PtO@MFI packaging structure catalyst for preparing synthesis gas through partial oxidation of methane and preparation method and application of catalyst

A technology of encapsulation structure and catalyst, which is applied in catalyst activation/preparation, molecular sieve catalyst, physical/chemical process catalyst, etc., can solve the problems of poor thermal stability and high cost of precious metal catalyst preparation, and improve the yield, catalyst activity and stability. Improve and reduce consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

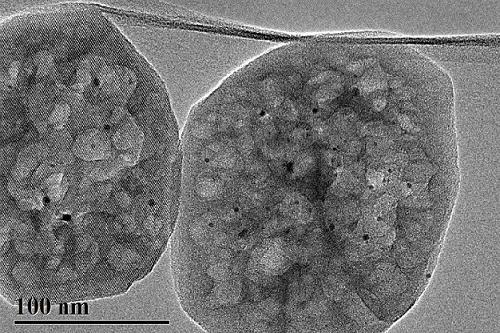

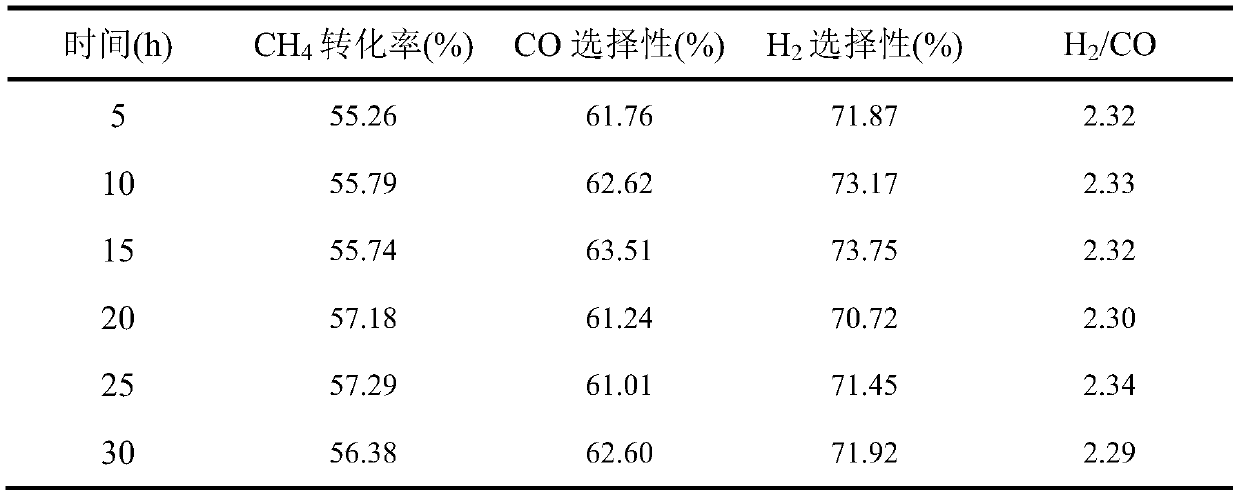

[0033] Catalyst preparation: weigh 0.03g H 2 PtCl 6 ·6H 2 O, dissolved in 1.5 ml deionized water to make a platinum salt solution; weigh 3 g of single crystal SiO with a size of 15 nm 2 , add the prepared chloroplatinic acid solution dropwise on the nano-silica, and stir well; ultrasonication for 1h, vacuuming for 1h to fully disperse the chloroplatinic acid on the silica; dry overnight in vacuum at 100°C , and then calcined in air at 400°C for 3h to obtain PtO / SiO 2 nanoparticles. Measure 10ml 25wt% TPAOH solution, add 50ml deionized water to make 60ml 0.2mol.L -1 solution; Weigh 2g PtO / SiO 2 Nanoparticles, dissolved in the prepared TPAOH solution, fully stirred, ultrasonic 2h to achieve maximum dispersion; the above solution was transferred to a 100ml polytetrafluoroethylene reactor, 170 ° C rotary hydrothermal crystallization 3d, rotating speed 60r / min; centrifuge the solution, wash it with excess deionized water until neutral; dry it in the air at 100°C overnight, an...

Embodiment 2

[0040] Catalyst preparation: weigh 0.03g PtN 2 o 6 , Dissolve it in 1.5ml deionized water to make a platinum salt solution; weigh 3g of single crystal SiO with a size of 20nm 2 , add the prepared platinum nitrate solution dropwise on the nano-silica, and stir thoroughly; ultrasonic for 1 hour, and vacuum for 1 hour to fully disperse the platinum nitrate solution on the silicon dioxide; dry overnight in vacuum at 100°C, Then calcined in air at 400°C for 3h to obtain PtO / SiO 2 nanoparticles. Measure 10ml 25wt% TPAOH solution, add 50ml deionized water to make 60ml 0.2mol L -1 solution; Weigh 2g PtO / SiO 2 Nanoparticles, dissolved in the prepared TPAOH solution, fully stirred, ultrasonic 2h to achieve maximum dispersion; the above solution was transferred to a 100ml polytetrafluoroethylene reactor, 170 ° C rotary hydrothermal crystallization 3d, rotating speed 60r / min; centrifuge the solution, wash it with excess deionized water until neutral; dry it in the air at 100°C overni...

Embodiment 3

[0046] Catalyst preparation: weigh 0.03g Pt 2 Cl 4 , Dissolve it in 1.5ml deionized water to make a platinum salt solution; weigh 3g of single crystal SiO with a size of 50nm 2 , add the prepared platinum chloride solution dropwise onto the nano-silica, and stir thoroughly; ultrasonic for 1 hour, and vacuum for 1 hour to fully disperse the platinum chloride solution on the silicon dioxide; dry in vacuum at 100°C overnight, and then calcined at 400 °C in air for 3 h to obtain PtO / SiO 2 nanoparticles. Measure 10ml 25wt% TPAOH solution, add 50ml deionized water to make 60ml 0.2mol L -1 solution; Weigh 2g PtO / SiO 2 Nanoparticles, dissolved in the prepared TPAOH solution, fully stirred, ultrasonic 2h to achieve maximum dispersion; the above solution was transferred to a 100ml polytetrafluoroethylene reactor, 170 ° C rotary hydrothermal crystallization 3d, rotating speed 60r / min; centrifuge the solution, wash it with excess deionized water until neutral; dry it in the air at 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com