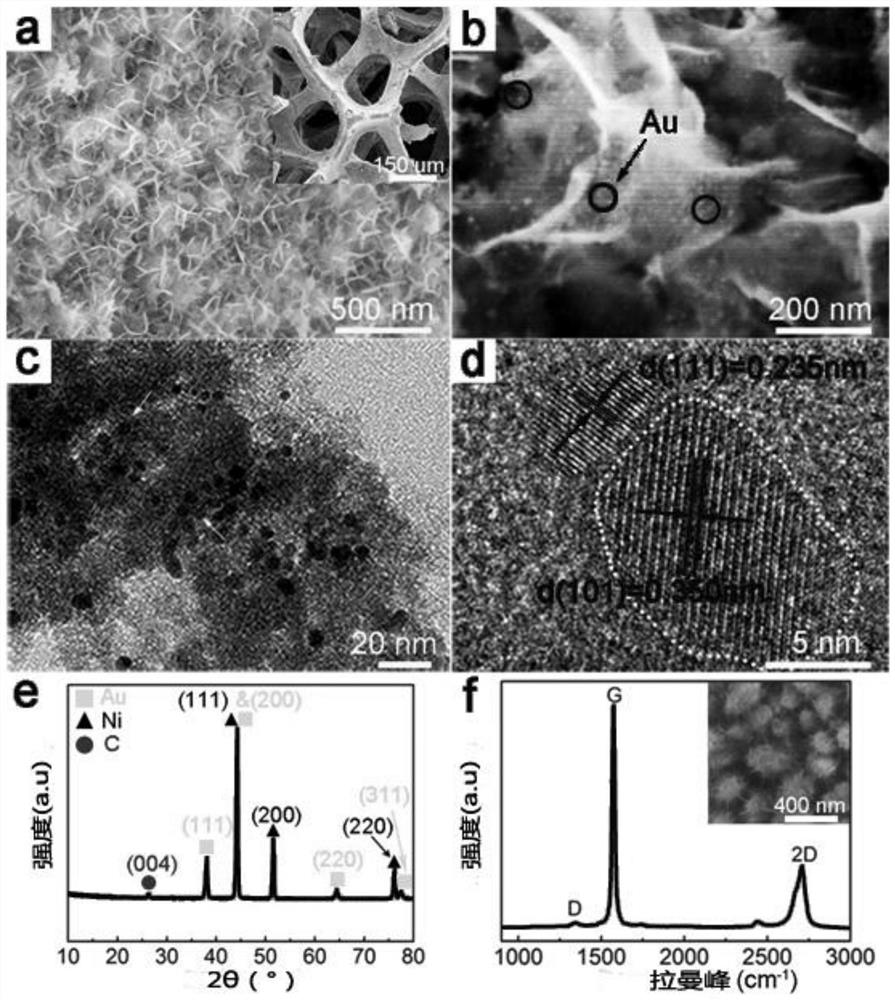

Preparation method of double-quantum dot modified flower-like three-dimensional graphene and photocatalytic material

ActiveCN108246287AEfficient electron transportEfficient photocatalytic activityCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsElectron holeFlower like

The invention discloses a preparation method of a double-quantum dot modified flower-like three-dimensional graphene and a photocatalytic material. Specifically, the method includes: preparing three-dimensional graphene on foam nickel; preparing an electrodeposition precursor solution containing Au; and preparing an Au@TiO2@3DGFs composite material by electrochemical deposition: putting a three-dimensional graphene into the precursor solution to serve as a working electrode for deposition of TiO2 and noble metal Au double quantum dots, thus forming flower-like three-dimensional graphene with Au and TiO2 double quantum dots evenly distributed on the surface in the electrochemical deposition process. The three-dimensional graphene electron-hole pair prepared by the method provided by the invention has the characteristics of low recombination rate, high photoelectrocatalytic activity, and high sunlight utilization.

Owner:XIFENG 2D FUJIAN MATERIAL TECH CO LTD

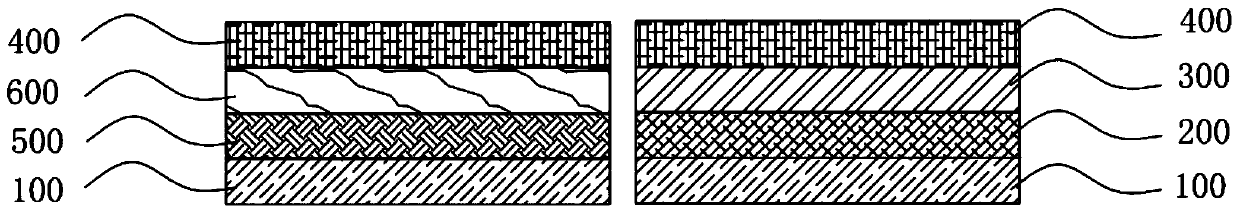

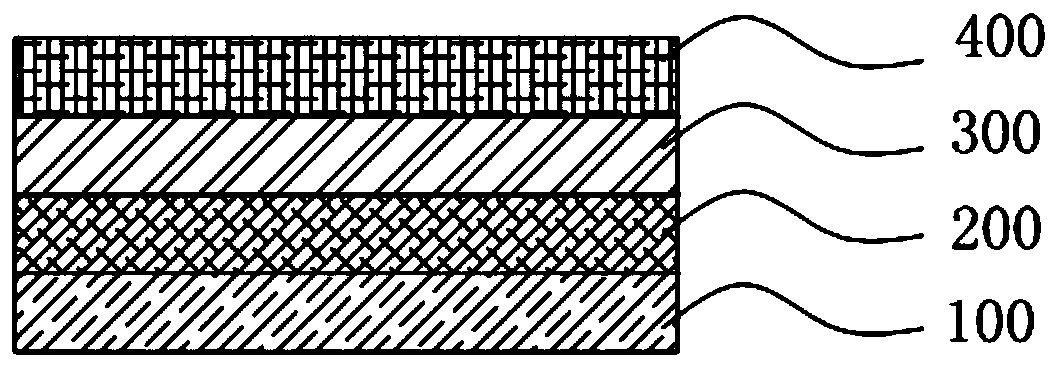

Catalyst and preparation method and application thereof

ActiveCN111530283AImprove adsorption capacityImprove stabilityMolecular sieve catalystsInternal combustion piston enginesMolecular sievePlatinum

The invention belongs to the field of catalysts, and discloses a catalyst, which contains modified alumina and / or a modified beta molecular sieve. The modified beta molecular sieve is a beta molecularsieve modified by at least one of Ag, Fe, Pt or Rh; the molar ratio of SiO2 to Al2O3 in the modified beta molecular sieve is (150-200): 1. Specifically, the catalyst sequentially comprises a substrate, a second carrier layer, a third noble metal layer and a second noble metal layer from bottom to top; the second carrier layer comprises an oxygen storage material and a modified beta molecular sieve; the third noble metal layer contains an oxygen storage material, platinum and / or rhodium and a modified beta molecular sieve, and platinum or rhodium is loaded in the modified beta molecular sieve;and the second noble metal layer contains an oxygen storage material, platinum, rhodium and modified aluminum oxide, the platinum is loaded in the oxygen storage material, and the rhodium is simultaneously loaded in the oxygen storage material and the modified aluminum oxide. The catalyst has long-lasting HC purification performance, meets the European V emission standard, and is particularly suitable for motorcycle tail gas purification treatment.

Owner:JIANGMEN DACHANGJIANG GROUP CO LTD

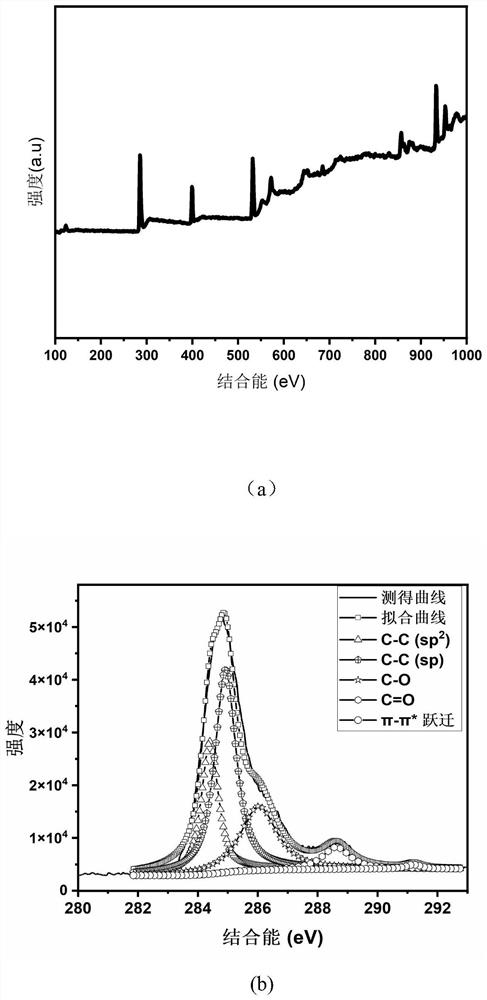

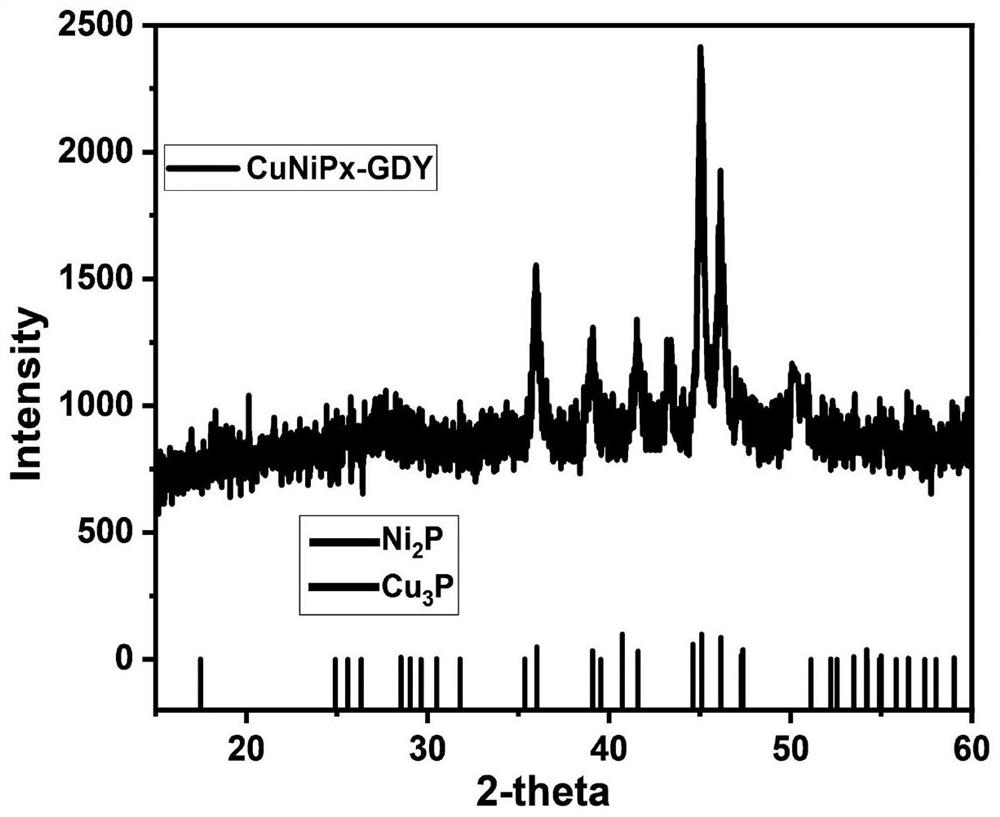

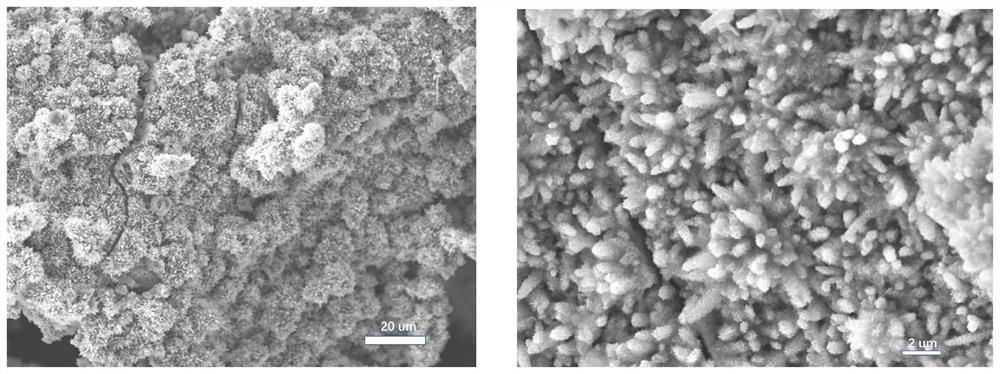

Self-supporting layered bimetallic phosphide-graphdiyne composite catalyst as well as preparation method and application thereof

The invention relates to a self-supporting layered bimetallic phosphide-graphdiyne composite catalyst. The catalyst comprises a carrier and an active component, and the active component is a self-supporting layered composite material formed by uniformly dispersing bimetallic phosphide nano particles on graphdiyne; the composite material has a multi-stage ordered structure, and an atomic-scale heterojunction structure is arranged between bimetallic phosphides; the carrier is selected from one or more of foamed nickel, foamed copper, carbon cloth, aluminum oxide and titanium oxide; and the double metals are selected from two of copper, nickel, iron, cobalt, manganese, zinc and molybdenum. The nano electrocatalyst has abundant interface defects and vacancies, enriches active sites, improves the electron interaction, and improves the electrocatalytic performance. In the whole water separation process, the stability is excellent, attenuation will not happen within 24 hours, and the catalyst is suitable for the fields of HER, OER and electrochemical complete water splitting.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

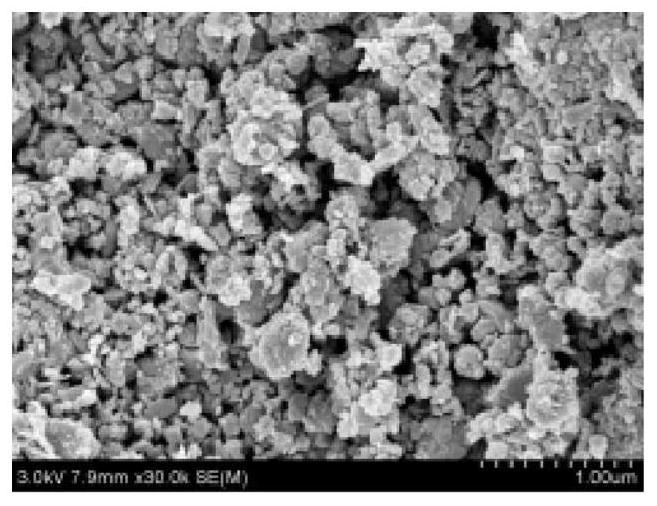

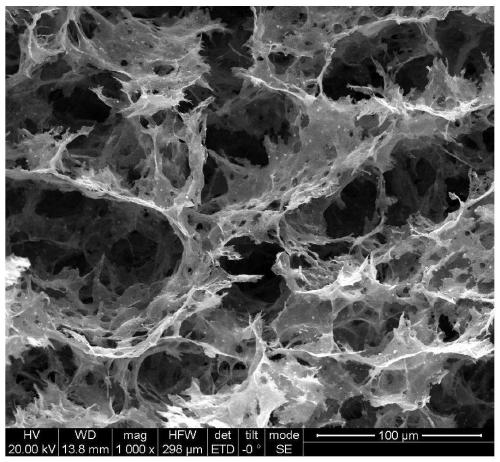

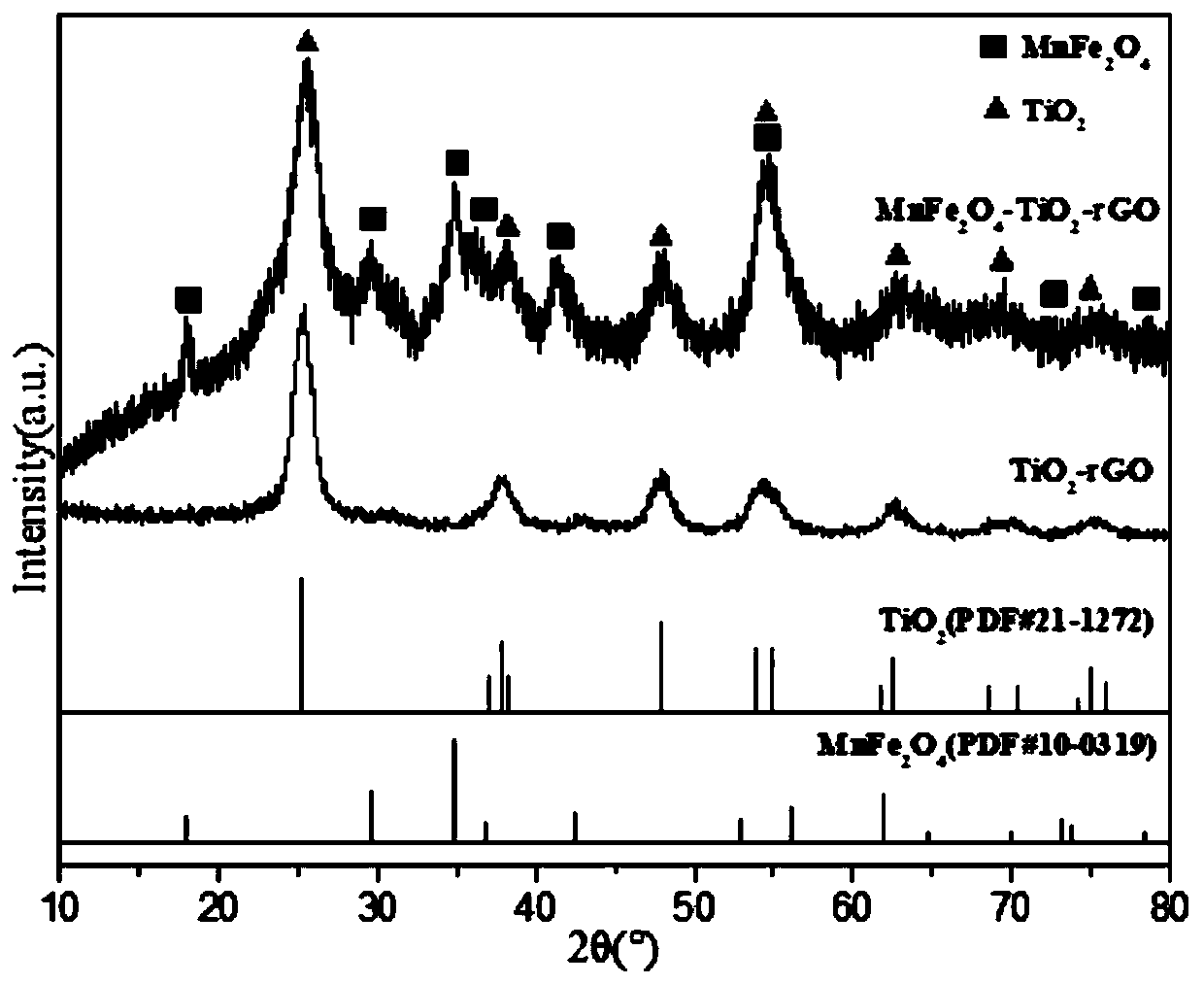

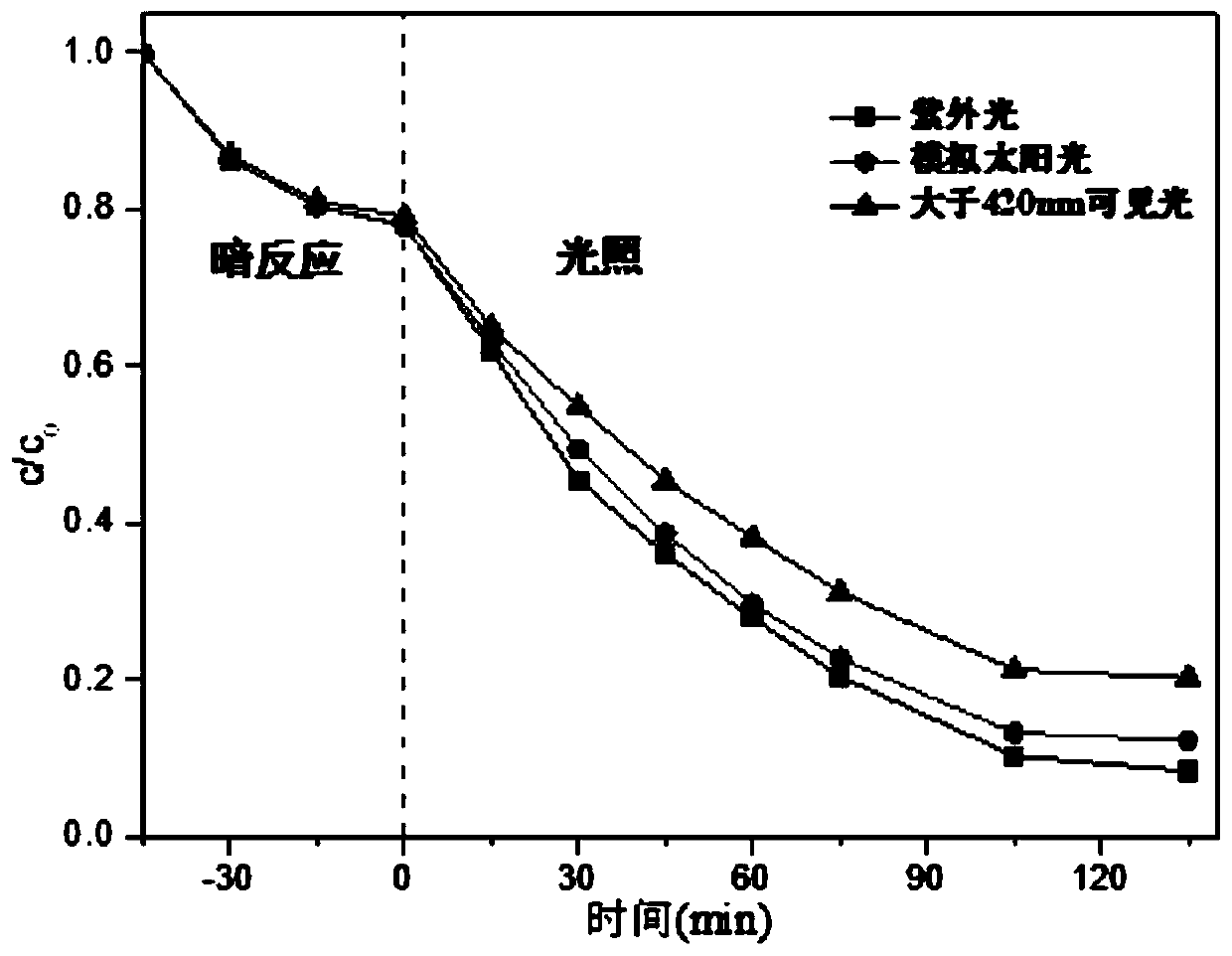

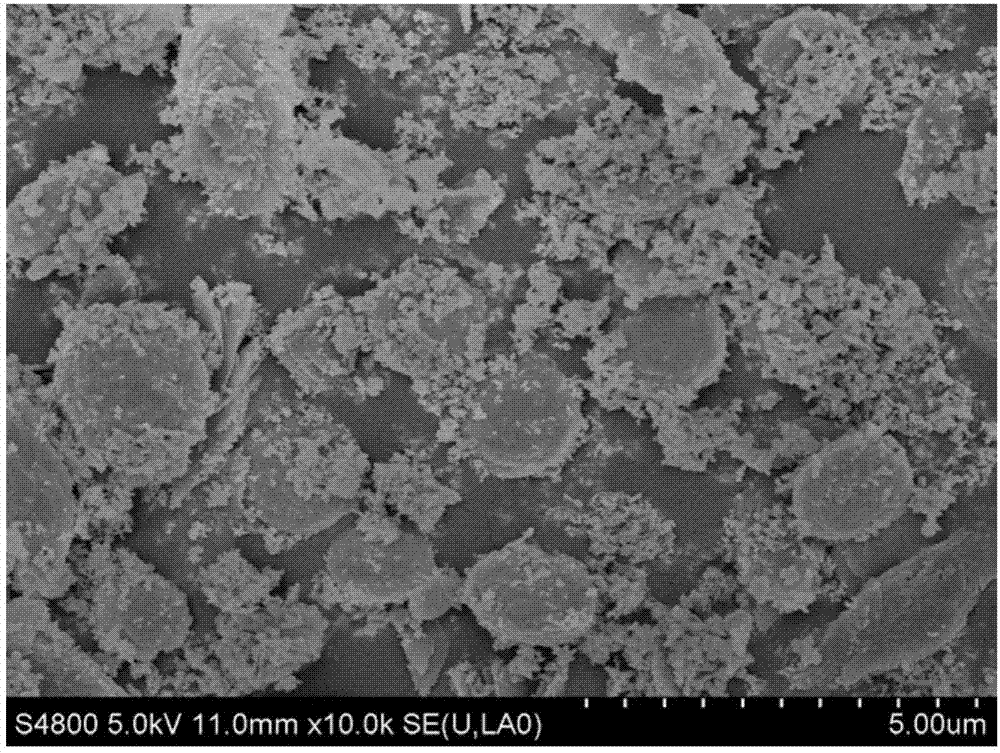

Preparation method of MnFe2O4-TiO2-graphene aerogel

PendingCN111569899AHigh mechanical strengthRich in active sitesAerogel preparationMetal/metal-oxides/metal-hydroxide catalystsPtru catalystFreeze-drying

The invention discloses a preparation method of MnFe2O4-TiO2-graphene aerogel. The preparation method comprises the following steps: (1), mixing a graphene oxide aqueous solution with absolute ethyl alcohol, then carrying out ultrasonic treatment, y adding ferric nitrate and manganous nitrate salt solutions, then adding polyethyleneimine for ultrasonic treatment, and finally adding tetrabutyl titanate for ultrasonic treatment to form a good dispersion liquid; (2), transferring the dispersion liquid into a high-temperature and high-pressure reaction kettle for reaction; and (3), after finishingof the reaction, taking out the sample, soaking the sample in ammonia water (10v / v%), and soaking the sample in 20% ethanol before freeze drying to prepare MnFe2O4-TiO2-graphene aerogel. According tothe preparation method, aerogel is synthesized through a one-step hydrothermal method, reduction of graphene oxide is promoted through addition of polyethyleneimine, self-assembly of the aerogel is easier to complete, and amino is introduced to enhance the mechanical strength of the aerogel. The preparation method of the aerogel is simple and convenient, the aerogel serving as a catalyst is easyto recycle, secondary pollution is reduced, and the visible light utilization rate is increased.

Owner:SUZHOU UNIV OF SCI & TECH

Gear-shaped biodiesel catalyst and preparation method thereof

ActiveCN107252683ALarge specific surface areaRich in active sitesFatty acid esterificationBiofuelsBiodieselReactive site

The invention discloses a gear-shaped biodiesel catalyst and a preparation method thereof. The preparation method comprises the following steps: preparing a Ca / Al / La biodiesel catalyst with a pore structure from graphite phase-like carbon nitride (g-C3N4) as a template agent, that is, roasting melamine so as to prepare g-C3N4, dispersing CaCl2, Al(NO3).9H2O, La(NO3)3.6H2O and g-C3N4 in water, after dispersion, slowly dropping a NaOH into a mixed solution, performing continuous reaction for a certain time, performing reaction in an oven, performing suction filtration, drying, and roasting, thereby obtaining the Ca / Al / La biodiesel catalyst. The catalyst disclosed by the invention is relatively large in specific surface area, rich in active site and very high in catalysis activity and can be repeatedly used, and the use amount of the catalyst only accounts for 0.5-2% of the mass of biomass oil.

Owner:SHANGHAI INST OF TECH

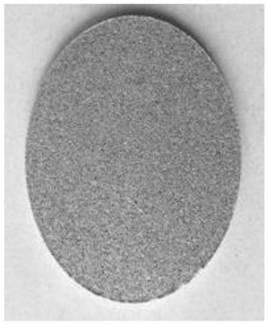

Preparation method of titanium foam

ActiveCN111230119AWide variety of sourcesNot easy to absorb waterWater contaminantsWater/sewage treatmentFixed bedCoking wastewater

The invention belongs to the technical field of electrode base materials, and provides a preparation method of titanium foam. The method comprises the steps that coke is adopted as a pore forming agent and mixed with titanium powder to be sintered, the pore forming agent is removed, and the titanium foam is obtained, wherein the volume ratio of the coke to the titanium powder is (0.5-2):1, the grain size of the coke is 1-6 mm, the sintering temperature is 1,400-1,600 DEG C, and the grain size of the titanium powder is 400 meshes. The preparation method specifically comprises the following steps that S1, the coke and the titanium powder are compacted after being mixed to obtain a mixed sample; S2, the mixed sample is sealed, vacuumizing is performed repeatedly, argon is introduced till foreign gas is exhausted; S3, the temperature is increased to 1,400-1,600 DEG C, and sintering is performed; and cooling is performed to the room temperature to obtain a titanium foam midbody; S4, the midbody is placed into a coke gasification small fixed bed reaction device, the temperature is increased to 1,100 DEG C, CO2 is introduced with the flow being 400-600 ml / min, the reaction is performed for a period of time, heating is stopped, cooling is performed to reach the room temperature. According to the technical scheme, the prepared titanium foam is adopted as an anode, electro-catalysis treatment is performed on the coked wastewater, the number of active loci is large, and the degradation efficiency is high.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Copper and bismuth co-doped nano titanium dioxide photocatalyst and preparation and application thereof

ActiveCN102500388BEasy to separateImprove utilization efficiencyHydrocarbon from carbon oxidesOrganic compound preparationQuantum efficiencyPhysical chemistry

The invention belongs to the technical field of a nano titanium dioxide photocatalyst, and particularly relates to a copper and bismuth co-doped nano titanium dioxide photocatalyst and preparation and application thereof. In the photocatalyst, in molar fraction, the doping amount of copper is 0.2-3.0%, and the doping amount of titanium is 0.5-5.0%. The copper and bismuth co-doped nano titanium dioxide photocatalyst disclosed by the invention is in an anatase type, is used for the reaction for preparing methane, methanol, and the like by photocatalytic reduction CO2, has the advantages that the photon efficiency is high, specific surface area is large, and CO2 adsorption ability is strong, and simultaneously, has visual photocatalytic activity and high sunlight utilization rate.

Owner:HENAN POLYTECHNIC UNIV

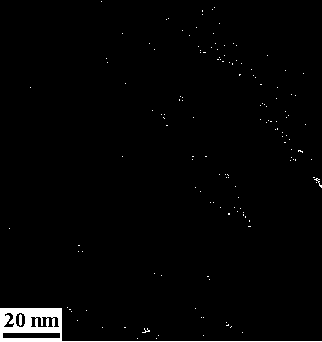

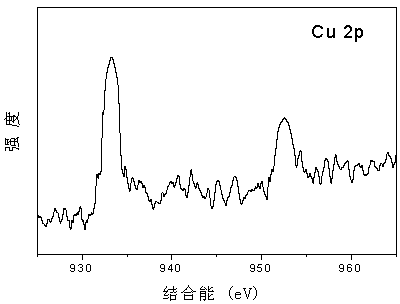

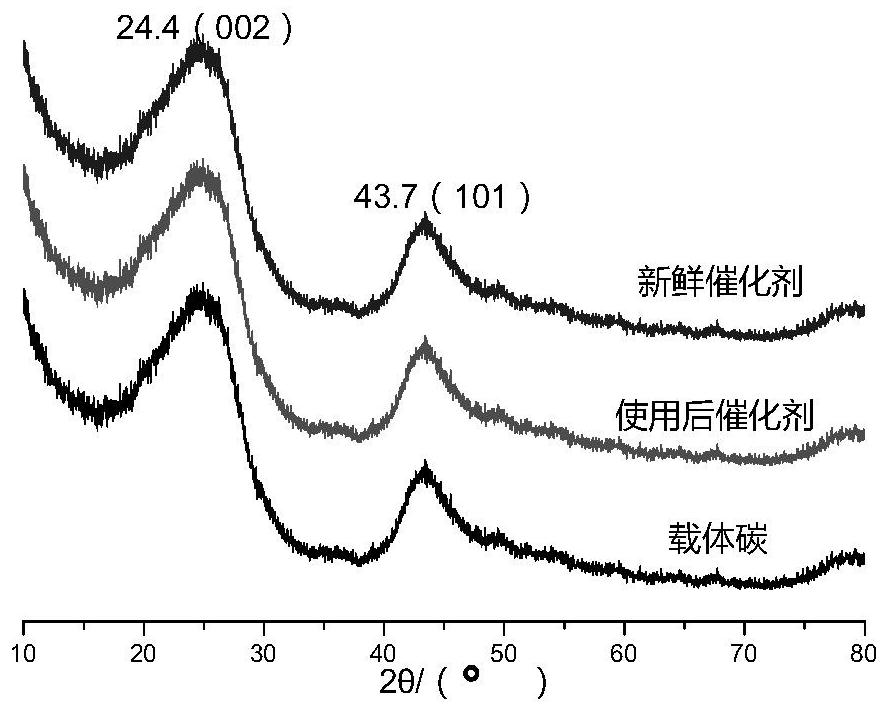

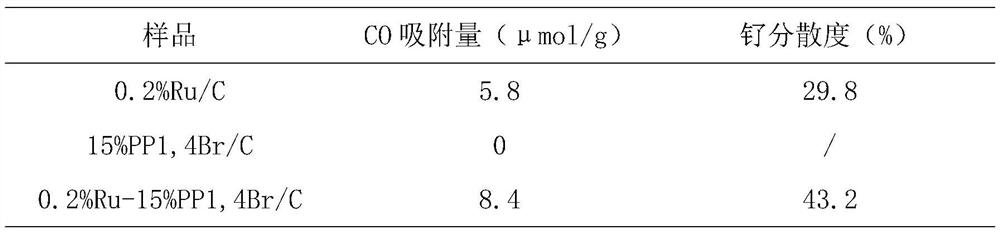

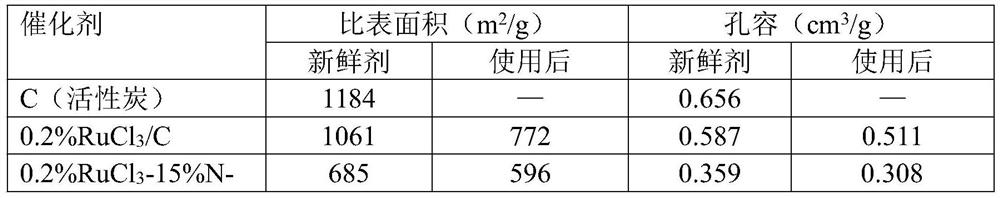

Supported ruthenium-pyrrolidine ionic liquid catalyst as well as preparation method and application thereof

PendingCN114308119AGood dispersionEvenly dispersedPreparation by halogen halide additionOrganic-compounds/hydrides/coordination-complexes catalystsCatalytic transformationPtru catalyst

The invention discloses a supported ruthenium-pyrrolidine ionic liquid catalyst, the catalyst is composed of RuCl3 and pyrrolidine ionic liquid, the catalyst is prepared by adopting a dipping-drying mode, and the catalyst has the advantages of multiple active sites, high dispersity, high catalytic conversion rate, high selectivity and good anti-carbon deposition effect.

Owner:贵州重力科技环保股份有限公司

Aluminum zirconate-doped lithium titanium phosphate two-component surface-modified ferric fluoride positive electrode material and preparation method thereof

ActiveCN103515598BIncrease contactRich in active sitesCell electrodesSecondary cellsElectrical conductorHigh energy

The invention discloses an aluminum zirconium acid ester-doped titanium phosphate dual-component surface-modified ferric fluoride anode material and a preparation method. The method is characterized by comprising the following steps: loading aluminum zirconium acid ester, silicon / aluminium-doped titanium phosphate Li1.3Al0.1Ti1.9Si0.2P2.8O12, and a synthetic raw materials into a high-energy ball mill, ball-milling for a certain period, and performing heat treatment to obtain the FeF3 anode material. The aluminum zirconium acid ester is a bimetal coupling agent, has multiple active sites, and bonds with Li1.3Al0.1Ti1.9Si0.2P2.8O12 by hydrolysis of multiple alkoxyl groups into hydroxyl groups while having condensation polymerization with hydroxyl groups on the surface of the FeF3 anode material, and zirconium is an electron acceptor, can coordinate with fluorine ions on surfaces of FeF3 particles, therefore, under the action of the aluminum zirconium acid ester, doped titanium phosphate Li1.3Al0.1Ti1.9Si0.2P2.8O12 is bonded to the surfaces of the FeF3 anode particles with good contact between particles, and Li1.3Al0.1Ti1.9Si0.2P2.8O12 is a good lithium ion conductor, and the ionic conductivity of Li1.3Al0.1Ti1.9Si0.2P2.8O12 is 103-104 times of that of lithium cobalt oxide. Therefore, the defect that the FeF3 anode material has an extremely-low ionic conductivity can be overcome, and the electrochemical properties of the FeF3 material are improved.

Owner:刘焕礼

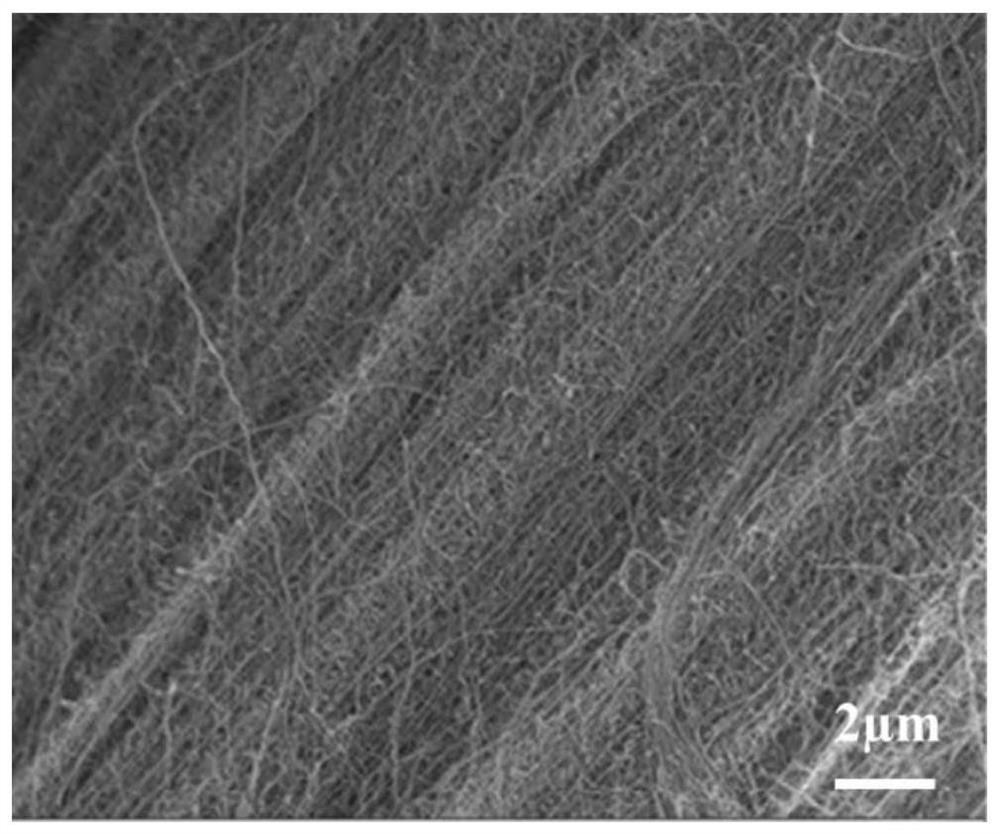

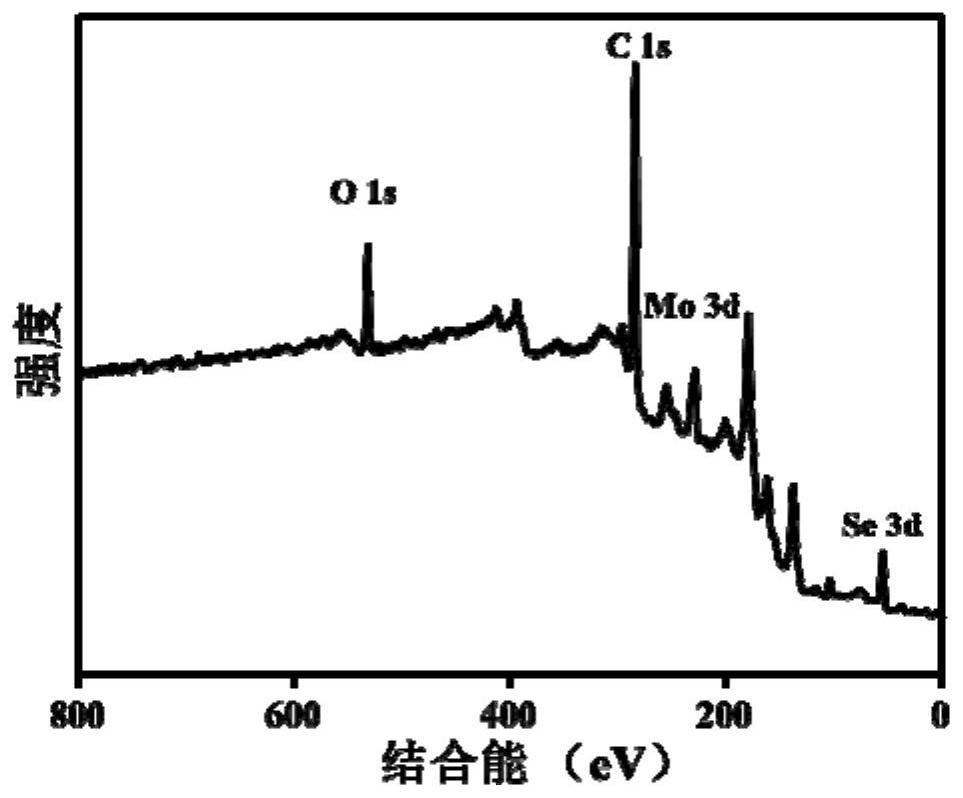

A molybdenum diselenide/carbon nanotube array composite electrode, preparation method and application

ActiveCN110890224BSlow release volume expansionImprove cycle stabilityHybrid capacitor electrodesHybrid/EDL manufactureCarbon nanotubeMolybdenum diselenide

The invention discloses a molybdenum diselenide / carbon nanotube array composite electrode, a preparation method and an application. Sodium molybdate, selenium powder and sodium borohydride are mixed according to a molar ratio of 1:3:1 and dissolved in deionized water. and anhydrous ethanol, then put the carbon nanotube array into the mixed solution, and conduct a hydrothermal reaction at 180-220°C for 36-48 hours to obtain a molybdenum diselenide / carbon nanotube array composite electrode; disselenide The molybdenum / carbon tube array composite electrode film is pressed on the current collector by pressure to obtain the supercapacitor electrode. In the present invention, molybdenum diselenide and carbon nanotube arrays are combined as an electrode material, and its specific surface area is greatly increased, and it has more abundant active sites, and these advantages enable its high theoretical specific capacity to be fully utilized. No binder is added when preparing the composite electrode, which not only reduces the weight of the entire electrode, but also makes the active component and the current collector directly and tightly combined, greatly reducing the contact resistance of the electrode.

Owner:NORTHWEST UNIV

Honeycomb wire mesh catalyst for stationary source tail gas denitration and preparation thereof

ActiveCN102166515BGuaranteed uptimeRich in active sitesDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsWater resistantHoneycomb like

Owner:DALIAN UNIV OF TECH

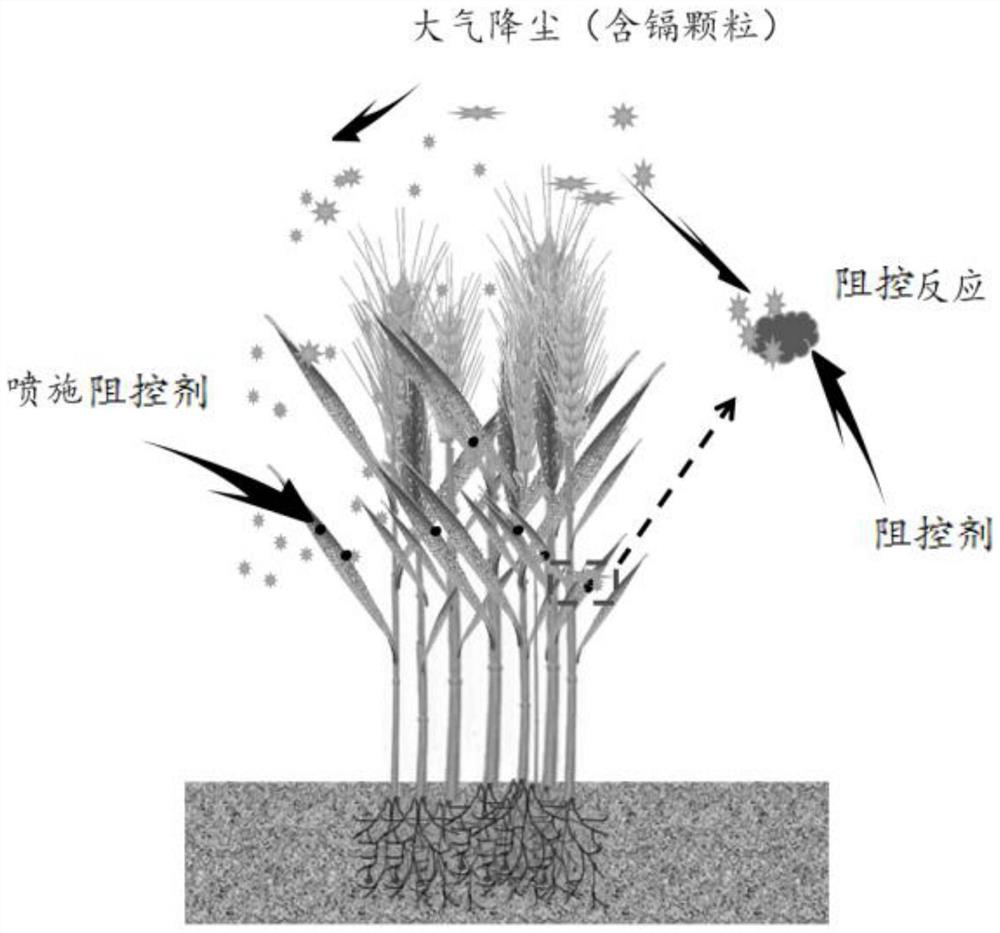

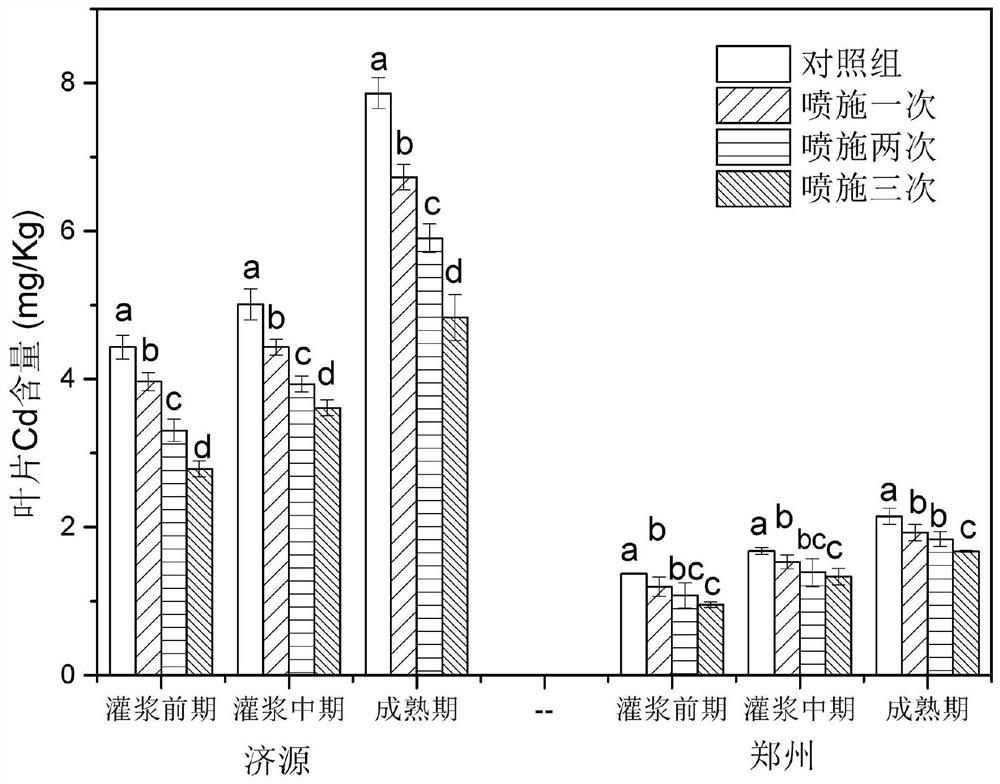

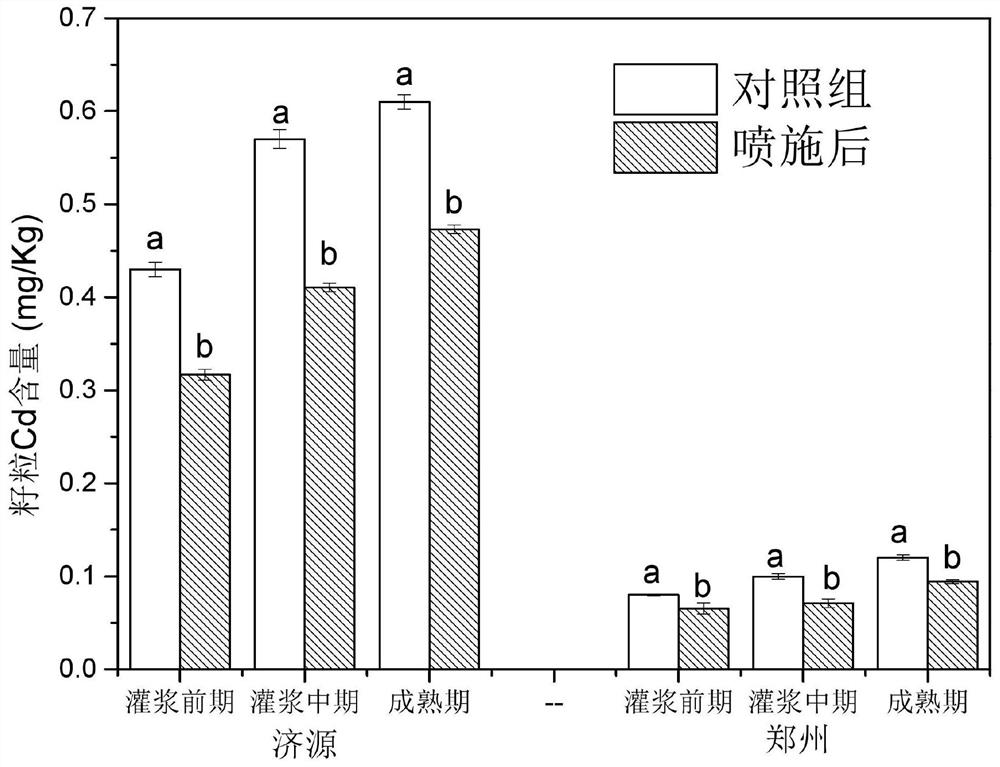

A kind of foliar inhibitor for suppressing cadmium pollution of wheat atmospheric dust and its application method

ActiveCN112913850BGood control effectReduce interfacial tensionBiocidePlant growth regulatorsSulfonateSoil science

The invention discloses a foliar resistance control agent for suppressing cadmium pollution from atmospheric dust in wheat and a method for using the same, belonging to the technical field of environmental pollution control. 3 o 4 @C‑NH 2 0.2%, alkyl naphthalene sulfonate 1‑2%, lambda-cyhalothrin 0.5‑1%, water 91.8‑95.3%; spray the foliar inhibitor on wheat leaves during the filling stage of wheat, which can reduce The bioavailability of cadmium in the atmospheric dust adsorbed on the leaf surface directly cuts off the absorption of heavy metal cadmium in the atmospheric dust by the leaves, and then efficiently and significantly prevents the absorption of cadmium in the atmospheric dust and its transfer to the grain, reducing the cadmium content in the grain. It provides a new solution to control the cadmium pollution of wheat grains caused by cadmium in atmospheric dust.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

A kind of composite basalt fiber carrier material and preparation method thereof

ActiveCN106283315BIncrease loadLower surface energyInorganic material artificial filamentsYarnReactive sitePhosphate

The invention discloses a composite basalt fiber carrier material and a preparation method thereof. The carrier material comprises the following components in parts by weight: 95.0-99.9 parts of basalt and 0.1-5.0 parts of phosphate. Phosphorus is introduced in basalt fibers to increase active sites on the surfaces of the basalt fibers and reduce surface energy, so that microorganisms can be easily loaded on the basalt fibers, an adhesive force is large, the loading amount of the microorganisms is large, the purifying efficiency of a microorganism purifying material which takes the basalt fibers as a carrier is improved, and popularization and application of the basalt fiber material in water purification are promoted.

Owner:江苏金荣泰新材料科技有限公司

A kind of preparation method of the catalyst that uses expanded graphite as carrier to catalyze the decomposition of ozone

ActiveCN107744806BSimple processLow costWater treatment compoundsCatalyst activation/preparationPtru catalystDiethylenetriamine

The invention provides a method for preparing a catalyst for catalytically decomposing ozone using expanded graphite as a carrier. The method mainly involves sequentially carrying out ozone oxidation, chemical oxidation intercalation, diethylene triamine amination and impregnation to support cerium ions on flake graphite, and Subsequent microwave expansion treatment prepared expanded graphite loaded with the active component cerium; then the prepared expanded graphite was impregnated, loaded with manganese ions, and subjected to high-temperature sintering to obtain an expanded graphite carrier loaded with the active component cerium. and manganese catalysts. The catalyst prepared by the invention can efficiently catalyze ozone to generate hydroxyl radicals, thereby achieving excellent removal of refractory and highly toxic organic pollutants in the water environment. Its application prospects in the field of wastewater pollution control are promising.

Owner:秦皇岛晟创科技有限公司

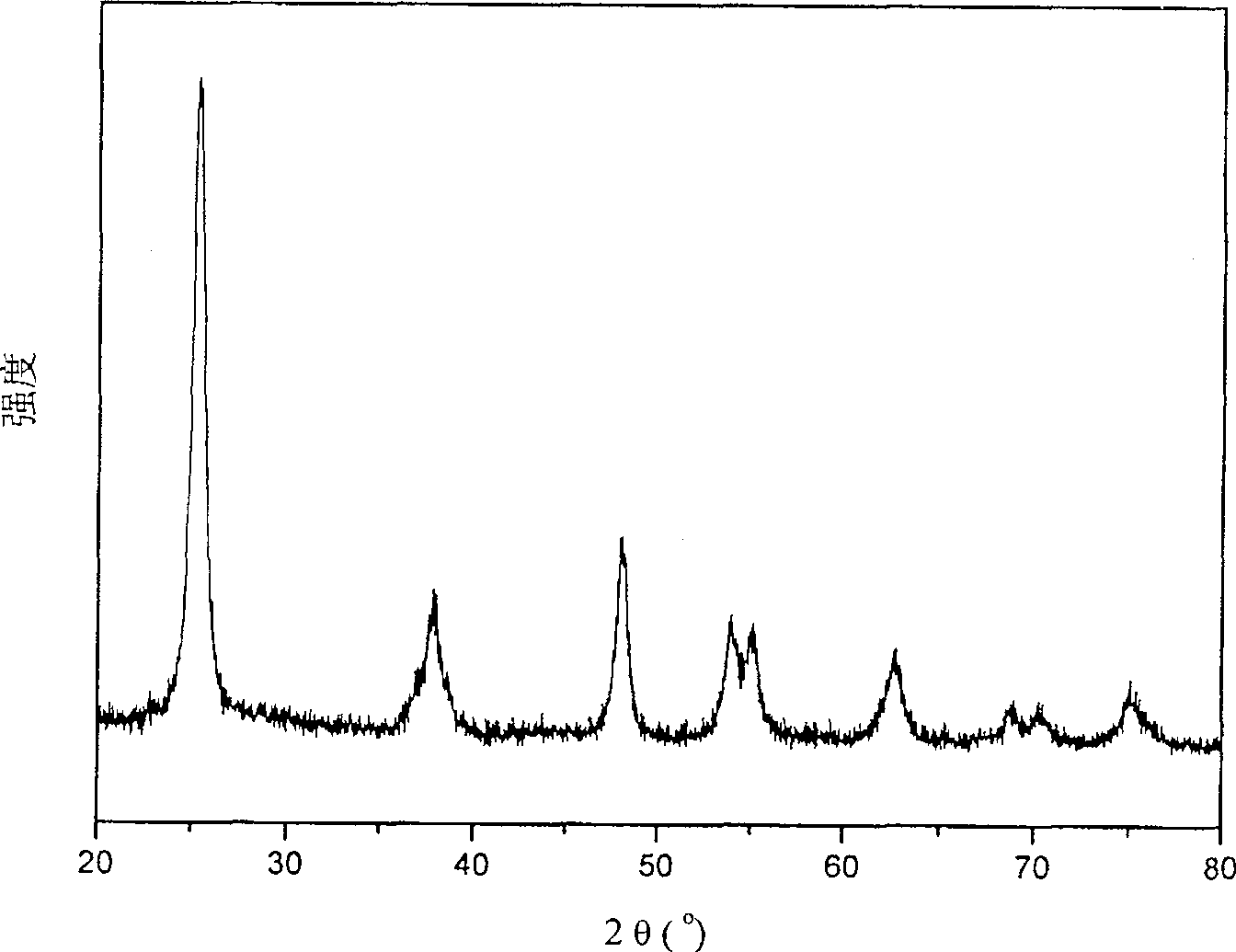

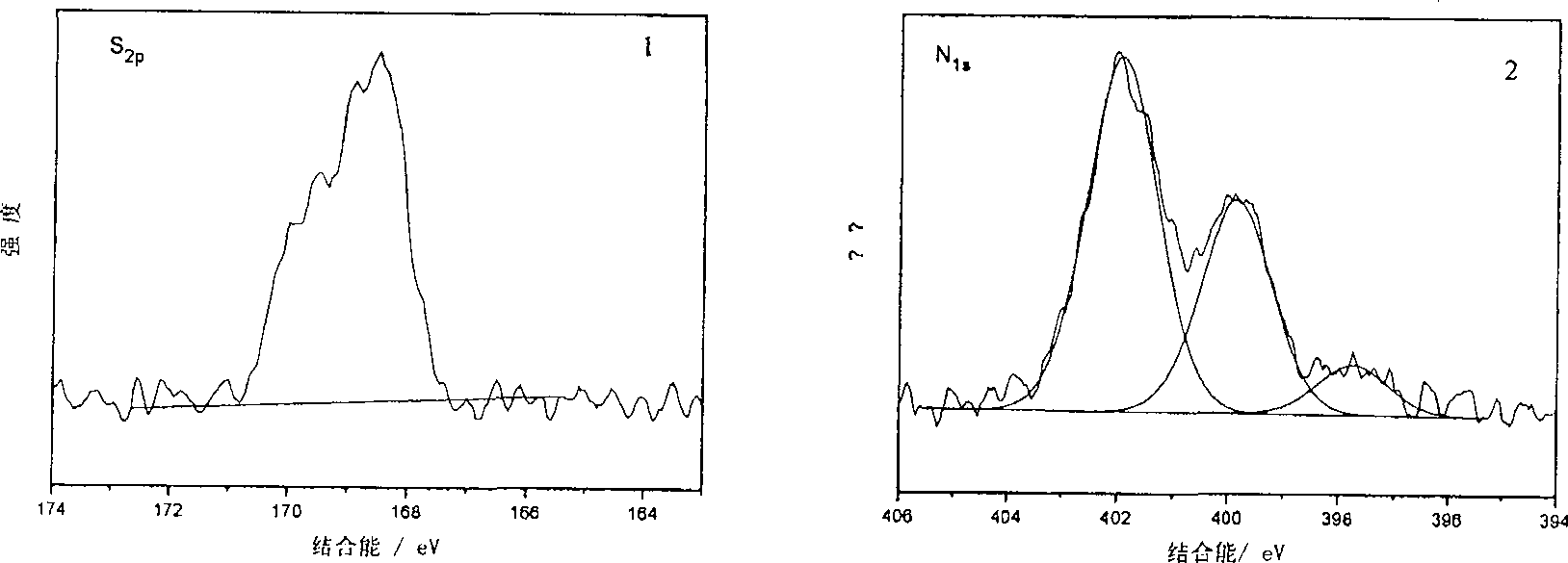

Cation S and anion N doped one-dimensional nano-structured Ti0* photocatalyst and method of producing the same

ActiveCN100503036CReduce processing costsComprehensive areaPhysical/chemical process catalystsDeodrantsNano structuringThiourea

Owner:ZHEJIANG ZHONGDE IND

A kind of gear-shaped biodiesel catalyst and preparation method thereof

ActiveCN107252683BLarge specific surface areaRich in active sitesFatty acid esterificationBiofuelsPtru catalystBiodiesel

The invention discloses a gear-shaped biodiesel catalyst and a preparation method thereof. The preparation method comprises the following steps: preparing a Ca / Al / La biodiesel catalyst with a pore structure from graphite phase-like carbon nitride (g-C3N4) as a template agent, that is, roasting melamine so as to prepare g-C3N4, dispersing CaCl2, Al(NO3).9H2O, La(NO3)3.6H2O and g-C3N4 in water, after dispersion, slowly dropping a NaOH into a mixed solution, performing continuous reaction for a certain time, performing reaction in an oven, performing suction filtration, drying, and roasting, thereby obtaining the Ca / Al / La biodiesel catalyst. The catalyst disclosed by the invention is relatively large in specific surface area, rich in active site and very high in catalysis activity and can be repeatedly used, and the use amount of the catalyst only accounts for 0.5-2% of the mass of biomass oil.

Owner:SHANGHAI INST OF TECH

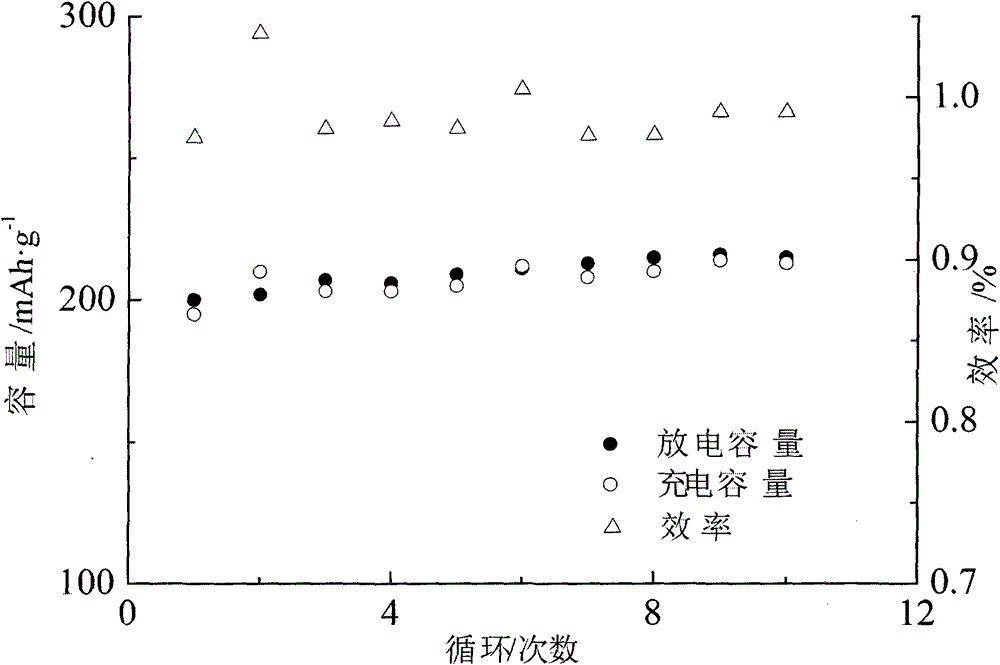

Lithium ion battery

PendingCN114843486AEasy to prepareEasy to operateFinal product manufactureCell electrodesElectrolytic agentElectrical battery

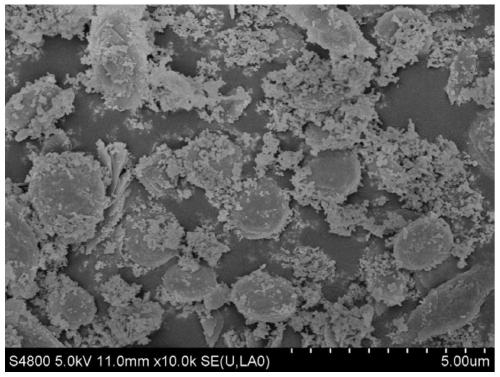

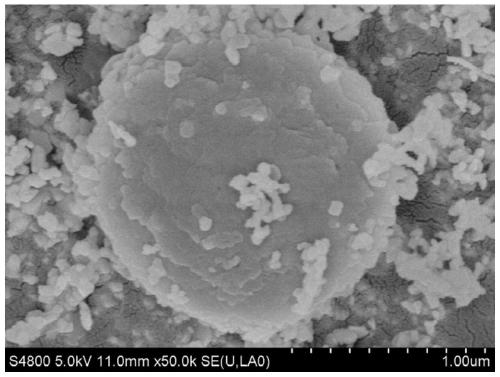

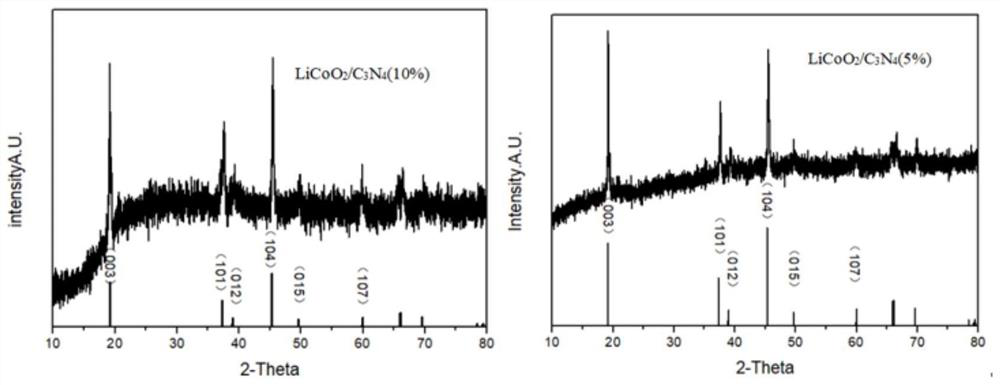

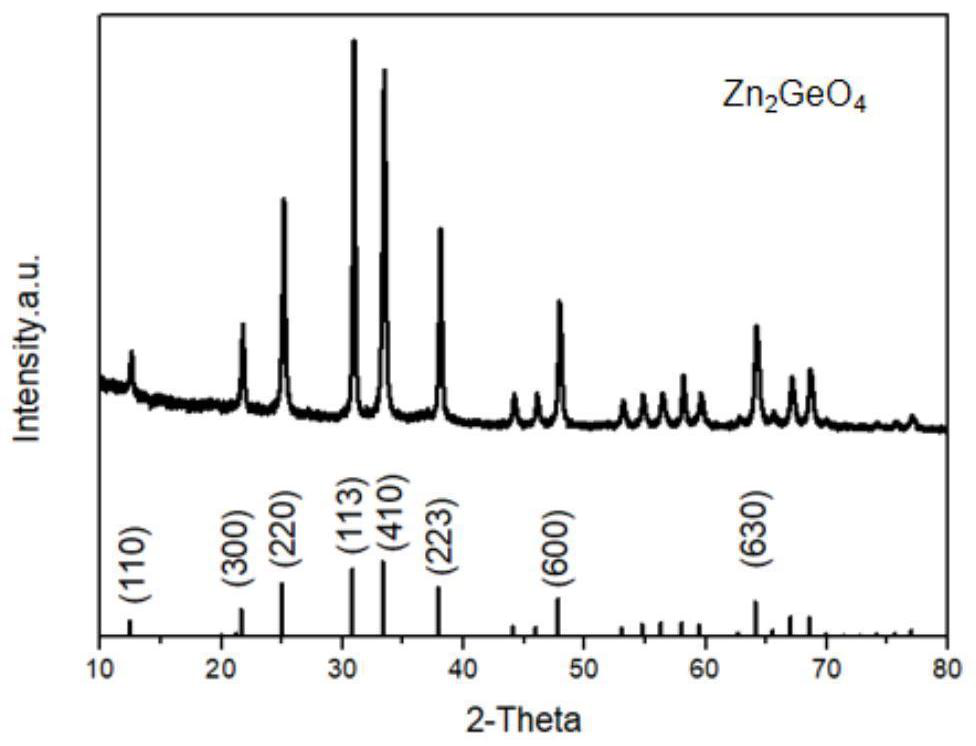

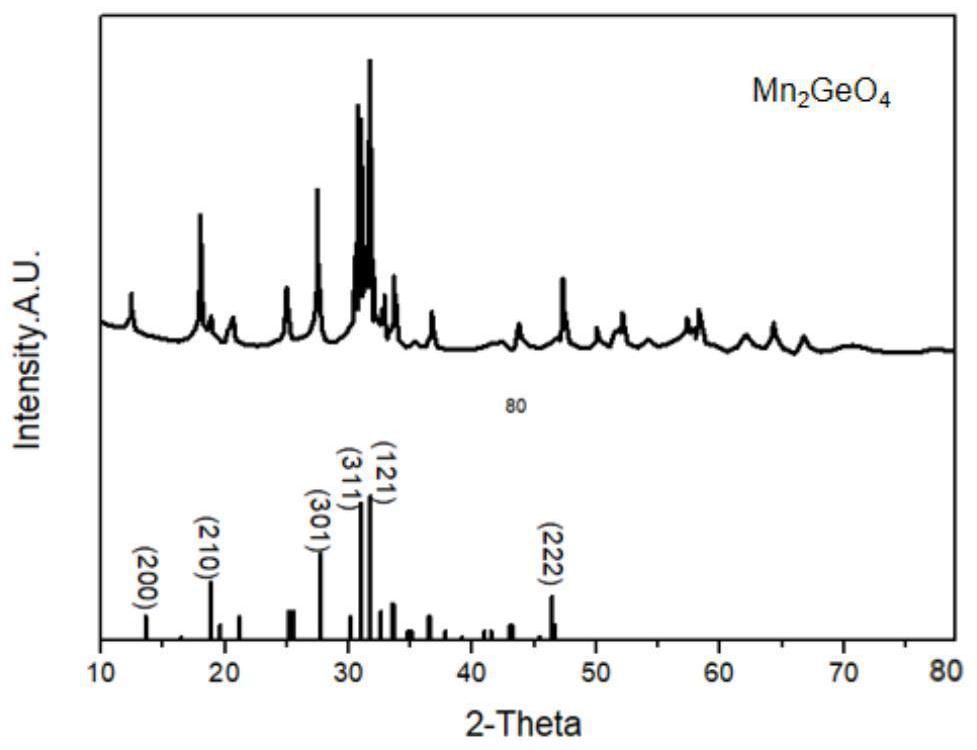

The invention relates to a lithium ion battery, which comprises the following structures: a winding battery cell assembly, electrolyte for impregnating the winding battery cell assembly, a metal shell for loading the winding battery cell assembly and the electrolyte, and a sealing cover for sealing the metal shell, the winding cell assembly comprises a positive electrode foil, a negative electrode foil and a diaphragm for separating the positive electrode foil from the negative electrode foil; the positive electrode foil comprises a positive electrode active material, and the positive electrode active material is a LiCoO2 / C3N4 composite material; the negative electrode foil comprises a negative electrode active substance, the negative electrode active substance is an M2GeO4 material, and M is selected from one or more of Zn, Mn, Co and Cd, specifically one of Zn2GeO4, Mn2GeO4, Co2GeO4 and Zn1. 8Cd0. 2GeO4; the battery provided by the invention has relatively high reversible capacity, relatively good cycle performance and rate capability, and relatively stable fast charging performance.

Owner:JIANGSU UNIV OF TECH

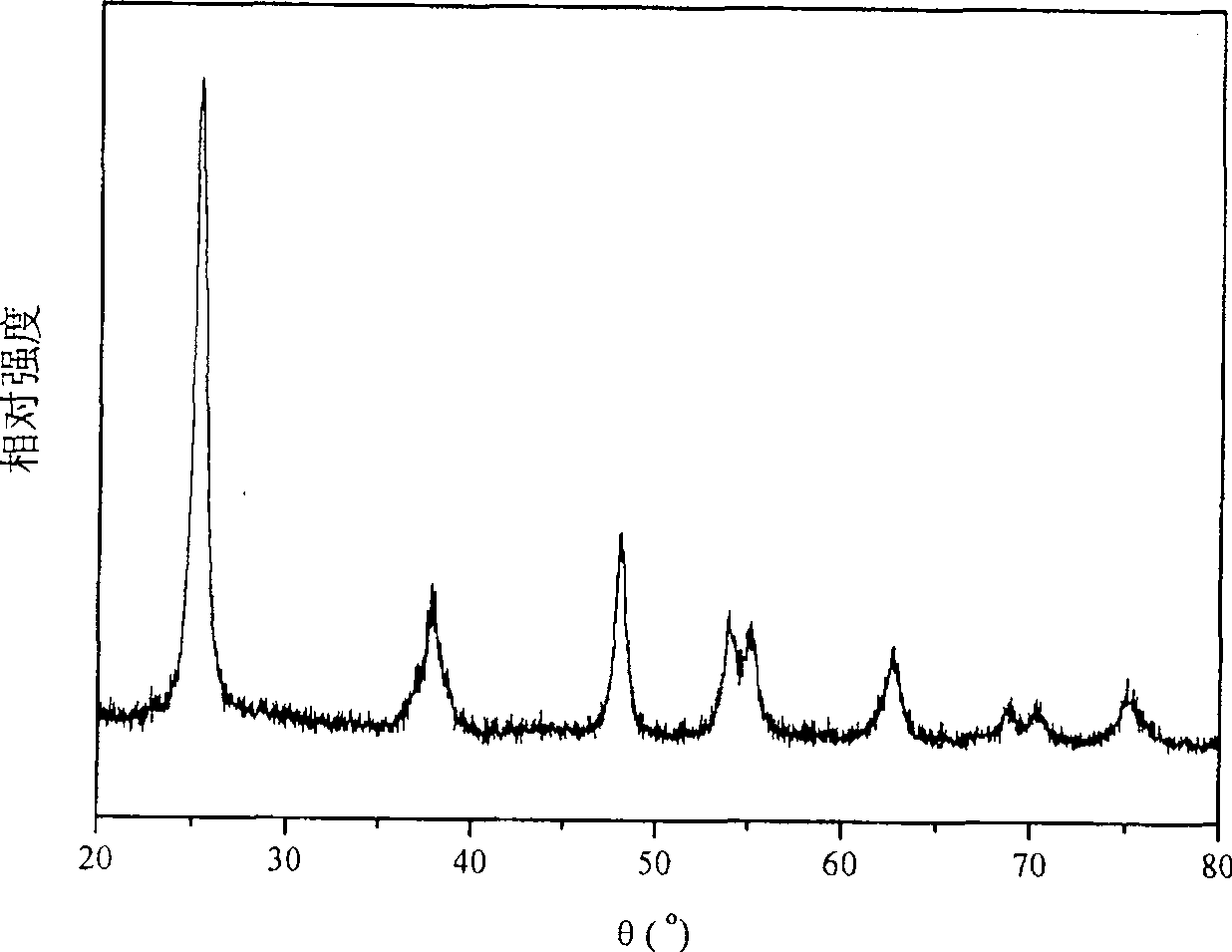

Non-metal N doped one-dimensional nano-structured Ti0* visible light catalyst and method for producing the same

ActiveCN100503035CEnhanced mass transferSpecial one-dimensional structurePhysical/chemical process catalystsNano structuringVisible light photocatalytic

The invention discloses a non-metallic N-doped one-dimensional nanostructure TiO2 visible light catalyst, which is prepared by the following method: (1) adopting a hydrothermal method to prepare nano-TiO2 powder, TiO2 colloid or Ti(OH)4 with an alkali solution into a mixed suspension for hydrothermal reaction; (2) after the hydrothermal reaction is completed, cool, filter out the precipitate, and wash to obtain white hydrotitanic acid; (3) mix hydrotitanic acid, doped nitrogen source and water into a mixed suspension, ultrasonically treated after stirring, and dried to obtain a uniform mixture of hydrotitanic acid and doped nitrogen source; (4) calcining the homogeneous mixture of hydrotitanic acid and doped nitrogen source to obtain non-metallic N-doped one-dimensional nano Structure TiO2 Visible Light Catalyst. The catalyst of the present invention has a one-dimensional structure with rich active sites, which can accelerate the mass transfer of pollutants to the catalytic material, thereby improving the photocatalytic efficiency; the special one-dimensional structure and the doping of non-nitrogen metal make it have excellent visible light catalytic activity .

Owner:ZHEJIANG ZHONGDE IND

Preparation method and photocatalytic material of flower-like three-dimensional graphene decorated with double quantum dots

ActiveCN108246287BEfficient electron transportEfficient photocatalytic activityCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsElectroless depositionGraphite

The invention discloses a preparation method of double quantum dot modified flower-like three-dimensional graphene and a photocatalytic material, wherein the method includes: preparing three-dimensional graphene on nickel foam; preparing an electrodeposition precursor solution containing Au; electrochemical deposition Preparation of Au@TiO 2 @3DGFs composite materials: Put three-dimensional graphene into the precursor solution as a working electrode to deposit TiO 2 and precious metal Au double quantum dots, forming flower-like three-dimensional graphene during the electrochemical deposition process, with Au and TiO evenly distributed on its surface. 2 Double quantum dots. The three-dimensional graphene prepared by the invention has a low recombination rate of electron-hole pairs, high photoelectrocatalytic activity, and high utilization rate of sunlight.

Owner:XIFENG 2D FUJIAN MATERIAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com