Carbon nanorod with high specific surface area and high nitrogen doping content, and simple preparation and application thereof

A high specific surface area, carbon nanorod technology, applied in the field of electrocatalysis, can solve the problems of high cost, the inability of ZIFs particles to ensure stable binding, and harsh synthesis conditions, and achieve low cost, multiple catalytic active sites, and simple synthesis process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

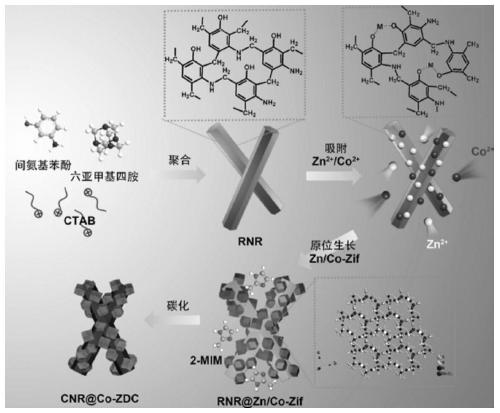

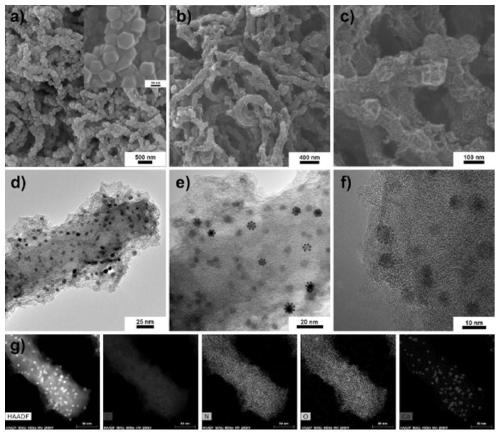

[0042] 1) Disperse 0.4g of m-aminophenol and 0.51g of hexamethylenetetramine (HMTA) in 40ml of water, stir for 20min, then add 0.3g of cetyltrimethylammonium bromide (CTAB), and gradually Add 0.2ml of ammonia solution dropwise and stir for 10min. Transfer to an 85°C water bath and stir for 24 hours, centrifuge, wash, and dry to obtain evenly dispersed resin nanorods (RNR). Disperse 150mg of RNR, 0.381g of zinc nitrate hexahydrate and 0.043g of cobalt nitrate hexahydrate in 25mL of methanol solution, after ultrasonic dispersion, add 25mL of methanol solution in which 0.99g of dimethylimidazole is dissolved, and stir at room temperature for 12h , washed by centrifugation, and dried to obtain a Zn / Co-Zif embedded resin nanorod composite (RNR@Zn / Co-Zif);

[0043] 2) Calcinate the dried above sample in a tube furnace with an argon atmosphere at 800°C for 5h, with a heating rate of 2°C min -1 , to obtain black one-dimensional carbon nanorods (CNR@Co-ZDC) with high specific surface...

Embodiment 4

[0059] 1) Disperse 0.4g of m-aminophenol and 0.51g of hexamethylenetetramine (HMTA) in 40ml of water, stir for 20min, then add 0.3g of cetyltrimethylammonium bromide (CTAB), and gradually Add 0.2ml of ammonia solution dropwise and stir for 10min. Transfer to an 85°C water bath and stir for 24 hours, centrifuge, wash, and dry to obtain evenly dispersed RNR. Disperse 150mg RNR, 0.381g zinc nitrate hexahydrate and 0.043g cobalt nitrate hexahydrate in 25mL methanol solution, add 0.99g dimethylimidazole dissolved in 25mL methanol solution after ultrasonic dispersion, and stir at room temperature React for 12 hours, centrifuge, wash, and dry to obtain a Zn / Co-Zif embedded resin nanorod composite (RNR@Zn / Co-Zif);

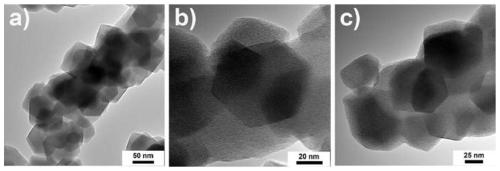

[0060] 2) Calcinate the dried above sample in a tube furnace with an argon atmosphere at 700°C for 5h, with a heating rate of 2°C min -1 , get CNR@Co-ZDC-700.

[0061] as attached Figure 13 As shown, it can be obtained by XRD analysis that its peak position basically ...

Embodiment 5

[0063] 1) Disperse 0.4g of m-aminophenol and 0.51g of hexamethylenetetramine (HMTA) in 40ml of water, stir for 20min, then add 0.3g of cetyltrimethylammonium bromide (CTAB), and gradually Add 0.2ml of ammonia solution dropwise and stir for 10min. Transfer to an 85°C water bath and stir for 24 hours, centrifuge, wash, and dry to obtain evenly dispersed RNR. Disperse 150mg RNR, 0.381g zinc nitrate hexahydrate and 0.043g cobalt nitrate hexahydrate in 25mL methanol solution, add 0.99g dimethylimidazole dissolved in 25mL methanol solution after ultrasonic dispersion, and stir at room temperature React for 12 hours, centrifuge, wash, and dry to obtain a Zn / Co-Zif embedded resin nanorod composite (RNR@Zn / Co-Zif);

[0064] 2) Calcinate the dried above sample in a tube furnace with an argon atmosphere at 900°C for 5h with a heating rate of 2°C min -1 , get CNR@Co-ZDC-900.

[0065] as attached Figure 13 As shown, it can be obtained by XRD analysis that its peak position basically c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Limiting current | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com