Polypyrrole nanosphere@titanium carbide composite material as well as preparation method and application thereof

A polypyrrole nanometer and composite material technology, applied in the direction of hybrid capacitor electrodes, etc., can solve the problems of affecting the cyclic stability of materials, easy transformation of materials as insulators, expansion and contraction of polymers, etc. Environmentally friendly, full contact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Step 1, lamellar Ti 3 C 2 preparation of

[0043] Weigh 2g of LiF and dissolve it in a 50mL polytetrafluoroethylene beaker containing 20mL of 9M HCl (15mL of concentrated HCl+5mL of water), stir for 10min to make it evenly mixed, and slowly add 2g of Ti to the above mixture 3 AlC 2 , magnetically stirred for 24h. After the reaction, centrifuge and wash to pH > 6, dissolve the centrifuged precipitate in 300mL of ultrapure water, carry out vacuum deoxygenation for 2 hours, after completion of ultrasonication for 1 hour, centrifuge for 1 hour, and freeze-dry the supernatant for 48 hours to obtain ultra-thin Ti 3 C 2 Powder.

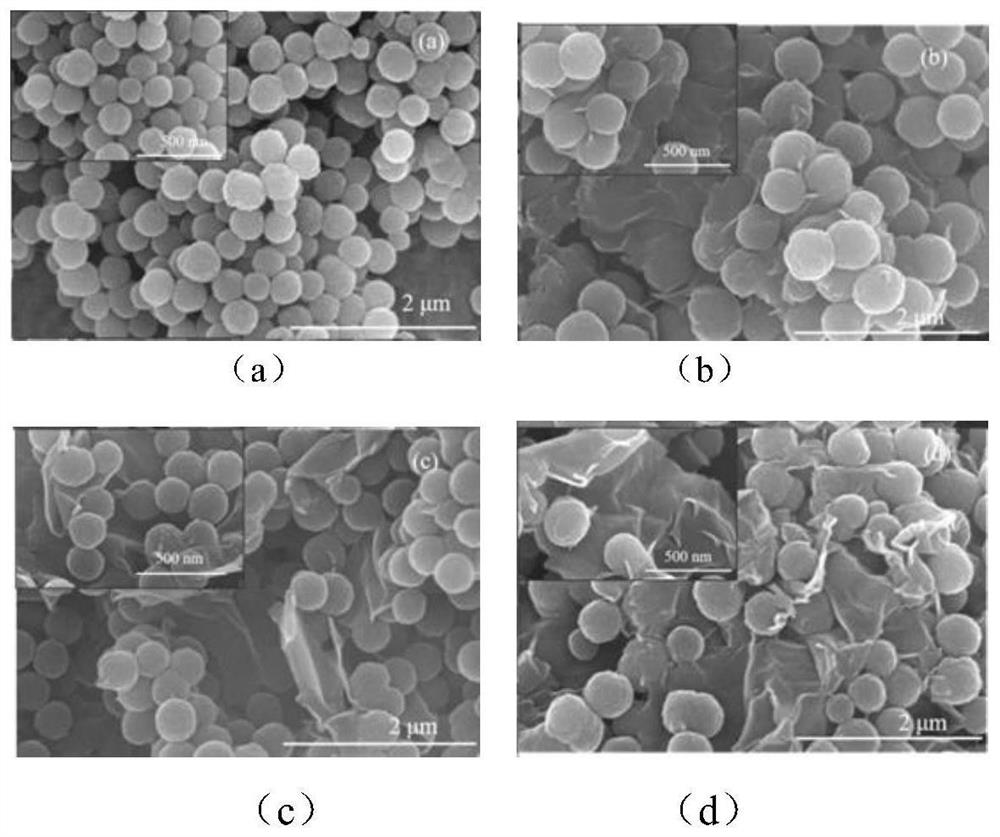

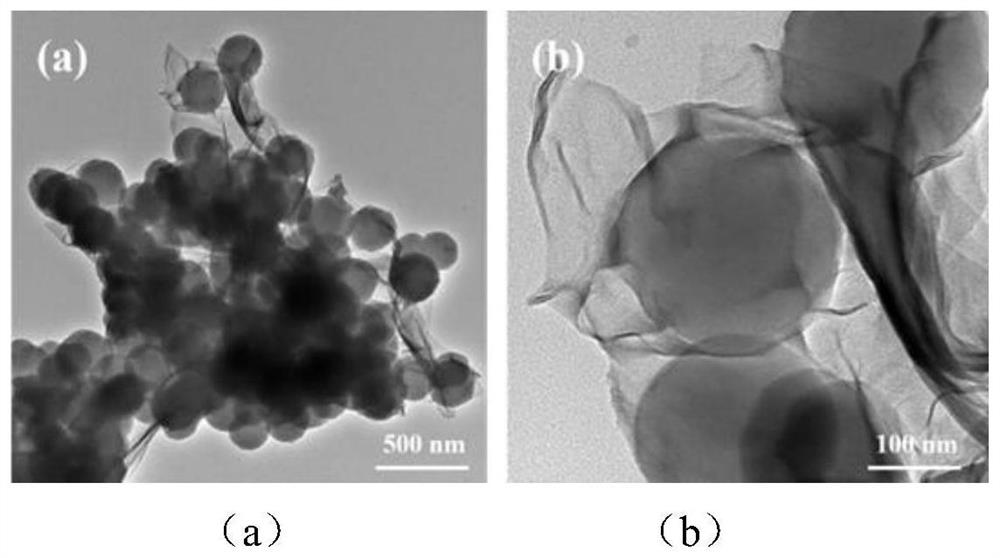

[0044] Step two, Ti 3 C 2 Preparation of @PPY composite nanospheres

[0045] Weigh 0.1g of polyvinyl alcohol (PVA) and 0.1g of sodium p-toluenesulfonate dissolved in 40mL of ultrapure water and mix evenly, then add 500mL of Py monomer to the above solution, stir at low temperature for 30min; then add 1.14g of persulfuric acid The APS solution...

Embodiment 2

[0047] Step 1, lamellar Ti 3 C 2 preparation of

[0048] Weigh 2g of LiF and dissolve it in a 50mL polytetrafluoroethylene beaker containing 20mL of 9M HCl (15mL of concentrated HCl+5mL of water), stir for 10min to make it evenly mixed, and slowly add 2g of Ti to the above mixture 3 AlC 2 , magnetically stirred for 24h. After the reaction, centrifuge and wash to pH > 6, dissolve the centrifuged precipitate in 300mL of ultrapure water, carry out vacuum deoxygenation for 2 hours, after completion of ultrasonication for 1 hour, centrifuge for 1 hour, and freeze-dry the supernatant for 48 hours to obtain ultra-thin Ti 3 C 2 Powder.

[0049] Step two, Ti 3 C 2 Preparation of @PPY composite nanospheres

[0050] Weigh 0.1g of polyvinyl alcohol (PVA) and 0.1g of sodium p-toluenesulfonate dissolved in 40mL of ultrapure water and mix evenly, then add 500mL of Py monomer to the above solution, stir at low temperature for 30min; then add 1.14g of persulfuric acid The APS solution...

Embodiment 3

[0055] Step 1, lamellar Ti 3 C 2 preparation of

[0056] Weigh 2g of LiF and dissolve it in a 50mL polytetrafluoroethylene beaker containing 20mL of 9M HCl (15mL of concentrated HCl+5mL of water), stir for 10min to make it evenly mixed, and slowly add 2g of Ti to the above mixture 3 AlC 2 , magnetically stirred for 24h. After the reaction, centrifuge and wash to pH > 6, dissolve the centrifuged precipitate in 300mL of ultrapure water, carry out vacuum deoxygenation for 2 hours, after completion of ultrasonication for 1 hour, centrifuge for 1 hour, and freeze-dry the supernatant for 48 hours to obtain ultra-thin Ti 3 C 2 Powder.

[0057] Step two, Ti 3 C 2 Preparation of @PPY composite nanospheres

[0058] Weigh 0.1g of polyvinyl alcohol (PVA) and 0.1g of sodium p-toluenesulfonate dissolved in 40mL of ultrapure water and mix evenly, then add 500mL of Py monomer to the above solution, stir at low temperature for 30min; then add 1.14g of persulfuric acid The APS solution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com