Textile fabric for manufacturing roller brush velvet and preparation method of textile fabric

A technology of textile fabrics and brushing velvet, applied in the field of textile fabric production, can solve problems such as unsatisfactory cost performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described below in conjunction with specific examples.

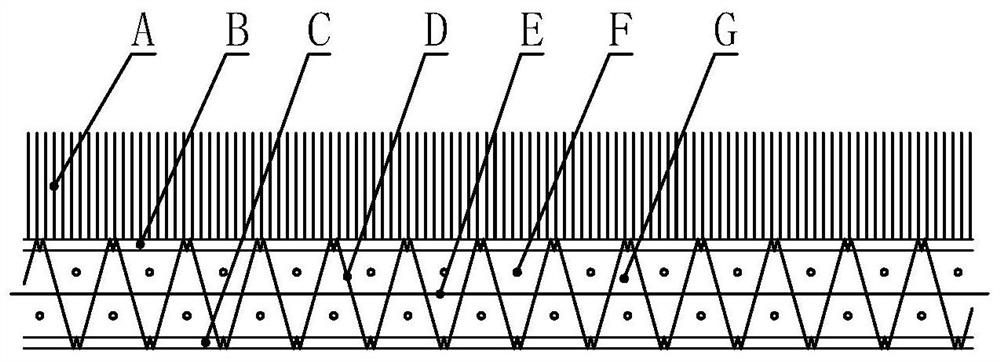

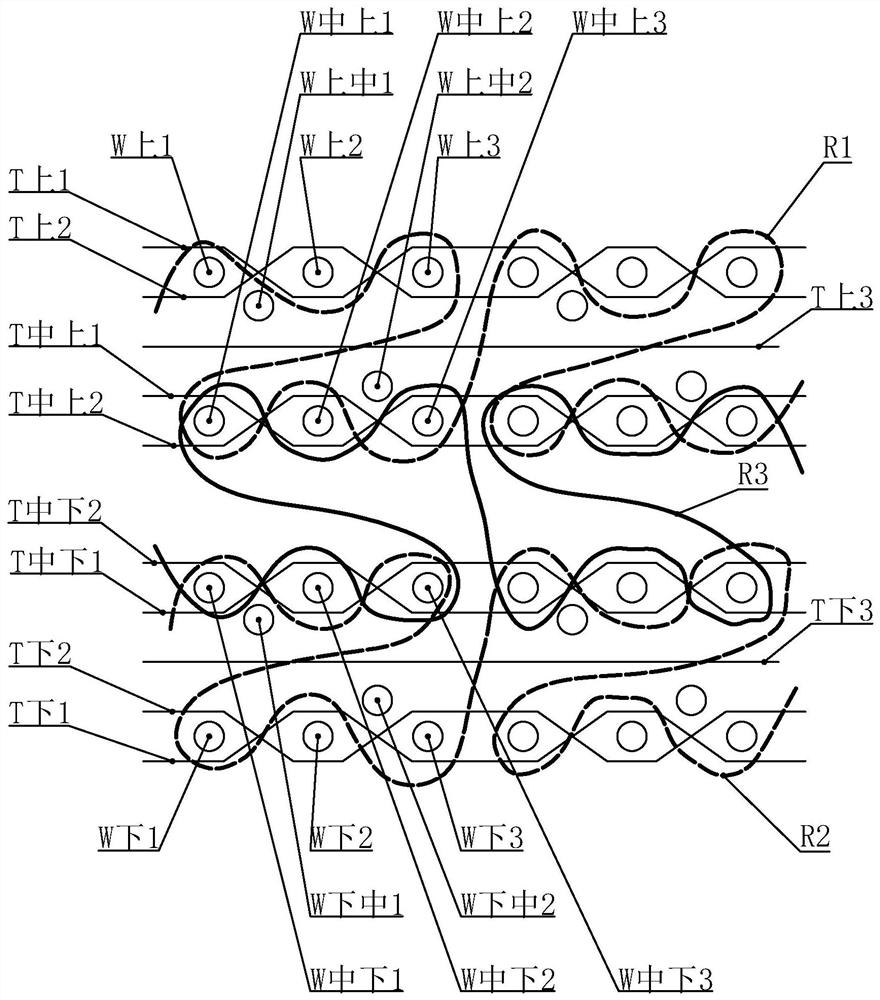

[0052] combine figure 1 with figure 2 , the present invention is described in detail. In a method for preparing a brushed fleece textile fabric according to the present invention, the rolled brushed fleece textile fabric comprises a fluff layer A and a slurry storage layer G. The slurry storage layer G includes a first base fabric layer B and a second base fabric layer C connected by a connecting thread D; interwoven warp yarn slivers are arranged between the first base fabric layer B and the second base fabric layer C E and weft yarn sliver F; the fluff of the fluff layer A is consolidated on the first base fabric layer B.

[0053] When the brush pile prepared by using the above-mentioned textile fabrics is working, when the fluff layer A is rolled on the working surface, the storage layer G is filled with slurry, and the slurry absorbed by the warp sliver E and the weft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com