Integral ozonolysis catalyst and preparation method thereof

An ozonolysis, integrated technology, applied in catalyst activation/preparation, molecular sieve catalysts, separation methods, etc., can solve the problems of low purification and degradation efficiency, large wind resistance, and inconvenient filling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

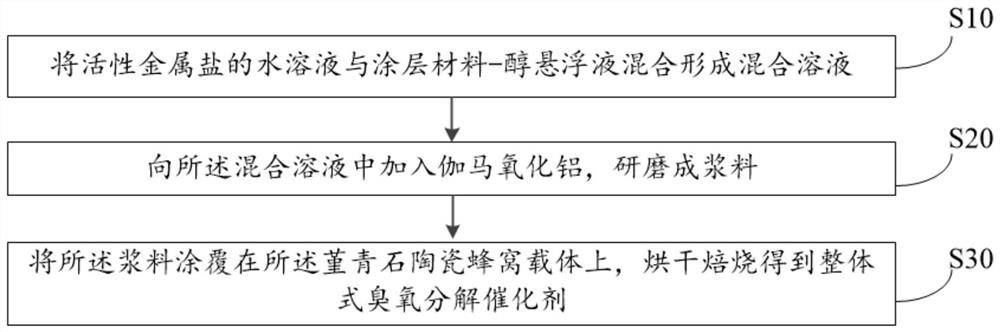

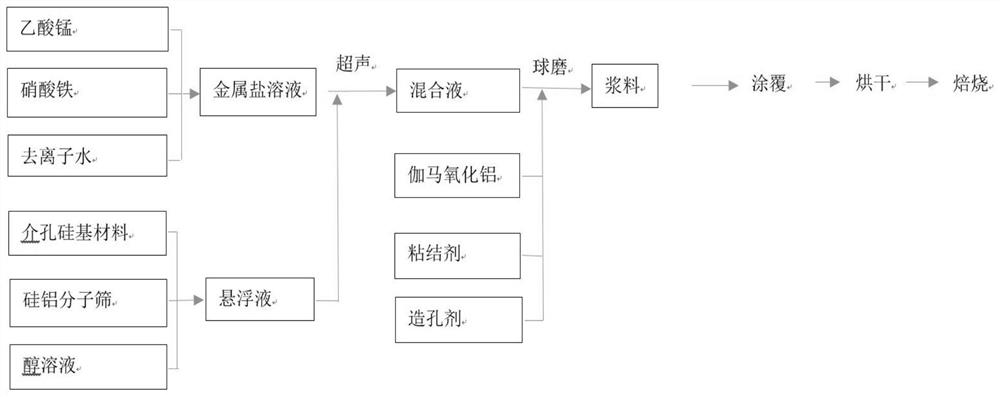

[0046] refer to figure 1 , the preparation method of the monolithic ozonolysis catalyst comprises the following steps:

[0047] Step S10, mixing the aqueous solution of the active metal salt with the coating material-alcohol suspension to form a mixed solution.

[0048] In this embodiment, the aqueous solution of the active metal salt and the coating material-alcohol suspension are mixed to form a mixed solution, wherein the active metal can be copper, nickel, cobalt, iron, manganese, etc., and the active metal salt in this embodiment is preferably manganese acetate and ferric nitrate to form manganese oxide and iron oxide after subsequent steps; the coating material includes at least one of silicon-based mesoporous materials and silicon-aluminum molecular sieves, wherein the silicon-based mesoporous materials include hierarchically porous silicon-based materials and One or more of MCM-41 molecular sieves; silica-alumina molecular sieves include one or more of ZSM-5 molecular...

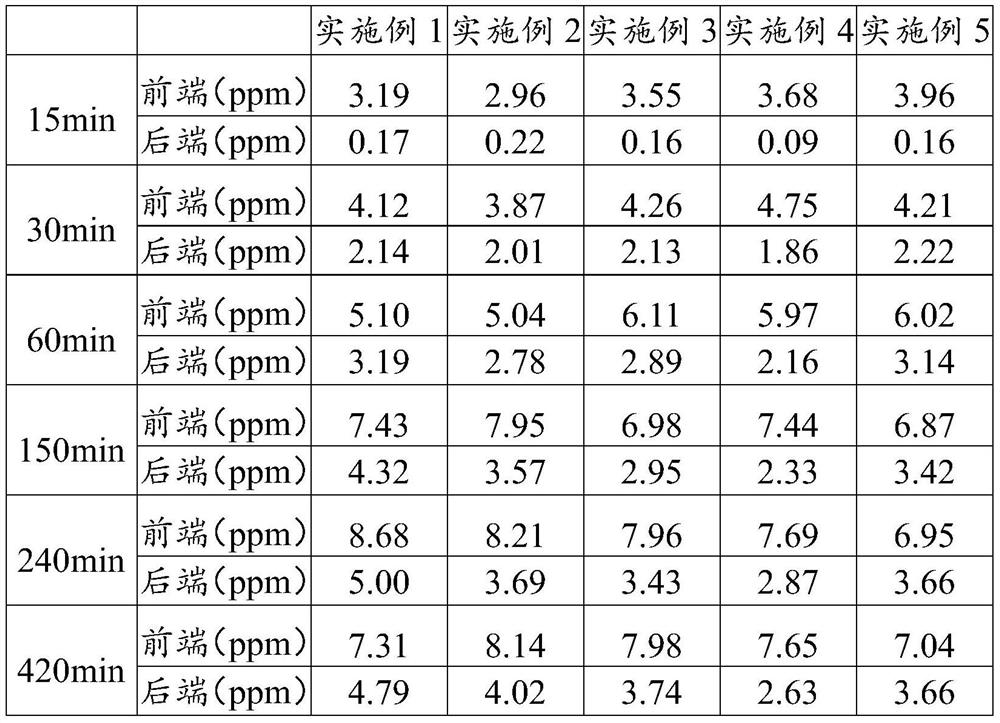

Embodiment 1

[0069] The catalyst in this example includes a carrier and a coating. Wherein, the carrier is a cordierite ceramic honeycomb; the coating includes active metal oxides, gamma alumina and coating materials, the active metal oxides are manganese acetate and iron nitrate, and the coating materials are hierarchical porous silicon-based materials.

[0070] The active metal oxide is dissolved in deionized water to make an aqueous solution of an active metal salt with a mass concentration of 20wt%; the coating material is added to ethanol, and ultrasonically dispersed into a coating material-alcohol suspension with a mass concentration of 40wt% . The aqueous solution of the active metal salt prepared above and the coating material-alcohol suspension were mixed according to the weight ratio of 3:6 to form a mixed solution. After 90 g of the mixed solution was ultrasonically treated for 30 min, 30 g of gamma alumina, 2 g of a binder, and 10 g of a pore-forming agent were sequentially a...

Embodiment 2

[0072] The catalyst in this example includes a carrier and a coating. Wherein, the carrier is a cordierite ceramic honeycomb; the coating includes active metal oxides, gamma alumina and coating materials, the active metal oxides are manganese acetate and iron nitrate, and the coating material is MCM-41 molecular sieve.

[0073] The active metal oxide is dissolved in deionized water to make an aqueous solution of active metal salt with a mass concentration of 5wt%; the coating material is added to ethanol, and ultrasonically dispersed into a coating material-alcohol suspension with a mass concentration of 30wt% . The aqueous solution of the active metal salt prepared above and the coating material-alcohol suspension were mixed according to the weight ratio of 4:6 to form a mixed solution. After 100 g of the mixed solution was ultrasonically treated for 1 min, 13.6 g of gamma alumina, 0.5 g of a binder, and 3.4 g of a pore-forming agent were sequentially added to it, so that th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com