Semiconductor memory device and manufacturing method thereof

A manufacturing method and semiconductor technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electric solid-state devices, etc., can solve the problems of reduced capacitive coupling rate of control gate, non-self-alignment of control gate and floating gate, complicated process, etc. , to achieve the effect of increasing storage density, reducing manufacturing cost, and reducing manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

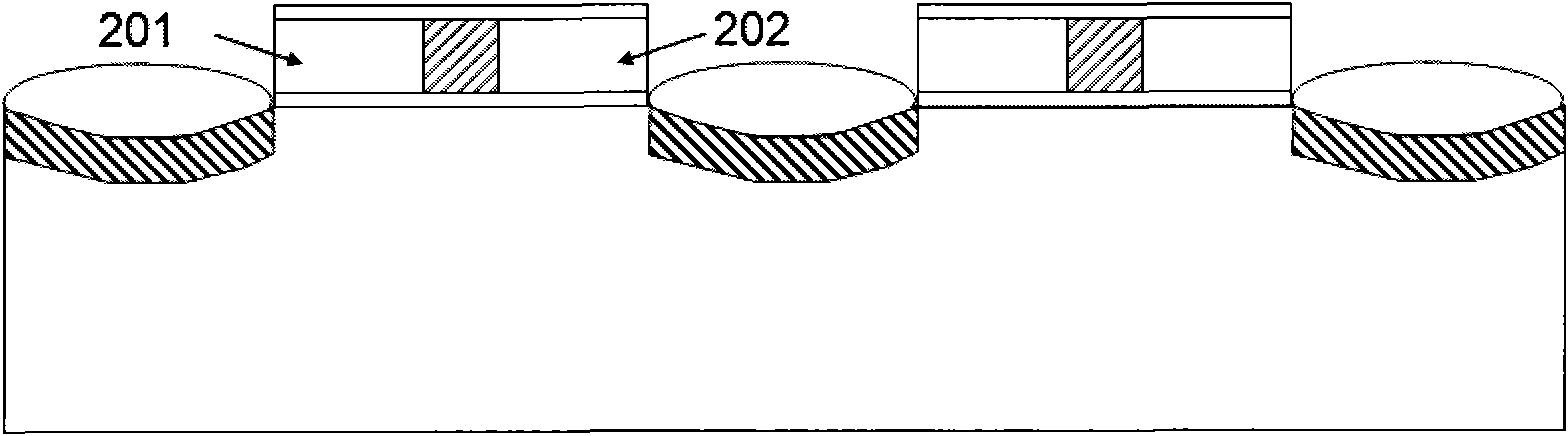

[0045] image 3 It is an embodiment of the semiconductor memory device 10 disclosed in the present invention, which is a cross-sectional view along the channel length direction of the device. This device has two floating gates separated by an insulator 304, namely, the floating gate 312 and the floating gate 313. The control gate is composed of a polysilicon layer 303 and a metal layer 302. Above the conductor layer of the control gate is an insulating layer 301. The word line side walls 305 and 311 are insulators such as Si 3 N 4 Materials, they surround the control gate conductor to insulate it from the other conductors of the device. The doping type of the source doped region 314 and the drain doped region 315 is generally opposite to that of the substrate 305. Between the source region and the drain region is the channel 320 of the device. The current between the source doped region 314 and the drain doped region 315 passes along the channel 320, and its density is affected b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com