Yarn drying device and yarn drying technology

A wire rack and membrane wire technology, which is applied in the fields of semi-permeable membrane separation, chemical instruments and methods, and membrane technology, can solve the problems of easy dripping of solutions on the ground, unhygienic ground, and labor-intensive, etc., so as to improve the working environment and save Cost, solution saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] The following part of this embodiment describes a silk drying device.

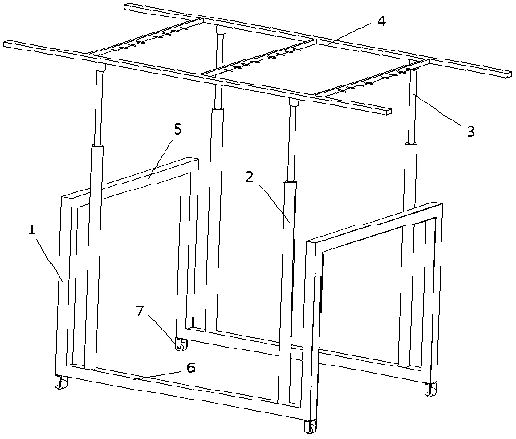

[0053] Such as figure 1 , 2 As shown, the silk drying device of the present embodiment is composed of a transfer car 1, a lifting support rod 2, a lifting rod 3, and a transfer drying rack 4.

[0054] The main frame of the transfer vehicle 1 is an undercarriage 6 and a structural frame 5 that are mutually connected and supported. The height of the structural frame 5 is slightly higher than the water tank where the membrane silk is soaked, so the transfer vehicle 1 can straddle directly above the water tank. Four corners are provided with four wheels 7 below the undercarriage 6, and the wheels 7 are universal wheels.

[0055] Lifting support bar 2 is fixedly installed on vehicle underframe 6, and its installation position matches with transfer wire drying rack 4. Lifting rod 3 is installed on the lifting support rod 2, and lifting rod 3 can rise to 2.3 meters from 1.3 meters.

[0056] The main fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com