Patents

Literature

84results about How to "Comprehensive area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Integrated control method capable of simultaneously removing inhalable particles and heavy metal from fire coal

InactiveCN101480555AEfficient removalRich in microporesDispersed particle filtrationLighting and heating apparatusFiberCarbon fibers

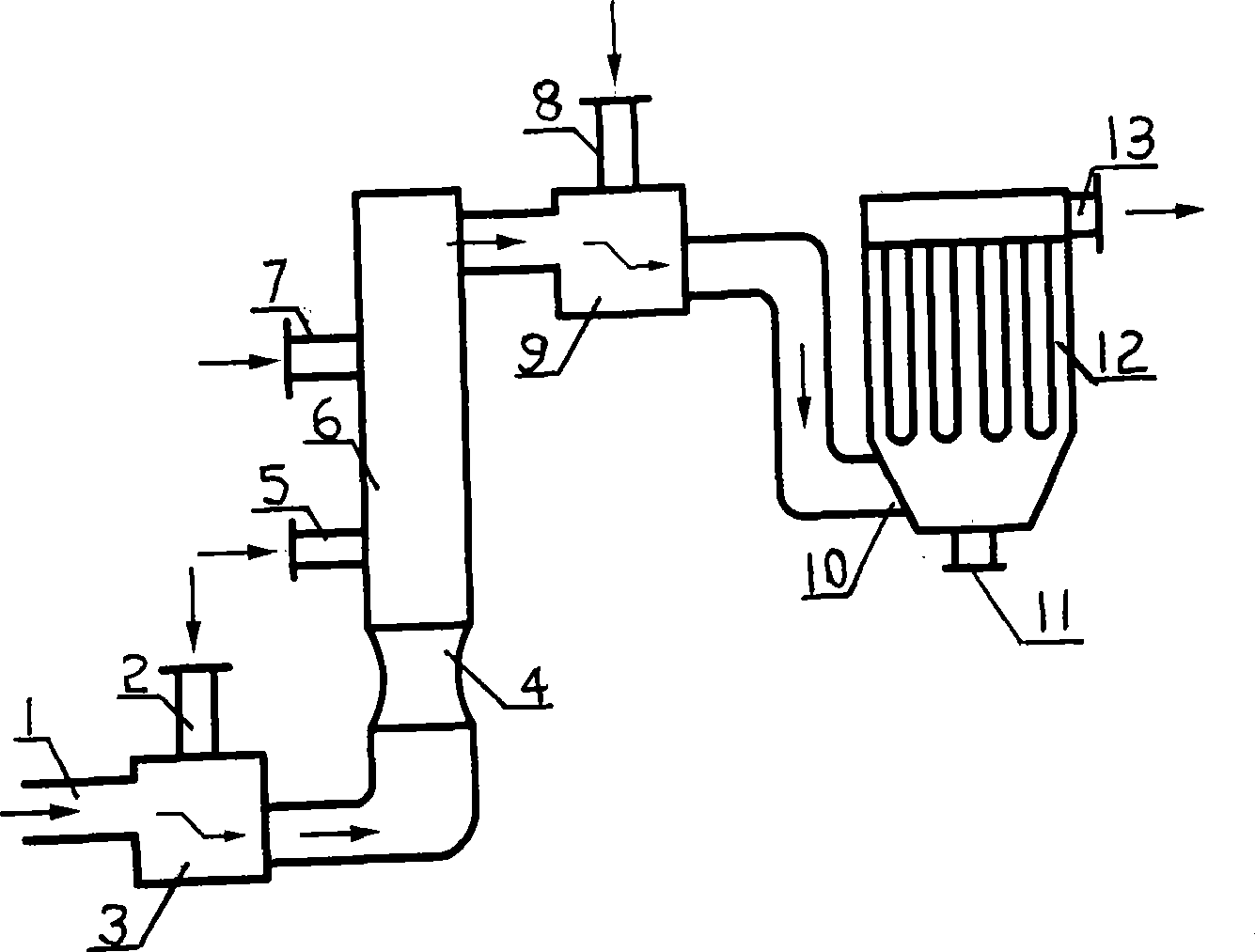

The invention relates to an integrated control method for simultaneously removing respirable particle substances and heavy metal in fire coal. The integrated control method is characterized in that fly ash residual carbon having good adsorption effect on the heavy metal is sprayed in the front end of a bag type filter to remove heavy metal mercury in fire coal flue gas; meanwhile, ferrum series oxides with catalysis are sprayed in lime and the fly ash to remove sulfur oxide, and the like in the fire coal flue gas in a fluid bed reactor; filter materials of the bag filter are made of carbon-doped fibers and can effectively remove the heavy metal mercury in the fire coal flue gas for the second time, thereby achieving the aim for simultaneously removing the respirable particle substances and the heavy metal in the fire coal flue gas. The method can remove PM2.5 level, particularly finer micrometer and nanometer respirable particle substances with the removal rate up to more than 98 percent, and can remarkably control the emission of the heavy metal mercury in the fire coal flue gas; the integrated control process is simple in operation, safe in running, remarkable in environment benefit, small in occupied area of the device and low in process cost.

Owner:DONGHUA UNIV

Display panel and display device

InactiveCN107610594AWeaken the jagged shapeReduce areaStatic indicating devicesSolid-state devicesDisplay deviceComputer vision

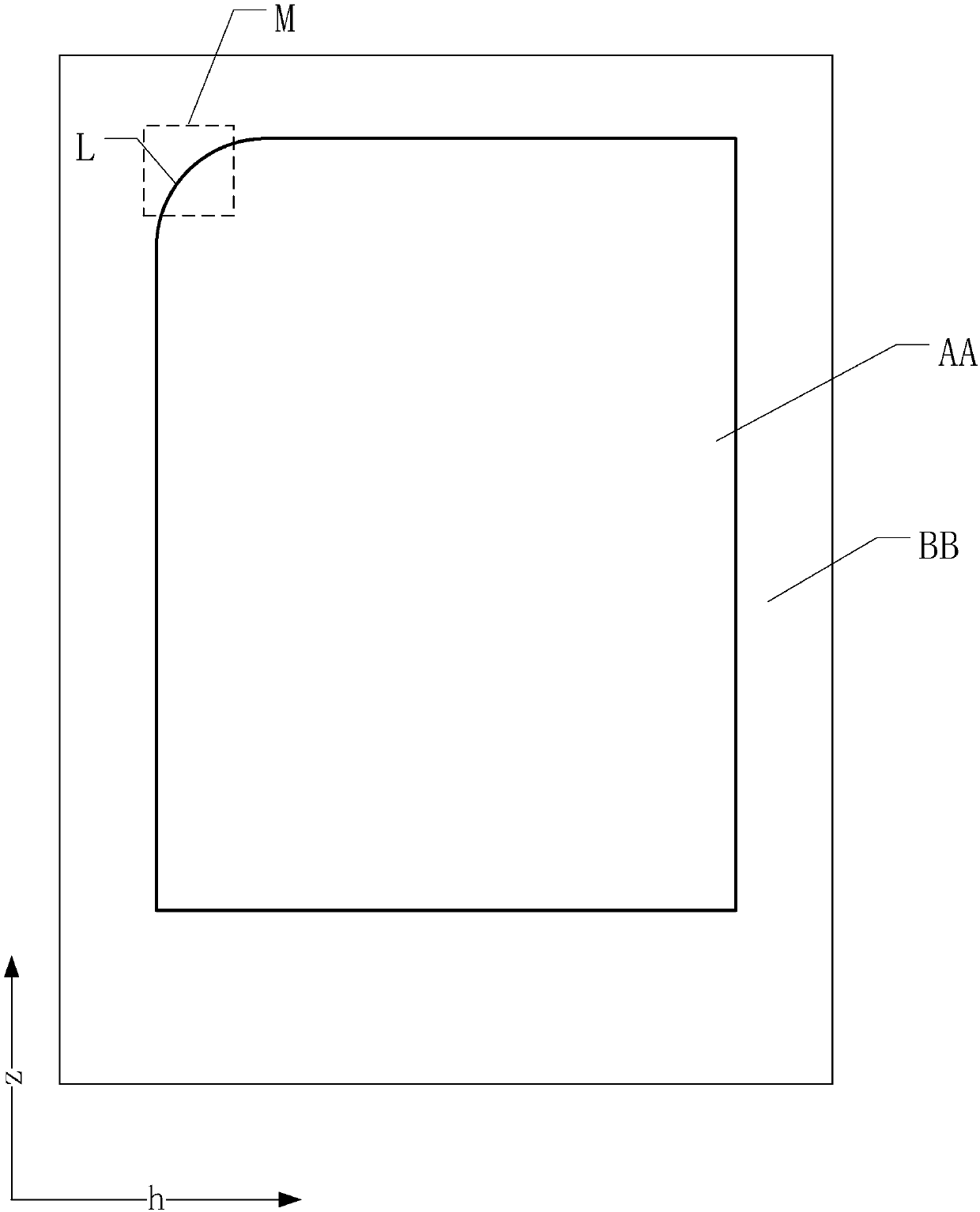

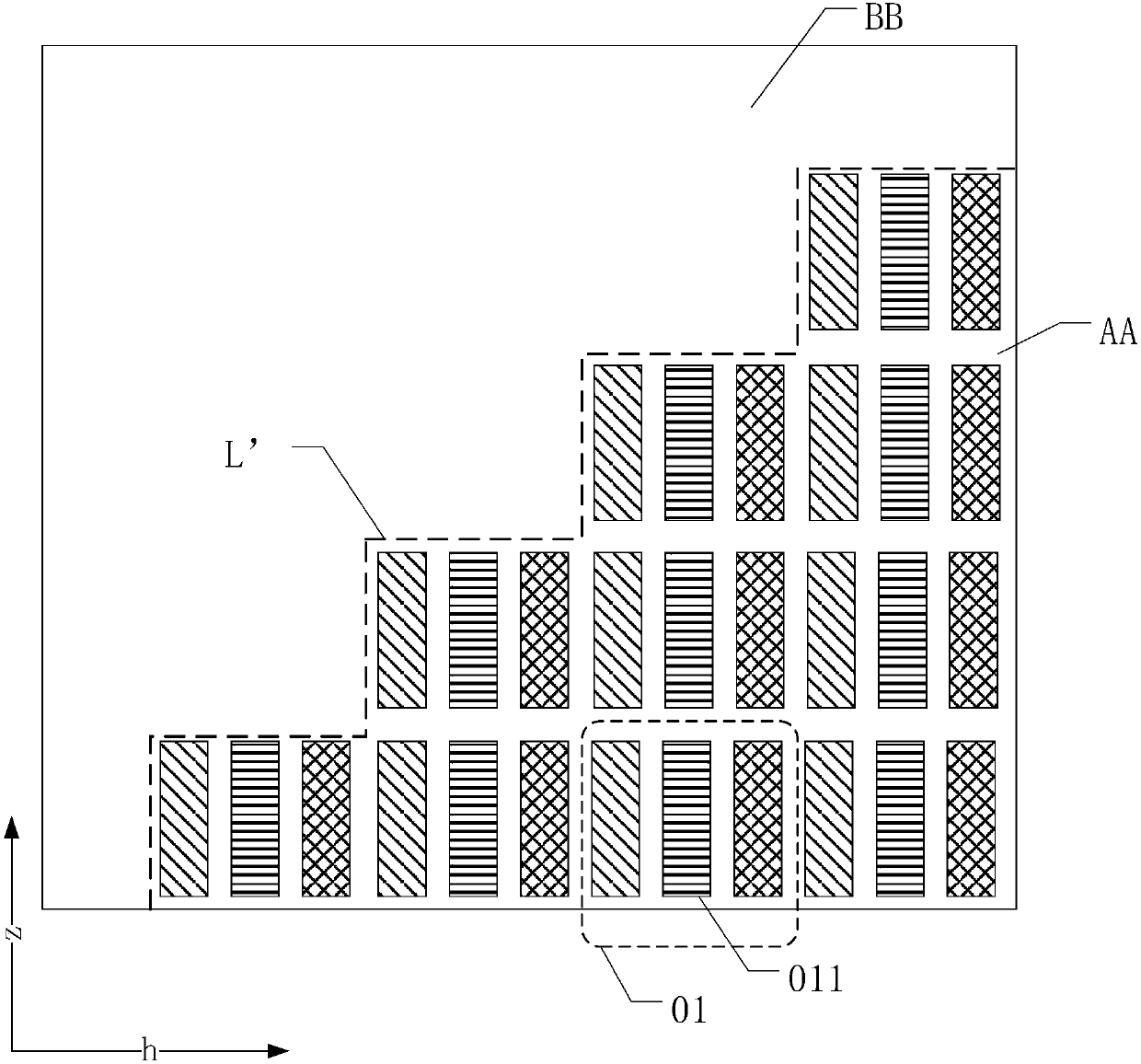

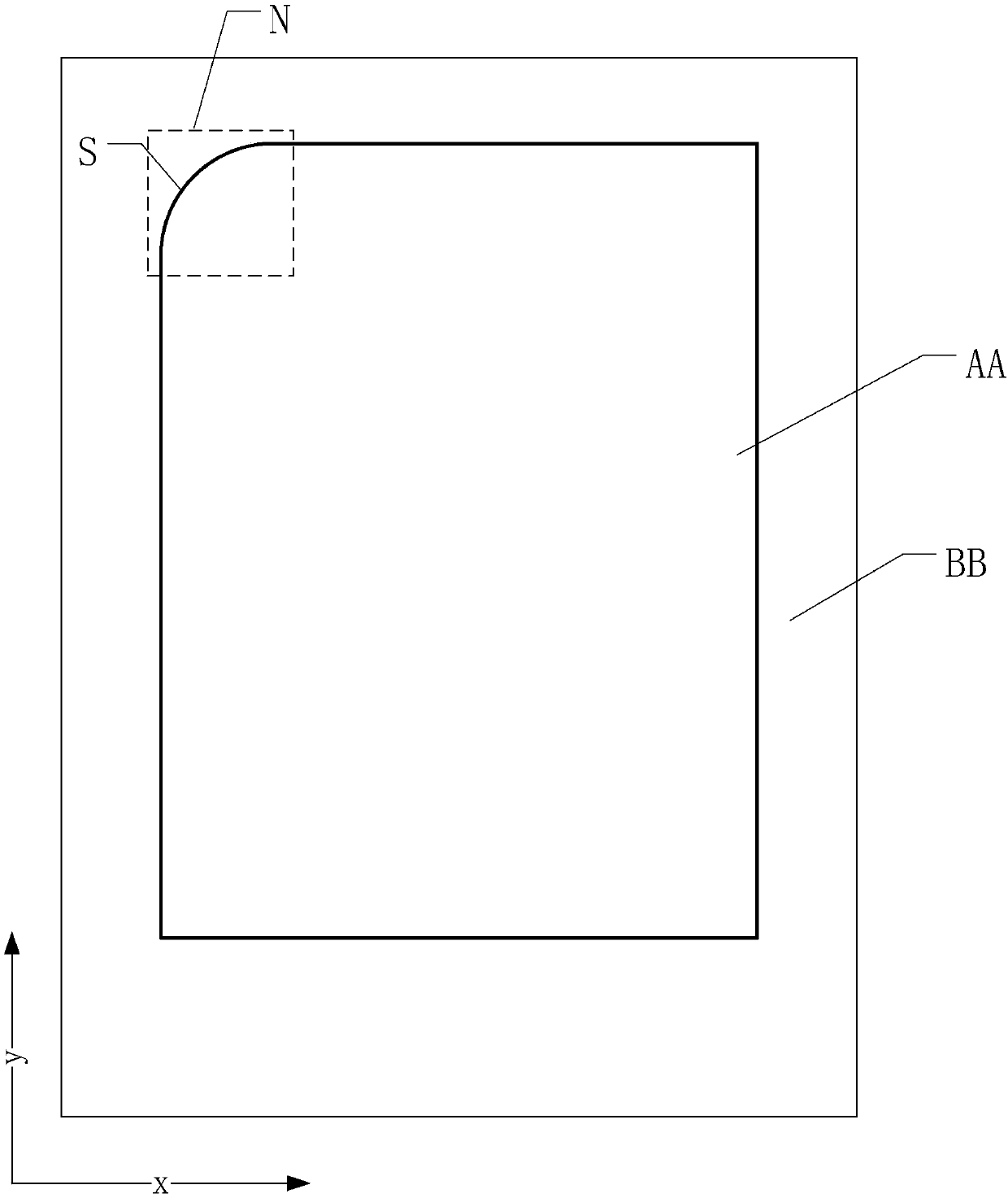

The invention discloses a display panel and a display device, and belongs to the technical field of display. The display panel comprises a display region and a non-display region; the display region comprises a plurality of pixels; a sub-pixel comprises a light transmitting region; the display region comprises special-shaped edges; the multiple pixel include the first pixels adjacent to the special-shaped edges and the other second pixels; the areas of the light transmitting regions of the first pixels are smaller than those of the second pixels; in a pixel set, the areas of the light transmitting regions, close to the first pixels, of the second pixels are larger than or equal to those of the light transmitting regions, far away from the first pixels, of the second pixels; the pixel set comprises a first pixel set and a second pixel set, and the number of the first pixels in the first pixel set is larger than that of the first pixels in the second pixel set; in the areas of the lighttransmitting regions of the at least two pixels in the first pixel set, x different values exist; in the areas of the light transmitting regions of the at least two pixels in the second pixel set, y different values exist, wherein x is larger than or equal to y. The sawtooth shape at the special-shaped edges can be weakened.

Owner:XIAMEN TIANMA MICRO ELECTRONICS

Preparation method for low-quality diesel hydrofining catalyst

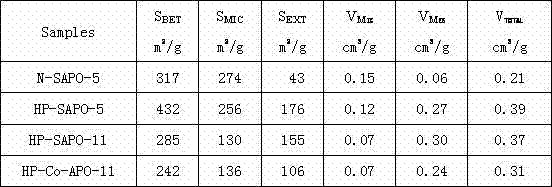

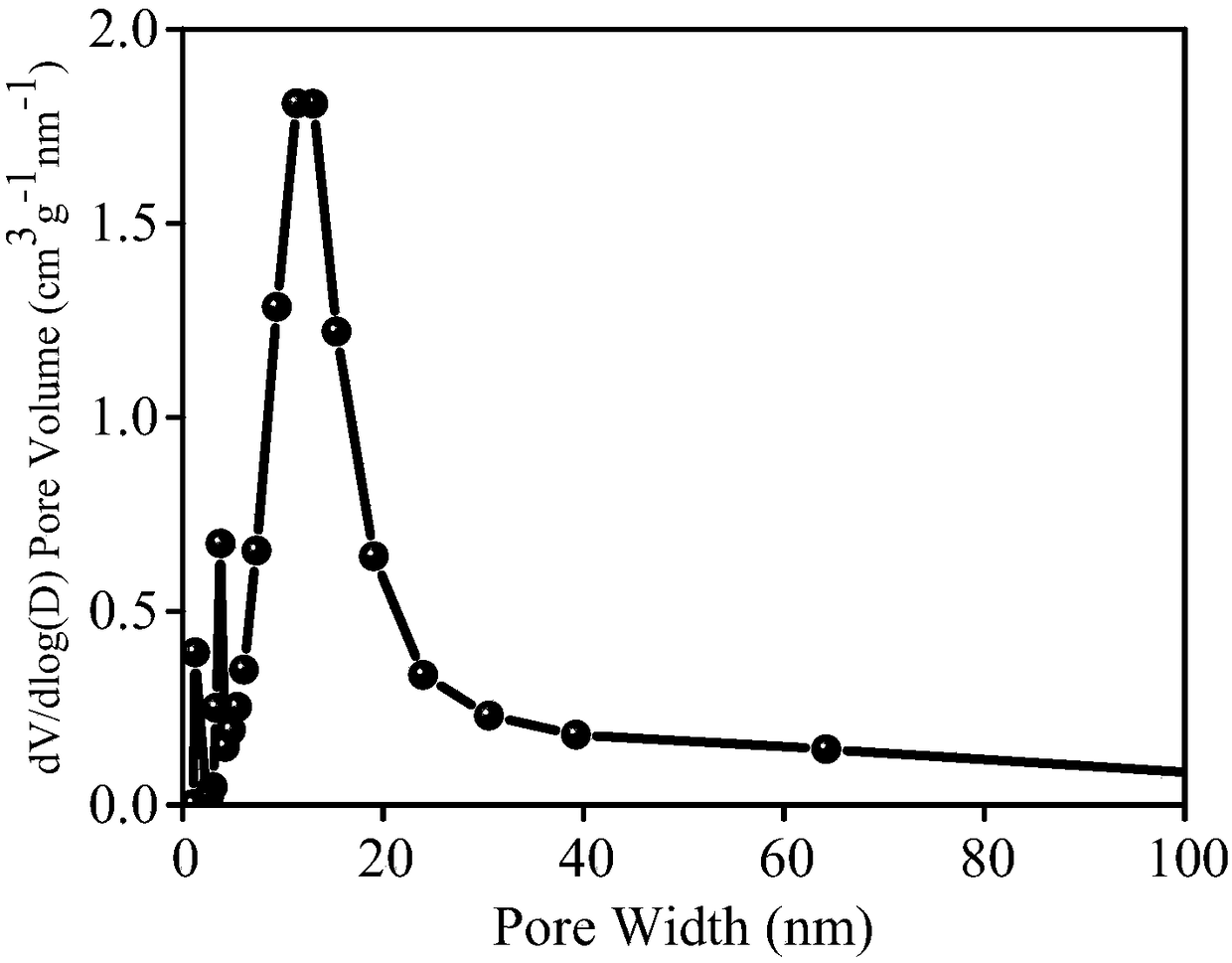

ActiveCN102872908ALow sulfurLow nitrogenMolecular sieve catalystsHydrocarbon oils refiningMolecular sieveActive component

The invention discloses a preparation method for a low-quality diesel hydrofining catalyst, which is characterized in that the low-quality diesel hydrofining catalyst comprises an active component, a carrier and an additive; the active component is composed of one or more than one metal of both VIB group and VIII group; the carrier is composed of a multi-orifice AFI, an AEL molecular sieve and a Gamma-Al2O3; the additive is one or more than one of SiO2, TiO2, F and P; and the weight contents of the components are respectively as follows: 5-30 wt percent of the multi-orifice AFI and the AEL molecular sieve, 12-25 wt percent of metals of the VIB group, 3-15 wt percent of metals of the VIII group, 0-15 wt percent of additive, and the balance Gamma-Al2o3. According to the method, the specific surface area is 200-300 m<2> / g, the pore size is 0.30-0.80 cm<3> / g, the average pore diameter is 6-15 nm, and the mechanical strength is not lower than 15 N / mm.

Owner:CHINA NAT OFFSHORE OIL CORP +1

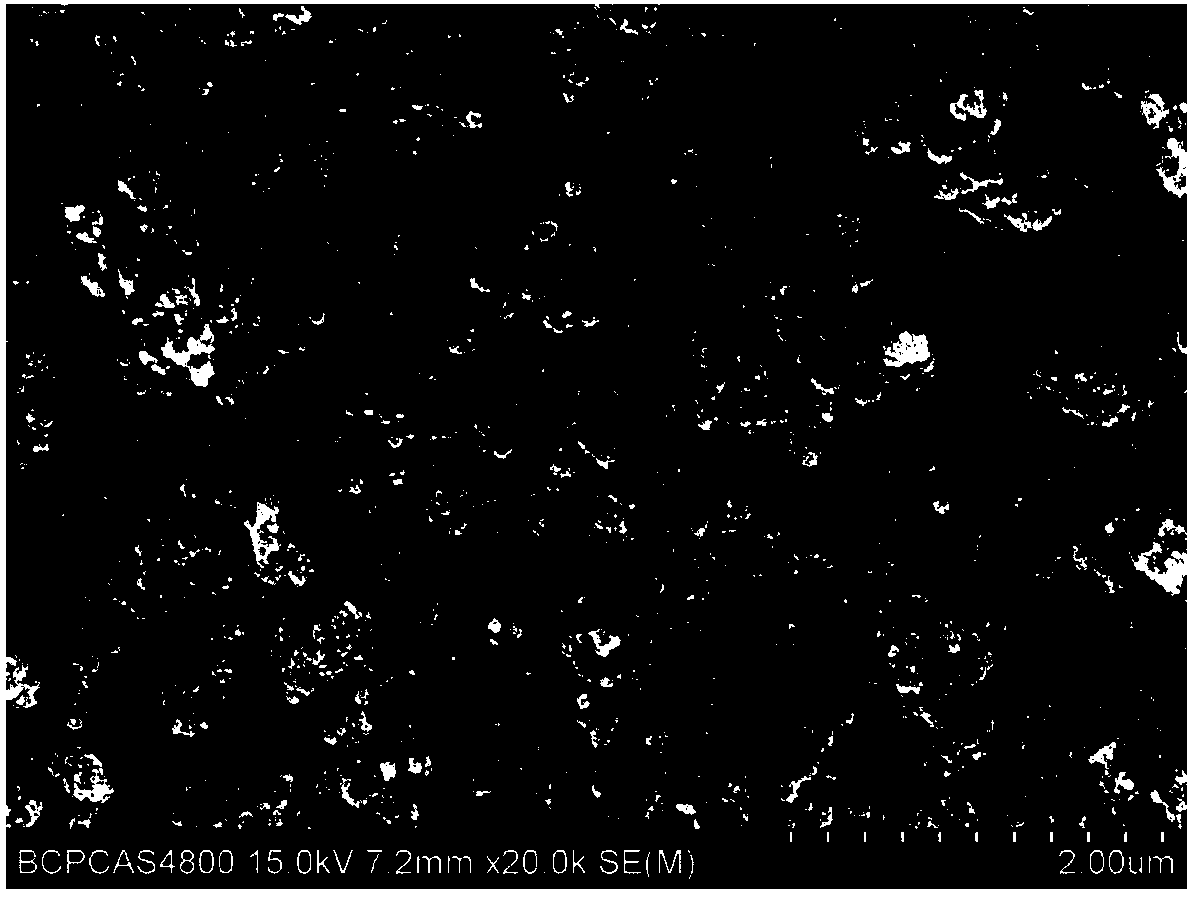

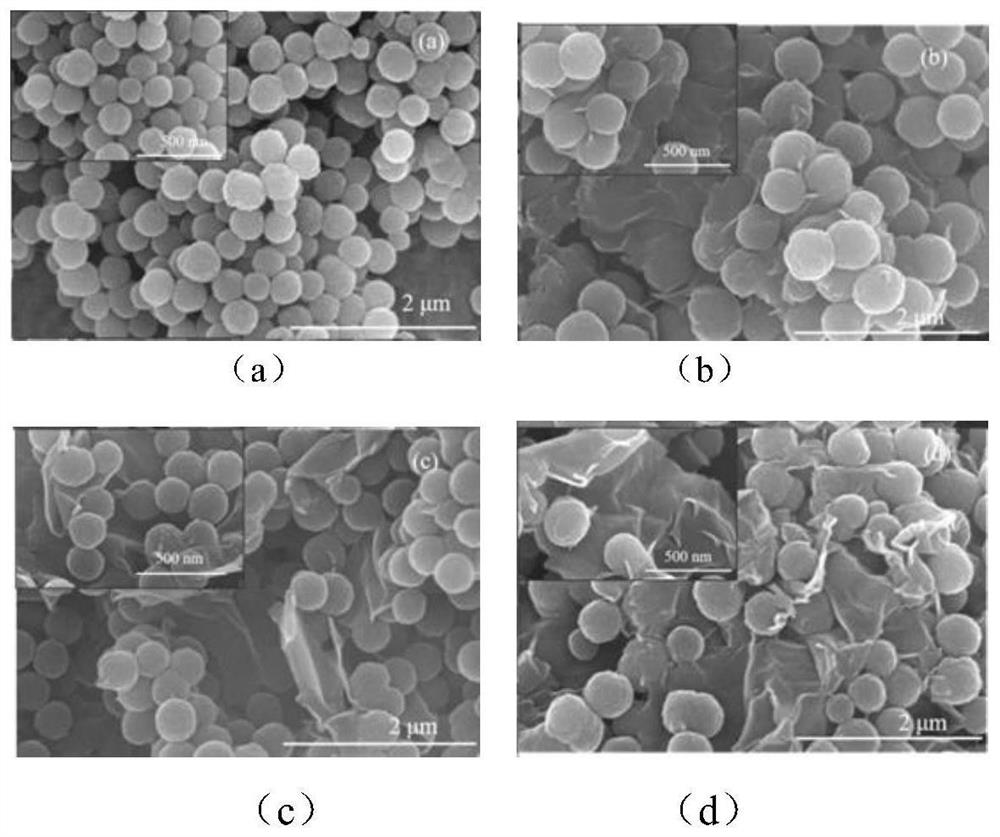

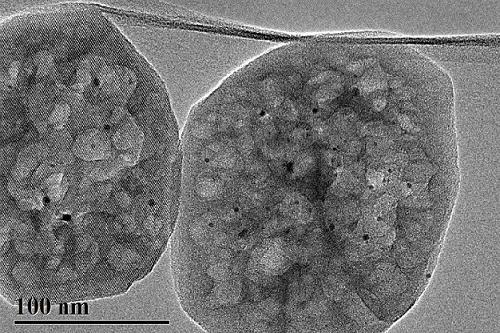

Thin-wall local graphitization porous carbon sphere material, preparation method thereof and application thereof in lithium sulfur battery

The invention discloses a thin-wall local graphitization porous carbon sphere material, a preparation method thereof and application thereof in a lithium sulfur battery. The porous carbon sphere material is a local graphitization porous carbon nanosphere with thin wall holes; the preparation method of the thin-wall local graphitization porous carbon sphere material comprises the steps that water-base resin, water-soluble inorganic salt, a surface active agent and transition metal salts are dissolved into water to obtain a spraying solution; the spraying solution is sprayed and dried to obtaina local graphitization porous carbon nanosphere precursor; the local graphitization porous carbon nanosphere precursor is subjected to pyrolysis to obtain the thin-wall local graphitization porous carbon sphere material. The preparation method is simple in technology and good in repeatability, the prepared thin-wall local graphitization porous carbon sphere material has the advantages of being good in electrical conductivity, large in aperture, high in specific surface area and the like, the thin-wall local graphitization porous carbon sphere material is applied to a lithium sulfur battery sulfur carrier, the high specific capacity, long cycling stability and high rate capability are achieved, and the wide application prospect is achieved.

Owner:CENT SOUTH UNIV

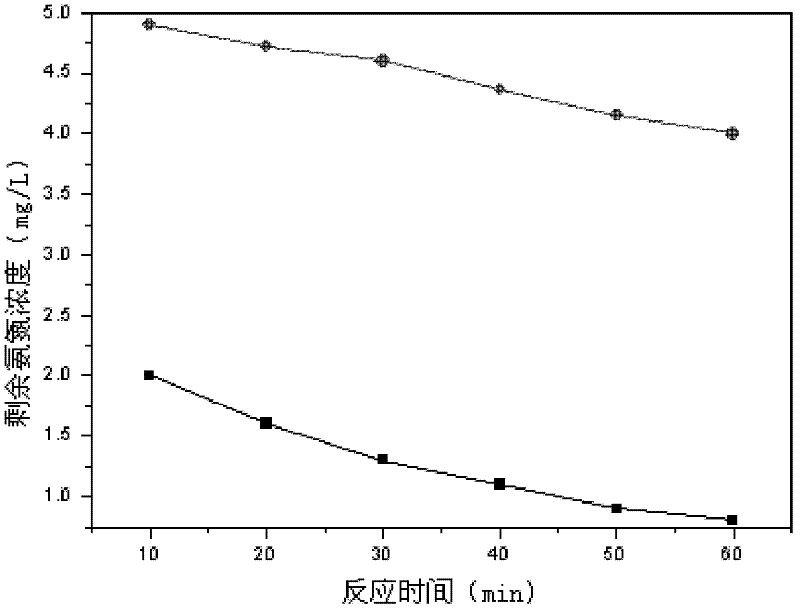

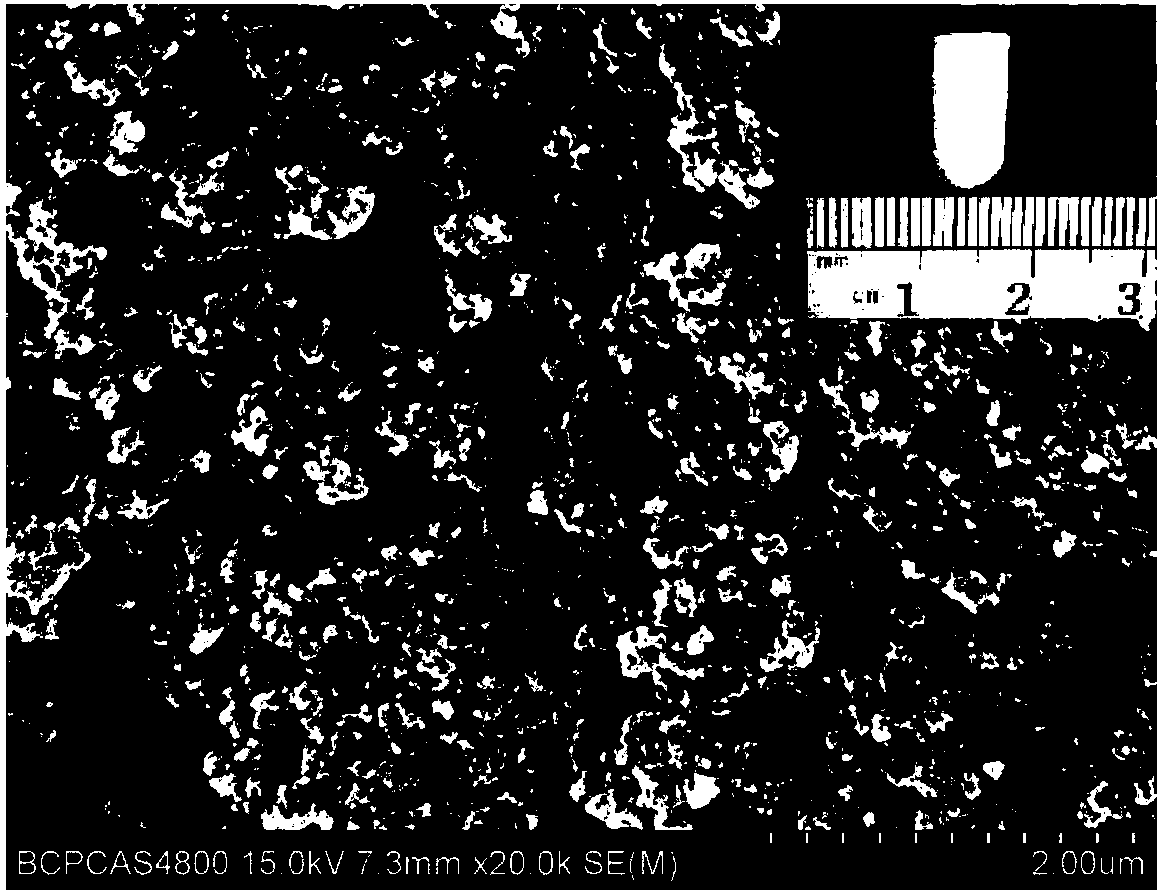

Preparation method and application of bamboo charcoal loaded au-tio2 composite material

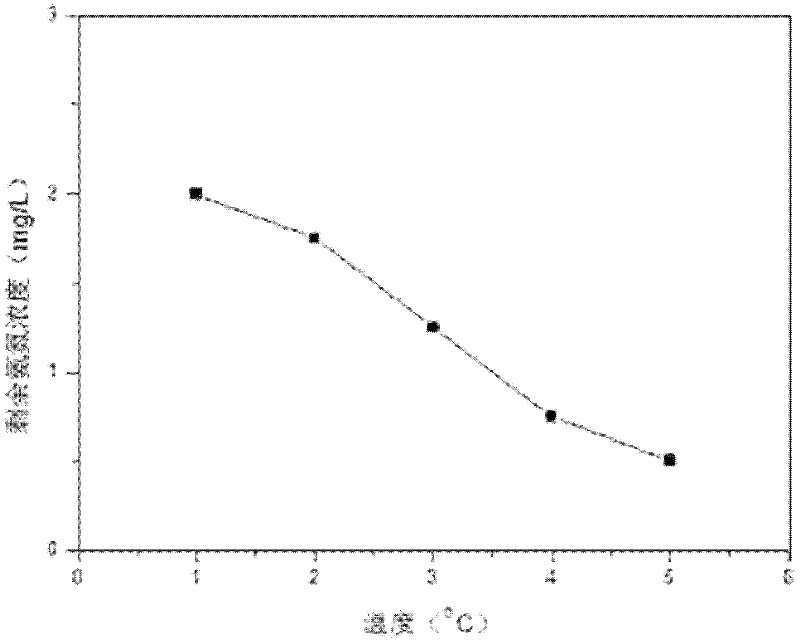

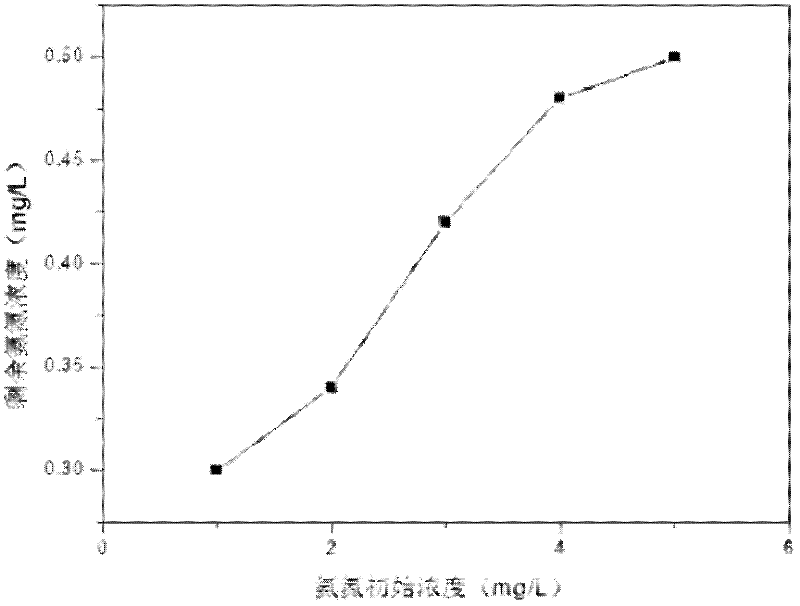

InactiveCN102294226AHigh porosityImprove removal efficiencyWater/sewage treatment by irradiationOther chemical processesPersistent organic pollutantAmmonia nitrogen

The invention relates to a preparation method of an Au-TiO2-bamboo charcoal composite material and its application, and aims to provide a solution to the problems of poor ability in removing ammonia nitrogen from a polluted water body at low temperature and unobvious effect in eliminating micro-pollution in present water treatment processes. The method first prepares Au-TiO2 nanometer powder by an isometric impregnation method, and then loads the Au-TiO2 nanometer powder on the bamboo charcoal. According to the invention, an Au-TiO2 nano-material with a large specific surface area and strong adsorption and oxidation performances is loaded into the pores of the bamboo charcoal, thus the bamboo charcoal simultaneously has the functions of ammonia nitrogen adsorption as well as photocatalytic oxidation of ammonia nitrogen. Therefore, the bamboo charcoal loaded Au-TiO2 composite material can remove ammonia nitrogen from low temperature water at efficiency of 60-90%, and heavy metals and persistent organic pollutants can be partly removed. Besides, the preparation method of the invention has a simple preparation process.

Owner:HARBIN INST OF TECH

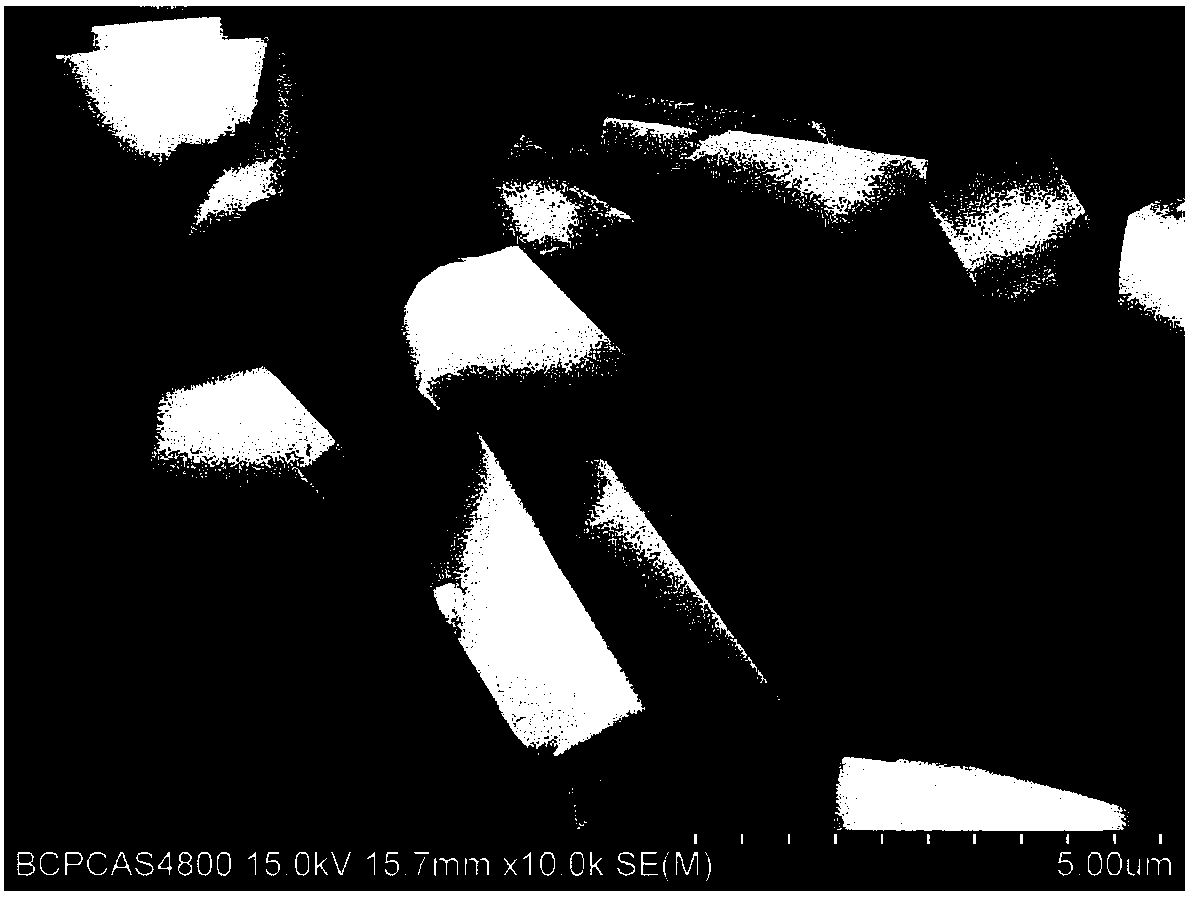

TS-1 zeolite material with multi-level pores and preparation method of TS-1 zeolite material

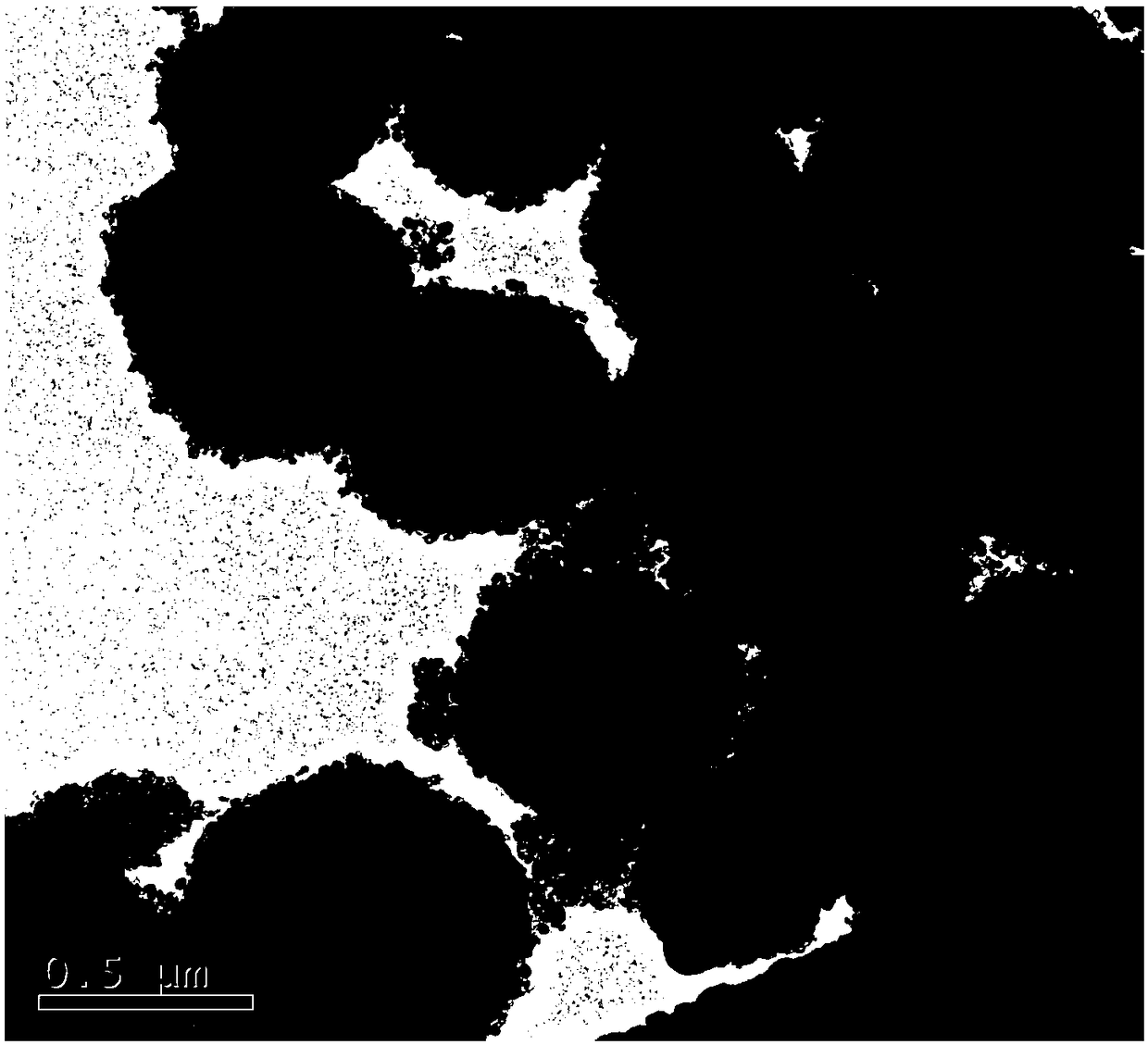

ActiveCN108658087AGuarantee structureUniform structureMolecular sieve catalystsMolecular-sieve silicatesMolecular sieveVapor phase

The invention discloses a TS-1 zeolite material with multi-level pores. The TS-1 zeolite material comprises TS-1 zeolite and a TiO2-SiO2 carrier, and a weight ratio of the TS-1 zeolite to the TiO2-SiO2 carrier is 1:(4.8-9); the zeolite material is an integral forming material having macropores of 0.20-2 [mu]m, mesopores of 2-15 nm and micropores of 0.5-2 nm, a crystal lattice structure of the zeolite material is that a part of Ti<4+> enters a molecular sieve skeleton, a part of Ti<4+> is uniformly embedded in a SiO2 skeleton in a manner of an anatase crystal form, and SiO2 exhibits an amorphous state. The zeolitic material disclosed by the invention adopts a TiO2-SiO2 material as the carrier, a silicon source and a titanium source, under the vapor phase condition, the skeleton is partiallyconverted into the TS-1 zeolite, and a micron-sized through-hole skeleton structure of the carrier is maintained; and the prepared TS-1 zeolite has an uniform and stable structure and the multi-levelpores communicating with one another, thereby having very important significance for a macromolecular catalytic reaction.

Owner:CHINA PETROLEUM & CHEM CORP +1

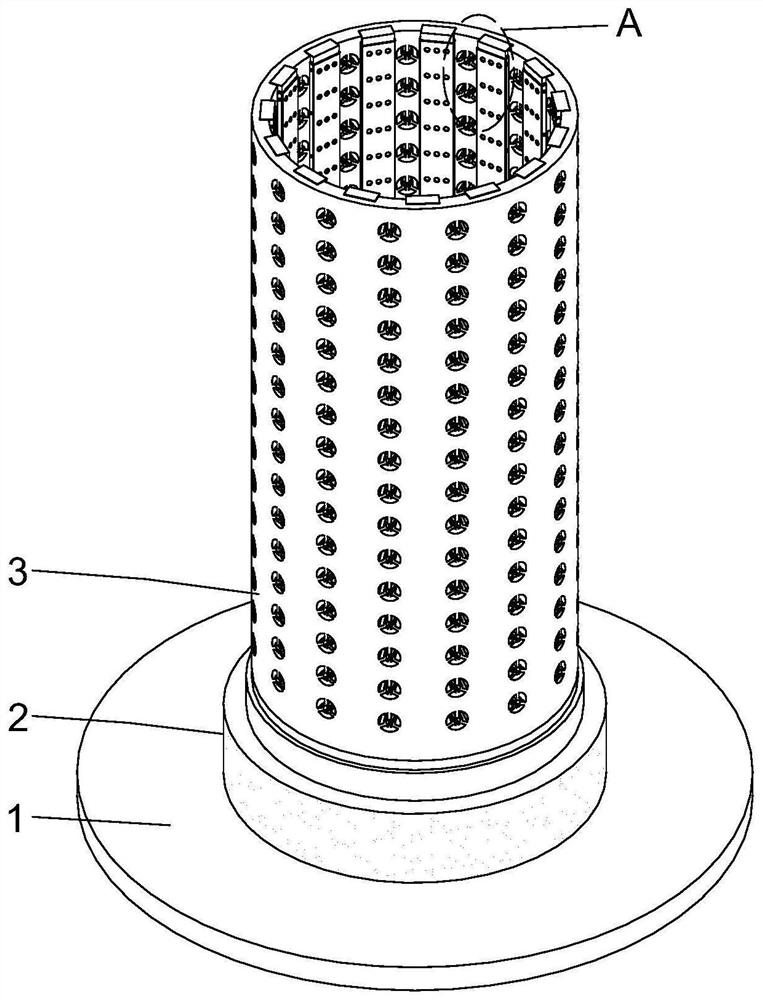

Portable catalytic combustion bed

InactiveCN107270311ALow costIncrease surface areaGas treatmentOther chemical processesDesorptionCatalytic oxidation

The invention discloses a portable catalytic combustion bed. The portable catalytic combustion bed comprises a shell; the shell is a cylinder structure, is manufactured by temperature resistant carbon steel, and is wrapped with an electromagnetic coil; a layer of insulation material covers the outer side of the electromagnetic coil; and a honeycomb-shaped molecular sieve absorbing material and a foam metal catalyst are arranged on the inner wall of the shell in sequence. A molecular sieve with a honeycomb structure is used for absorption and concentration; foam metal is used as a catalyst carrier; an electromagnetic induction heating mode is compounded to enable the foam metal to generate heat; excellent heat transfer of the foam metal is used for rising the room temperature to 200 DEG C within second minutes; and the desorption regeneration and catalytic oxidation of VOCs as carbon dioxide and water are realized through internal circulation.

Owner:南通斐腾新材料科技有限公司

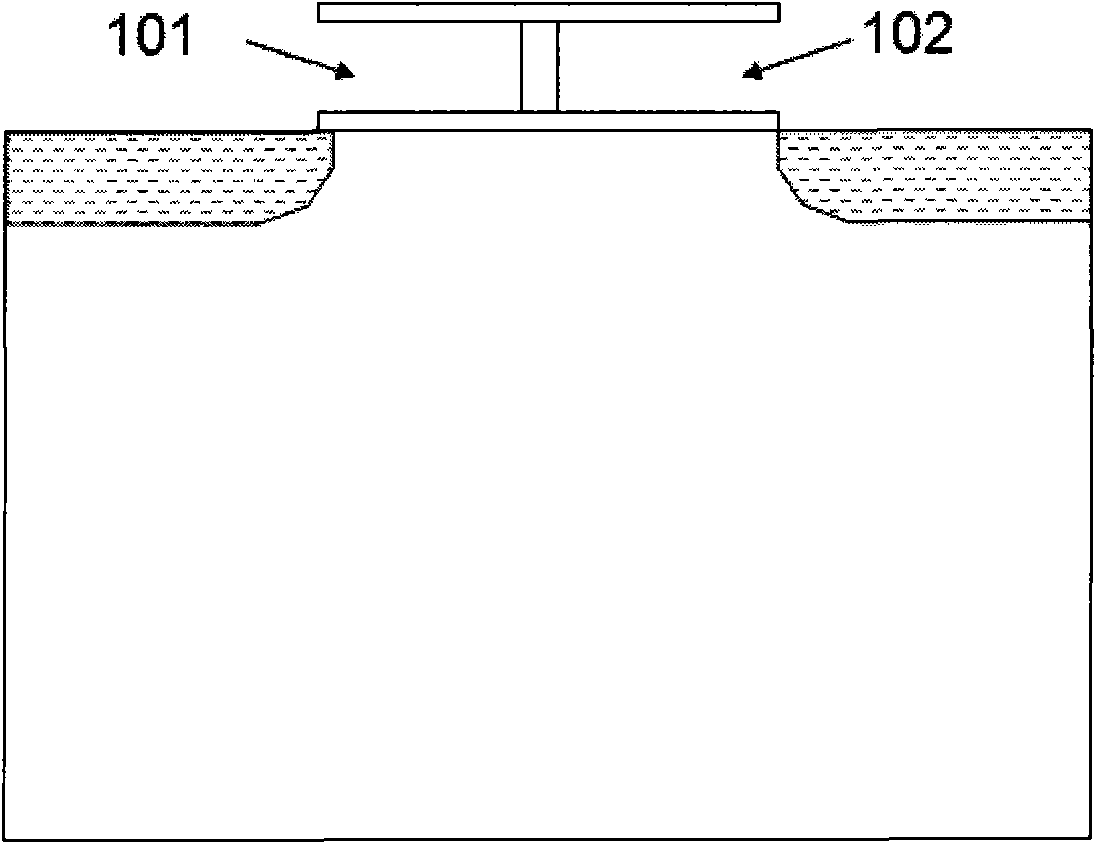

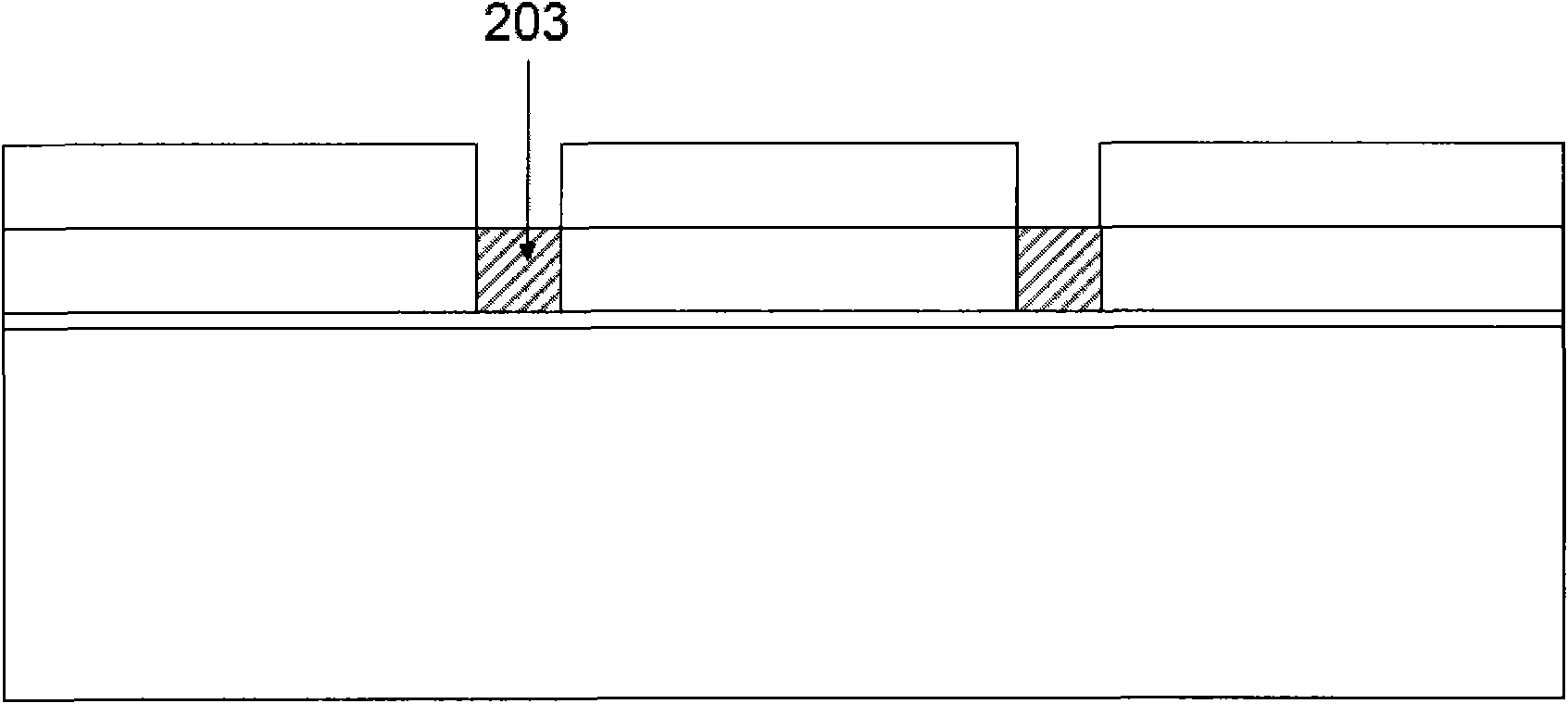

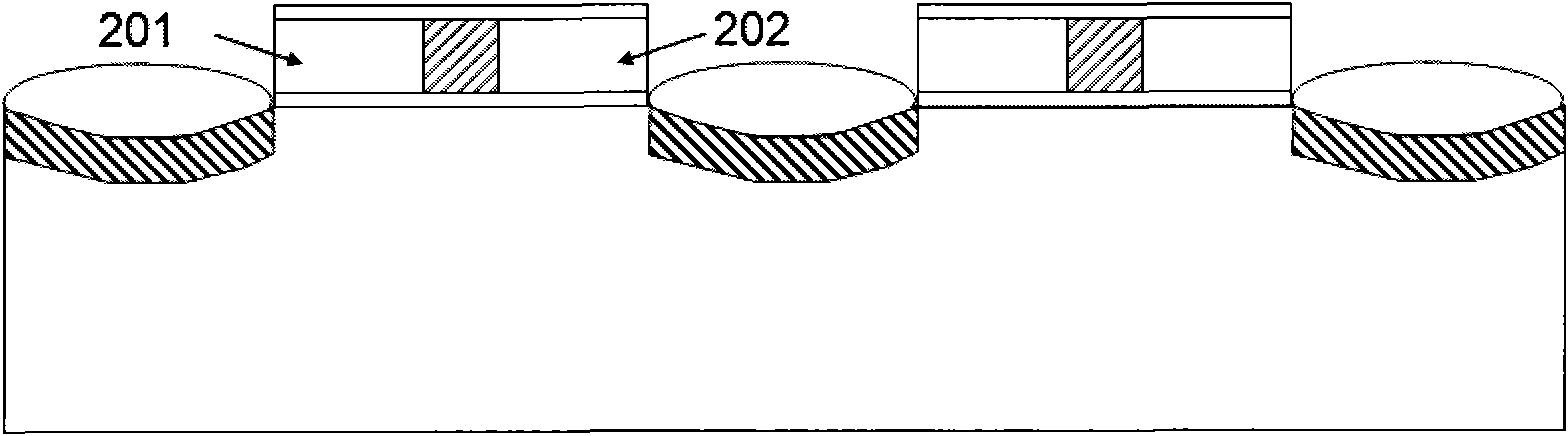

Semiconductor memory device and manufacturing method thereof

The invention discloses a semiconductor memory device, which comprises a source, a drain, two floating gate regions, a control gate, and a substrate pole, and the floating gate regions of the semiconductor memory device are used for storing charges. The invention further discloses a manufacturing method of the semiconductor memory device. The manufactured semiconductor memory device has the advantages of small unit area, simple manufacturing process and the like, and the use of the invention can reduce the manufacturing cost of a memory chip and improve the storage density.

Owner:SUZHOU ORIENTAL SEMICONDUCTOR CO LTD

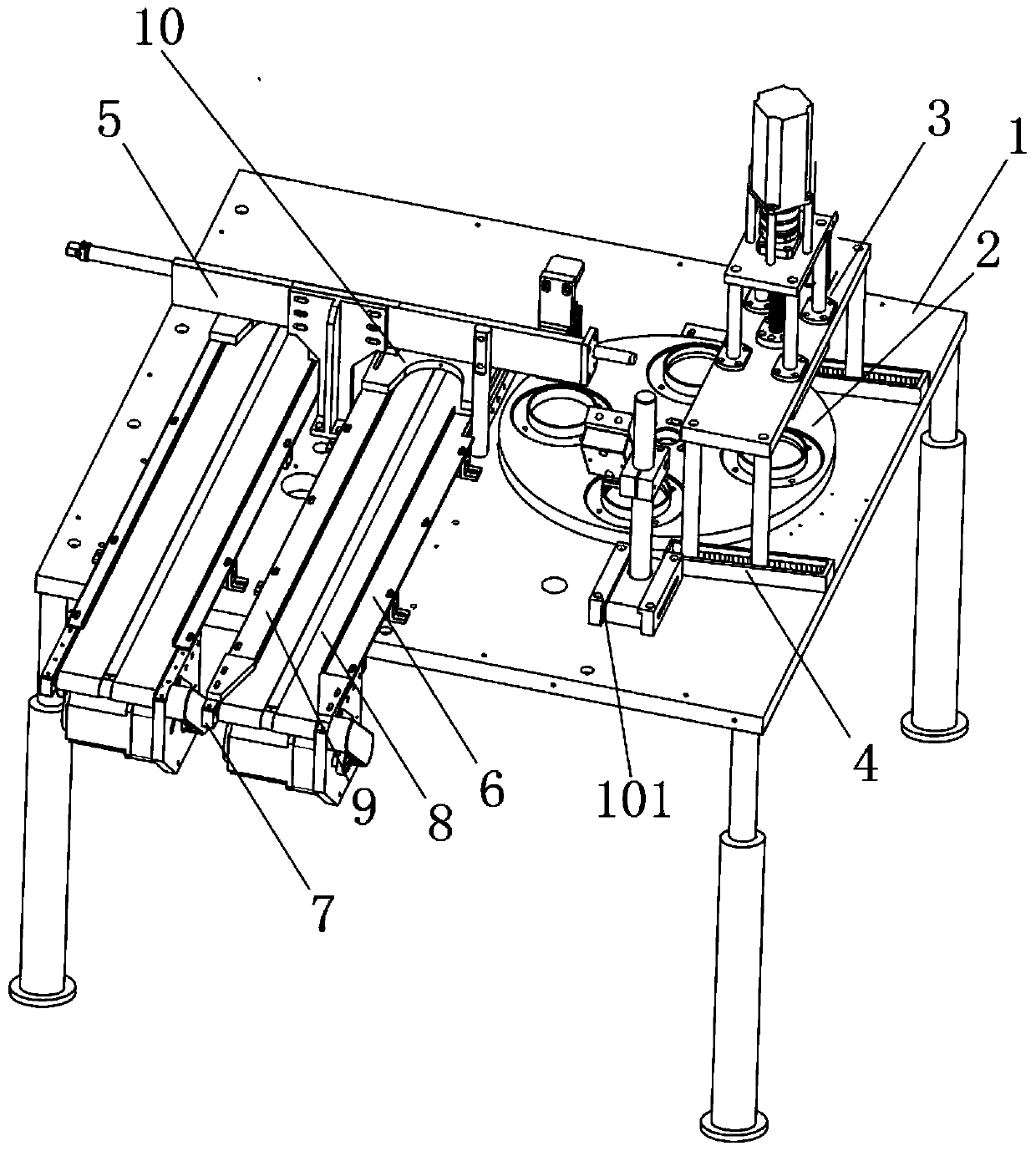

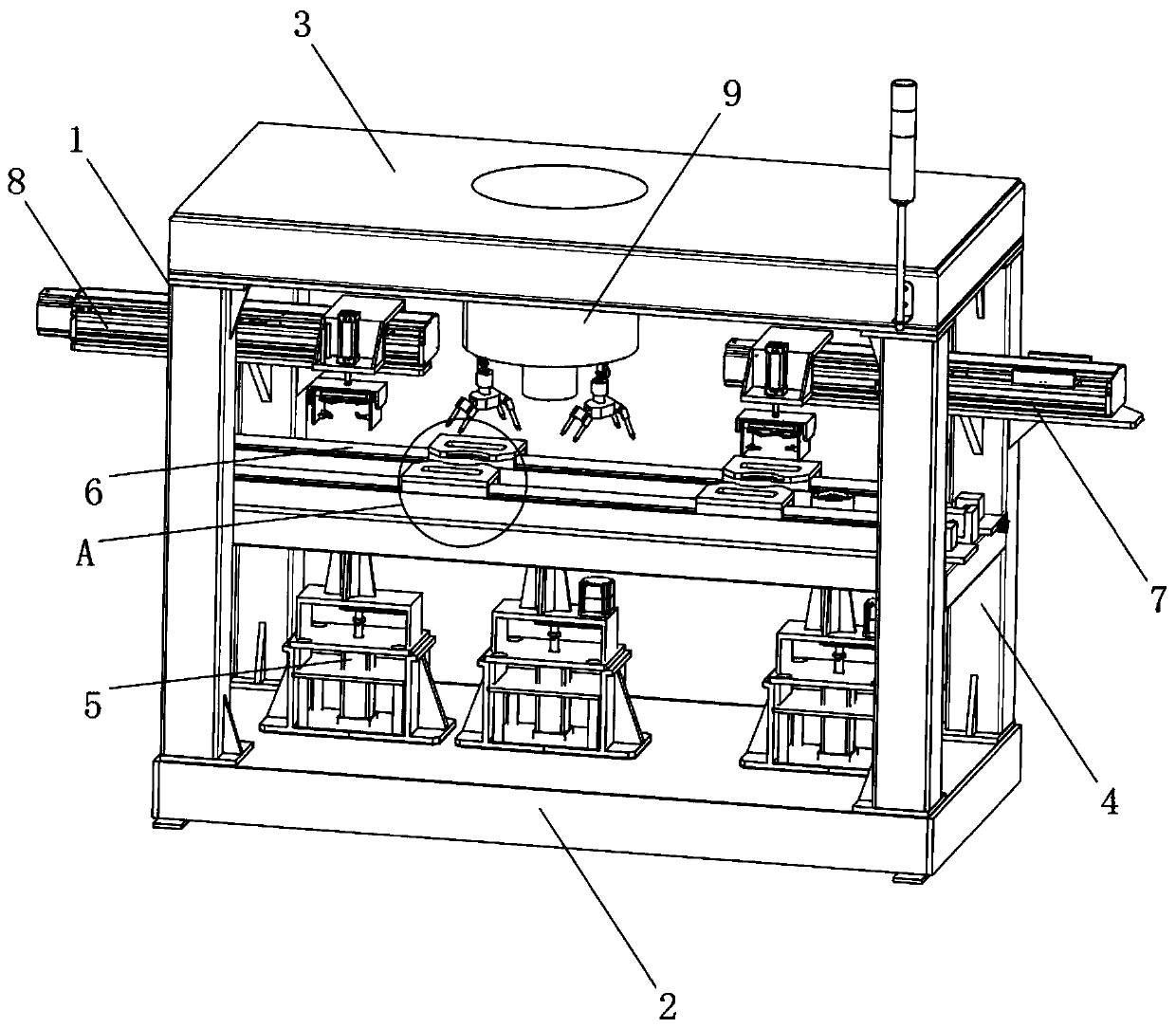

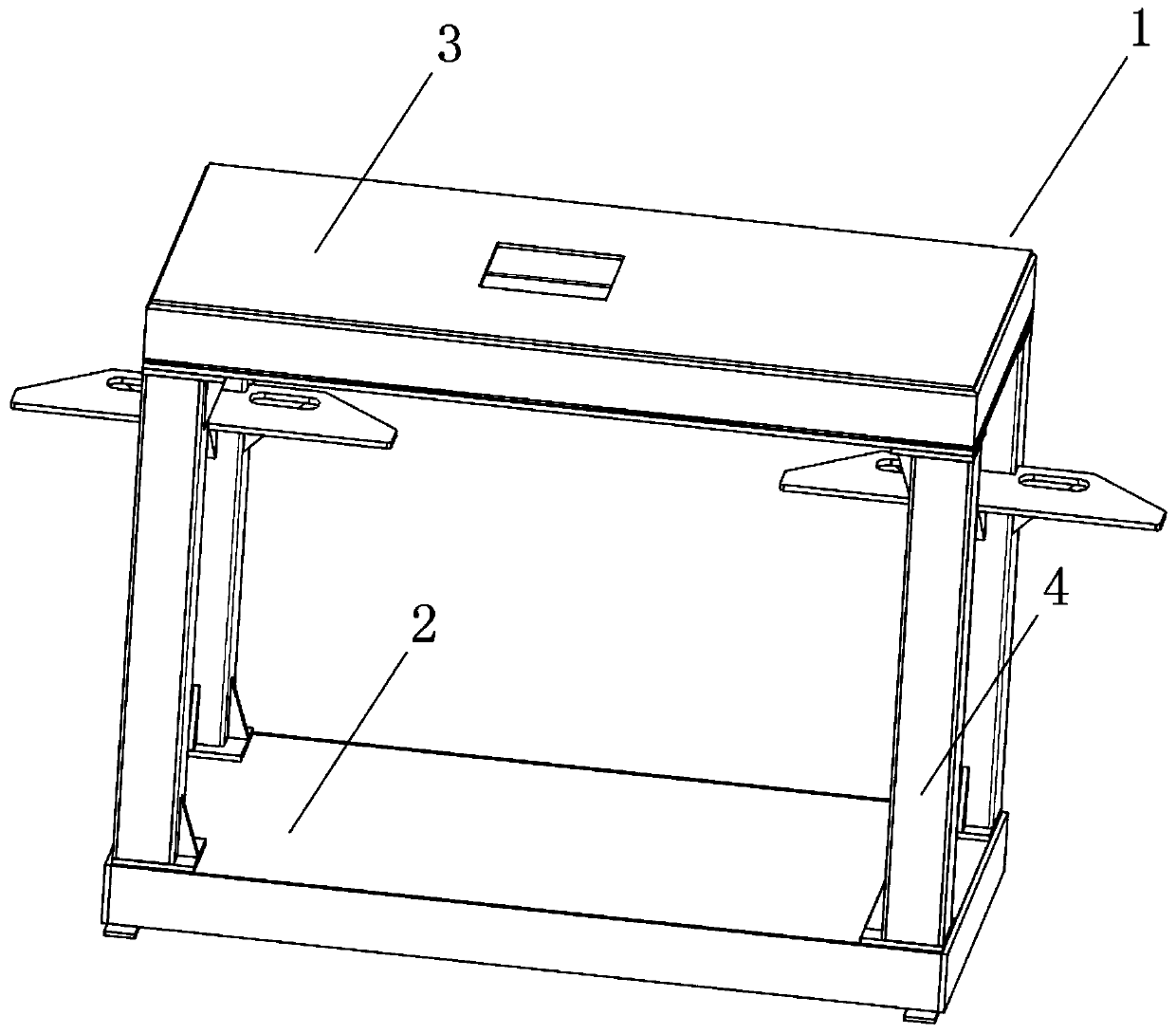

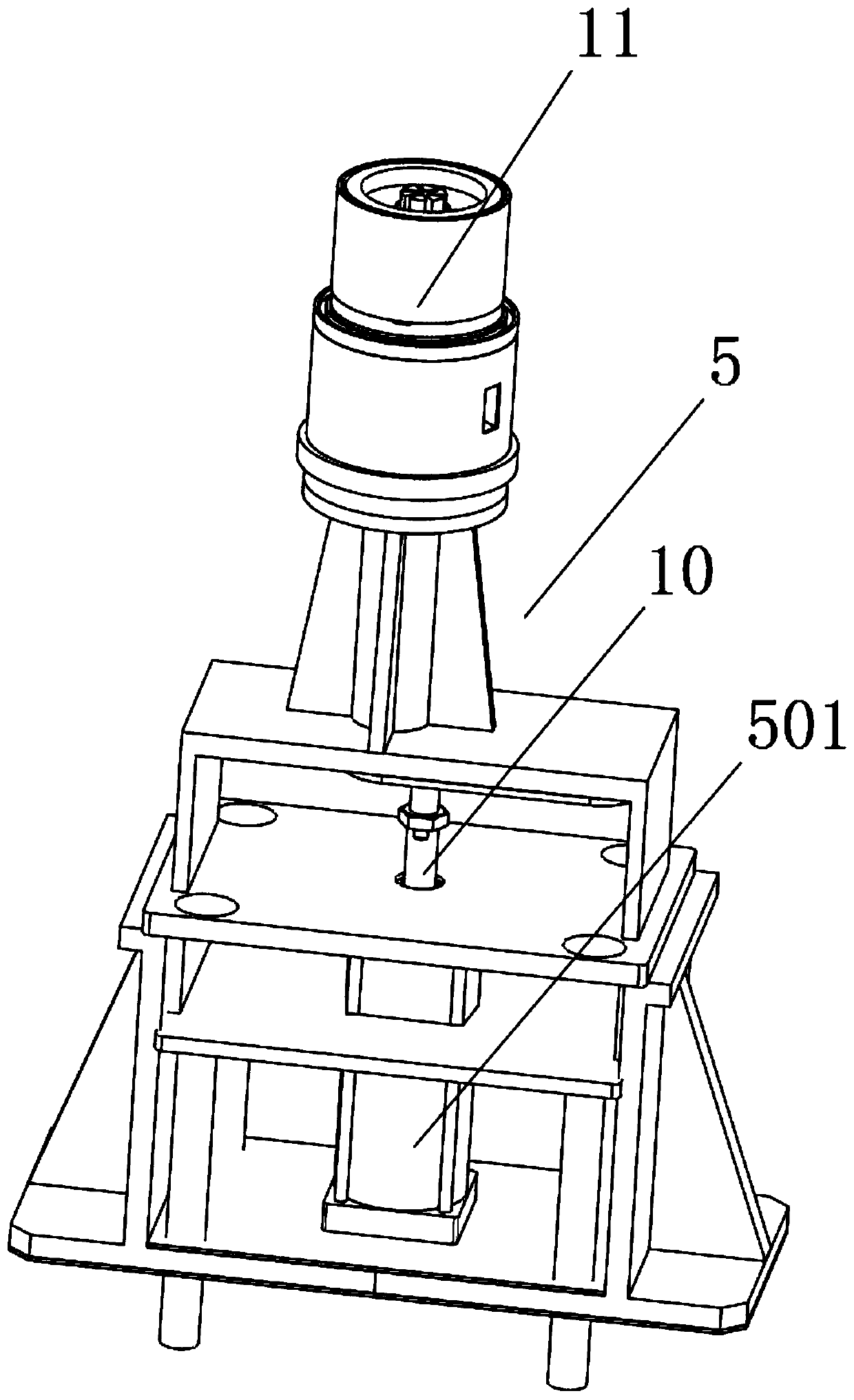

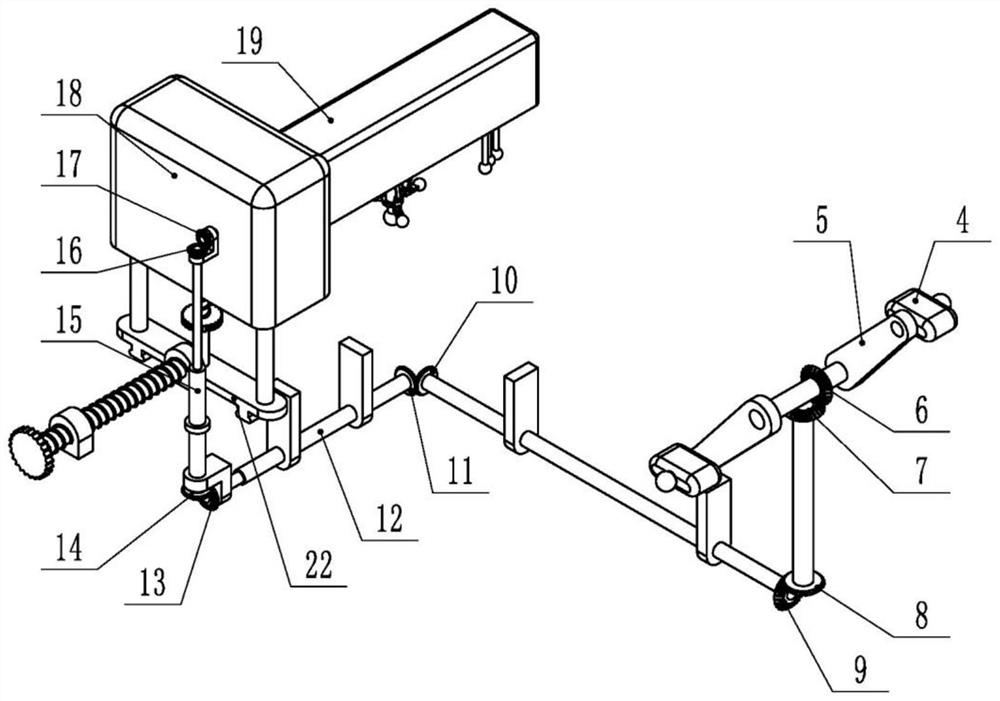

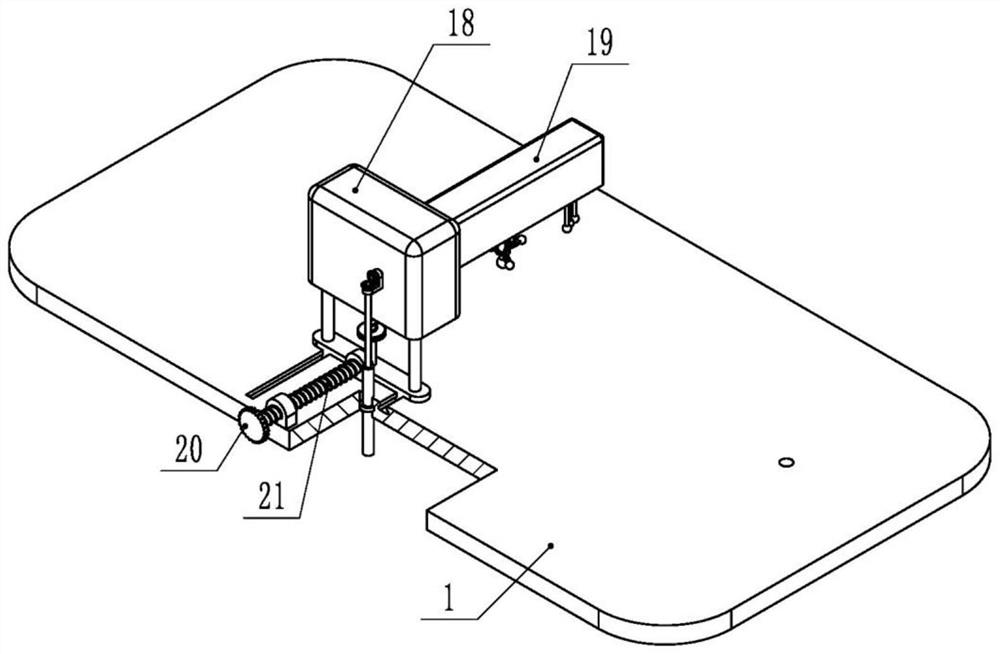

Perforating and finishing equipment for machining electricity meter shell and working method of perforating and finishing equipment

InactiveCN111098141AHigh precisionQuality improvementOther manufacturing equipments/toolsHydraulic cylinderPolishing

The invention discloses perforating and finishing equipment for machining an electricity meter shell. The perforating and finishing equipment comprises a horizontally arranged middle support plate I,a drilling mechanism, a horizontally arranged rotary mounting table, a shell polishing frame, a gripping and adjusting mechanism and two transfer tables, wherein the middle support plate I is of a cuboid structure; the drilling mechanism is vertically arranged above one end of the middle support plate I; and the rotary mounting table is arranged below one side of the drilling mechanism. The perforating and finishing equipment has the beneficial effects that two push-fit plates are tightly attached to the side walls of the two sides of the electricity meter shell respectively to tightly clamp and fix the electricity meter shell, thus it is ensured that the electricity meter shell is more stable and firmer when being perforated and finished, and the accuracy and quality of the perforating and trimming on the electricity meter shell by the equipment are improved; and first hydraulic cylinders drive the push-fit plates to adjust and move left and right through first hydraulic shafts to adjust the working distance between the two push-fit plates, so that it is ensured that push and clamp assemblies on the two sides of each rotary bucket are capable of adapting to clamping and fixing theelectric meter shells with different widths, and the working adaptation range of the equipment is improved.

Owner:王亚伟

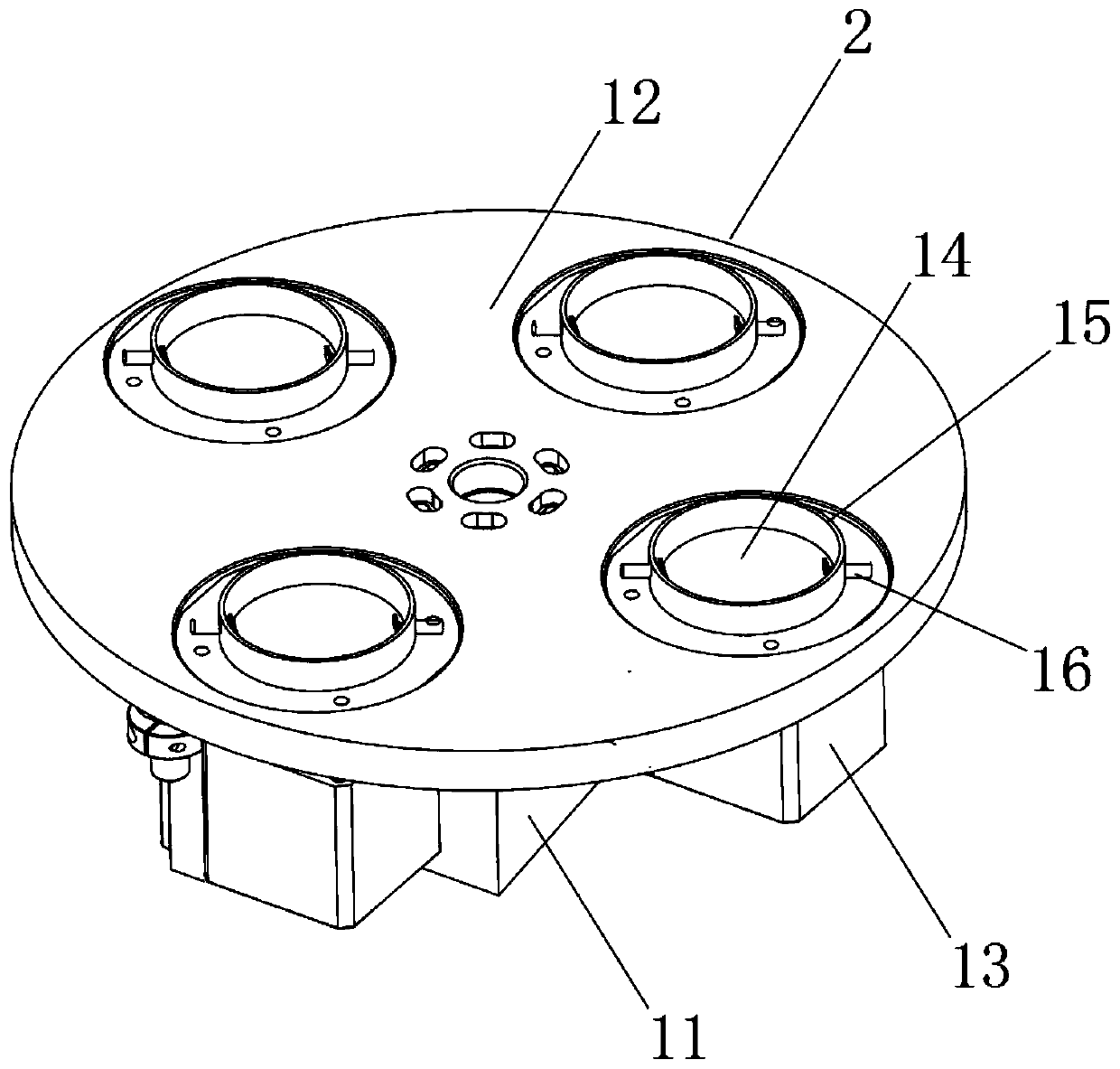

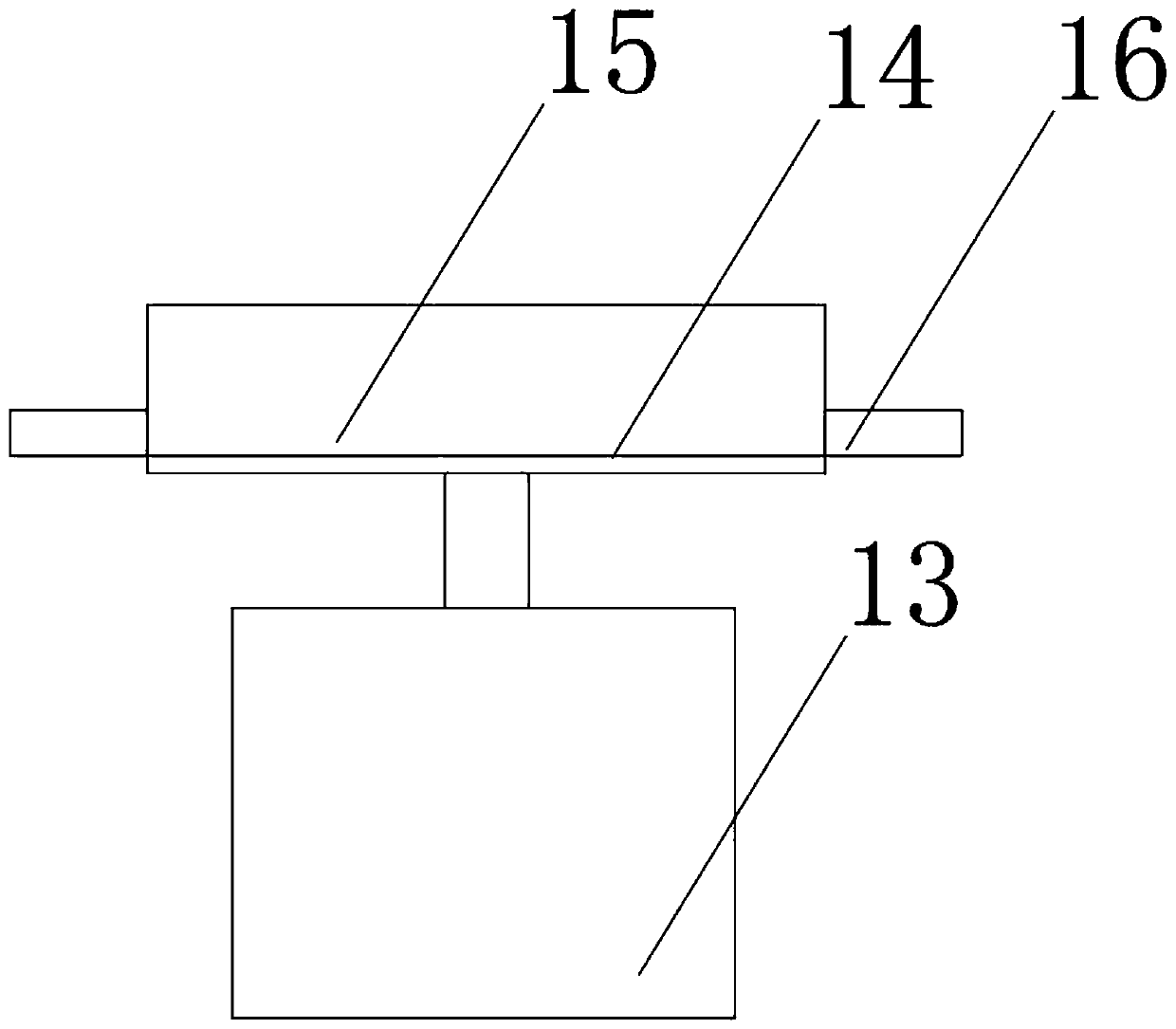

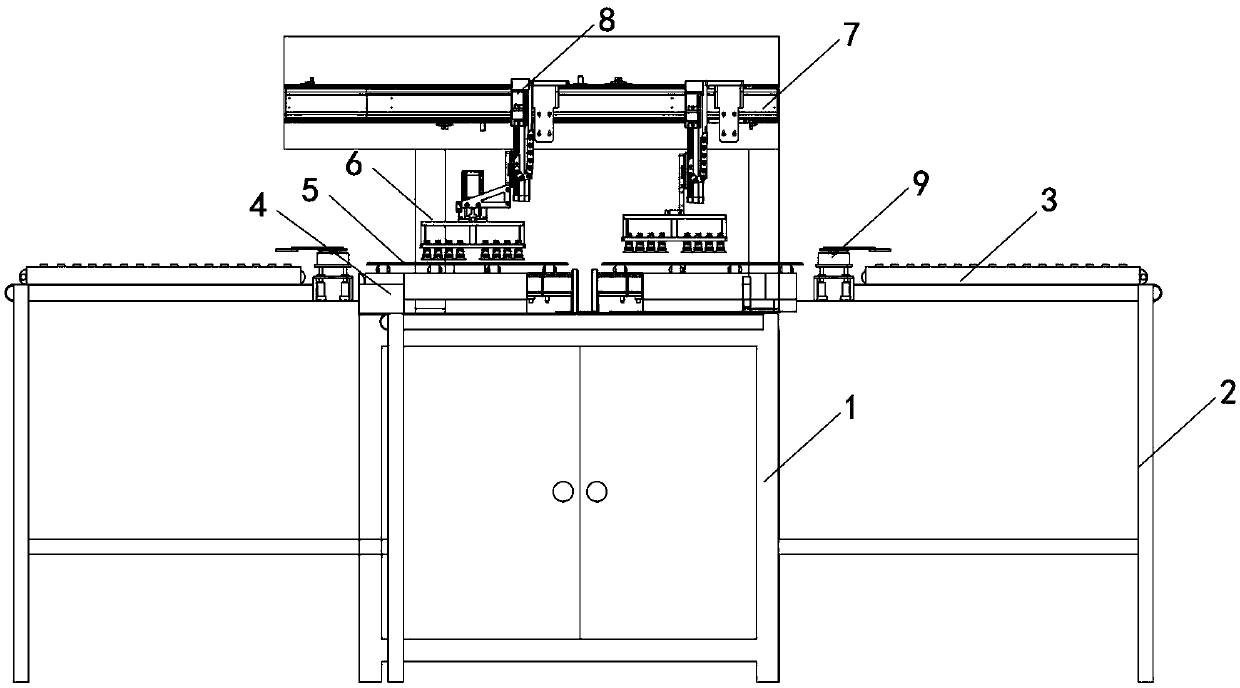

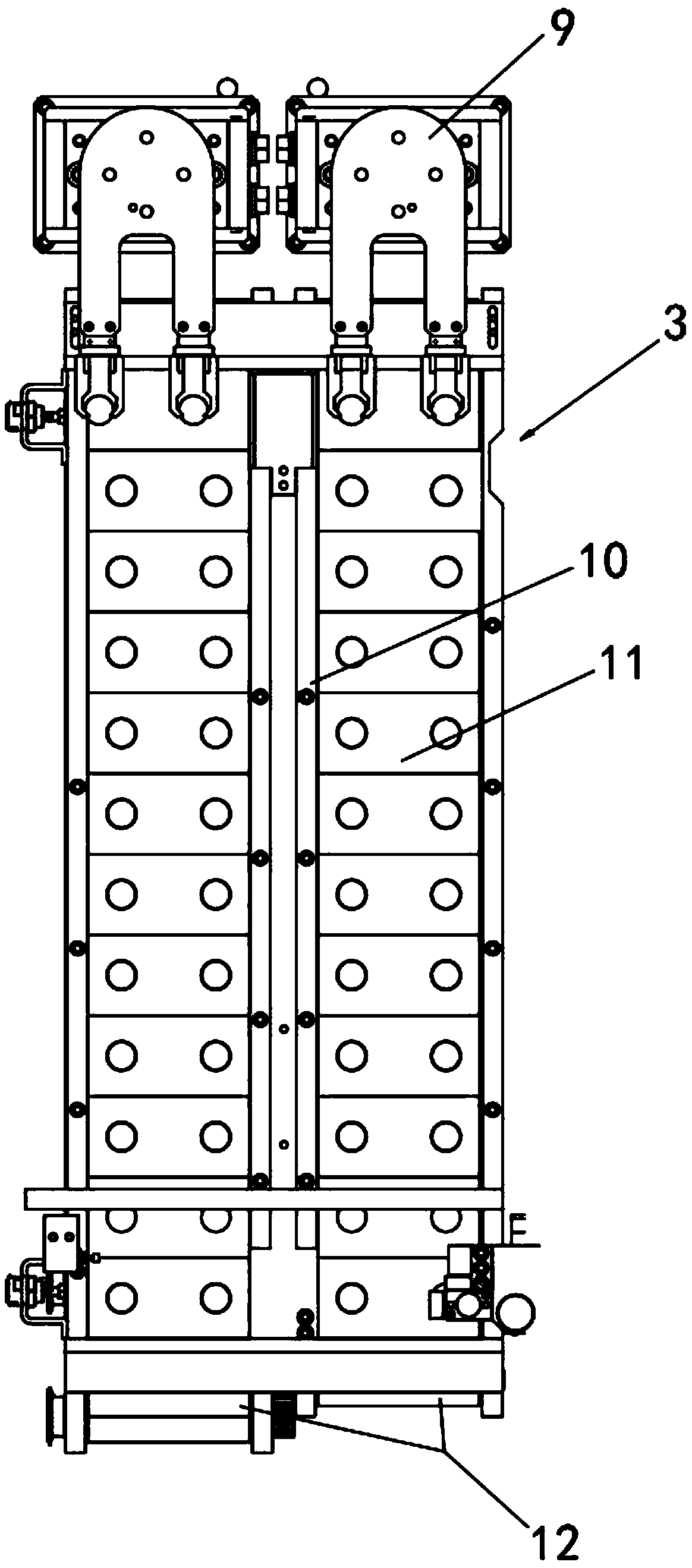

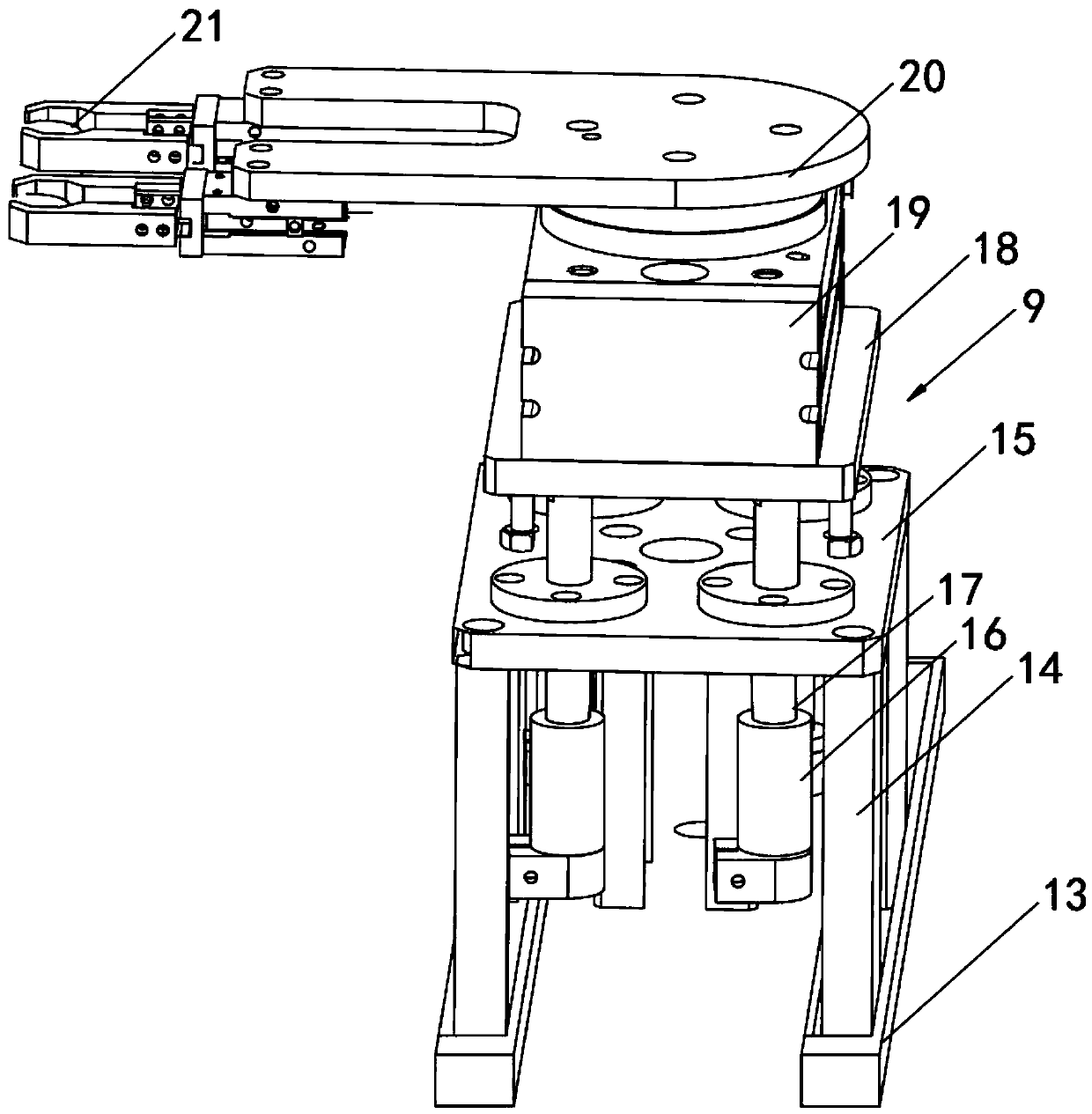

PCB automatic collecting and placing machine and working method thereof

ActiveCN109625948AGuaranteed drynessImprove cleanlinessCharge manipulationLoading/unloadingHydraulic pumpWheel drive

The invention discloses a PCB automatic collecting and placing machine and a working method thereof. The machine comprises a mounting seat, supporting frames, rolling and conveying discs, a collectingand placing cabinet, a rotary disc, an air blowing frame, a transverse rail rod, a longitudinal rail rod and a grabbing and placing seat, wherein the supporting frames are arranged at the two ends ofthe mounting seat, and the rolling and conveying discs are horizontally arranged above the two supporting frames. The machine has the beneficial effects that a plurality of air blowing cylinders on the air blowing frame synchronously blow hot air to a board body, so that the drying performance of a PCB is guaranteed when the PCB is collected and placed, dust and impurities on the PCB are blown away, so that the tidiness of the PCB when the PCB is collected and placed is guaranteed, then a hydraulic pump II on the collecting and placing cabinet drives a rotary disc to move downwards into a receiving bucket through a hydraulic rod, after a mechanical arm clamps the PCB through clamping jaws, the hydraulic rod drives the rotary disc to rise, a third rolling wheel drives the mechanical arm toextend out of a movable groove, and place the PCB into a loading groove of a loading frame, so that the automatic collecting and placing of the PCB can be completed, the operation of the collecting and placing machine is more time-saving and labor-saving, and the work is more efficient.

Owner:领跃电子科技(珠海)有限公司

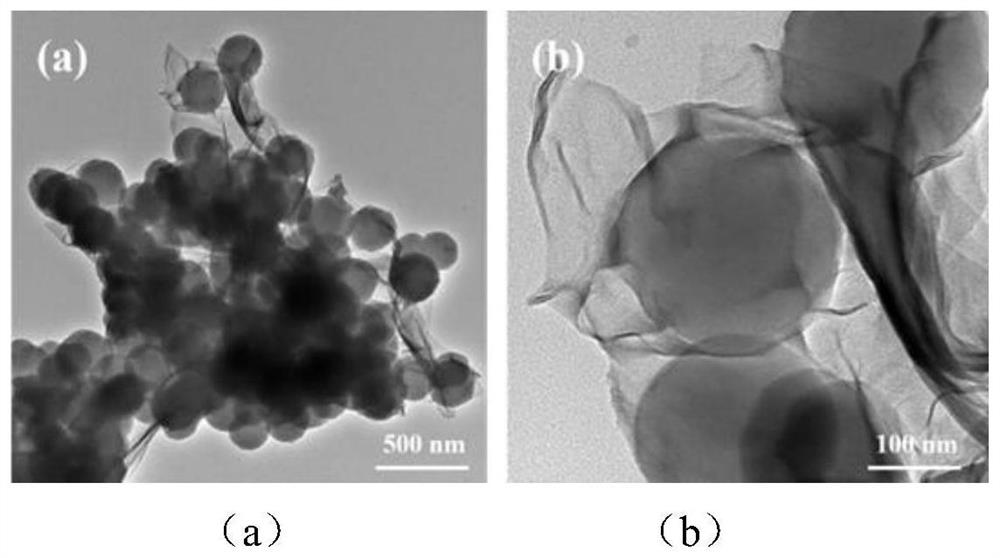

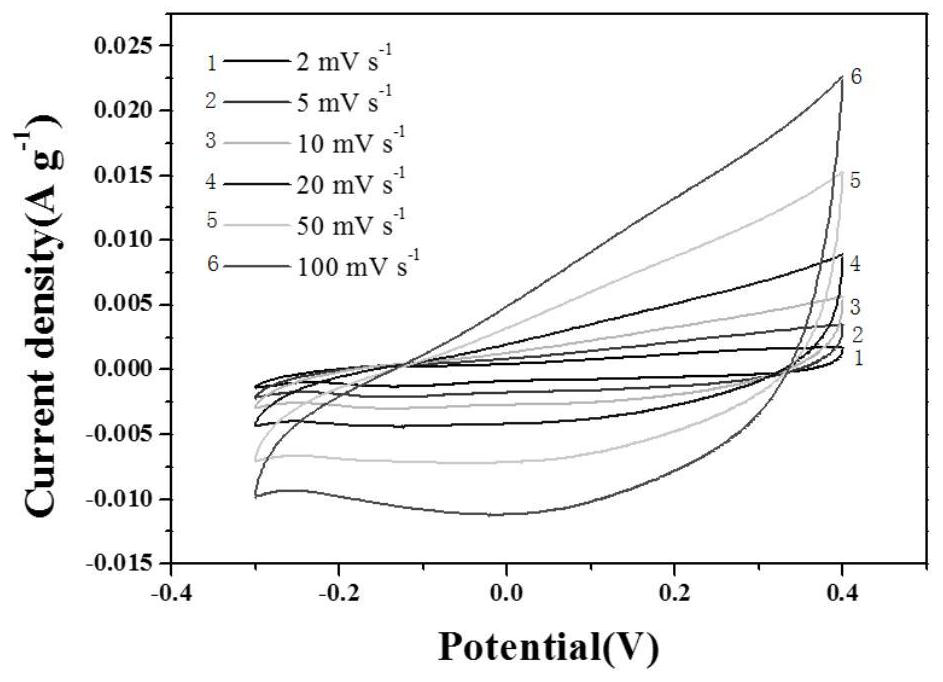

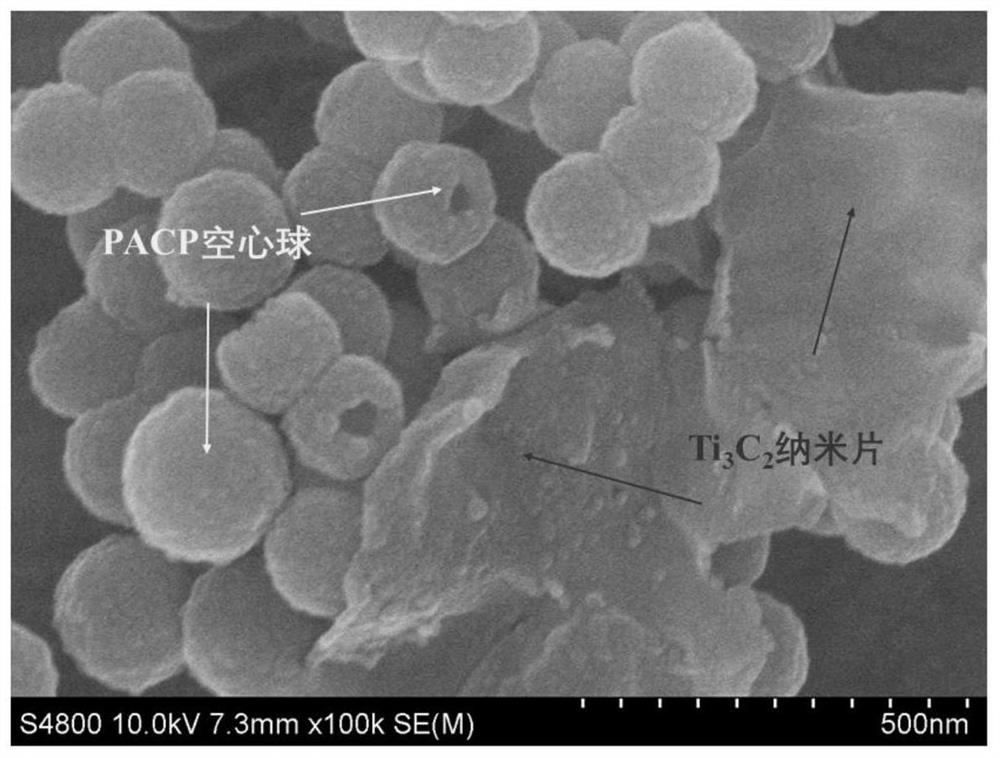

Polypyrrole nanosphere@titanium carbide composite material as well as preparation method and application thereof

InactiveCN111883366AStrong combinationGood electrochemical performanceHybrid capacitor electrodesElectron transmissionComposite material

The invention also discloses a polypyrrole nanosphere@titanium carbide composite material as well as a preparation method and application thereof. According to the preparation method, PPy and ultrathin titanium carbide are compounded by using a low-temperature chemical oxidation method to obtain a Ti3C2@PPy composite nanosphere material serving as an electrode material of a supercapacitor. An in-situ polymerization method is simple to operate, is environment-friendly and efficient, the nano spherical PPy and the layered ultrathin Ti3C2 are compounded, so that the nano spherical PPy and the layered ultrathin Ti3C2 can be in more sufficient contact, the specific surface area is larger, the particle transmission and diffusion are better facilitated, and the application performance is improved. According to the present invention, the Ti3C2@PP Ti3C2 nanospheres are mainly prepared by adopting a low-temperature chemical oxidation method, the preparation method is simple, convenient, efficient, green and environment-friendly, the Ti3C2@PPy with a spherical structure has the larger specific surface area, the electron transmission and ion diffusion are better facilitated, and the application range is wider; and the precursor is prepared for the further development and application in the fields of supercapacitors, lithium ion batteries, electronic induction products and the like.

Owner:SHAANXI UNIV OF SCI & TECH

Preparation for flexible paper-based platinumnanometer particle-ramosetitanium dioxidenanotube compound

InactiveCN109292733AEasy to prepareAbundant specific surface areaMaterial nanotechnologyIndividual molecule manipulationChemistryTitanium dioxide

The invention discloses a preparation method for a flexible paper-based platinum nanometer particle-ramose titanium dioxide nanotube compound. The preparationmethod comprises the following steps thatchromatographic paper is taken as a base, paper pieces modified by platinum nanometer particles are prepared, paper pieces modified by zinc oxide nanorods andplatinum nanometer particles jointly are prepared, paper pieces modified by ramosezinc oxide and platinum nanometer particles jointly are prepared, and the flexible paper-based platinum nanometer particle-ramose titanium dioxide nanotube compound is prepared. The preparation method has the advantages that the paper is selected as the base of the platinum nanometer particle-ramose titanium dioxide nanotube compound, the loading capacity ofthe compound can be greatly improved, the photoelectric conversion efficiency of a flexible titanium dioxide sensor is improved, and good foundation is laid for preparation of a multifunctional flexile titanium dioxidebiosensing platform.

Owner:UNIV OF JINAN

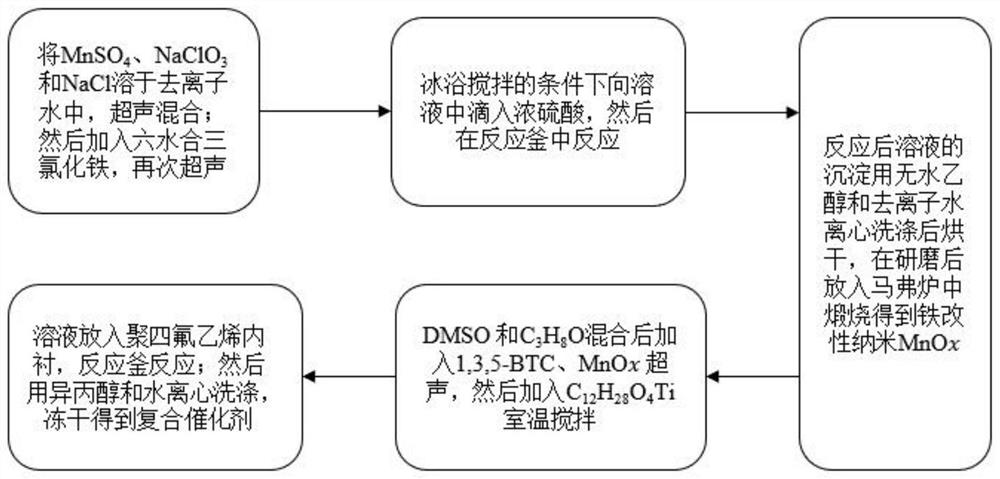

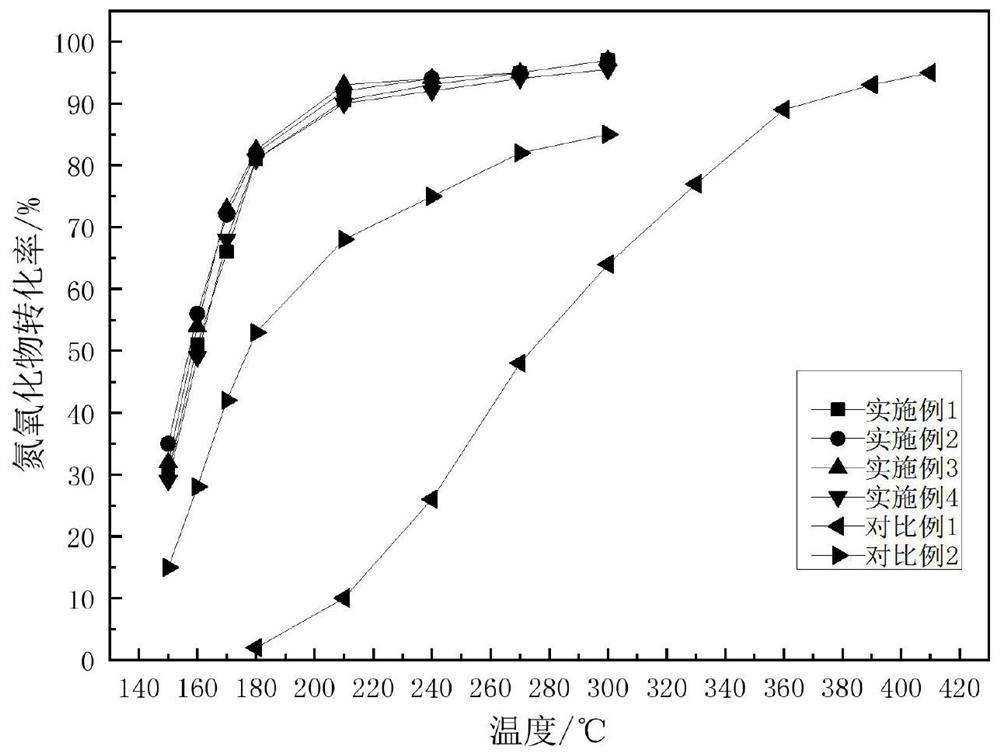

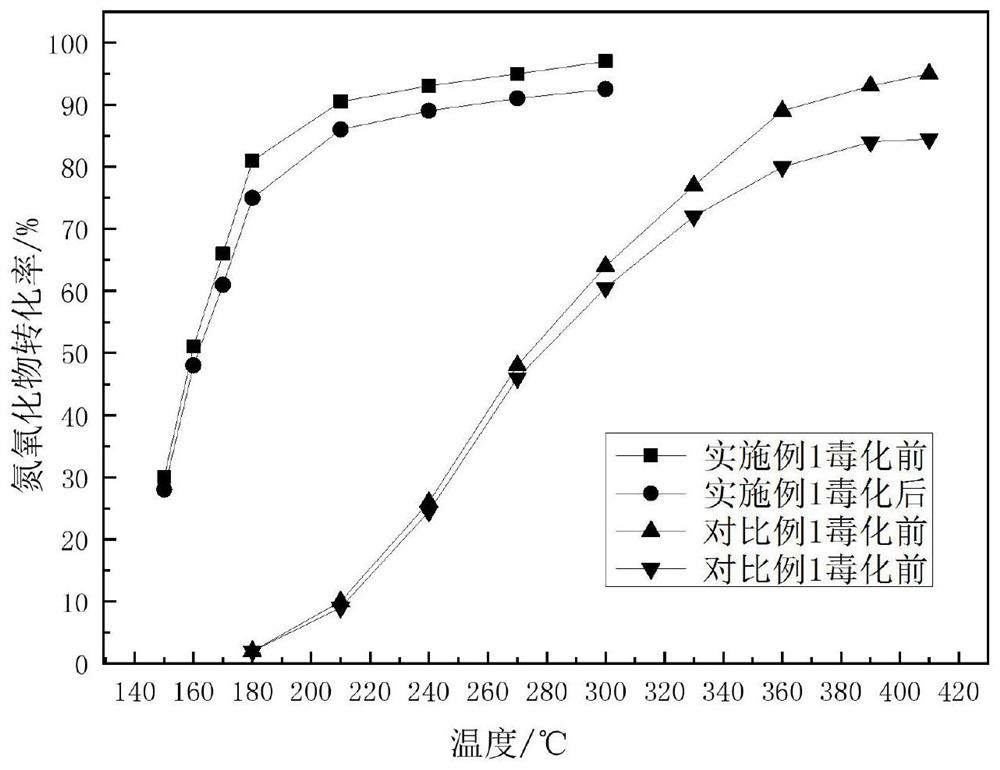

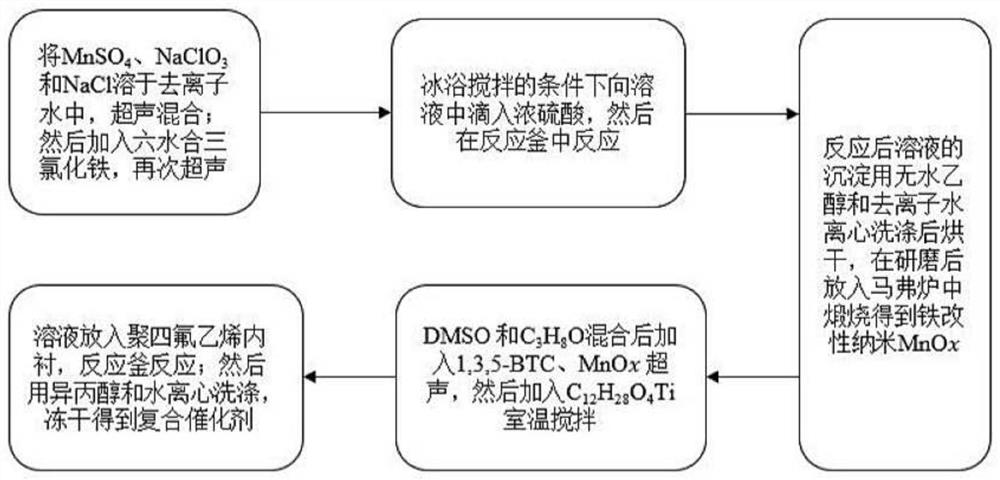

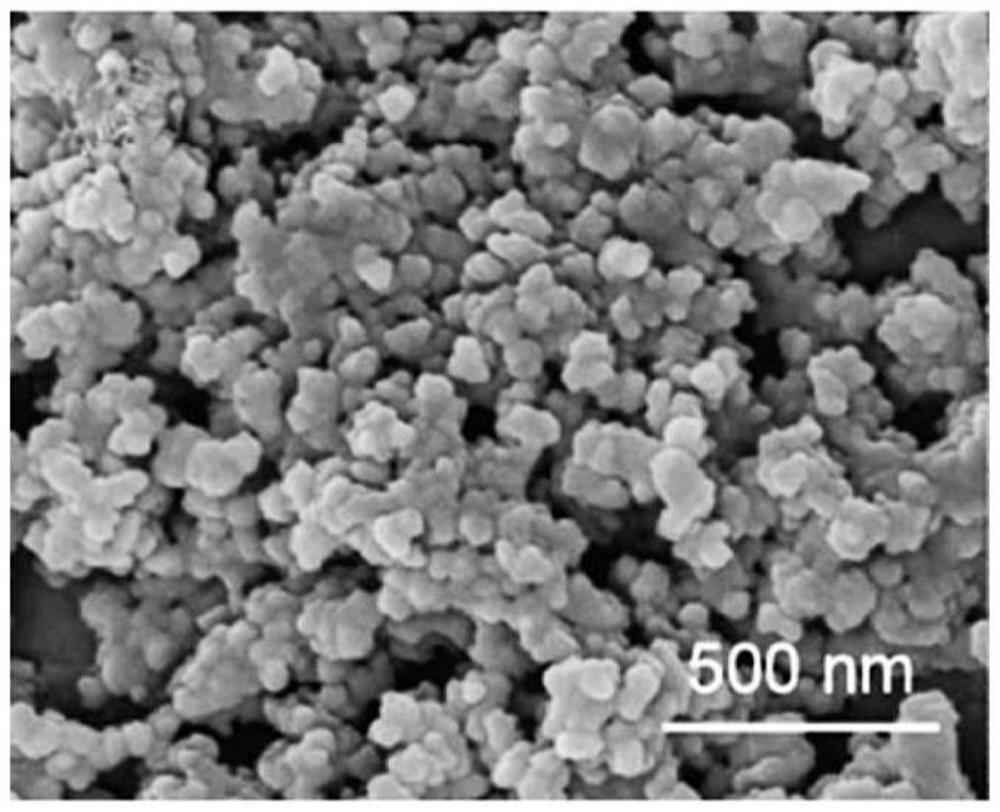

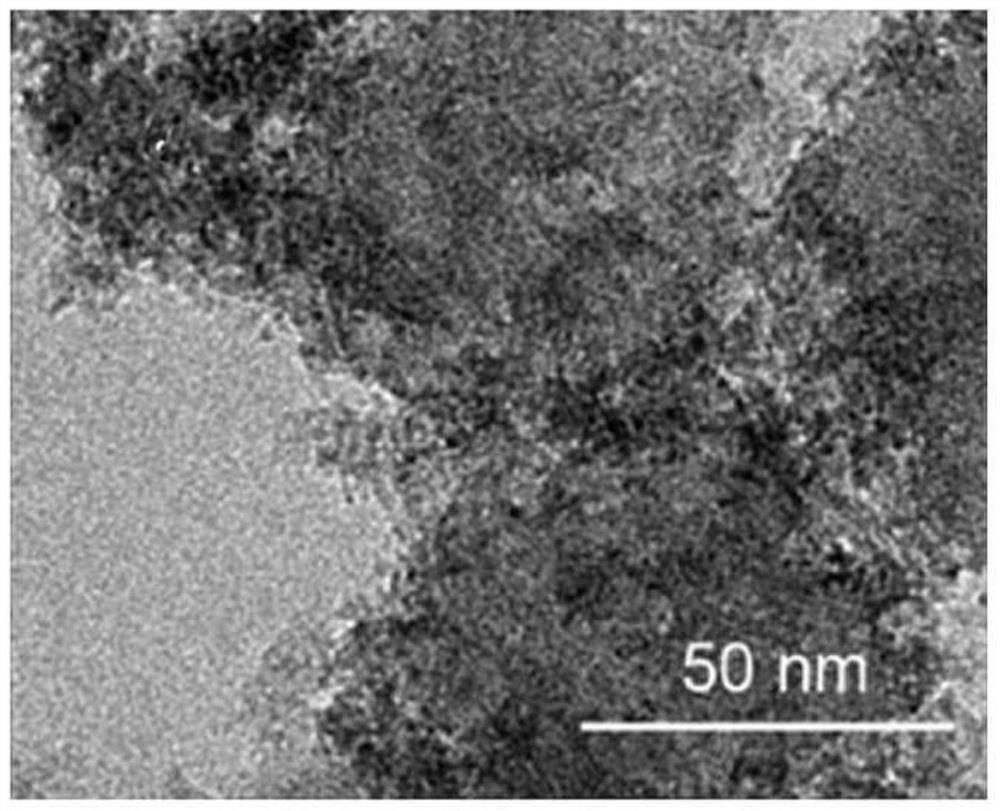

Fe-modified nano manganese oxide/MIL-125 (Ti) catalyst and preparation method thereof

ActiveCN111617807AImprove conversion rateRich variable valenceOrganic-compounds/hydrides/coordination-complexes catalystsDispersed particle separationHydration reactionPtru catalyst

The invention belongs to the technical field of composite material preparation, and particularly relates to a Fe-modified nano manganese oxide / MIL-125 (Ti) catalyst and a preparation method thereof. The preparation method comprises the following steps: A, ultrasonically mixing MnSO4, NaClO3 and NaCl in deionized water; adding ferric trichloride hexahydrate for ultrasonic treatment; then dropwise adding concentrated sulfuric acid into the solution under the condition of ice bath stirring, and reacting in a reaction kettle; B, centrifugally washing the precipitate with absolute ethyl alcohol anddeionized water, drying, grinding, and calcining in a muffle furnace to obtain iron modified nano MnOx; C, after DMSO and C3H8O are mixed, adding 1, 3, 5-BTC and nano MnOx for ultrasonic treatment, and then dropwise adding C12H28O4Ti during stirring at the room temperature; putting the solution into a reaction kettle to react; and finally, centrifugally washing with isopropanol and water, and freeze-drying to obtain the composite catalyst. The composite catalyst provided by the invention can effectively reduce the conversion temperature of nitrogen oxides, improve the toxicity resistance andprolong the service life of the catalyst.

Owner:ZHEJIANG ZHIYUAN ENVIRONMENTAL TECH CO LTD

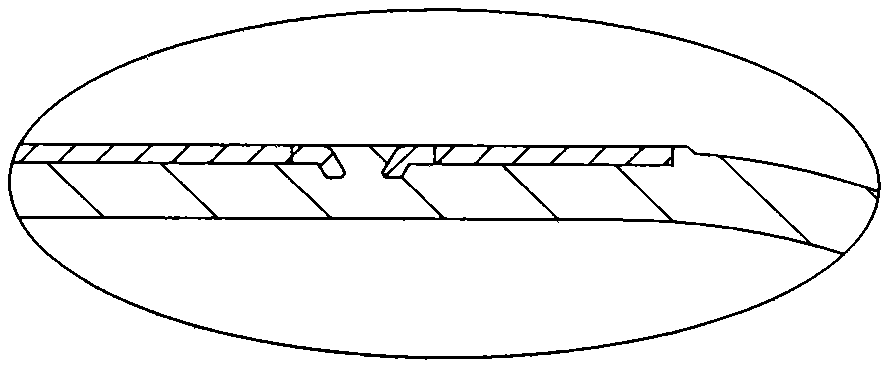

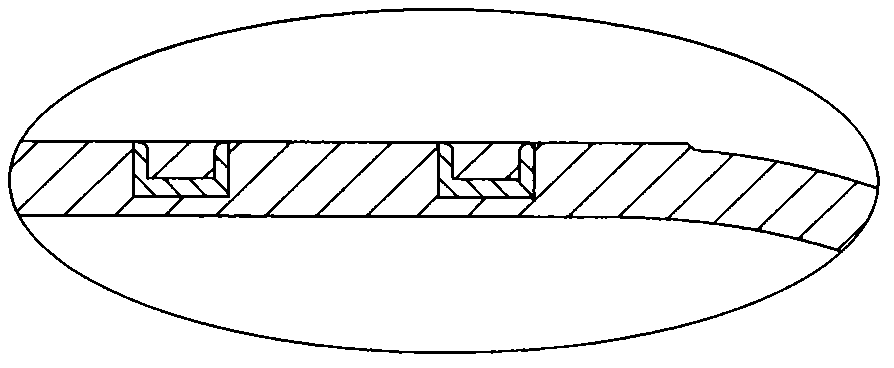

Compressor air filter element

InactiveCN112065694AEffective secondary filtrationImprove adsorption capacityPositive displacement pump componentsPumpsFiberAir filter

The invention relates to the technical field of compressor accessories, in particular to a compressor air filter element. The compressor air filter element comprises a mounting plate, an inner container filter element piece, an outer container filter element piece and a shell. The inner container filter element piece is mounted in the mounting plate through a connecting seat. The outer container filter element piece is erected in the mounting plate and is fixedly mounted on the mounting plate through the shell, and the outer container filter element piece and the inner container filter elementpiece are sleeved with the shell and are arranged with the same axis as the shell. Because of protruding hollow blocks arranged in the inner container filter element piece, on one hand, the flow speed of air discharged out of filtration pores is slowed down, and on the other hand, secondary filtration is carried out on part of air to enable the part of air to be filtered better. Because of an extension mechanism, the flowing travel of the air is prolonged, and under the action of centrifugal force, the air in each layer of gap of a spiral piece diffuses more powerfully and further, the filtering efficiency of a filtering pipe is improved, and the dust suction force of carbon fiber sheets in the protruding hollow blocks is effectively increased.

Owner:胡单

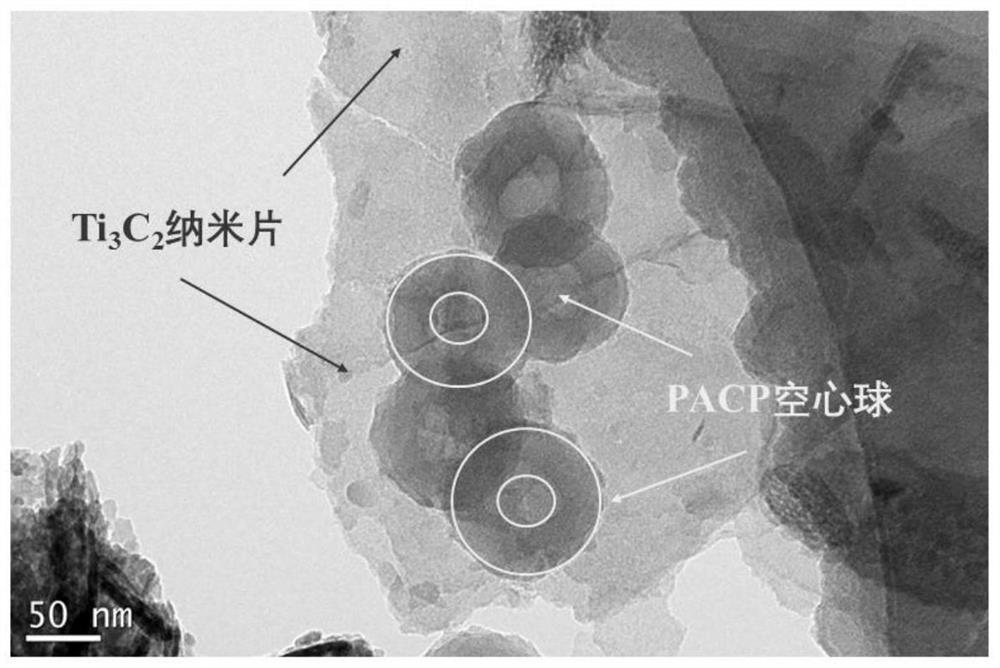

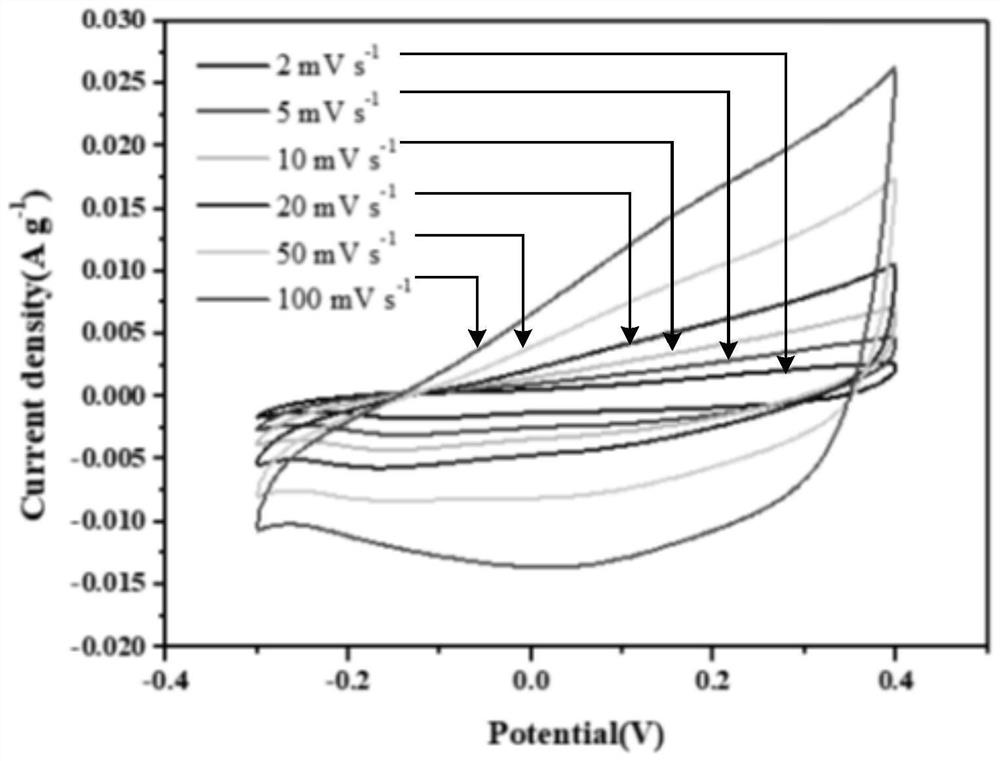

Conductive polymer hollow sphere PACP@ titanium carbide composite material and preparation method thereof

ActiveCN111627719AEasy transferFacilitated DiffusionHybrid capacitor electrodesHybrid/EDL manufacturePolypyrroleConductive polymer

The invention discloses a conductive polymer hollow sphere PACP@ titanium carbide composite material and a preparation method thereof. According to the preparation method, a PACP (a copolymer of polyaniline PANI and polypyrrole PPy) and ultrathin titanium carbide are compounded through a chemical oxidation method under a low-temperature condition to obtain a Ti3C2@ PACP hollow sphere nano composite material as an electrode material of a supercapacitor, an in-situ polymerization method is simple to operate, efficient and environment-friendly, and the hollow spherical PACP and the layered ultrathin Ti3C2 are compounded, so that the hollow spherical PACP and the layered ultrathin Ti3C2 can be in more sufficient contact, the specific surface area is larger, the particle transmission, diffusionand the like are better facilitated, and the energy storage performance of the conductive polymer hollow sphere PACP@ titanium carbide composite material used for the supercapacitor electrode is improved.

Owner:SHAANXI UNIV OF SCI & TECH

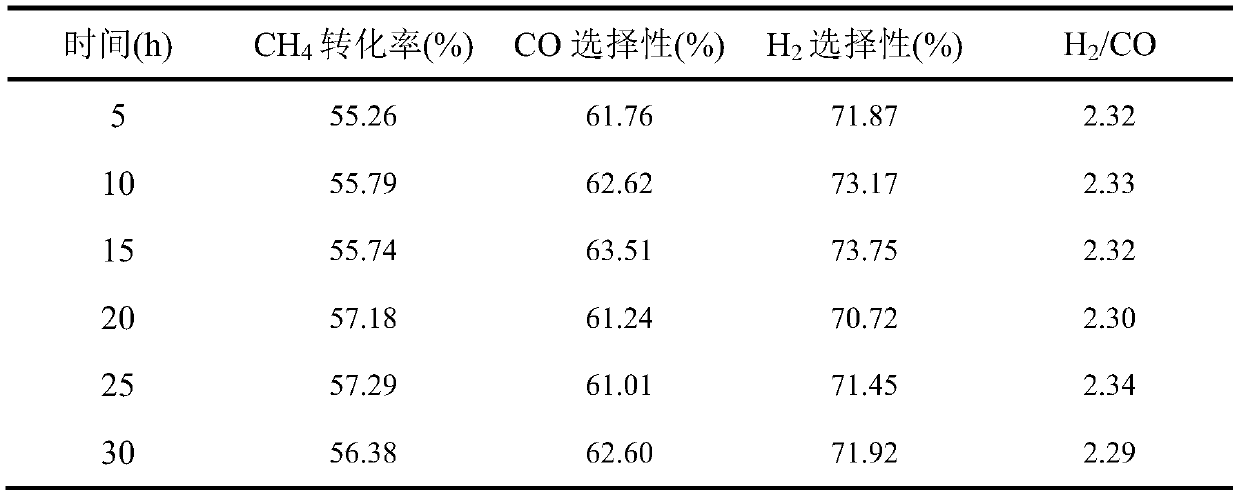

PtO@MFI packaging structure catalyst for preparing synthesis gas through partial oxidation of methane and preparation method and application of catalyst

InactiveCN109876852AReduce aggregationHigh activityHydrogenMolecular sieve catalystsMolecular sievePartial oxidation

The invention belongs to the technical field of methane catalytic conversion, and particularly discloses a packaging structure catalyst for preparing synthesis gas through partial oxidation of methaneand a preparation method of the catalyst. The packaging structure catalyst for preparing the synthesis gas through partial oxidation of methane is prepared from 1wt%-5wt% of active component metal Pt, and 95wt%-99wt% of a carrier. The preparation method of the catalyst includes the steps that nano-silica, namely PtO / SiO2 nanoparticles, for loading the active component Pt is prepared; with the PtO / SiO2 nanoparticles as a silicon source, an MFI structure molecular sieve is synthesized through a template; and the MFI structure molecular sieve is roasted to obtain the core-shell structure catalyst with the active component Pt being packaged in the molecular sieve, namely PtO@MFI. The prepared PtO@MFI catalyst has high activity and stability in reaction of preparing the synthesis gas through partial oxidation of methane, and through the special packaging structure, the stability of the catalyst and the sintering resistance of the active component are further improved.

Owner:TAIYUAN UNIV OF TECH

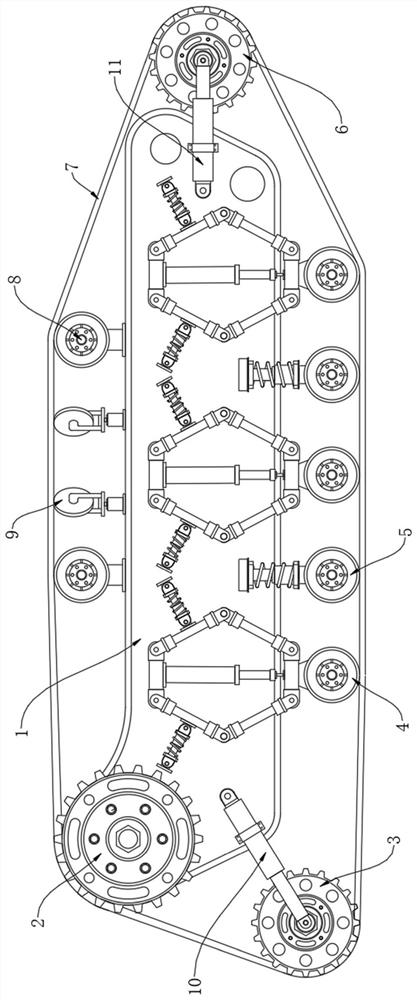

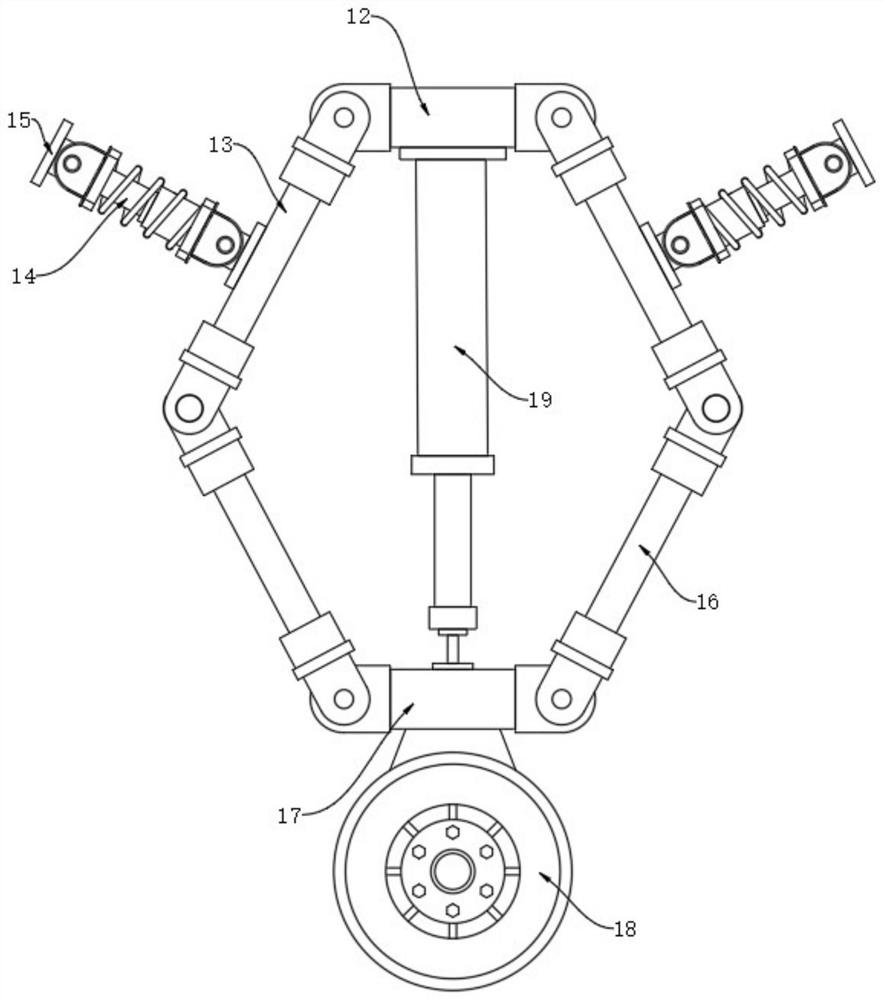

Tracked vehicle chassis suitable for complex terrain

PendingCN112550502AReduce the gripReduce fuel consumptionEndless track vehiclesDrive wheelControl theory

The invention discloses a tracked vehicle chassis suitable for a complex terrain. The chassis comprises a fixing frame and a track, a driving wheel is arranged at the upper end of one end of the fixing frame, a guide wheel is arranged under the driving wheel, the guide wheel is fixedly connected with the fixing frame through a first telescopic rod, and a plurality of weighing wheel mechanisms arearranged on the lower side of the fixing frame. An auxiliary weighing wheel is arranged between every two adjacent weighing wheel mechanisms, a tensioning wheel is arranged at the other end of the fixing frame, the tensioning wheel is fixedly connected with the fixing frame through a second telescopic rod, and a plurality of supporting auxiliary wheels are symmetrically arranged above the fixing frame. The track is arranged outside the driving wheel, the guide wheel, the weighing wheel mechanism, the auxiliary weighing wheel, the tensioning wheel and the supporting auxiliary wheel. According to the chassis, the damping effect is further enhanced, and the width of a track shoe can be efficiently adjusted as required.

Owner:中国人民解放军陆军装甲兵学院蚌埠校区

High-temperature-resistant anti-rutting asphalt mixture and preparation method thereof

ActiveCN111574112APromotes self-healingAchieve recyclabilitySolid waste managementPolymer scienceSilicic acid

The invention discloses a high-temperature-resistant anti-rutting asphalt mixture and a preparation method thereof. The asphalt mixture is prepared from, by weight, 15-18 parts of pretreated asphalt,30-35 parts of zinc chloride, 5-10 parts of a heat conduction material, 8-12 parts of glass fibers, 5-10 parts of an admixture and 90-100 parts of an aggregate. The pretreated asphalt is prepared fromthe following raw materials by weight: 8 to 14 parts of modified asphalt, 6 to 8 parts of dihydroxyl-terminated polydimethylsiloxane, 14 to 16 parts of polycaprolactone glycol, 2 to 4 parts of 1,6-hexamethylene diisocyanate, 0.5 to 1 part of dibutyltin dilaurate, 4 to 6 parts of 4,4'-dimethyl-2,2'-dipyridyl and 0.5 to 0.8 part of 1,4-butanediol. The asphalt mixture is reasonable in process designand proper in component proportion, the prepared asphalt mixture has excellent anti-rutting capacity, the high-temperature stability and the water stability of the asphalt mixture are improved, and the asphalt mixture can be applied to roads with large traffic volume and more heavy-load and overload vehicles and has higher practicability.

Owner:SHANDONG HUITONG CONSTR GRP CO LTD

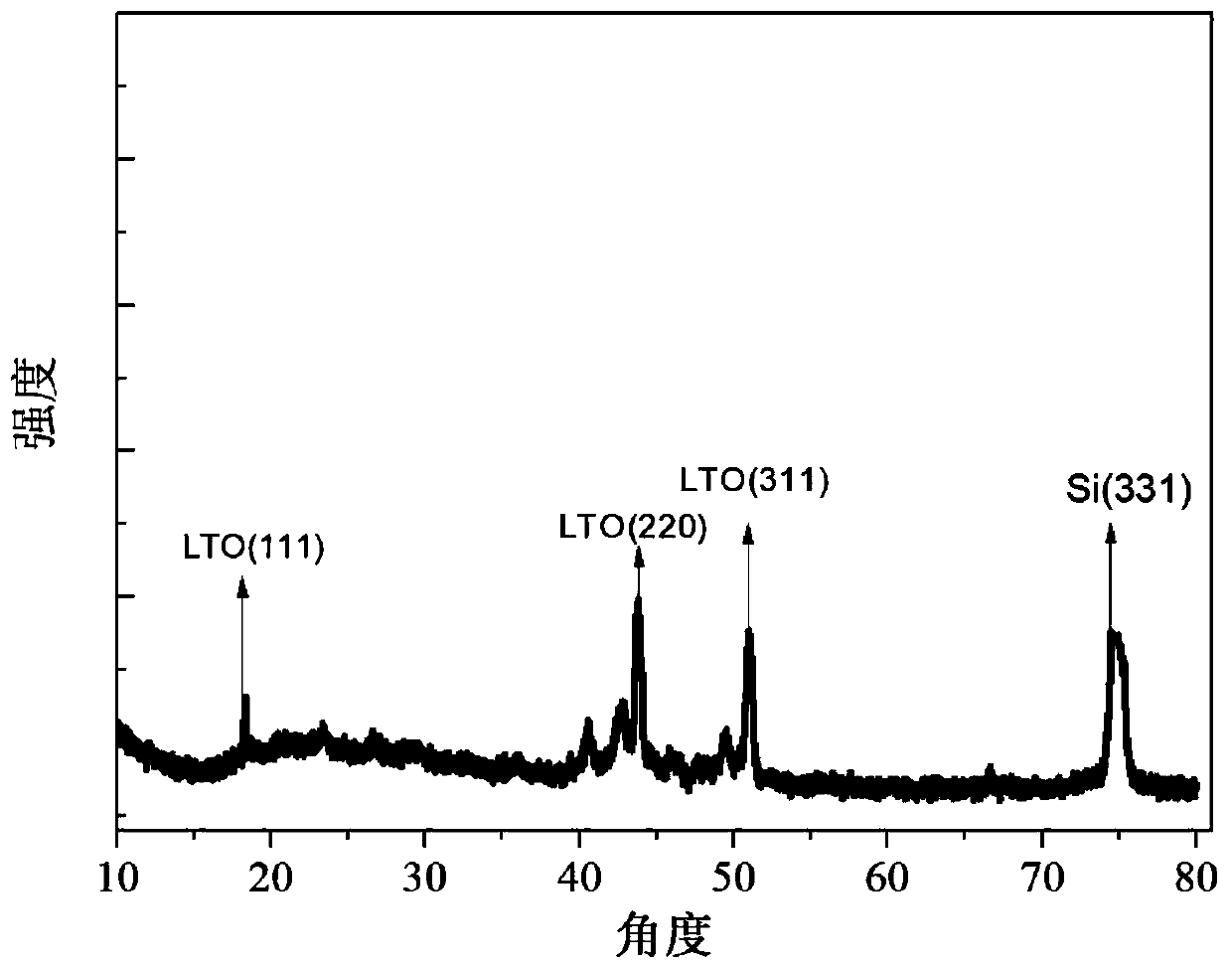

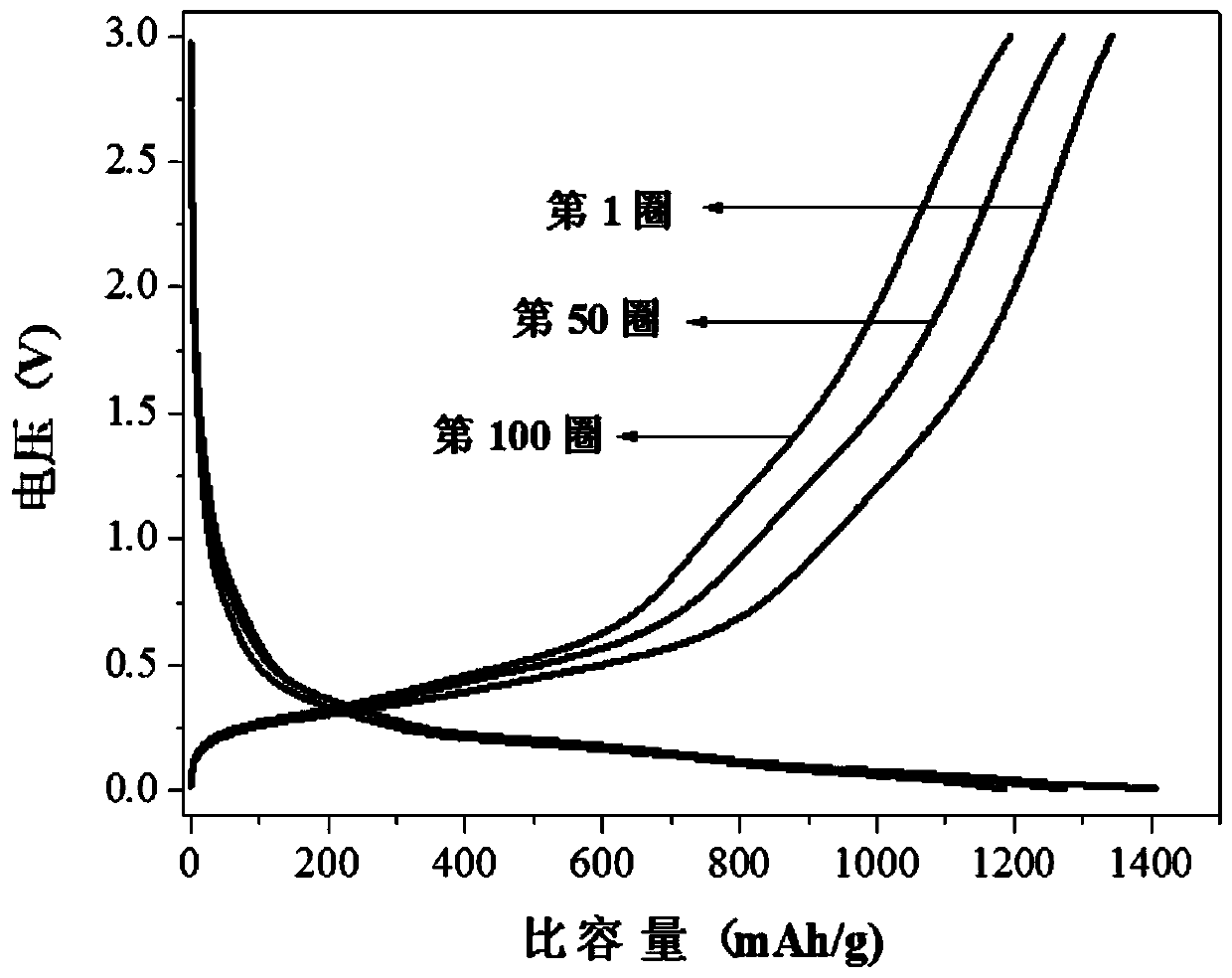

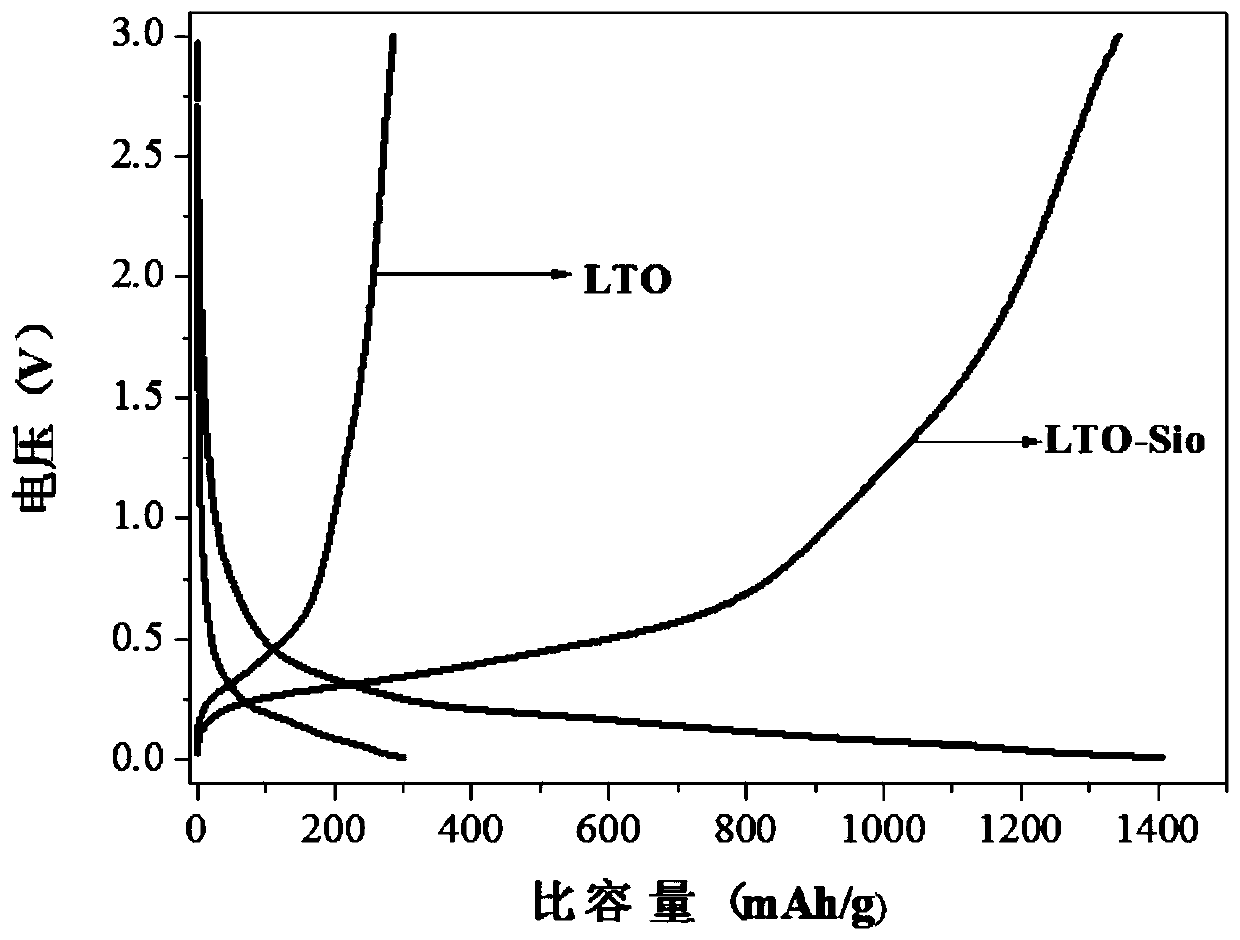

Composite lithium titanate thin film as well as preparation method and application thereof

InactiveCN110176586AImprove structural stabilityStable chemical propertiesHybrid capacitor electrodesCell electrodesLithiumSide reaction

The invention provides a composite lithium titanate thin film as well as a preparation method and an application thereof. The preparation method of the composite lithium titanate thin film comprises the following steps of carrying out co-sputtering treatment on a lithium titanate target material and an energy density contribution main body element target material in an inert atmosphere, and growing the composite lithium titanate thin film on a substrate. According to the preparation method of the composite lithium titanate thin film, the lithium titanate target material and the energy densitycontribution main body element target material are directly deposited and formed by adopting a co-sputtering method. Therefore, the grown composite lithium titanate thin film has a rich channel structure and is stable in structure, so that high lithium ion transmission rate can be provided, and high cycling reversibility and relatively high specific capacity are maintained; and meanwhile, the direct contact of an electrolyte and a nano-scale energy density contribution main body element is effectively prevented, the irreversible side reaction between the electrolyte and the energy density contribution main body can be reduced and blocked, and the generation of a solid electrolyte membrane (SEI) is reduced.

Owner:GUILIN UNIV OF ELECTRONIC TECH

Preparation method of waterborne polyurethane resin

InactiveCN108586694AComprehensive areaRich in functional groupsAnti-corrosive paintsPolyurea/polyurethane coatingsVitamin CFluorescence

The invention discloses a preparation method of waterborne polyurethane resin. The preparation method comprises the following steps: 1) carrying out polymerization, namely mixing the components in parts by weight: 0.1-20 parts of graphene oxide, 200-230 parts of poly(neopentyl glycol adipate), 40-50 parts of dimethylolpropionic acid, 40-70 parts of N-methylpyrrolidone and 500-700 parts of deionized water, placing the mixture into reaction kettle, and slowly dropping 100-120 parts of diisocyanate; 2) carrying out chain extension, namely adding triethylamine for neutralization, carrying out a reaction for 1h, adding 30-50 parts of acetone, carrying out rapid cooling to 10-20 DEG C, adding 30-70 parts of ketimine, and carrying out decompression to remove acetone to obtain a fluorescent semitransparent waterborne polyurethane dispersoid; and 3) dropwise adding a vitamin C solution for an in-situ reduction reaction. The preparation method is simple and convenient in process, low in cost andenvironment-friendly, and the waterborne polyurethane resin is particularly suitable for application as a coating raw material of water supply pipelines for residents due to good water resistance andno environment pollution and can also be used for sockets for residential electricity and wire coatings due to good insulation properties and corrosion resistance.

Owner:安徽皖东树脂科技有限公司

Automatic grinding device for permanent magnet ferrite square block and grinding method thereof

ActiveCN110962005AMobile fasteningThe clamping movement is fastened firmlyEdge grinding machinesGrinding drivesElectric machineryHydraulic pump

The invention discloses an automatic grinding device for a permanent magnet ferrite square block and a grinding method of the automatic grinding device. The automatic grinding device comprises a loading frame, a carrying and support table, a first mounting table, a second mounting table and a vertical loading cylinder. The carrying and support table is horizontally arranged in the middle of the loading frame. A bottom support plate is arranged at the bottom of the carrying and support table. A top mounting plate is arranged on the top of the carrying and support table. Two side support rods are vertically arranged at the two ends between the top mounting plate and the bottom support plate. The first mounting table is arranged above one end of the carrying and support table. The automatic grinding device has the beneficial effects that a fourth hydraulic pump drives a grinding column to vertically adjust the height through a fourth hydraulic shaft, in cooperation with a sixth motor, a rotating disc drives a grinding and loading seat to rotate to adjust the position, it is guaranteed that the grinding position of the permanent magnetic ferrite square block by the device is more precise and suitable, the precision of grinding the permanent magnetic ferrite square block by the device is greatly improved, and it is guaranteed that the area of the device for grinding and covering thepermanent magnet ferrite square block is more comprehensive. The device has the beneficial effects of high automation degree and very time-saving and labor-saving use.

Owner:安徽中马磁能科技股份有限公司

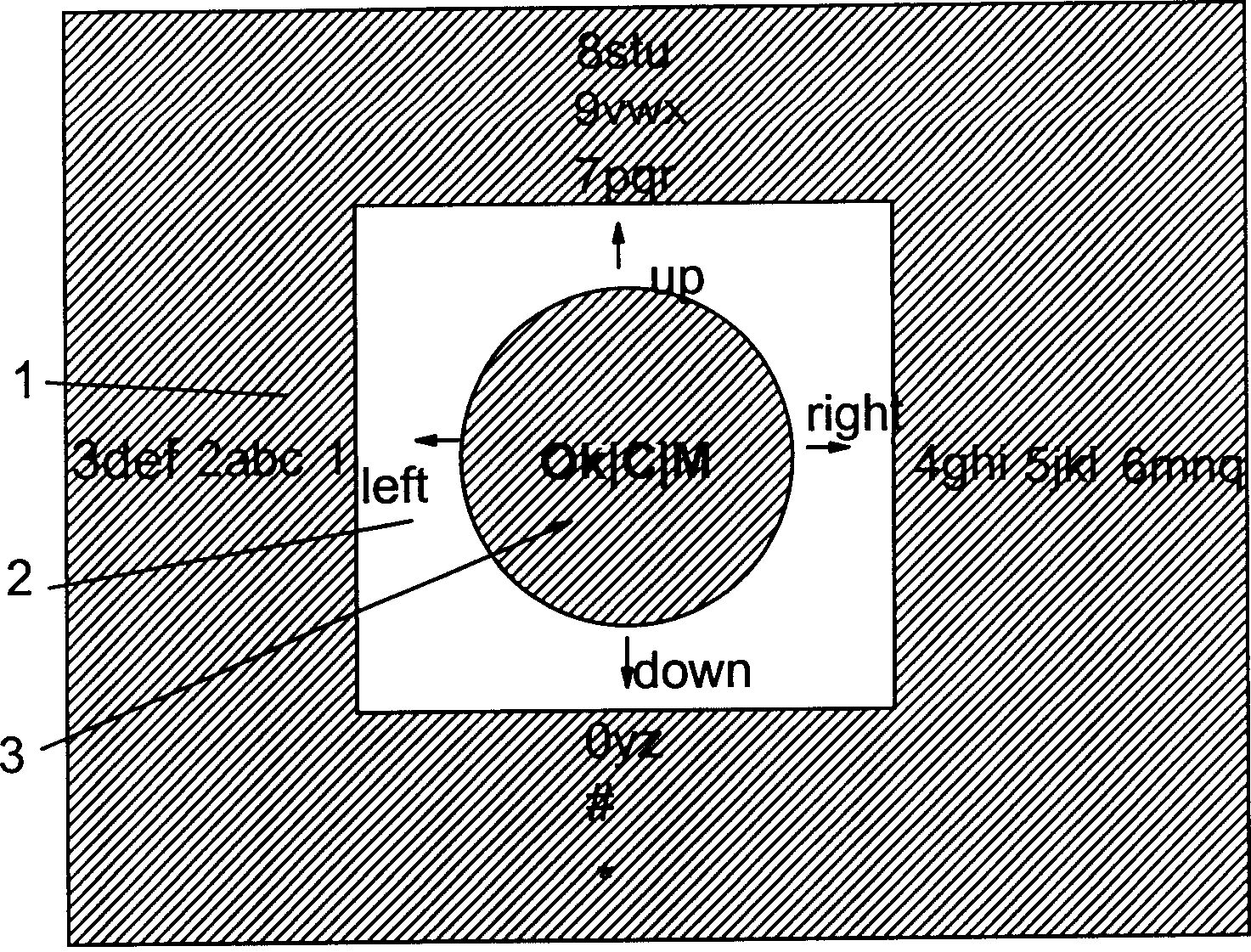

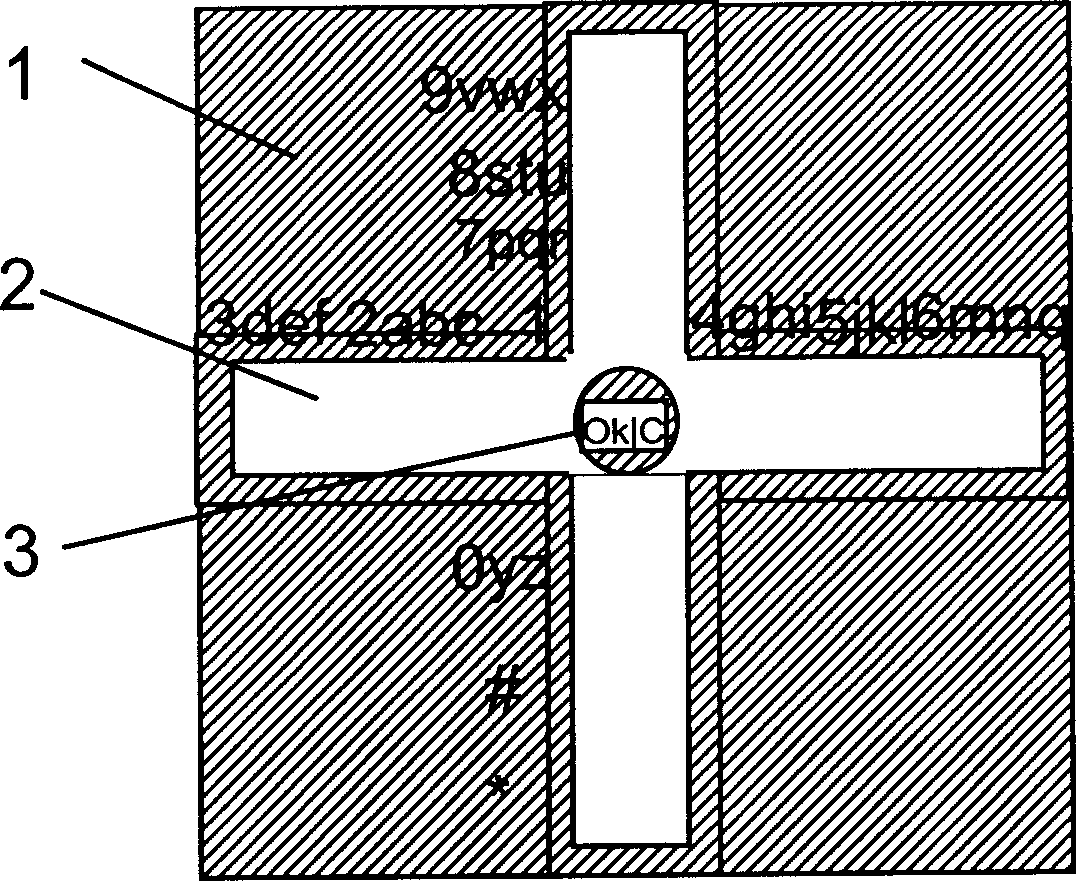

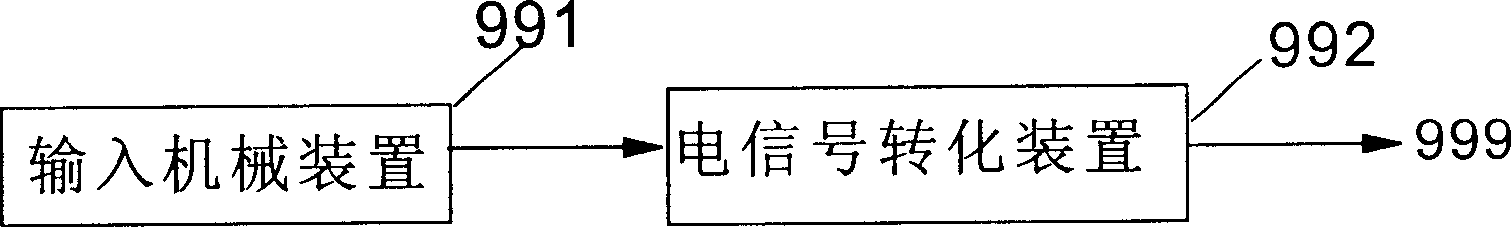

Device for inputting characters

InactiveCN1519685AReduce areaComprehensive areaTelephone set constructionsInput/output processes for data processingElectricityHand held devices

The device composed of only one pushbutton can input a character among 1-9, A-Z by one time of operation of pushing the pushbutton. The device includes a mechanical motion set and an electric signal conversion set. Button in the mechanical motion set can be moved in up, down, left and right directions as well as can control additive switch. One time of operation of pushing button can generate sequence of electric signal from multiple switchers. The electric signal conversion set converts switch sequence to electric signals, which represent characters. The invention is applicable to input device of hand held devices such as handset, PDA etc.

Owner:胡林龙

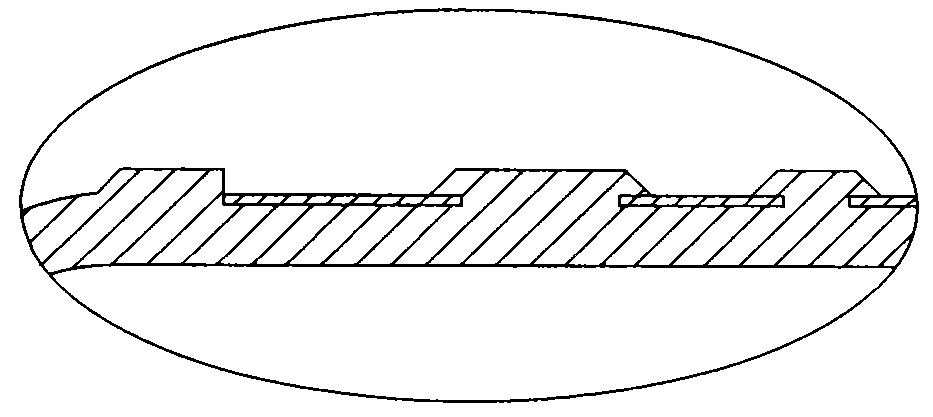

Method for manufacturing aluminum pot used by special mold for gravity cast energy-saving aluminum pot

ActiveCN103192059BTo achieve no deformation and no falling offAvoid deformationFoundry mouldsCooking vesselsForming processesRivet

The invention discloses a gravity cast method for an energy-saving aluminum pot for an induction cooker. The method comprises the steps of preparing a stainless iron plate cast at the bottom of the pot; preparing a special mold matched with the stainless iron plate; and performing gravity casting, wherein the gravity casting comprises a molding process of a pot body and the stainless iron plate, rivet processing at the outer bottom of the pot and processing of the shrinkage cavity surface of a casting surface. According to the gravity cast method and a special mold for the gravity cast energy-saving aluminum pot for the induction cooker, the stainless iron plate and the pot body can be cast integrally; and the heat conduction is uniform, the electromagnetic power is high, energy is saved, and the pot bottom and the stainless iron plate can be combined precisely during usage, so that deformation and falling are prevented.

Owner:福建鼎厨王厨具有限公司

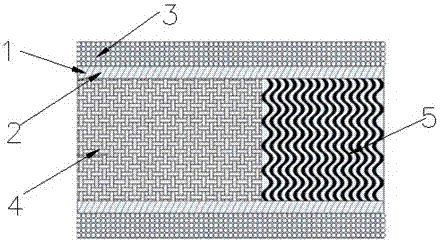

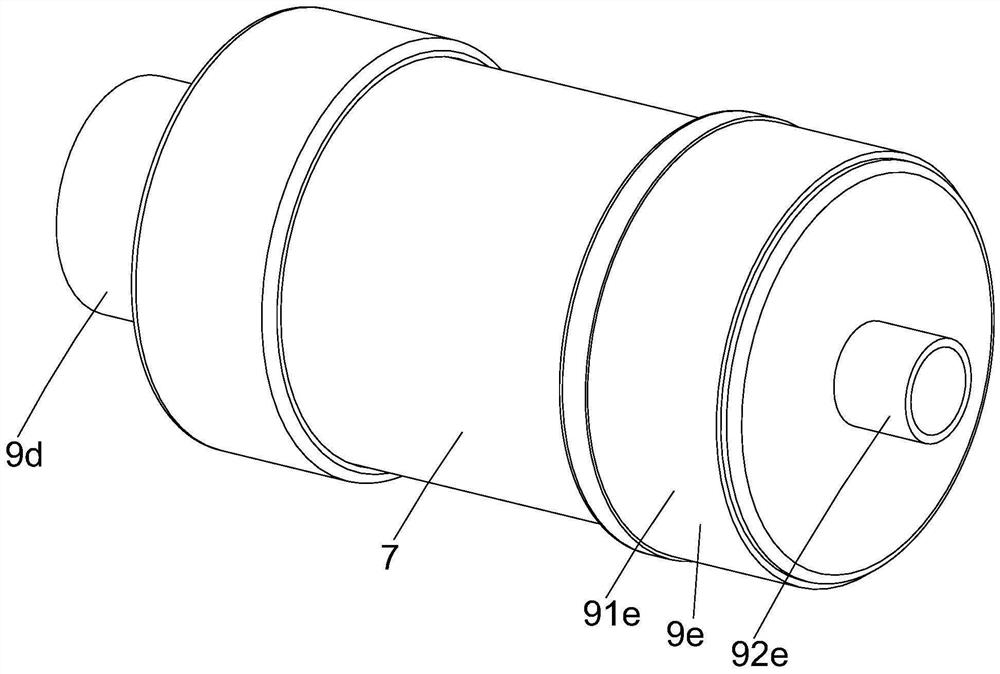

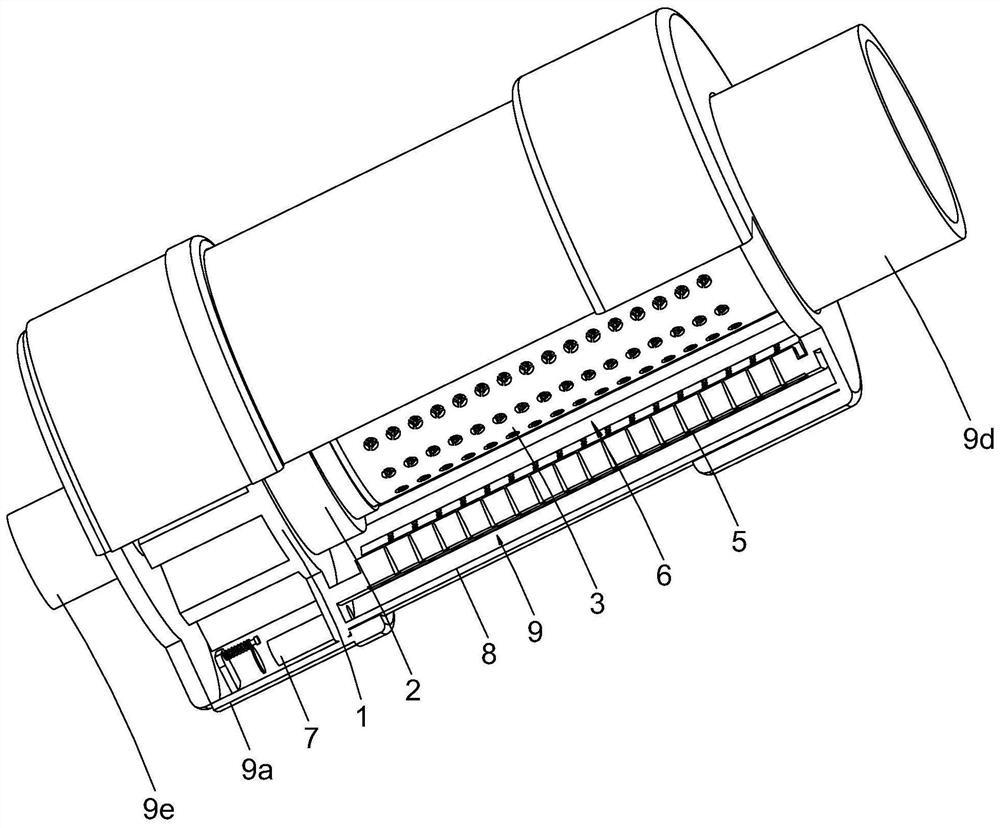

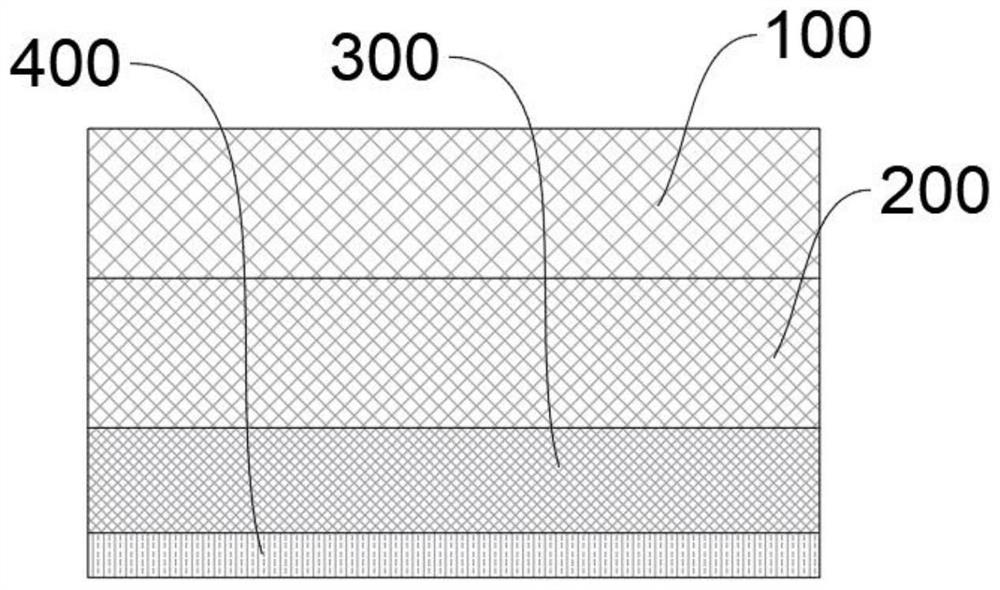

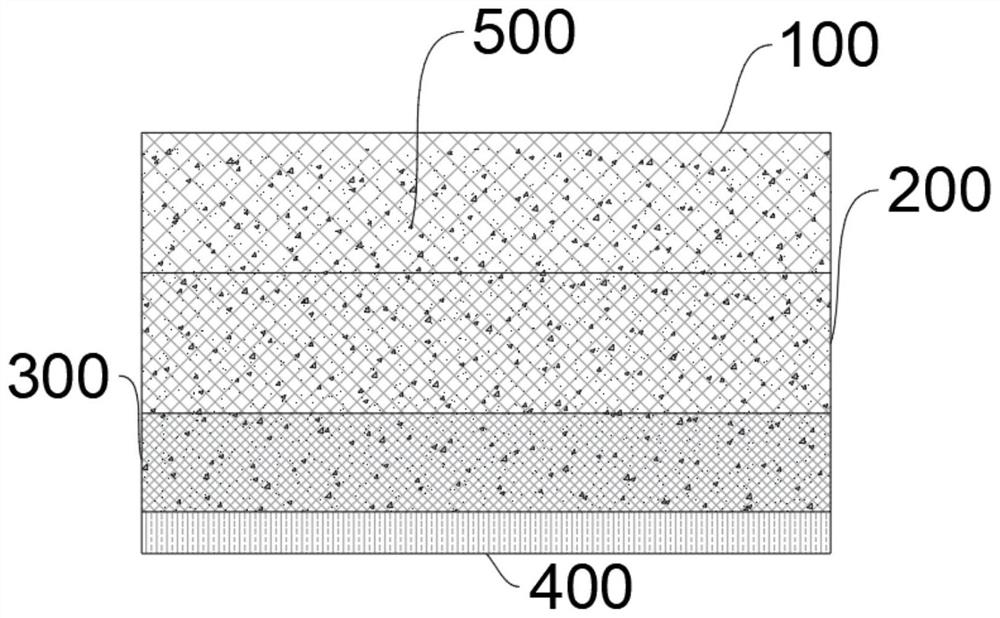

Asymmetric low-temperature catalytic filter material and preparation method thereof

ActiveCN112473684AGood catalytic effectOptimal selective catalytic reaction effectHuman health protectionGas treatmentCorrosion resistantComposite structure

The invention belongs to the field of catalytic materials, and particularly relates to an asymmetric low-temperature catalytic filter material and a preparation method thereof. The asymmetric low-temperature catalytic filter material comprises a plurality of layers of metal fiber filter screens, wherein the plurality of layers of metal fiber filter screens are formed by weaving metal fibers with different wire diameters, the metal fiber filter screens are arranged in a stacked mode from large to small or from small to large according to the mesh number, and a multi-layer fiber screen compositestructure is formed through pressure sintering; alloy powder is sprayed on the metal fiber filter screen on the smallest mesh number side of the multi-layer fiber net composite structure, and an oversintered metal powder filter layer is formed after sintering; and the metal fiber filter screen is loaded with a denitration catalyst. The filter material provided by the invention can improve the efficiency and quality of industrial flue gas treatment, has good mechanical properties and corrosion resistance, and can prevent smoke particles from entering a catalyst loading part, avoid erosive wearand smoke coverage and prolong the service life compared with a homogeneous filtration catalytic material, and is also easy to regenerate and reuse.

Owner:ZHEJIANG UNIV OF TECH

Porcelain body glaze repairing method

The invention relates to the high voltage electrical porcelain production technology field, specifically relating to a porcelain body glaze repairing method which comprises the following steps: a. mixing two parts of resin type electrical porcelain repairing agents, one part of curing type electrical porcelain repairing agent and pigment to prepare a repairing mixture; b. cleaning a place to be repaired with acetone, and drying the place with a blower; c. diluting the repairing mixture with acetone to a degree that a mixed solution of the repairing mixture and the acetone can pass through a filter screen of 50-70 meshes, then allowing the mixed solution to pass through a filter screen of 50 meshes, adding the mixed solution into a spray gun after filtering, and using the spray gun to spray the mixed solution on the place to be repaired. Preferably, a step d of drying a spraying position with a hot air blower is provided after the step c. Preferably, high pressure gas used in the spray gun in the step c is oxygen, nitrogen or acetylene, and the porcelain body glaze repairing method has the advantages of good quality and flattening of glaze repairing, a larger repairing area of unit repairing agent and raw material saving.

Owner:HENAN DEXIN ELECTROCERAMICS

High-temperature-resistant anti-rutting asphalt mixture

InactiveCN112679146AImprove crack resistanceImprove mechanical propertiesSolid waste managementPolymer scienceSilicic acid

Owner:马瓯丽

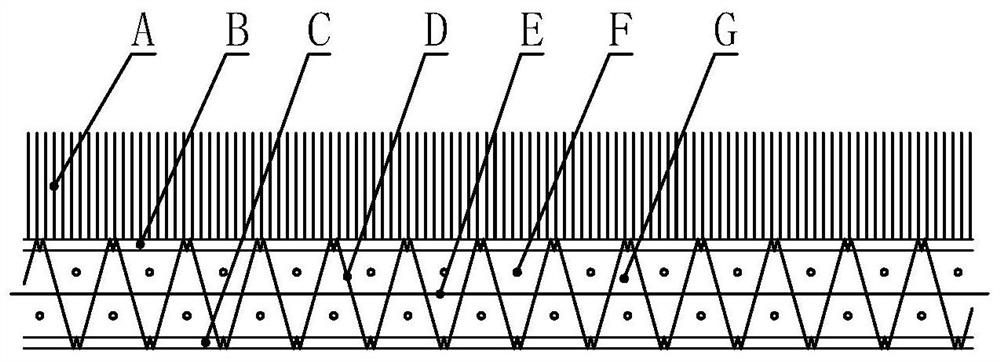

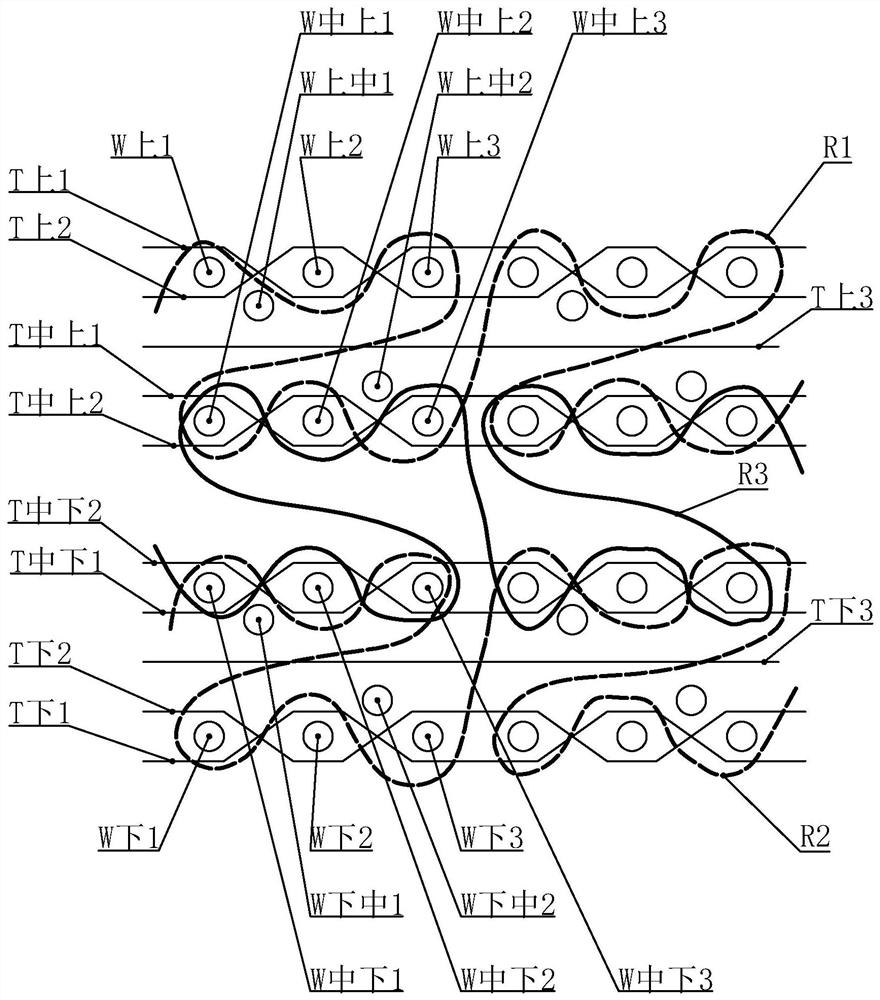

Textile fabric for manufacturing roller brush velvet and preparation method of textile fabric

The invention discloses a textile fabric for manufacturing roller brush velvet and a preparation method of the textile fabric. The textile fabric comprises a fluff layer and a size storage layer; the size storage layer comprises a first base cloth layer and a second base cloth layer which are connected by connecting lines; interwoven warp cotton slivers and weft cotton slivers are arranged between the first base cloth layer and the second base cloth layer; and fluff of the fluff layer is fixedly connected to the first base cloth layer. The preparation method comprises the following steps of performing velvet cutting and after-finishing on a four-layer fabric consisting of upper-layer base cloth, middle-upper-layer base cloth, middle-lower-layer base cloth, lower-layer base cloth, an upper-layer connecting line, a lower-layer connecting line and a middle-layer connecting line. The textile fabric has the fluff layer and the size storage layer, and the interwoven warp cotton slivers and weft cotton slivers are arranged in the size storage layer; and the warp cotton slivers and the weft cotton slivers release coating little by little under the working pressure, so that under the management of the smooth and neat fluff layer, water dripping and size hanging are avoided, more areas can be brushed, and flatness and smoothness can be realized.

Owner:ZHEJIANG INNOVATION TEXTILE CO LTD

A kind of Fe modified nano manganese oxide/mil-125(ti) catalyst and preparation method thereof

ActiveCN111617807BImprove conversion rateRich variable valenceOrganic-compounds/hydrides/coordination-complexes catalystsDispersed particle separationHydration reactionPtru catalyst

The invention belongs to the technical field of composite material preparation, in particular to Fe-modified nano-manganese oxide / MIL-125 (Ti) catalyst and a preparation method thereof, the steps of the preparation method comprising: A, MnSO 4 , NaClO 3 Ultrasonic mixing with NaCl in deionized water; then adding ferric chloride hexahydrate for ultrasonication; then dripping concentrated sulfuric acid into the solution under the condition of stirring in an ice bath, and reacting in the reactor; B, precipitation with absolute ethanol and deionized water Centrifugal washing, drying, grinding and calcining in a muffle furnace to obtain iron-modified nano-MnOx; C, DMSO and C 3 h 8 After mixing O, add 1,3,5-BTC, nano-MnOx ultrasonic, and then drop into C while stirring at room temperature 12 h 28 o 4 Ti; the solution is put into a reaction kettle for reaction; finally, it is centrifuged and washed with isopropanol and water, and freeze-dried to obtain a composite catalyst. The composite catalyst of the invention can effectively reduce the conversion temperature of nitrogen oxides, improve anti-toxicity and prolong the service life of the catalyst.

Owner:ZHEJIANG ZHIYUAN ENVIRONMENTAL TECH CO LTD

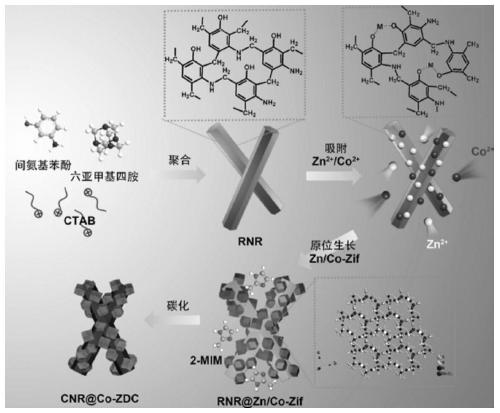

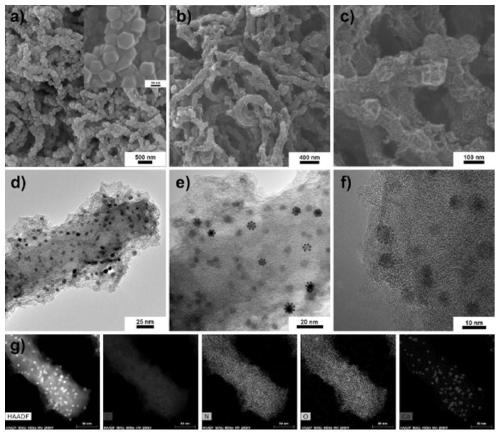

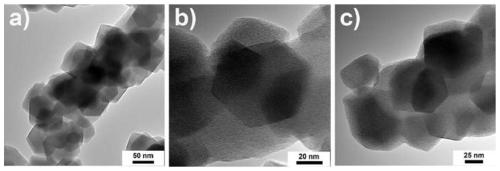

Carbon nanorod with high specific surface area and high nitrogen doping content, and simple preparation and application thereof

ActiveCN109809389AThe synthesis process is simpleLow costFuel and primary cellsCell electrodesReactive siteQuantum dot

The invention relates to a carbon nanorod with high specific surface area and high nitrogen doping content capable of being applied to a positive electrode catalyst for a zinc air battery and a simplepreparation method of the carbon nanorod. The carbon nanorod is a composite of a resin-based carbon nanorod and a zeolitic imidazolate framework-derived carbon material, the length is 2-4 mum, the nitrogen content is 10.29%, the surface of the carbon nanorod contains micropores, the specific surface area of the carbon nanorod is 478.7 m<2>g<-1>, and uniform cobalt quantum dots are dispersed inside the carbon nanorod. Compared with the prior art, the carbon nanorod and the preparation method thereof have the following advantages: the synthesis process is simple and the cost is low; a one-dimensional structure and in-situ highly-doped N content can effectively improve the electrical conductivity and electrochemical performance of the material; Co quantum dots can be uniformly distributed inthe nanorod and more catalytic active sites are provided; Zn / Co-Zif-derived microporous carbon has a particle size of about 80 nm, and the microporous carbon is embedded in the carbon nanorod to avoid agglomeration.

Owner:WUHAN UNIV OF TECH

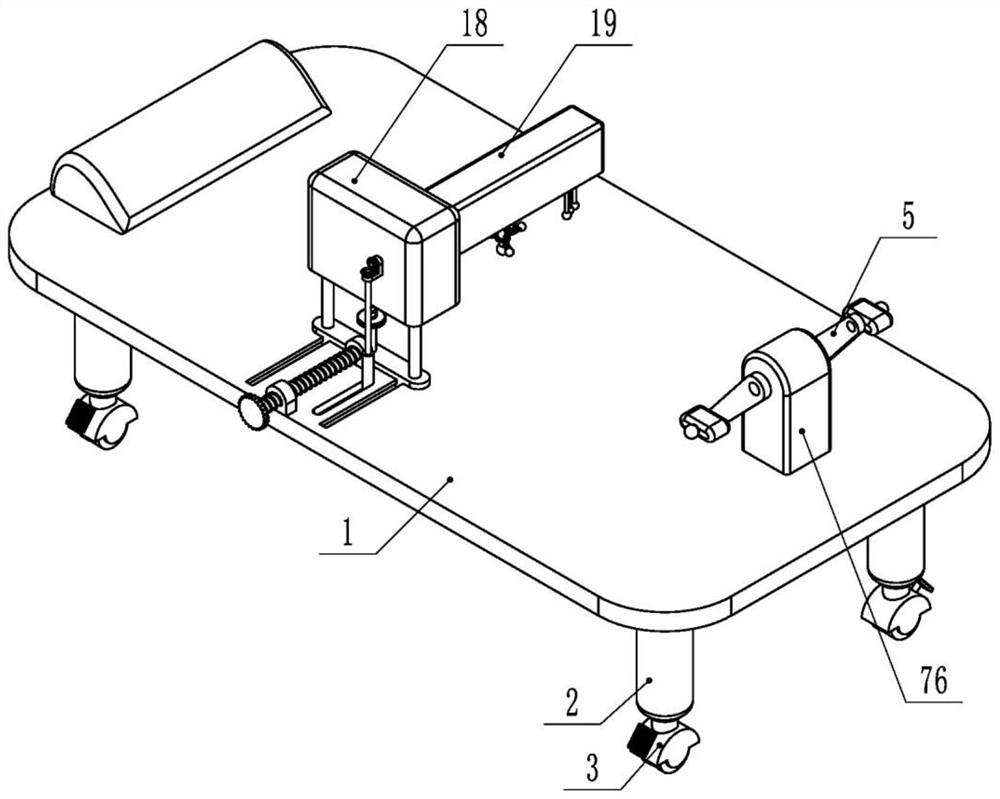

Stomach disease nursing device for gastroenterology department

The invention discloses a stomach disease nursing device for a gastroenterology department. The device comprises a bed board; a U-shaped box is fixedly connected to the front side of the upper end surface of the bed board; labor-saving connecting rods which are centrosymmetric and rotatable are installed on the upper sides of the left end surface and the right end surface of the U-shaped box; whenthe labor-saving connecting rods rotate, a structure that a massage box reciprocates forwards and backwards and a supporting plate reciprocates leftwards and rightwards can be formed; a second massage ball capable of moving up and down while rotating is installed in the middle of the lower end of the supporting plate, and three first massage balls which are uniformly distributed and can be foldedinwards or spread outwards at the same time are installed on the outer side of the lower end of the supporting plate; and three third massage balls are installed on each of the left side and the right side of the lower end of the massage box, and when the supporting plate reciprocates leftwards and rightwards, a structure that the third massage balls rotate circumferentially and automatically, move up and down and move left and right simultaneously can be formed. By means of the rotatable labor-saving connecting rods, the first massage balls, the second massage ball and the third massage balls, massage and exercise can be achieved at the same time.

Owner:新乡市中心医院

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com