Patents

Literature

38results about How to "Developed specific surface area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

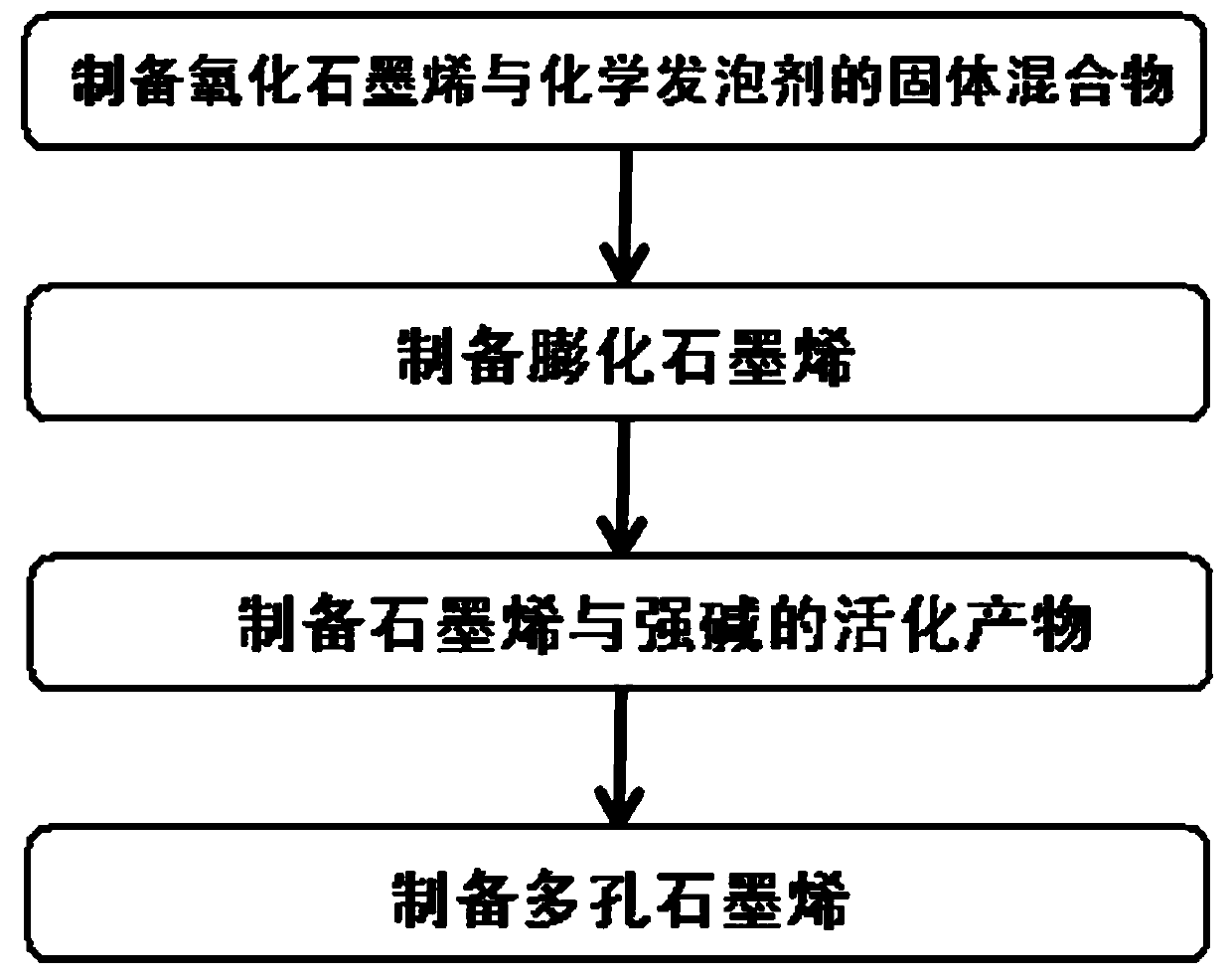

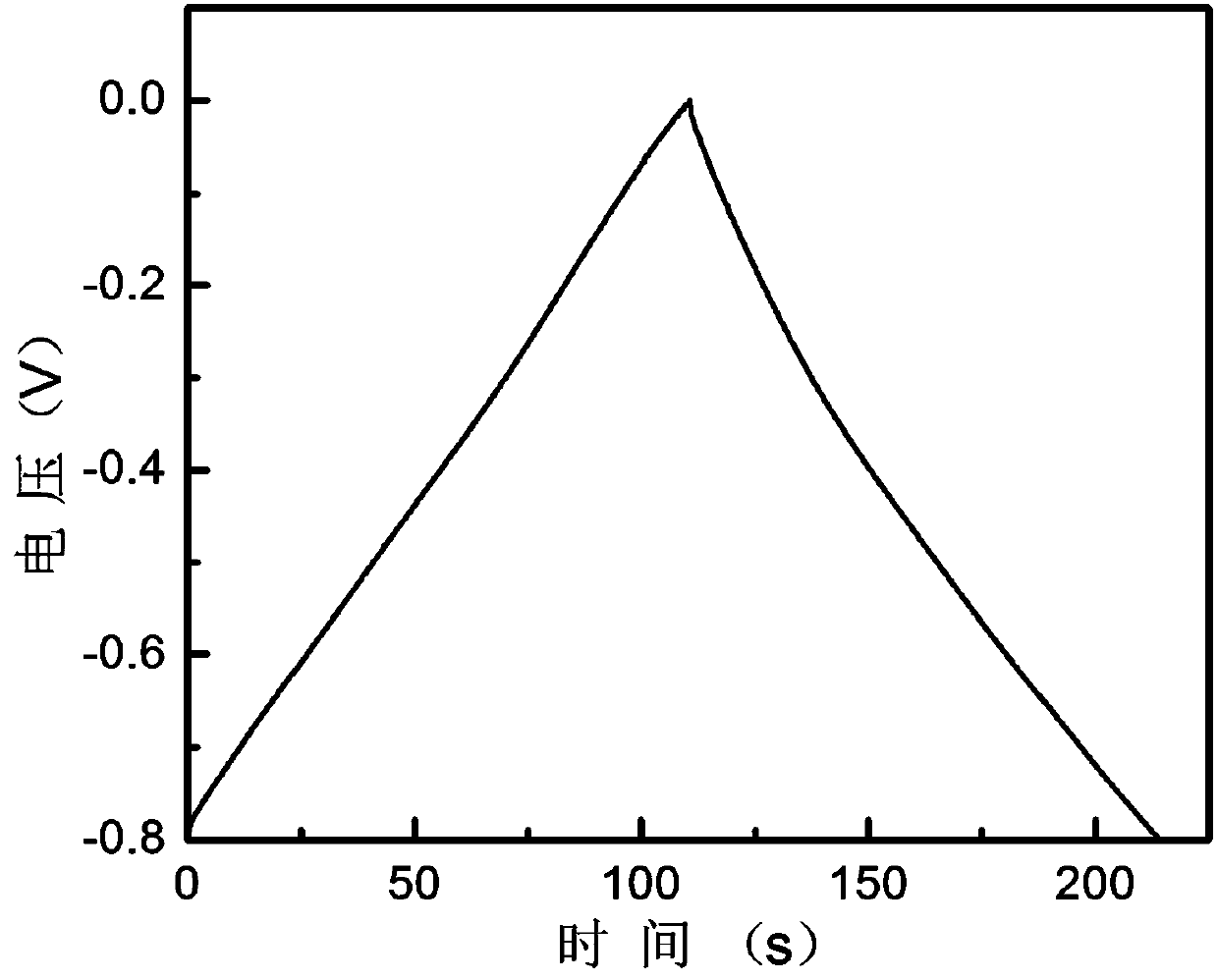

Preparation method of porous graphene

InactiveCN103466604AInhibit high temperature agglomeration effectHigh degree of peelingCarbon compoundsPorous grapheneCapacitance

The invention discloses a preparation method of porous graphene. The method comprises the steps of: (1) stripping graphite oxide in a water / ethanol mixed solution with pH of 9-10, adding a chemical foaming agent and mixing them uniformly, carrying out filtering and drying to obtain a solid mixture; (2) placing the mixture in a reducing atmosphere, and performing heating expansion reduction to obtain expanded graphene; (3) blending the expanded graphene with strong base, and conducting high temperature activation; and (4) washing the product with hydrochloric acid and deionized water, and performing drying so as to obtain porous grapheme. The porous graphene prepared by the method involved in the invention has a specific surface area up to 2075m<2> / g, a pore volume up to 1.8cm<3> / g, and an average pore size of 1-7nm. As a supercapacitor electrode material, the specific capacitance can reach 155F / g under a current density of 1Ag<-1>. As a porous graphene electrode, the specific capacitance can reach 84.4% along with the increase of current density from 0.2Ag<-1> to 20Ag<-1>. The porous graphene has high specific capacitance and cycle stability. The preparation method disclosed in the invention has the advantages of simple process, low cost, and easy scale production.

Owner:EAST CHINA UNIV OF SCI & TECH

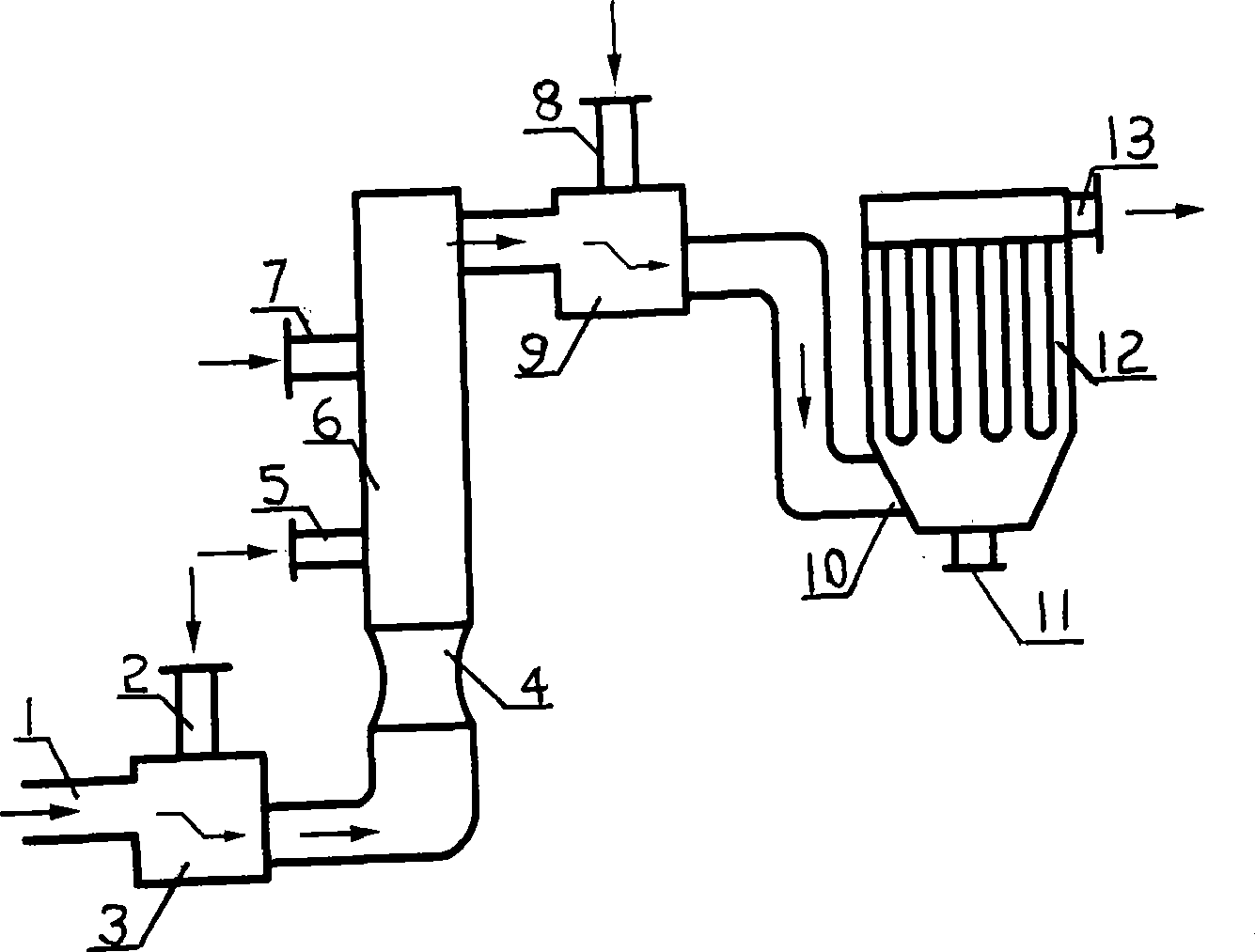

Integrated control method capable of simultaneously removing inhalable particles and heavy metal from fire coal

InactiveCN101480555AEfficient removalRich in microporesDispersed particle filtrationLighting and heating apparatusFiberCarbon fibers

The invention relates to an integrated control method for simultaneously removing respirable particle substances and heavy metal in fire coal. The integrated control method is characterized in that fly ash residual carbon having good adsorption effect on the heavy metal is sprayed in the front end of a bag type filter to remove heavy metal mercury in fire coal flue gas; meanwhile, ferrum series oxides with catalysis are sprayed in lime and the fly ash to remove sulfur oxide, and the like in the fire coal flue gas in a fluid bed reactor; filter materials of the bag filter are made of carbon-doped fibers and can effectively remove the heavy metal mercury in the fire coal flue gas for the second time, thereby achieving the aim for simultaneously removing the respirable particle substances and the heavy metal in the fire coal flue gas. The method can remove PM2.5 level, particularly finer micrometer and nanometer respirable particle substances with the removal rate up to more than 98 percent, and can remarkably control the emission of the heavy metal mercury in the fire coal flue gas; the integrated control process is simple in operation, safe in running, remarkable in environment benefit, small in occupied area of the device and low in process cost.

Owner:DONGHUA UNIV

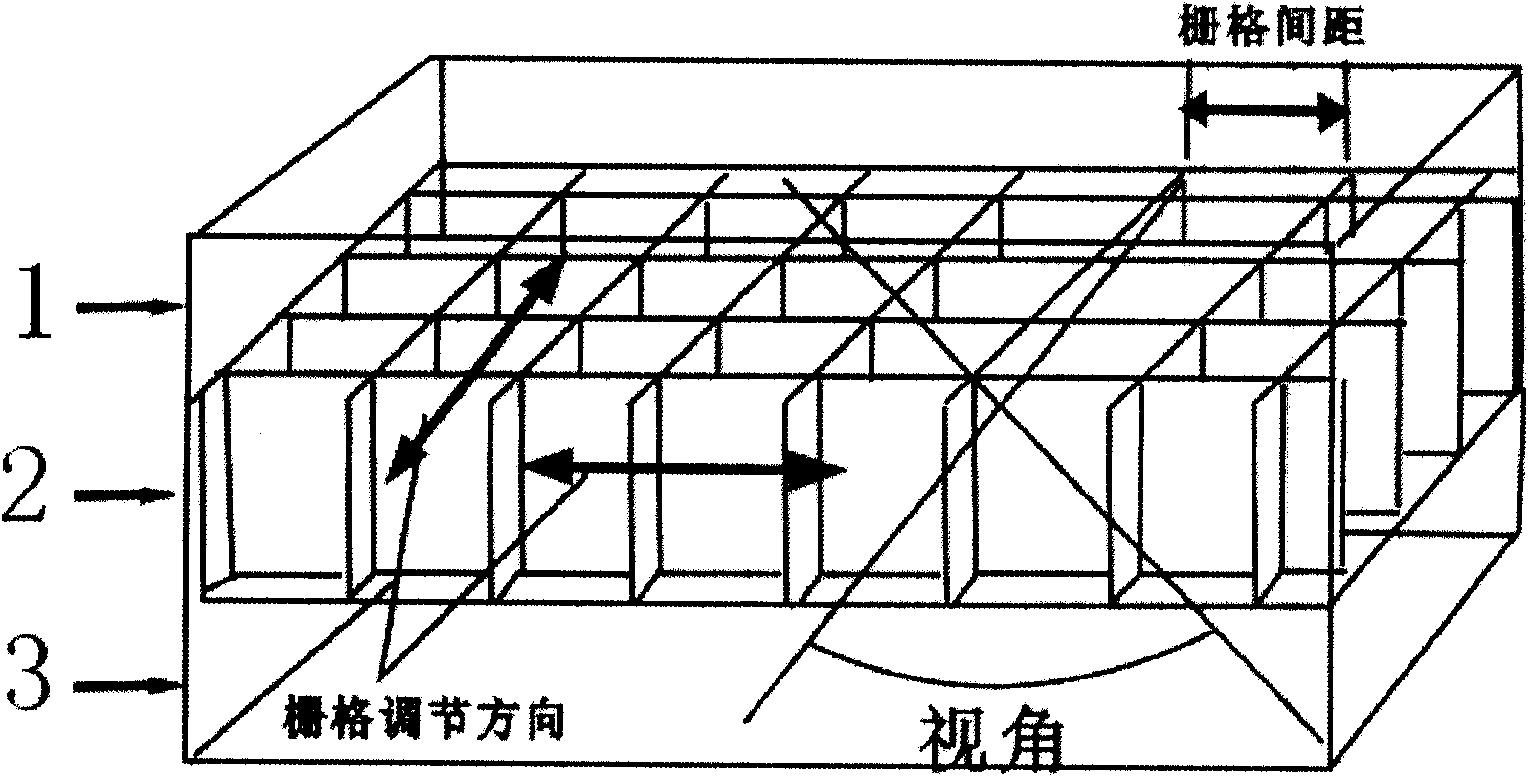

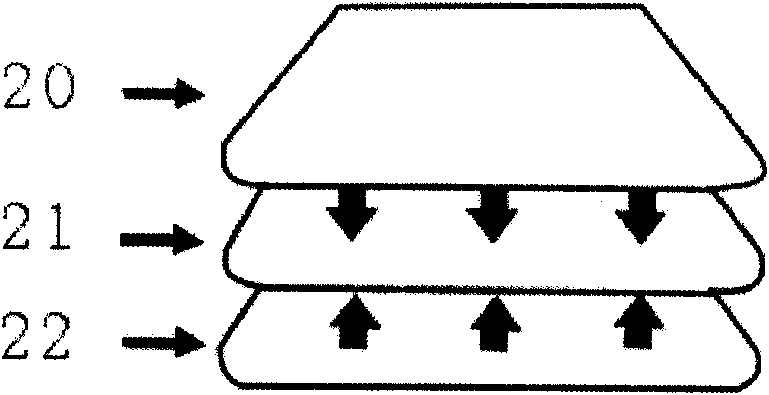

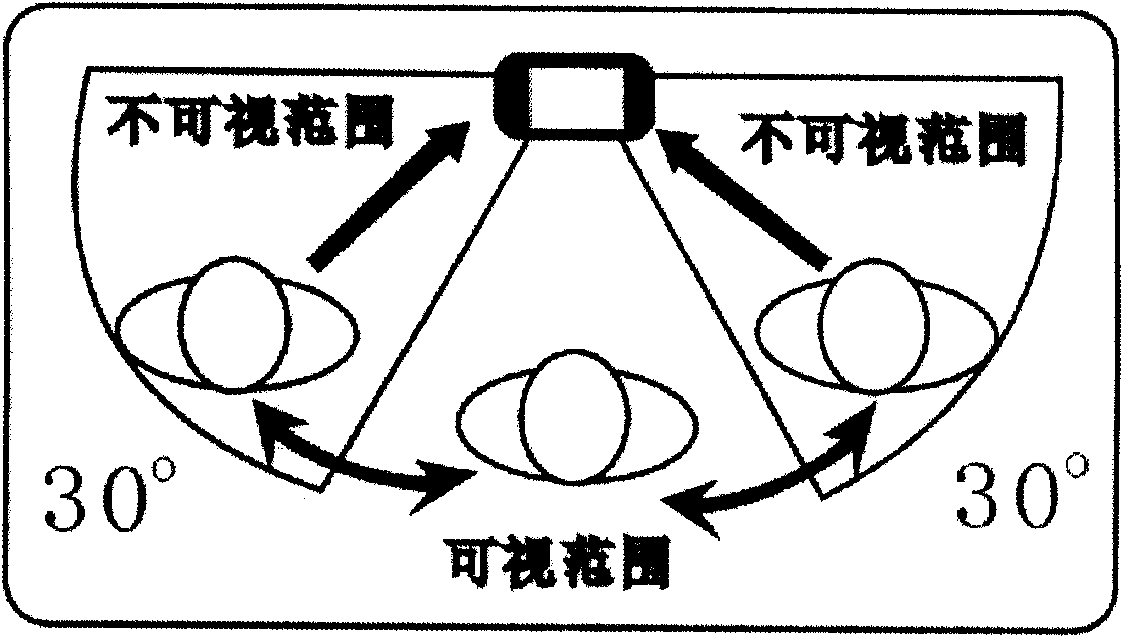

Parallel adjustable grid eyeshield privacy protecting adhesive film

InactiveCN101604033ACorrosion resistanceElectrically insulatingSynthetic resin layered productsOptical elementsPolyethylene terephthalateProtecting eye

The invention discloses a parallel adjustable grid eyeshield privacy protecting adhesive film which comprises a surface layer, a middle main film and a bottom layer. The surface layer is a polyethylene layer, the bottom layer is a polyethylene layer, and the middle main film comprises an upper layer, a middle layer and a lower layer, wherein the upper layer is a polyethylene terephthalate layer, the lower layer is a polyethylene terephthalate layer, and the middle layer is an active carbon fiber layer. The protecting adhesive film adopts a screen privacy dark technology and can prevent confidential information from being revealed and lead a screen to be only browsed by a front person, and other persons can only view a dark picture at both sides; a visual range of an LCD screen is limited in a certain range (preferably 60 degrees), the picture can be clearly viewed in the right side, but can not be viewed at both the left side and the right side, and the privacy performance is improved on the basis of original scratch, corrosion, glare and radiation resistance.

Owner:梁晓斌

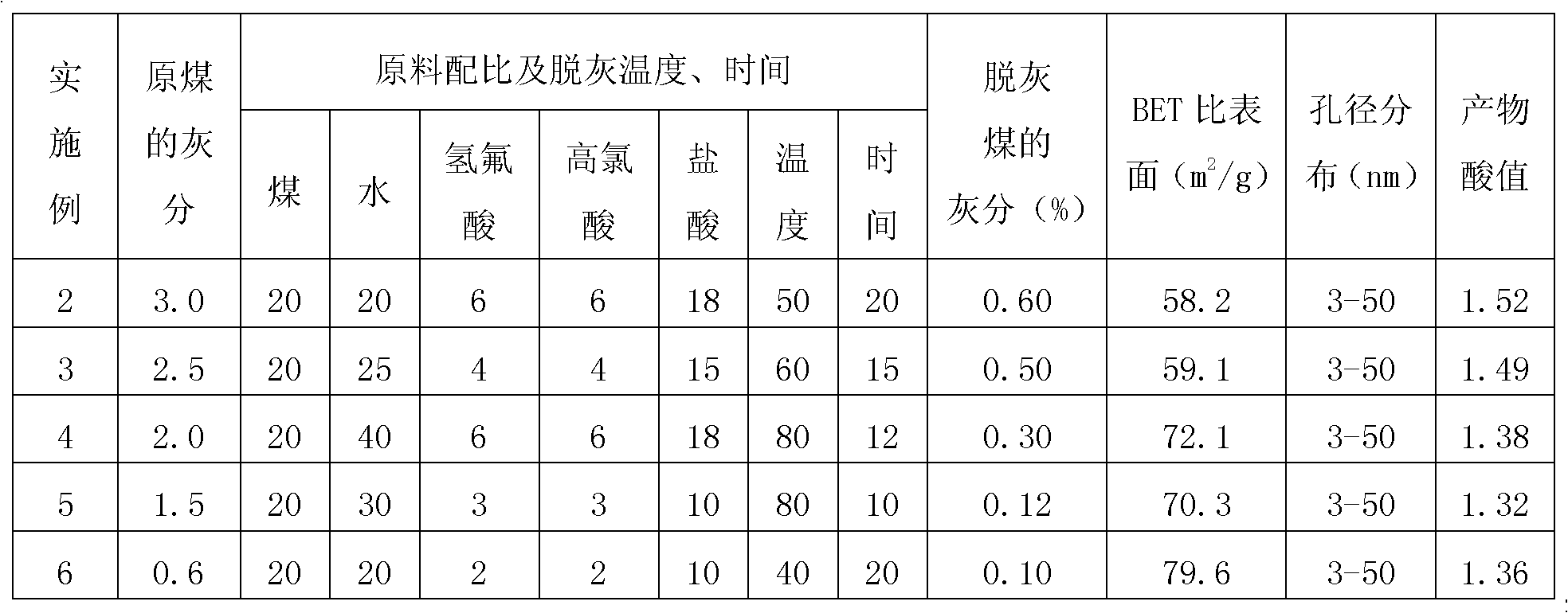

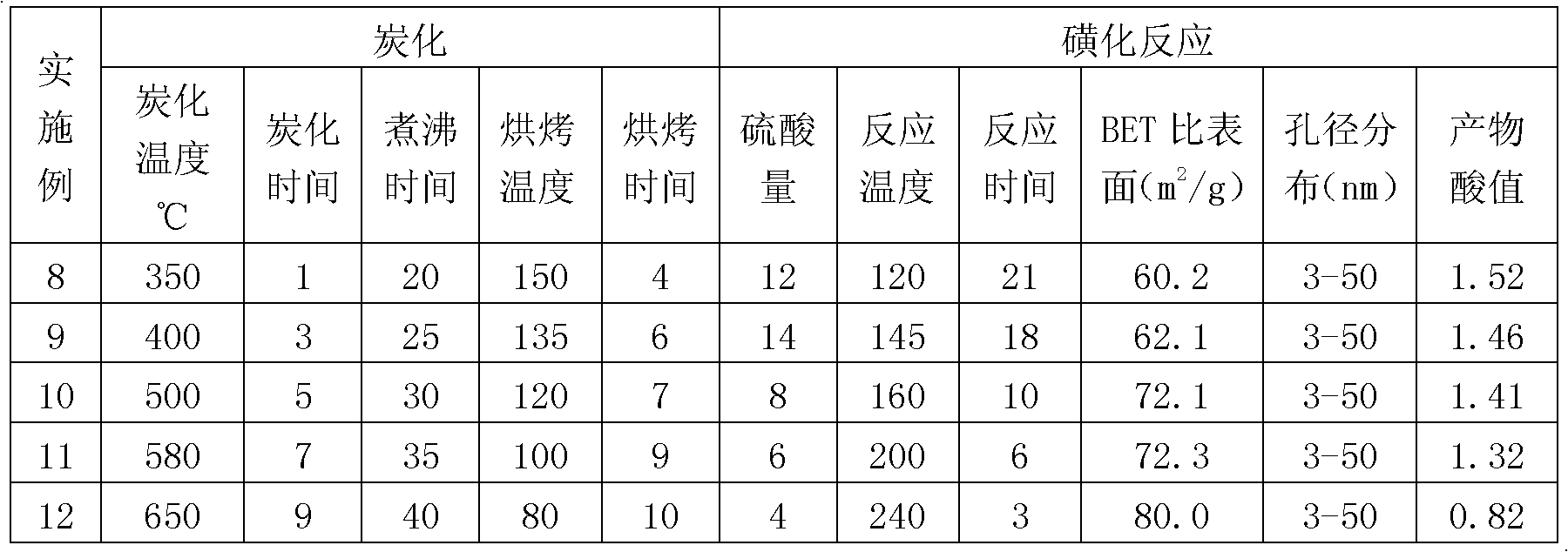

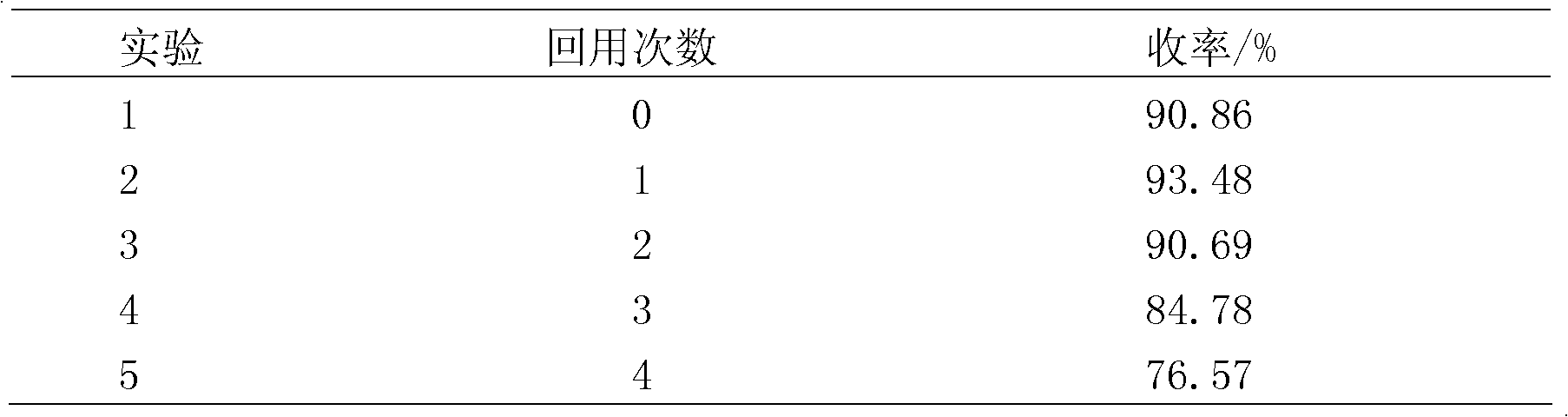

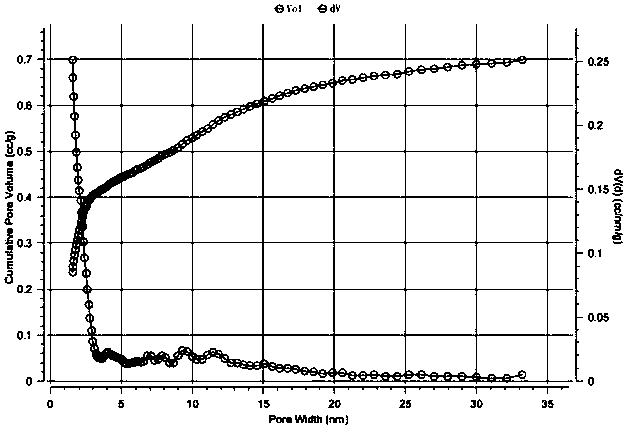

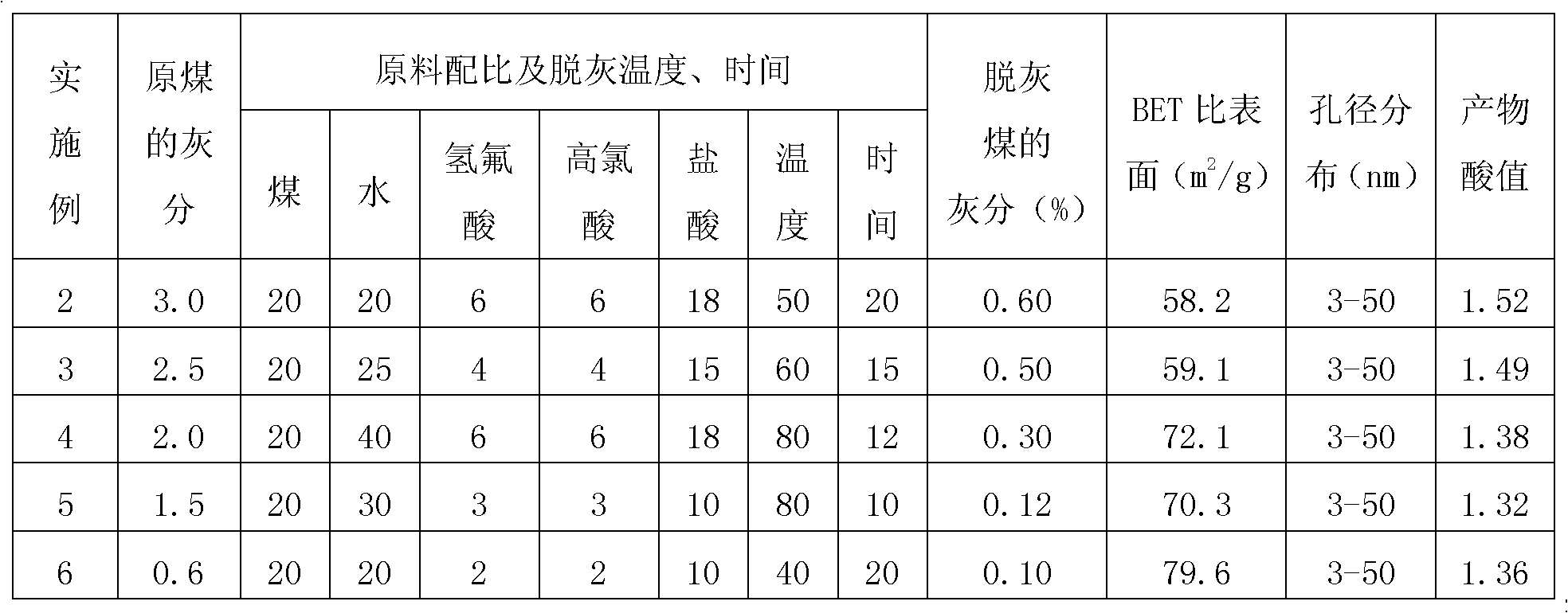

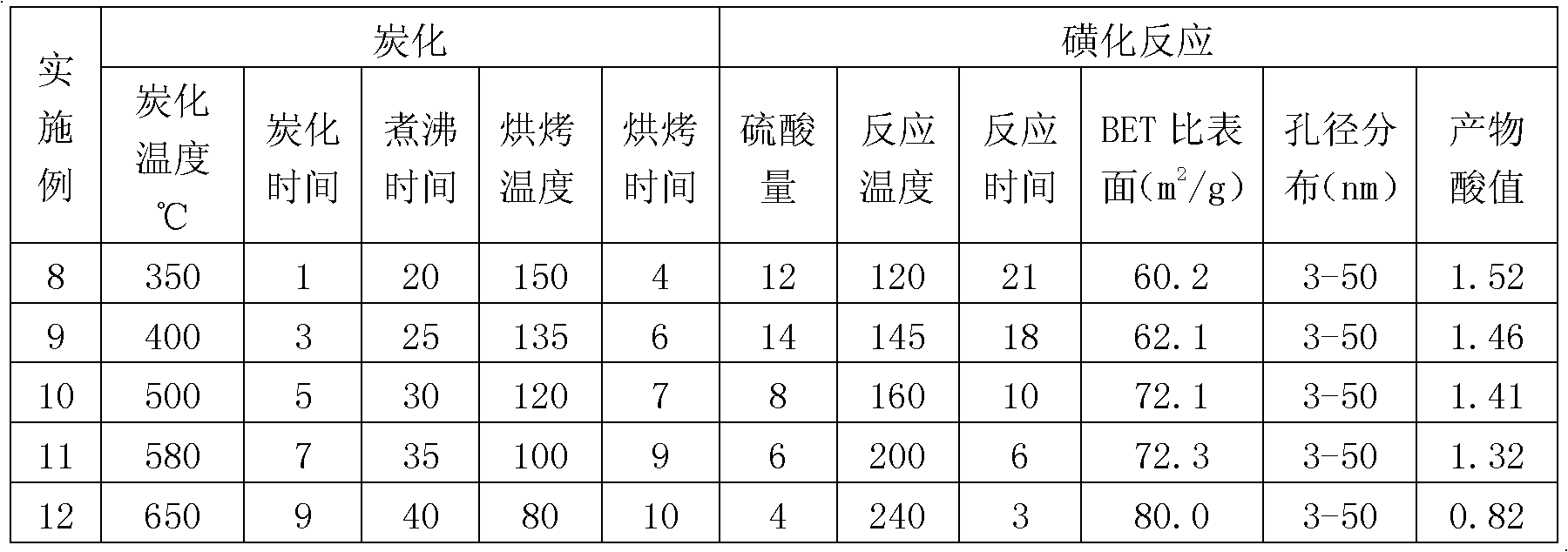

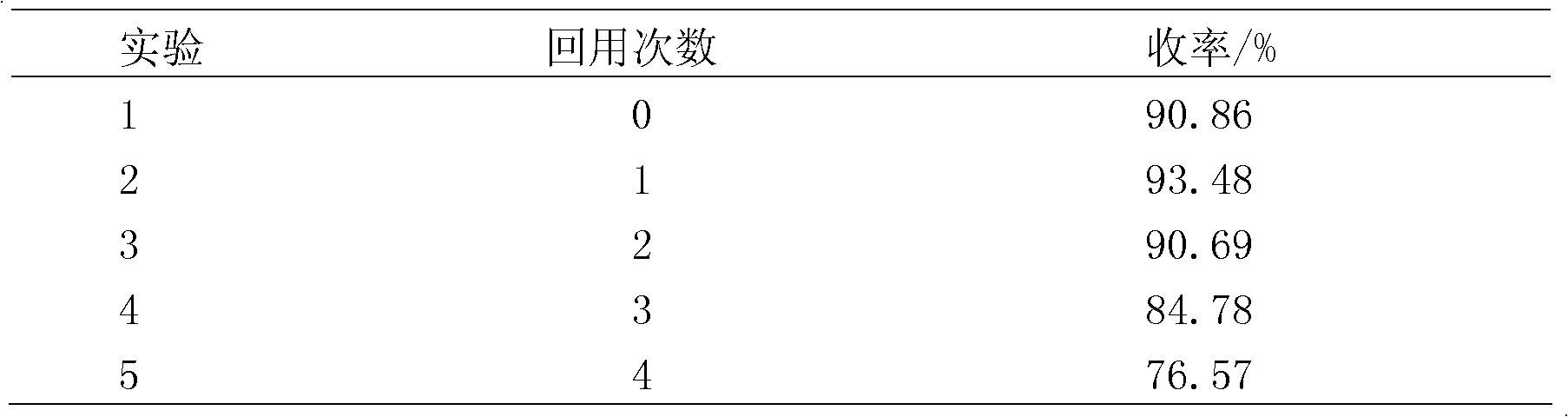

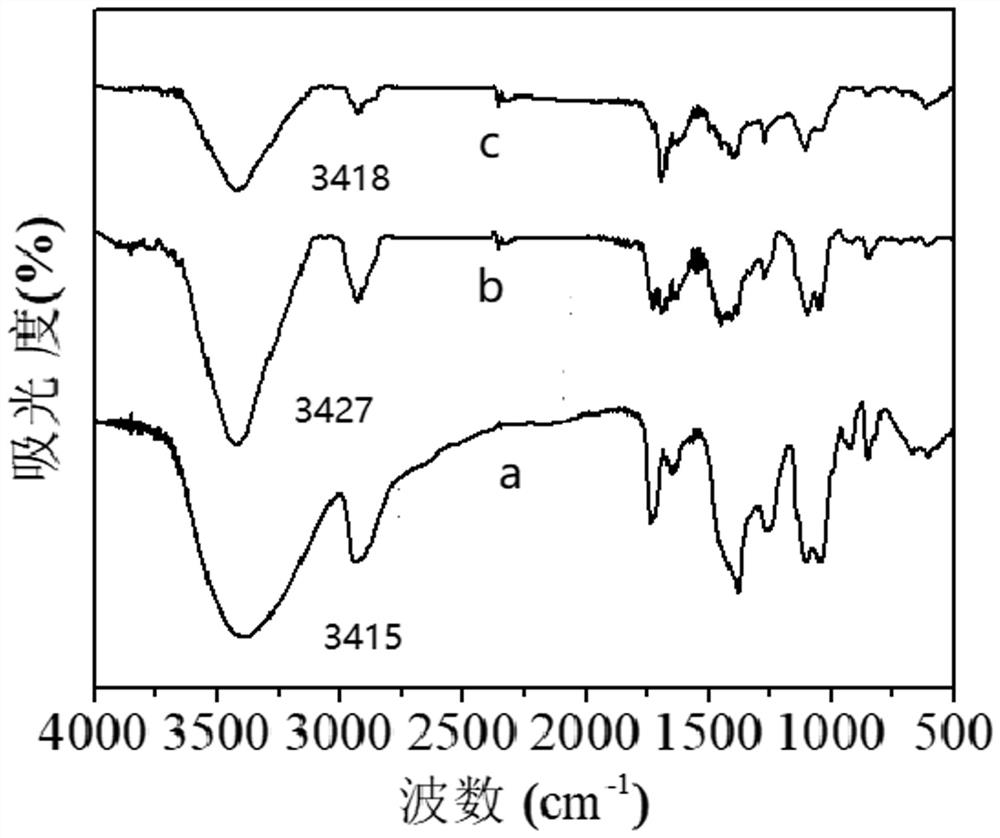

Carbon-based solid acid catalyst and preparation method thereof

InactiveCN102600893AHigh catalytic activityEasy to recycleOrganic-compounds/hydrides/coordination-complexes catalystsPorositySolid acid

The invention relates to preparation of a catalyst, in particular to a carbon-based solid acid catalyst and a preparation method thereof. The carbon-based solid acid catalyst has a pore size distribution of 3-50nm, a BET (Brunauer, Emmett and Teller) specific surface of 40-80m<2> / g and an acid value of 0.82-1.52mmol / g. The carbon-based solid acid catalyst is used for thermally decomposing granular carbon-based sulfonic acid under the temperature at 300 DEG C. The preparation method for preparing the carbon-based solid acid catalyst according to claim 1 is characterized by comprising the following steps of: preparing a modified coal precursor; preparing a compounding raw material; and carbonizing and sulfonating to obtain the solid acid catalyst. The carbon-based solid acid catalyst provided by the invention has the advantages that the preparation process is simple; the adopted raw materials are low in cost and easily obtained; based on a lyophobic amorphous carbon structure which is obtained by calcining an ultralow ash Taixi coal compound, a sulfo group is connected, and thus the carbon-based solid acid catalyst has porosity characteristic, developed mesopores, increased specific surface area and excellent heat stability; and the catalytic activity of the carbon-based solid acid catalyst is higher than that of the traditional acid catalyst, and the carbon-based solid acid catalyst is reusable and easy to be recovered.

Owner:NINGXIA UNIVERSITY

Optimized thin-type and electrode-tube-type seal power lead-acid storage battery and manufacturing method thereof

ActiveCN104466190AHigh mechanical strengthImprove corrosion resistanceFinal product manufactureElectrode carriers/collectorsRare-earth elementIon exchange

The invention belongs to the field of batteries, and particularly relates to an optimized thin-type and an electrode-tube-type seal power lead-acid storage battery. The optimized thin-type and the electrode-tube-type seal power lead-acid storage battery comprises a positive electrode plate and a negative electrode plate, wherein the positive electrode plate is made of a rare earth alloy, the negative electrode plate is prepared from the following raw materials: lead powder, barium sulfate, humic acid, complex tannin extract, carbon black, ion exchange water and vitriol. The invention also provides a preparation method of the optimized thin-type and an electrode-tube-type seal power lead-acid storage battery. The preparation method comprises the following steps: melting the rare earth element into the lead so as to prepare a positive plate grid, enabling a sheath and a dacron calandria to sleeve the grid, then filling the powder, smashing an upper back cover, soaking, solidifying and drying, so as to prepare the positive electrode plate; and after preparing the positive electrode plate and the negative electrode plate, assembling and forming the positive electrode plate and the negative electrode plate into a finished battery. The rare earth alloy is adopted by the positive electrode plate, so that the mechanical strength of the grid and the corrosion resistance of the grid are improved, the service life of the battery is prolonged, the complex formula of the negative electrode plate is used for improving the battery active substance use ratio and the battery capacity, and the low-temperature discharge performance of the battery is enhanced.

Owner:淄博明泰电器科技有限公司

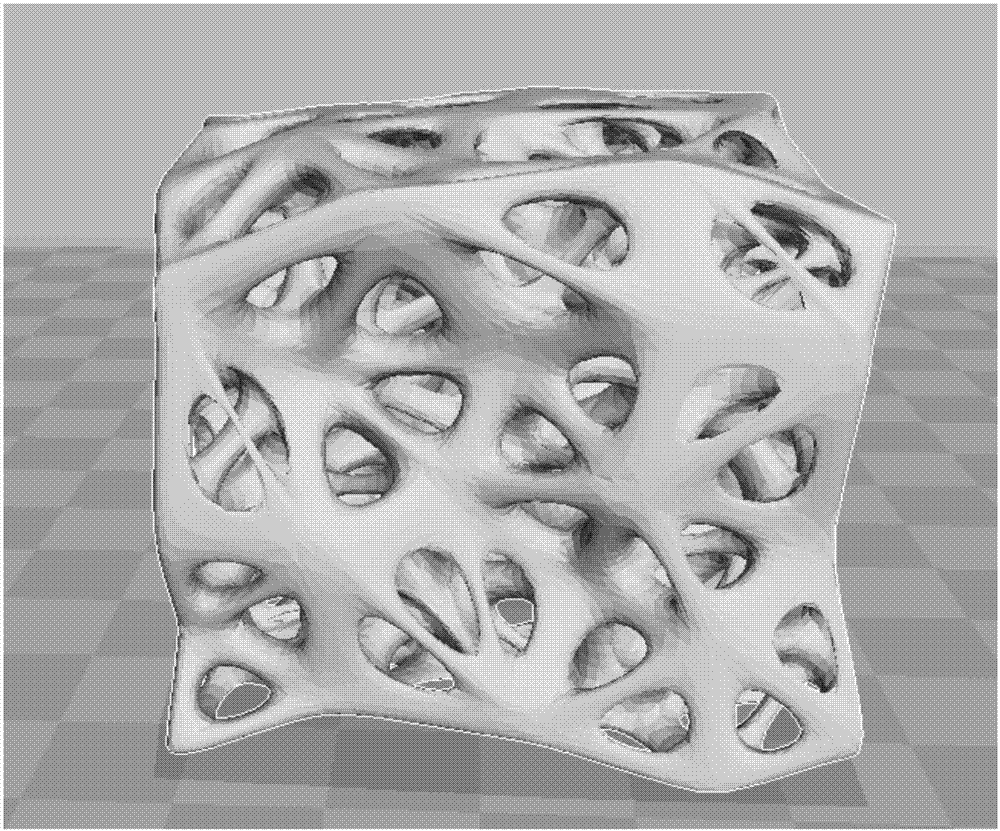

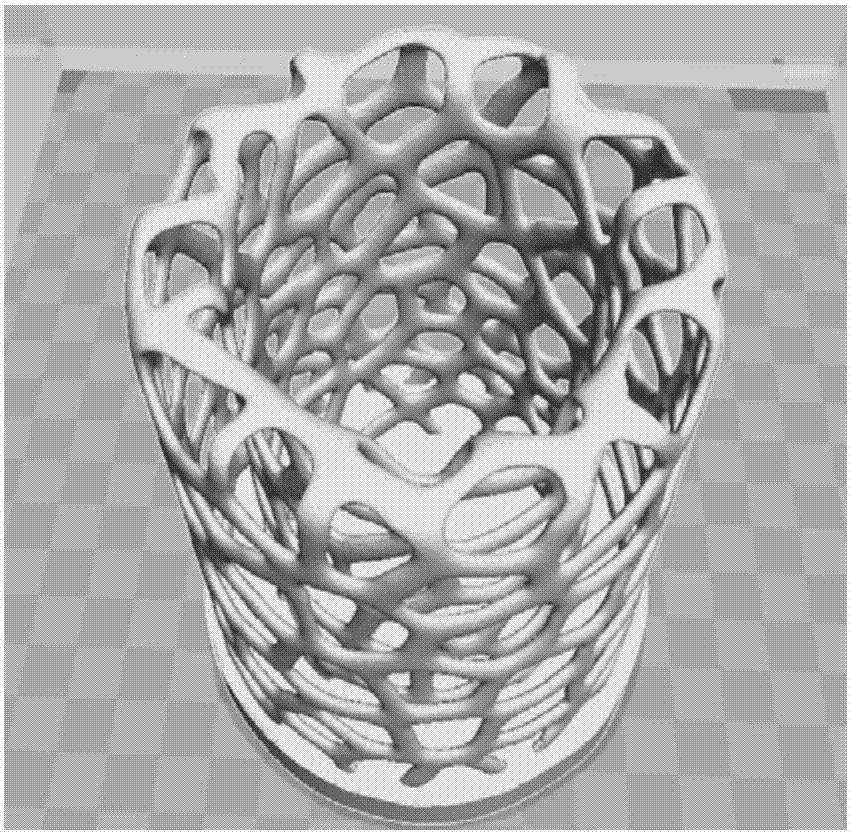

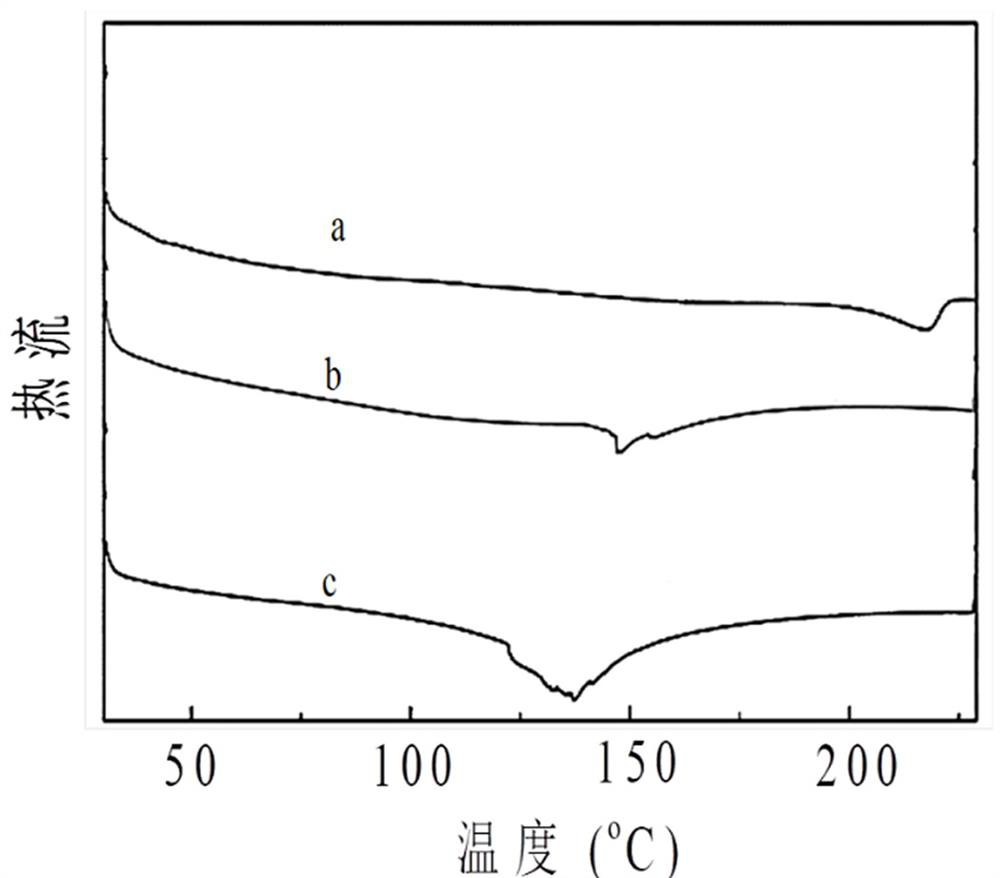

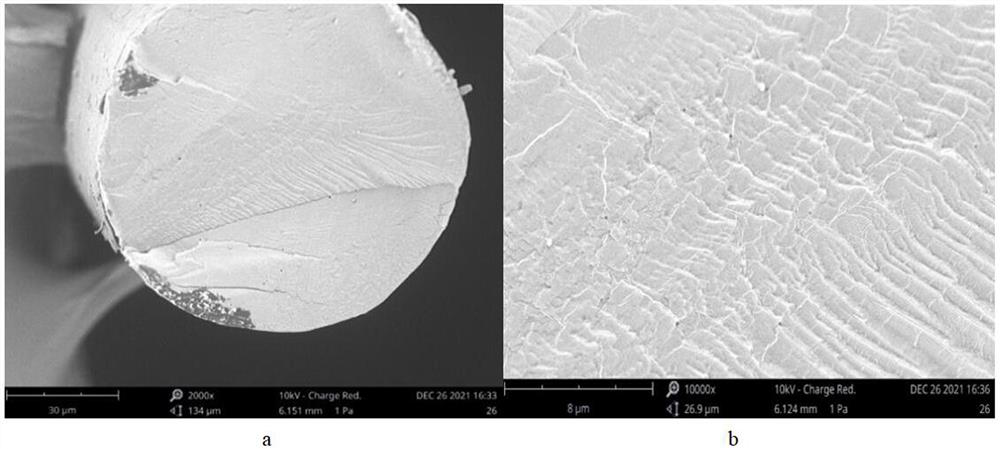

Deodorizing and antibacterial 3D (three-dimensional) printing reed fiber composite material and preparation method and application thereof

InactiveCN106995597AImprove mechanical propertiesGood deodorizing and antibacterial functionAdditive manufacturing apparatusActivated carbonFibrous composites

The invention discloses a deodorizing and antibacterial 3D (three-dimensional) printing reed fiber composite material and a preparation method and application thereof. The deodorizing and antibacterial 3D printing reed fiber composite material is prepared from the following components in parts by weight: 50 to 95 parts of macromolecular polymer, 5 to 30 parts of reed fiber, 0.01 to 0.2 part of coupling agent, 1 to 10 parts of toughener, 1 to 30 parts of activated carbon, and 0.1 to 5 parts of antibacterial agent. The deodorizing and antibacterial 3D printing reed fiber composite material has the advantages that on the basis of maintaining the original property of the macromolecular material polymer, the self antibacterial and mildew-proof abilities are improved, and the deodorizing function is improved.

Owner:GUANGZHOU FEISHENG HIGH POLYMER MATERIAL CO LTD +1

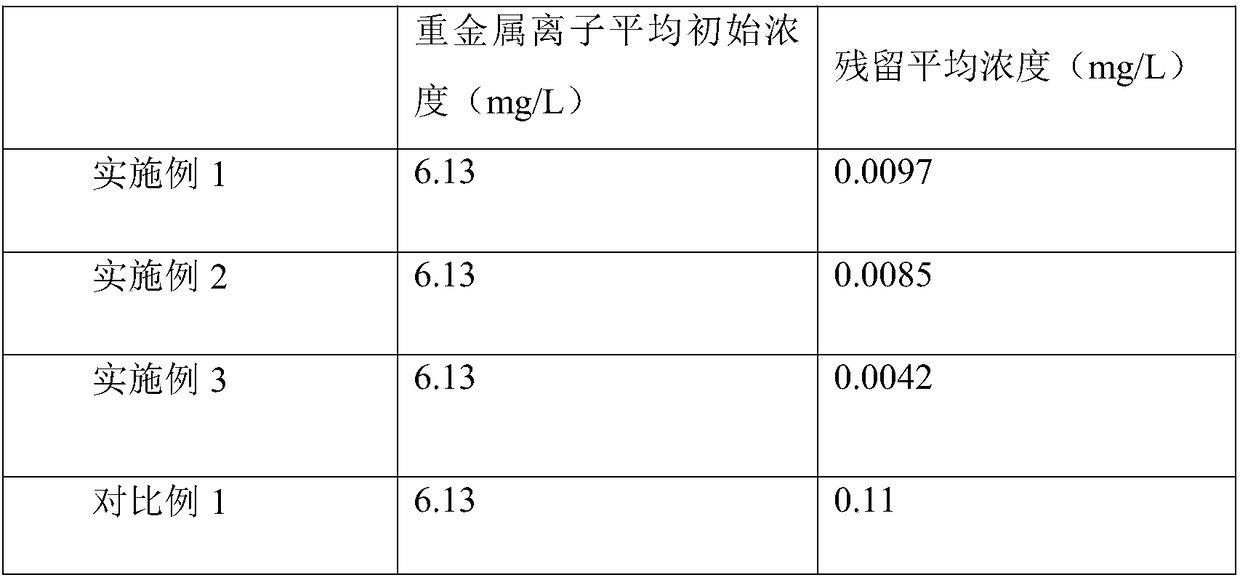

Nano-composite material used for water purification and preparation method thereof

InactiveCN108928876AWith photocatalytic effectDeveloped specific surface areaPhysical/chemical process catalystsWater/sewage treatment by irradiationCross-linkActivated carbon

The invention discloses a nano-composite material used for water purification, which includes, by weight, 48-54 parts of chitosan, 12-16 parts of nano-TiO2, 24-28 parts of active carbon supported nano-bentonite and 3-6 parts of nano-hydrotalcite, wherein the mass ratio of the chitosan, the nano-TiO2, the active carbon supported nano-bentonite to the nano-hydrotalcite is (65-75):(8-12):(14-18):4. With chitosan being a carrier, the product has stable properties. The cross-linked structure in the active carbon form fine pores, so that the product has well-developed pore structure; by supporting the nano-bentonite on the active carbon, the nano-bentonite is increased in specific surface area, so that the product is enhanced in heavy metal adsorption effect.

Owner:合肥岑遥新材料科技有限公司

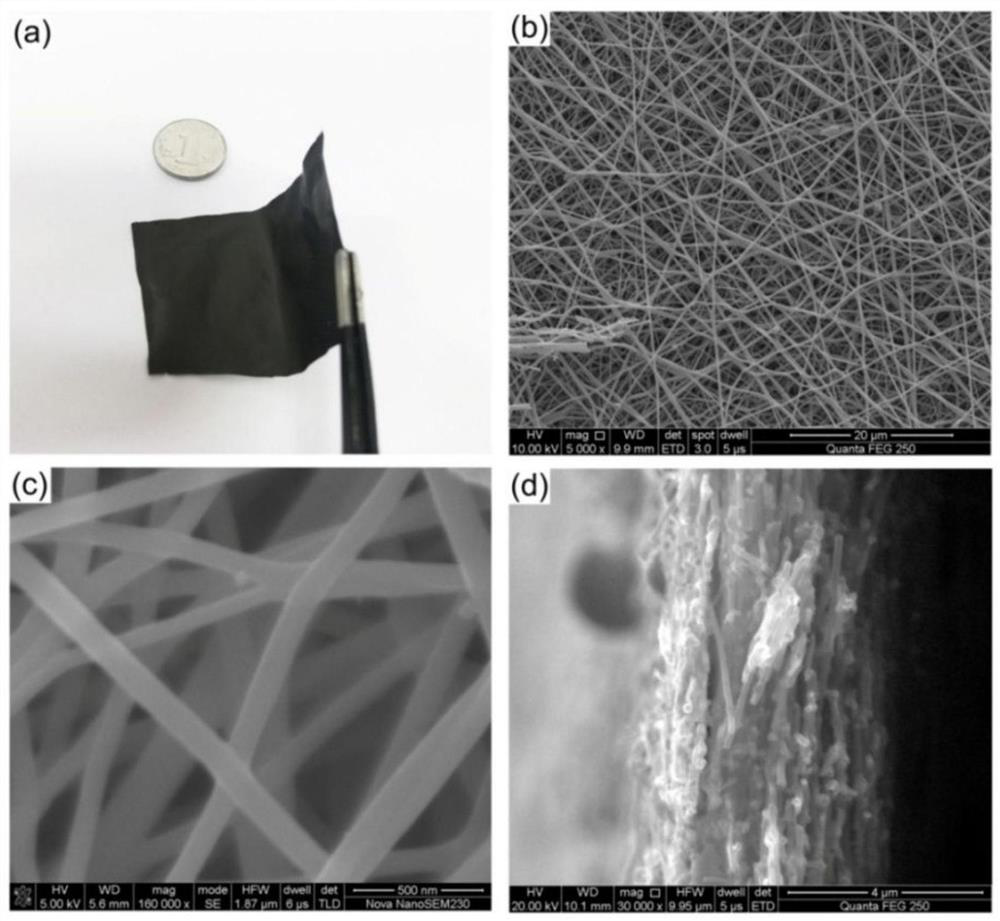

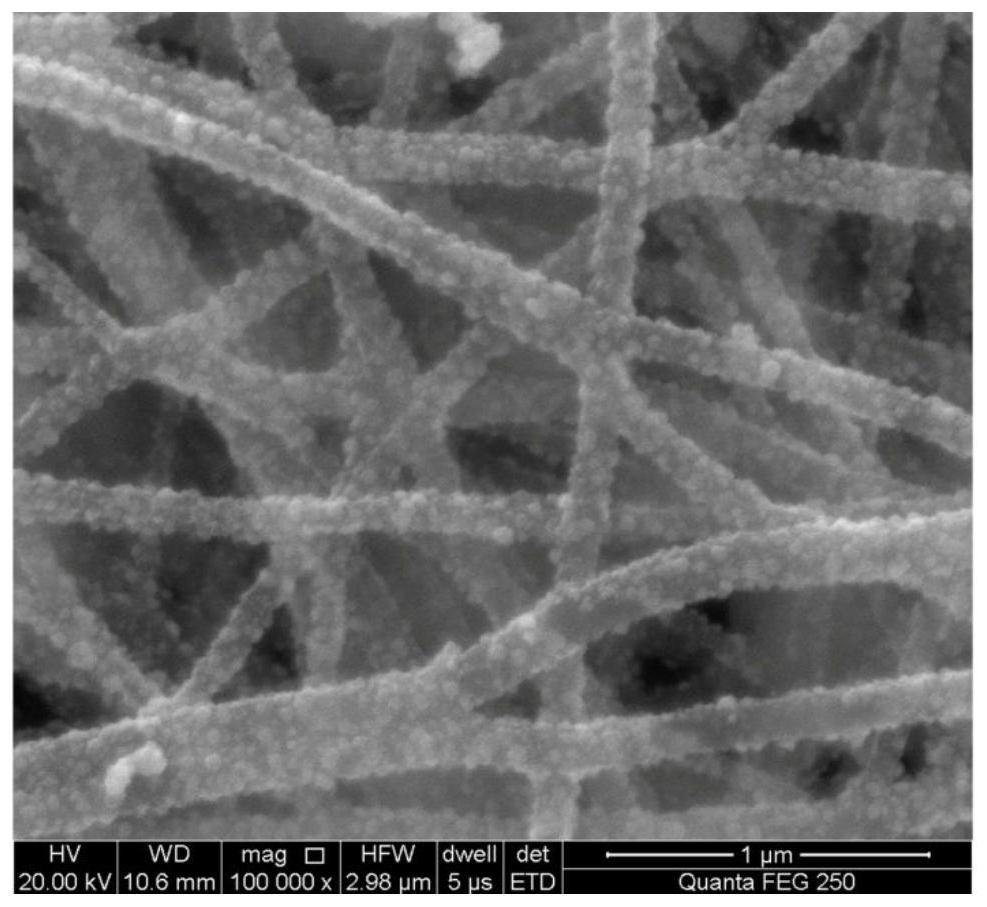

Integrated PtCu/carbon nanofiber catalyst layer, preparation method thereof and application thereof in fuel cell

ActiveCN111916773AImprove load stabilityHigh catalytic activityMaterial nanotechnologyCell electrodesFiberCarbon fibers

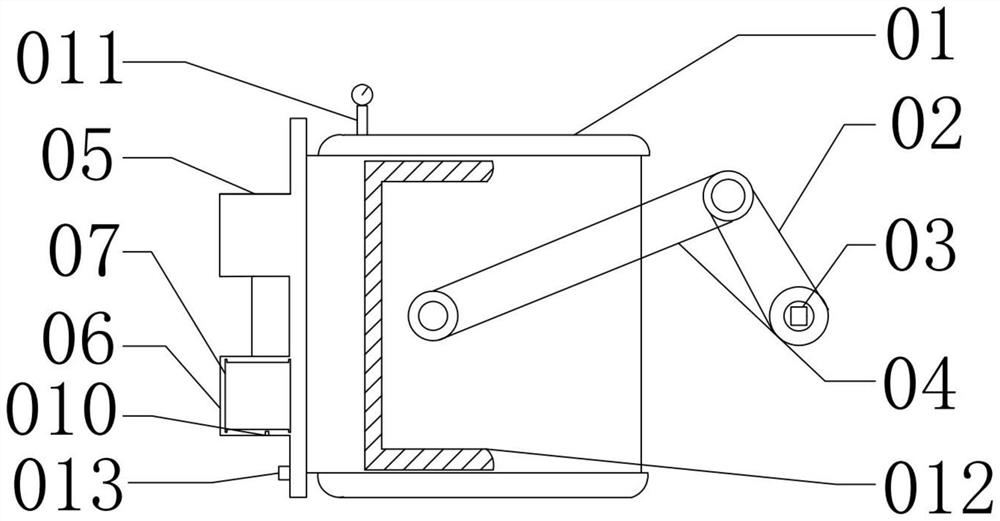

The invention discloses an integrated PtCu / carbon nanofiber catalyst layer, a preparation method thereof and an application thereof in a fuel cell. The preparation method of the integrated PtCu / carbonnanofiber catalyst layer comprises the following steps: obtaining a nano polymer fiber membrane through electrostatic spinning, carrying out heat treatment on the nano polymer fiber membrane to obtain a carbon nanofiber membrane, depositing copper nanocrystals on the carbon nanofiber membrane through a pulse electrodeposition method, alloying the copper nanocrystals through an in-situ replacementmethod, and obtaining a PtCu alloy / carbon nanofiber film; soaking the PtCu alloy / carbon nanofiber film in a perfluorosulfonic acid resin solution, and adhering the PtCu alloy / carbon nanofiber film toa proton exchange membrane for mould pressing and curing to obtain the PtCu / carbon nanofiber catalyst layer. The preparation method has the advantages of being efficient, low in cost and environmentally friendly, the obtained integrated PtCu / carbon nanofiber catalyst layer is high in catalytic activity and good in stability, the problems of falling and uniformity of materials in the using processcan be avoided, and meanwhile the membrane electrode assembling efficiency is improved.

Owner:CENT SOUTH UNIV

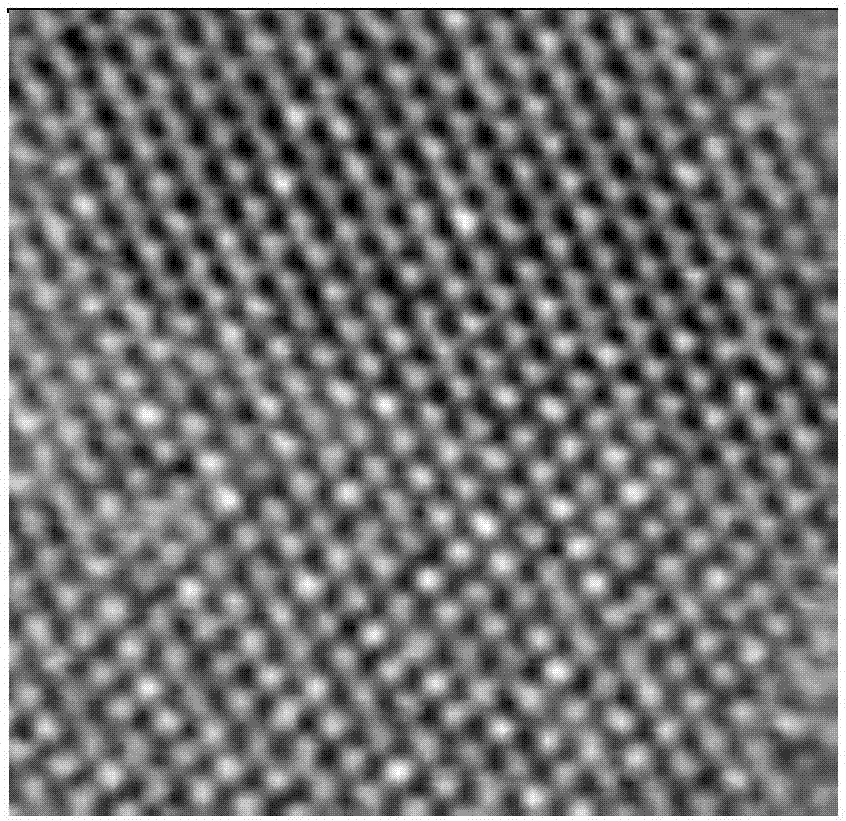

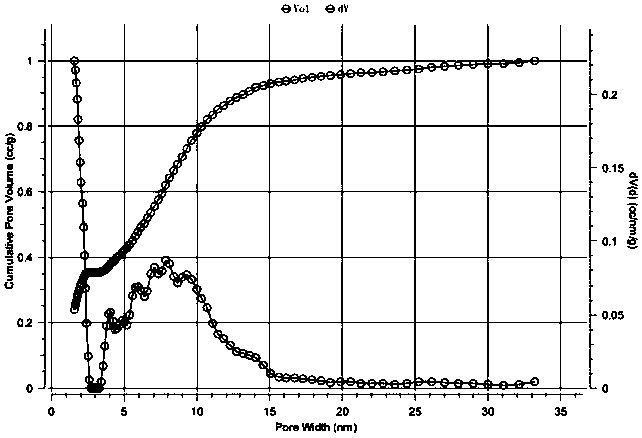

Preparation method for para-aminophenol ordered mesoporous carbon catalyst

ActiveCN107570157AAbundant and cheap raw materialsOrdered mesoporous structureOrganic compound preparationMetal/metal-oxides/metal-hydroxide catalystsCarbonizationPara-aminophenol

The invention discloses a preparation method for a para-aminophenol ordered mesoporous carbon catalyst. The preparation method is characterized in that chitosan is taken as a raw material, and non-precious metal compounds are used as a doping source, meanwhile, a triblock copolymer surfactant is added, after performing self-produced high pressure treatment under a high temperature hydrothermal condition, filtering is performed so as to obtain a dark brown solid product, the solid product is dried, ground, and then put into a tubular calcinator, and high temperature carbonization under inert gas atmosphere protection is performed, so as to obtain a high-stable metal-doped carbon-based catalyst with different ordered mesoporous structures. The catalytic efficiency of the high-stable metal-doped carbon-based catalyst for para-nitrophenol hydrogenation catalysis generating para-aminophenol is investigated. The operation process has the main characteristics that the biomass resource chitosan is used as a raw material and is environmentally friendly, cheap and available; the surfactant is added, so that the formation of the ordered mesoporous structure is effectively controlled, the effective contact area between the reactant and the catalyst is increased, and the reaction conditions are mild; an active center and a carbon material are generated simultaneously, so that the structureis more stable, and the reaction process operationis simple.

Owner:QINGDAO UNIV OF SCI & TECH

Polyvinyl chloride with good thermal stability

The invention discloses polyvinyl chloride with good thermal stability. The polyvinyl chloride with good thermal stability comprises the following raw materials in parts by weight: 40-70 parts of polyvinyl chloride, 5-10 parts of polystyrene, 10-25 parts of polymethyl methacrylate, 0.5-1.5 parts of polyethylene wax, 0.4-0.8 part of rare earth metal compound, 1-2 parts of chlorinated paraffin, 0.5-1 part of maleic anhydride-grafted ethylene propylene diene monomer rubber, 0.2-0.8 part of dibutyl tin dilaurate, 0.2-0.6 part of dodecenylsuccinic anhydride, 0.5-1.5 parts of dicumyl peroxide, 1-4 parts of vermiculite power, 6-10 parts of talcum powder, 0.5-2 parts of precipitated barium sulphate, 5-9 parts of nylon fiber, 4-8 parts of mica powder, 6-10 parts of calcium silicate, 8-12 parts of composite carbon, 2-4 parts of a titanate coupling agent, 0.5-1.5 parts of an antioxidant, 0.5-1 part of an lubricant and 0.5-1.5 parts of a light stabilizer.

Owner:ANHUI JINZHENG PLASTIC

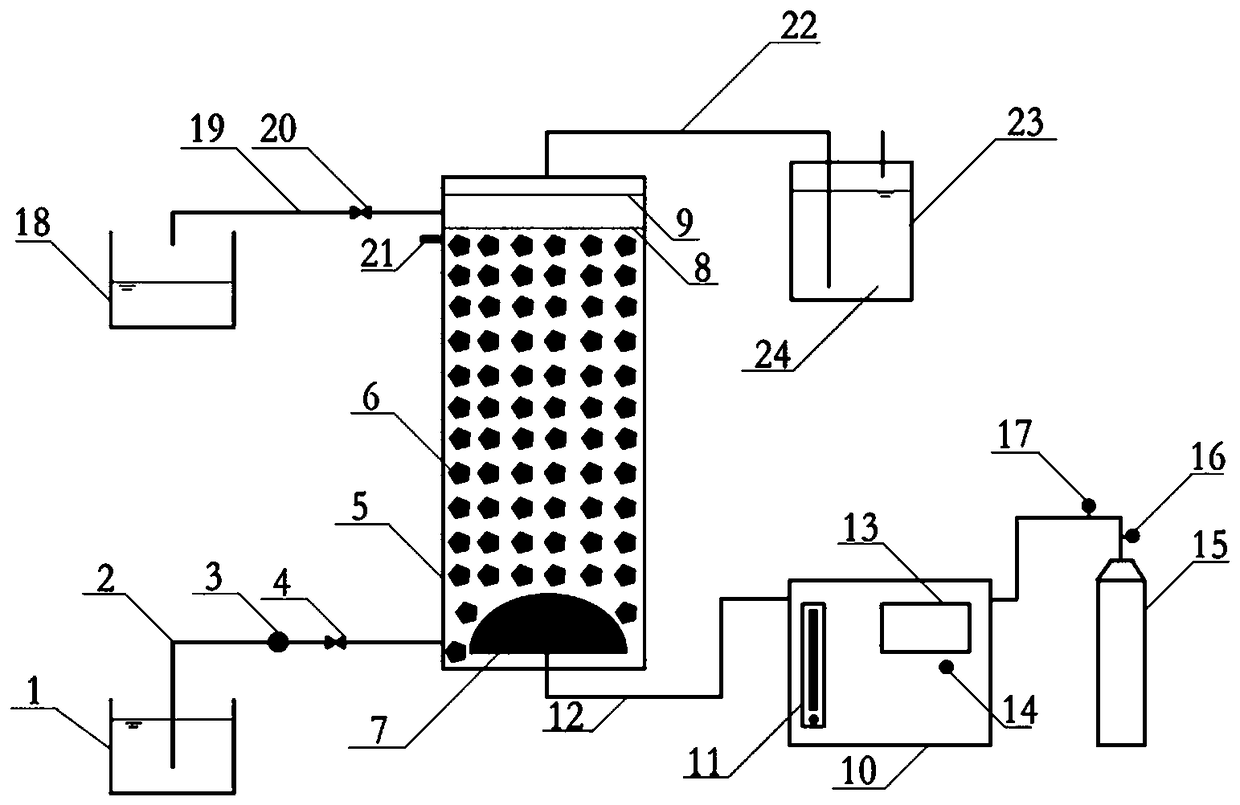

Device and method for deeply treating coal gasification wastewater

ActiveCN109231416AIncrease mass transfer rateEasy to handleWater contaminantsWater/sewage treatment by oxidationCoal gasification wastewaterOzone generator

The invention provides a device and a method for deeply treating coal gasification wastewater and belongs to the technical field of wastewater treatment. The device comprises a water storage tank, a deep treatment reactor, an ozone generator, a gas cleaning tank and a clean water tank; a micro-pore titanium aerator is arranged on the bottom of the deep treatment reactor; a compound catalyst is filled in the deep treatment reactor. According to the invention, the micro-pore titanium aerator and a novel self-prepared efficient catalyst are combined for treating biochemical effluent of coal gasification wastewater, so as to realize standardized discharge of coal gasification wastewater. The catalyst prepared according to the invention has an efficient catalytic performance and is easy for recycling; the treatment process of coal gasification wastewater is simple; the reaction energy consumption is less; the treating device occupies less area.

Owner:ZHENGZHOU UNIV

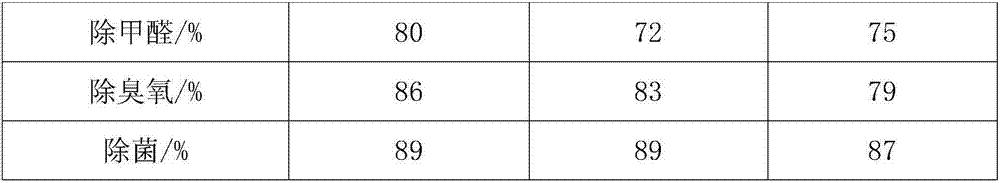

Mn-doped TiO2-loaded activated carbon fiber air purifier filtering net and preparation method thereof

InactiveCN107175077ADeveloped specific surface areaImprove your own performanceOther chemical processesDispersed particle separationEpoxyFiber

The invention provides a Mn-loaded TiO2-doped activated carbon fiber air purifier filtering net, which comprises the following materials in parts by weight: 8-10 parts of bentonite, 5-8 parts of Mn-doped TiO2, 20-22 parts of activated carbon powder, 0.5-1 parts of nano-silver, 15-20 parts of epoxy resin crosslinker, and 60-75 parts of activated carbon fiber. In the filtering net disclosed by the invention, Mn is doped into titanium oxide to improve photon utilization rate during reaction, Mn-doped TiO2 and other material are together loaded on activated carbon fiber, and the adsorptive action of the porous structure of the activated carbon fiber is utilized to enhance the air purification effect.

Owner:ANHUI SANPIN TECH SERVICE CO LTD

Manufacturing method of water-purifying porous ceramic

InactiveCN108424113AHigh porosityUniform pore size distribution and size controllableCeramic materials productionCeramicwareFiltrationKaolin clay

The invention provides a manufacturing method of water-purifying porous ceramic. The water-purifying porous ceramic comprises the following components in percentage by mass: 60 to 80 percent of diatomite, 0 to 5 percent of limestone, 0 to 13 percent of kaolin, 0 to 12 percent of Datong soil, 0 to 10 percent of quartz, 0 to 20 percent of aluminum oxide, 0 to 5 percent of lithium chinastone and 0 to10 percent of dolomite. The water-purifying porous ceramic adopts a dry ball-milling, balling, heating and firing process; the prepared water-purifying porous ceramic has high chemical stability, high porosity, high permeability, high strength, high rigidity, high heat stability, good self-cleaning state, small volume density, high reproducibility, long service life and high antibacterial property, is not liable to be degraded by bacteria and is suitable for water filtration.

Owner:FOSHAN RIRISHENG TECH CO LTD

Composite water purification material preparation method

InactiveCN108569731AEfficient removalEffective breedingTreatment involving filtrationWater/sewage treatment by substance additionMolecular sieveMaterials preparation

The invention provides a composite water purification material preparation method. The steps are as follows: (1) KDF, limonite, tourmaline and mesoporous composite molecular sieve are mixed accordingto a certain proportion, added with water and stirred for 20 to 30 minutes; (2) the mixed material is homogenized for 30 to 40 minutes, added with clay and uniformly stirred again; (3) the material obtained in step 2 is dewatered to be concentrated and produced into spherical raw material balls; (4) the spherical raw material balls are sintered under high temperature, and thereby the composite water purification material disclosed by the invention is prepared. The composite water purification material disclosed by the invention can effectively remove harmful elements and impurities in water, can release a variety of trace elements benefiting the human body, and can also effectively inhibit the breeding of bacteria.

Owner:FOSHAN RIRISHENG TECH CO LTD

Preparation method of biological water purifier

InactiveCN107487862ALow costReduce contentWater contaminantsMicroorganism based processesEutrophicationWater quality

The invention discloses a preparation method of a biological water purifier. The method comprises the steps of activation, loading, extraction of a flocculating active substance, preparation of nanometer iron oxide, and compounding. The biological water purifier can effectively remove ammonia nitrogen and nitrites from water, improve the water pollution, degrade organic macromolecules, reduce the eutrophication degree in water and decompose the organic macromolecules in water into carbohydrates, amino acids, vitamins and bioactive substances which can be absorbed by animals and plants, also can adsorb non-degradable substances, degrade heavy metal ions and inhibit the growth of algae, has a strong flocculation and precipitation effect on suspended solids in the water, and is safe and high-efficient biological water purifier.

Owner:兰溪市普润斯水产养殖技术有限公司

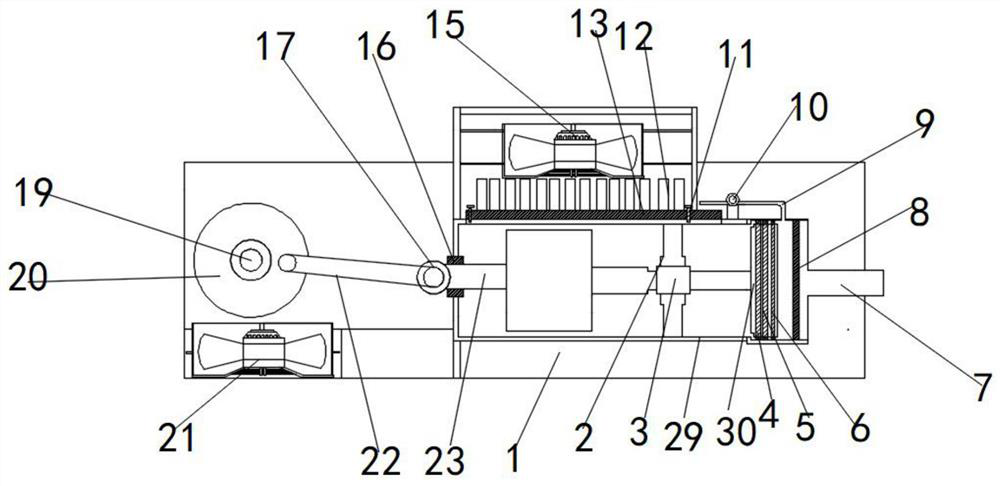

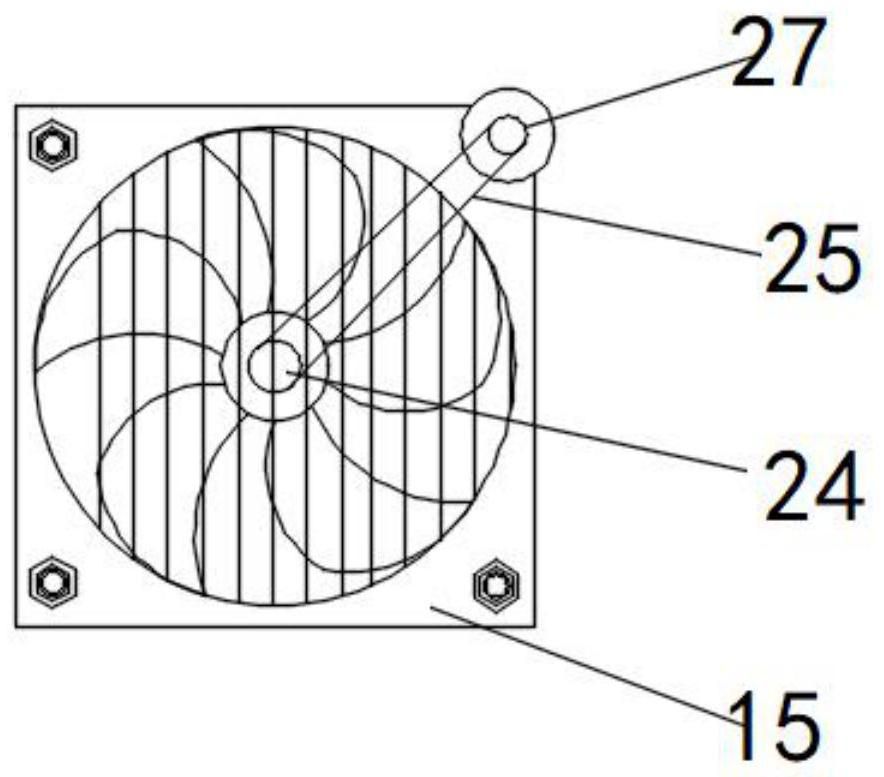

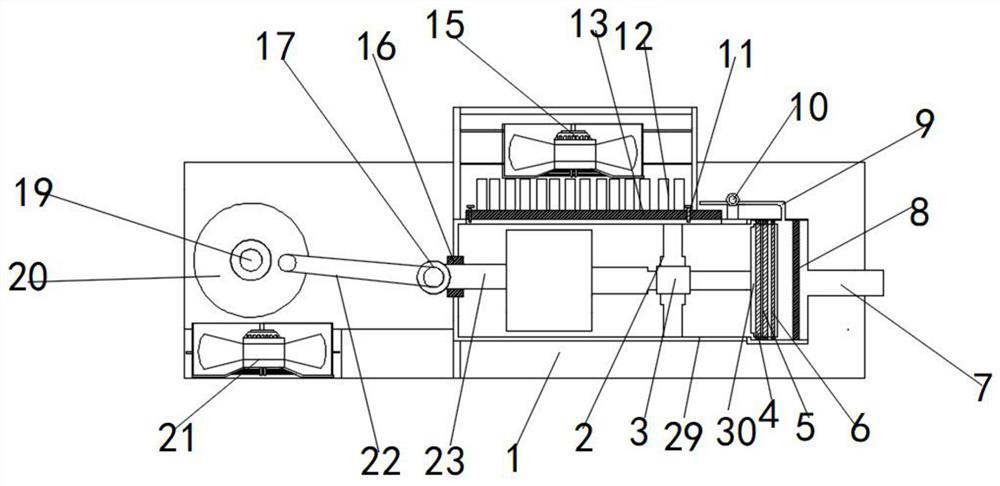

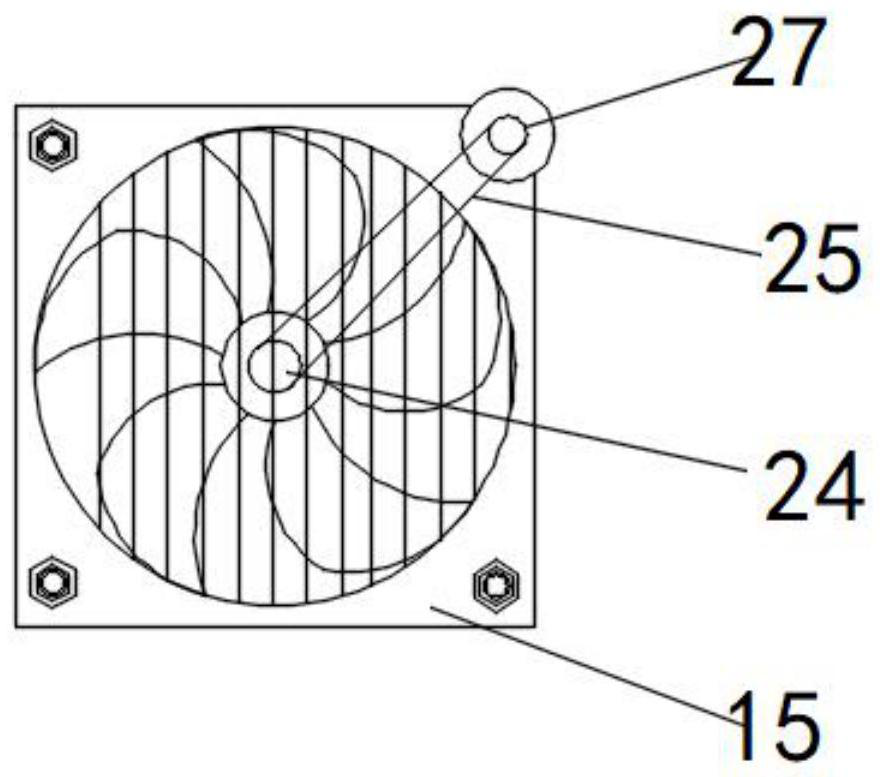

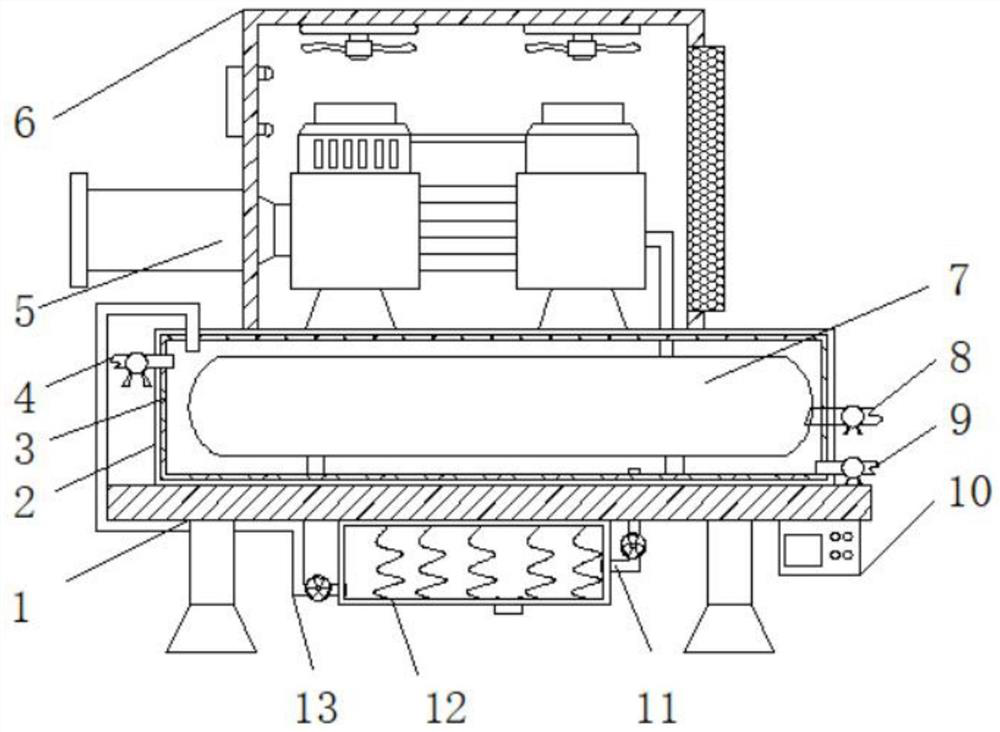

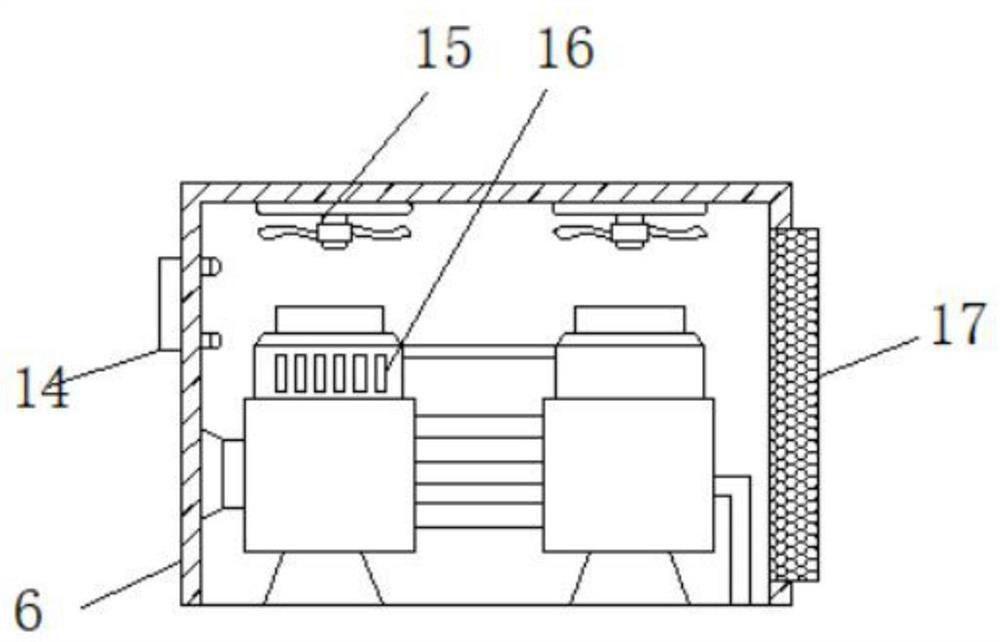

Air-cooled compressor for shale gas recovery

ActiveCN111677643AInefficient recyclingLow costPump testingPositive displacement pump componentsInlet valveElectric machinery

The invention discloses an air-cooled compressor for shale gas recovery. The air-cooled compressor comprises a compression device and an oil-gas separation device; the compression device comprises a shell; a compression mechanism is fixedly installed in the shell, and the compression mechanism comprises a compression rod, a sealing ring, a rotating shaft and a piston; the oil-gas separation devicecomprises a cylinder body; a piston cylinder is connected to the inner side wall of the cylinder body in a clearance mode; a crankshaft is mounted on the right side of the outer side wall of the piston rod and penetrates through the right side of the outer side wall of the cylinder body; a crankshaft connecting rod is mounted at the other end of the crankshaft; a second motor is mounted at the other end of the crankshaft connecting rod; an air inlet valve is mounted on the left side of the outer side wall of the cylinder body; and an air outlet pipe communicates with an air inlet valve. The air-cooled compressor for shale gas recovery can be used for carrying out simultaneous or continuous compression and separation, the recovery efficiency of shale gas can be greatly improved, the cost is reduced, and the air-cooled compressor is safe and reliable and can be operated for a long time.

Owner:德耐尔能源装备有限公司

Waterproof anti-aging polyethylene plastic

The invention discloses a waterproof anti-aging polyethylene plastic which is prepared from the following raw materials in parts by weight: 20-50 parts of polycarbonate, 15-35 parts of polyethylene terephthalate, 10-20 parts of polyethylene, 1-3 parts of n-butyl 4,4-bis-(tert-butyl-peroxy)valerate, 0.5-1 part of 4,4'-diamidodicyclohexyl methane, 1-2 parts of potassium dichromate, 2-6 parts of composite carbon, 0.5-1.5 parts of silane coupling agent, 10-18 parts of zinc borate, 2-8 parts of ground calcium carbonate, 1-5 parts of muscovite, 1-6 parts of calcium silicate hydrate, 1-5 parts of meerschaum, 1-4 parts of aluminum tripolyphosphate, 0.5-1.5 parts of molybdenum disulfide, 1-3 parts of trimethyl phosphate, 0.1-0.6 part of rare earth compound, 1-2 parts of ethylene glycol monobutyl ether, 1-2 parts of lubricant, 1-3 parts of antioxidant and 1-3 parts of light stabilizer.

Owner:ANHUI JINZHENG PLASTIC

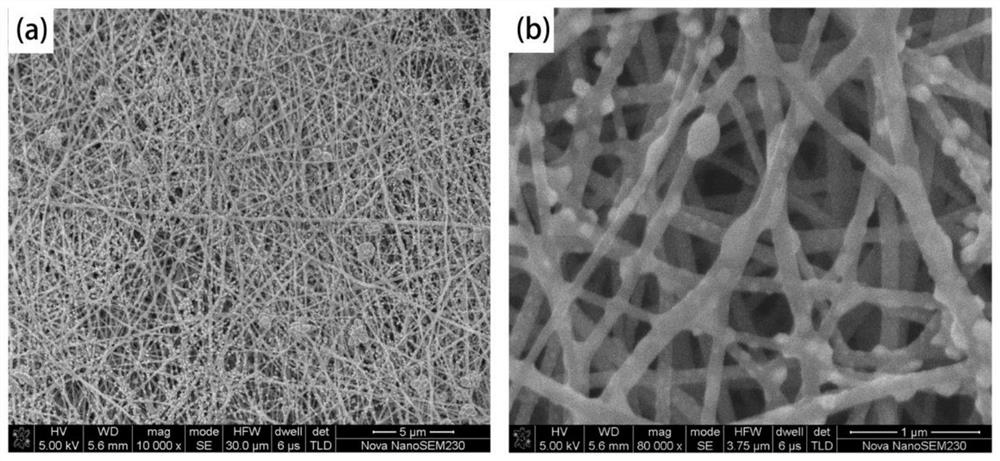

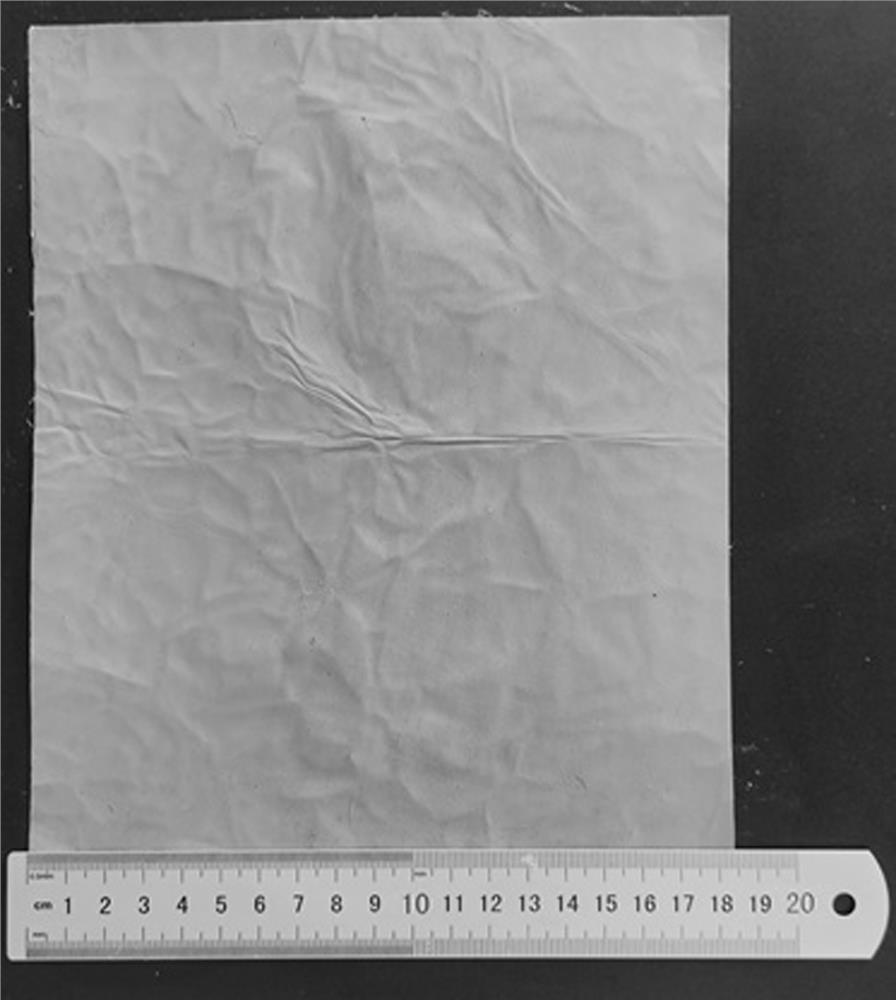

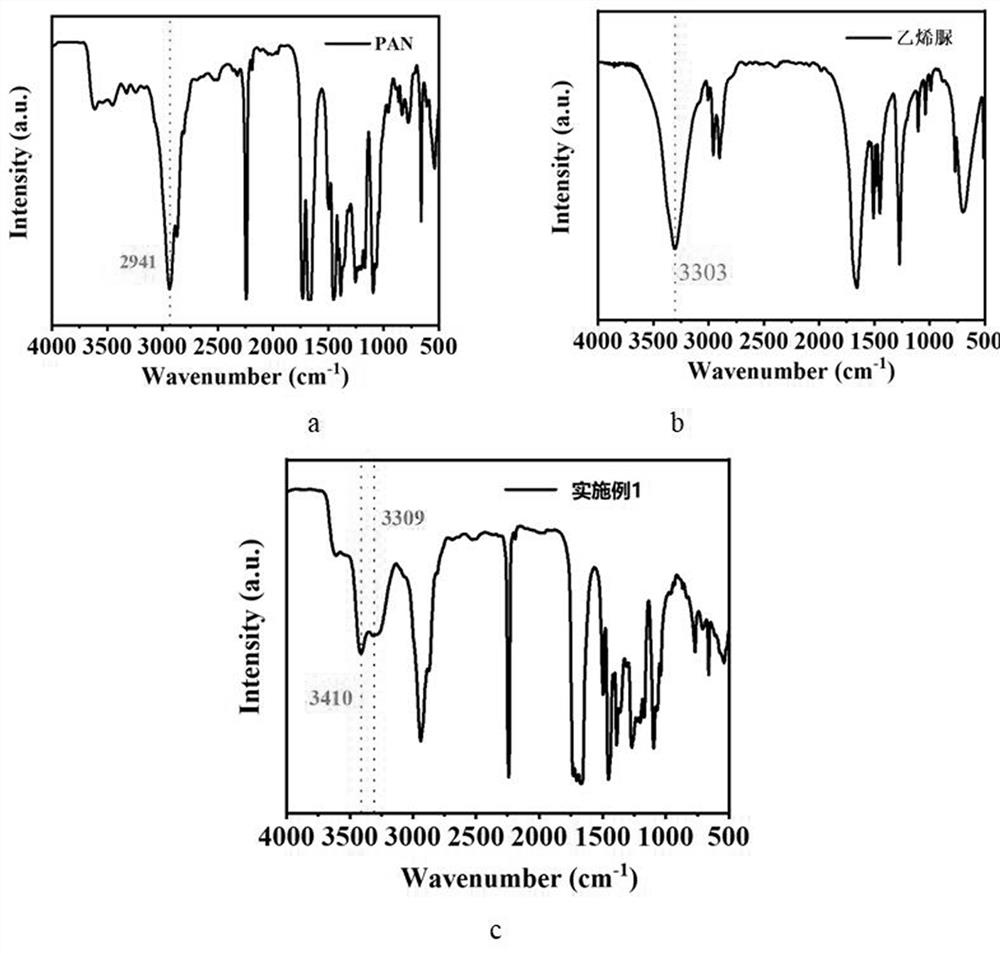

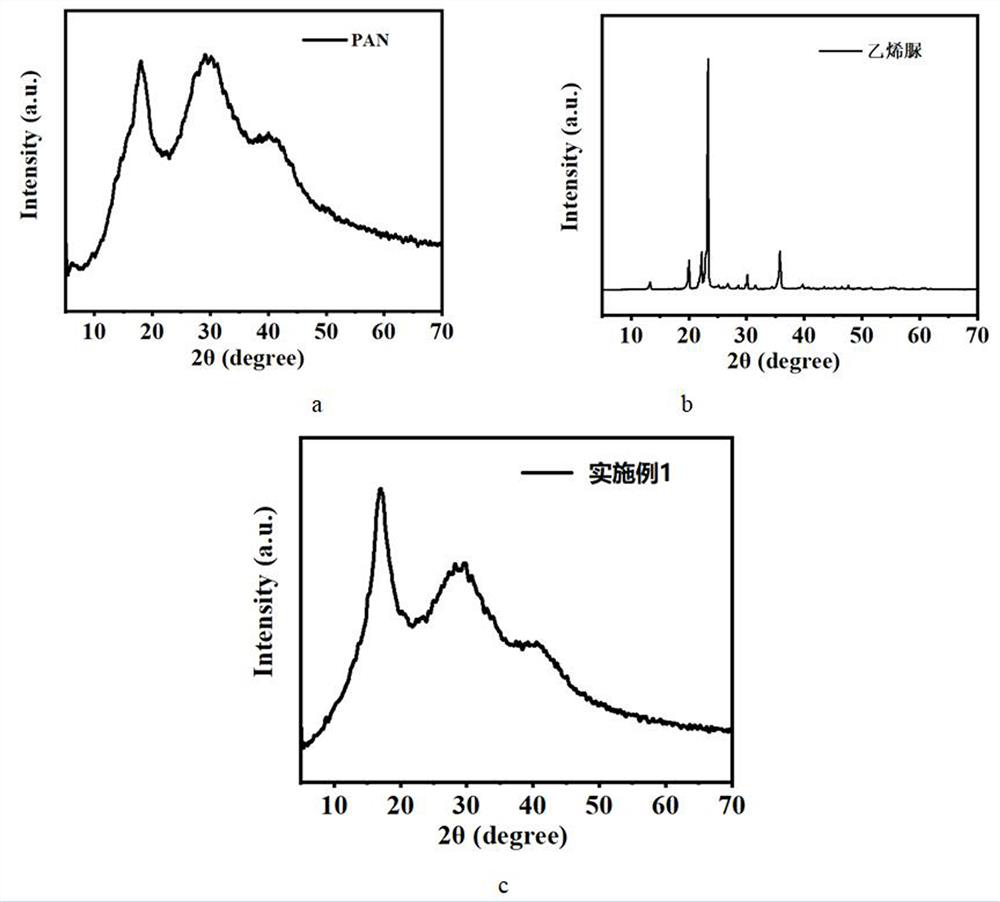

Ethylene urea/polyacrylonitrile formaldehyde-removing nanofiber membrane prepared by electrostatic spinning method as well as preparation method and application of ethylene urea/polyacrylonitrile formaldehyde-removing nanofiber membrane

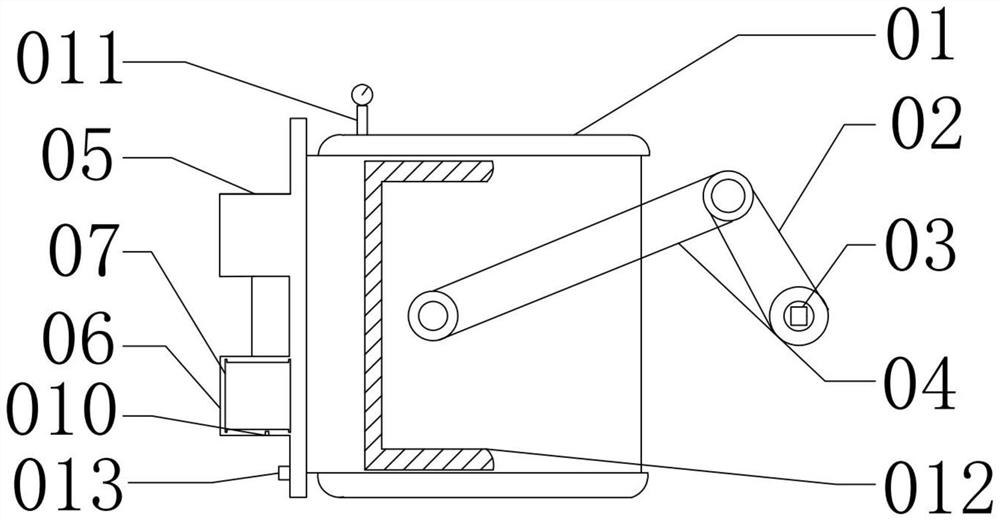

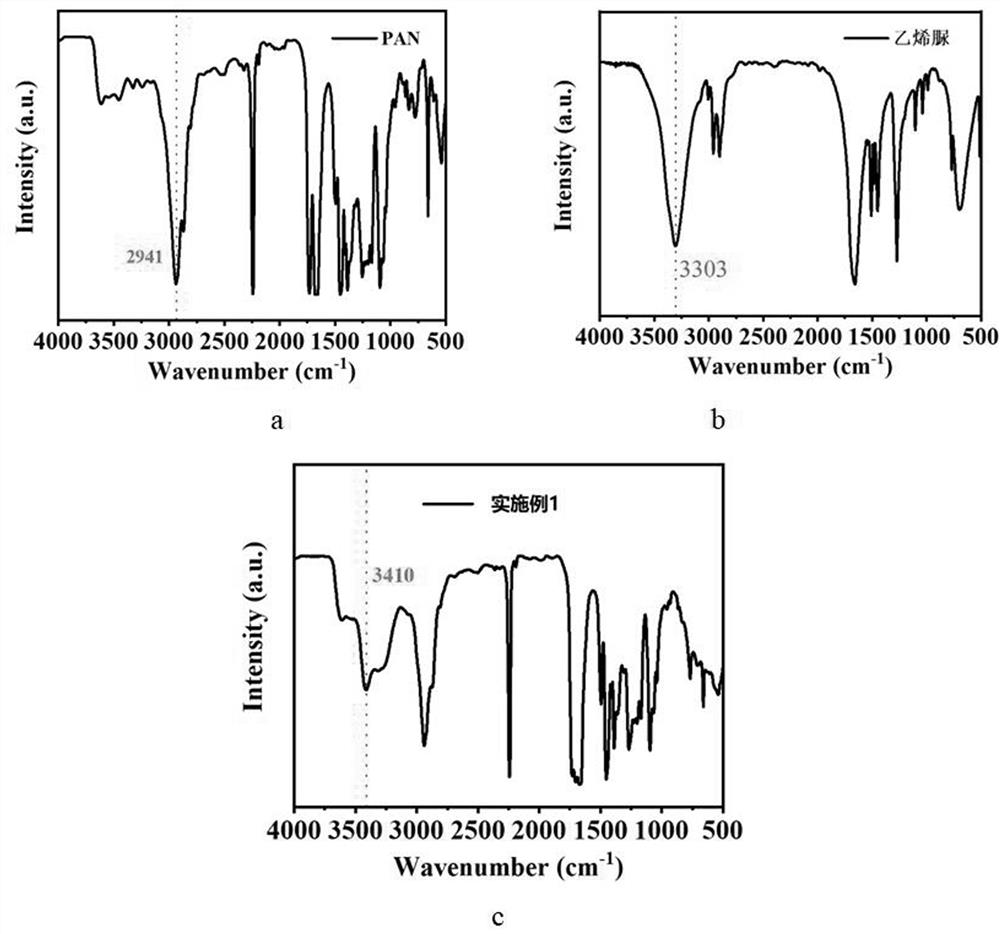

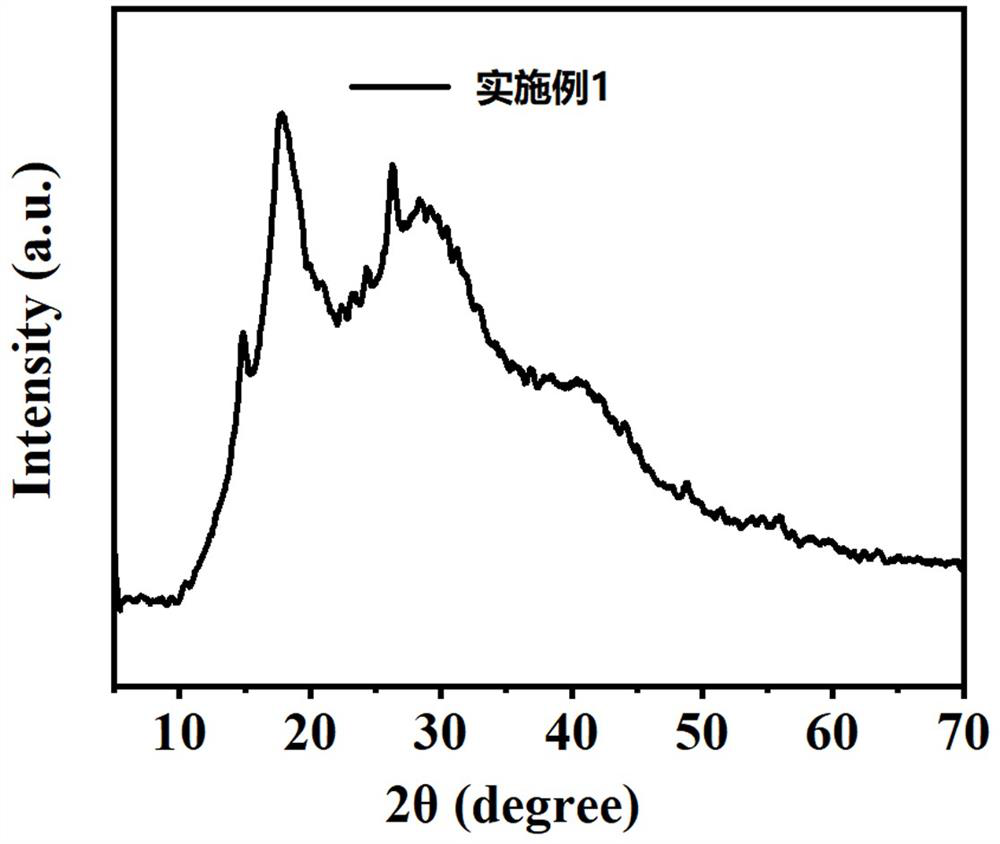

ActiveCN114657704AIncrease gas concentrationWell formedOther chemical processesDispersed particle separationSpinningAcrylonitrile

The invention belongs to the field of nanofiber membranes, and relates to an ethylene urea / polyacrylonitrile formaldehyde-removing nanofiber membrane prepared by an electrostatic spinning method as well as a preparation method and application of the ethylene urea / polyacrylonitrile formaldehyde-removing nanofiber membrane. The preparation method comprises the following steps: (1) adding dried polyacrylonitrile and ethylene urea into N-N dimethylformamide, and stirring to obtain an electrostatic spinning solution; and (2) performing electrostatic spinning on the electrostatic spinning solution in the step (1) to obtain a nanofiber membrane, and then drying the nanofiber membrane to remove the solvent to obtain the ethylene urea / polyacrylonitrile formaldehyde-removing nanofiber membrane. An electrostatic spinning method and a chemical formaldehyde purification method are combined, and the nanofiber with the efficient formaldehyde purification function is prepared by utilizing the advantages that polymer superfine fibers are convenient to form and can adsorb formaldehyde gas, increase the concentration of the formaldehyde gas around ethylene urea and improve the catalytic efficiency due to the relatively high specific surface area.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Water purifying device for shower device

InactiveCN108529702AQuick installationEasy to replaceWater/sewage treatment by substance additionWaste water treatment from bathing facilitiesForeign matterTrace element

The invention provides a water purifying device for a shower device. The water purifying device has the advantages that the water purifying device can be fast mounted on an existing shower device in aDIY manner without changing the other structures of the shower device, the water purifying material used by the water purifying device can effectively remove harmful elements and impurities in water,release various trace elements beneficial to human bodies and effectively inhibit bacterium breeding and is good in self-cleanliness state, nontoxic and odorless, free of foreign matter falling, freeof secondary pollution, small in volume density, large in specific surface area and unique in surface features.

Owner:FOSHAN RIRISHENG TECH CO LTD

Heat-insulation waterproof roll for roofs and preparation method thereof

InactiveCN113863581AGood heat insulationHigh porosityRoof covering using flexible materialsPolyureas/polyurethane adhesivesChemistryPhenols

The invention discloses a heat-insulation waterproof roll for roofs and a preparation method thereof. The heat-insulation waterproof roll is prepared by bonding the upper face and the lower face of a heat insulation layer to a waterproof layer through a binder, the heat insulation layer is high in porosity and small in volume density and has a developed specific surface area, and therefore the prepared waterproof roll has a good heat-insulation effect; aluminum hydroxide reacts with phosphoric acid to form a phosphate solution, the phosphate solution is blended with polyurethane to obtain a binder, the binder contains a large amount of phosphate, the phosphate has a certain binding effect, and meanwhile the surface of the heat insulation layer contains a large amount of nano titanium dioxide, one phenolic hydroxyl group on a catechol group in the binder is chelated through nitrogen atoms and peroxide atoms and active hydroxyl groups on the surface of titanium dioxide, the other hydroxyl group and adjacent catechol form hydrogen-bond interaction, and the binder and active hydroxyl groups on the surface of a glass fiber felt in the waterproof layer are chelated; and the heat insulation layer and the waterproof layer are tightly bonded.

Owner:丛杉杉

Optimizing thin electrode tubular sealed power lead-acid battery and its manufacturing method

ActiveCN104466190BHigh mechanical strengthImprove corrosion resistanceFinal product manufactureElectrode carriers/collectorsRare-earth elementEngineering

The invention belongs to the field of batteries, and particularly relates to an optimized thin-type and an electrode-tube-type seal power lead-acid storage battery. The optimized thin-type and the electrode-tube-type seal power lead-acid storage battery comprises a positive electrode plate and a negative electrode plate, wherein the positive electrode plate is made of a rare earth alloy, the negative electrode plate is prepared from the following raw materials: lead powder, barium sulfate, humic acid, complex tannin extract, carbon black, ion exchange water and vitriol. The invention also provides a preparation method of the optimized thin-type and an electrode-tube-type seal power lead-acid storage battery. The preparation method comprises the following steps: melting the rare earth element into the lead so as to prepare a positive plate grid, enabling a sheath and a dacron calandria to sleeve the grid, then filling the powder, smashing an upper back cover, soaking, solidifying and drying, so as to prepare the positive electrode plate; and after preparing the positive electrode plate and the negative electrode plate, assembling and forming the positive electrode plate and the negative electrode plate into a finished battery. The rare earth alloy is adopted by the positive electrode plate, so that the mechanical strength of the grid and the corrosion resistance of the grid are improved, the service life of the battery is prolonged, the complex formula of the negative electrode plate is used for improving the battery active substance use ratio and the battery capacity, and the low-temperature discharge performance of the battery is enhanced.

Owner:淄博明泰电器科技有限公司

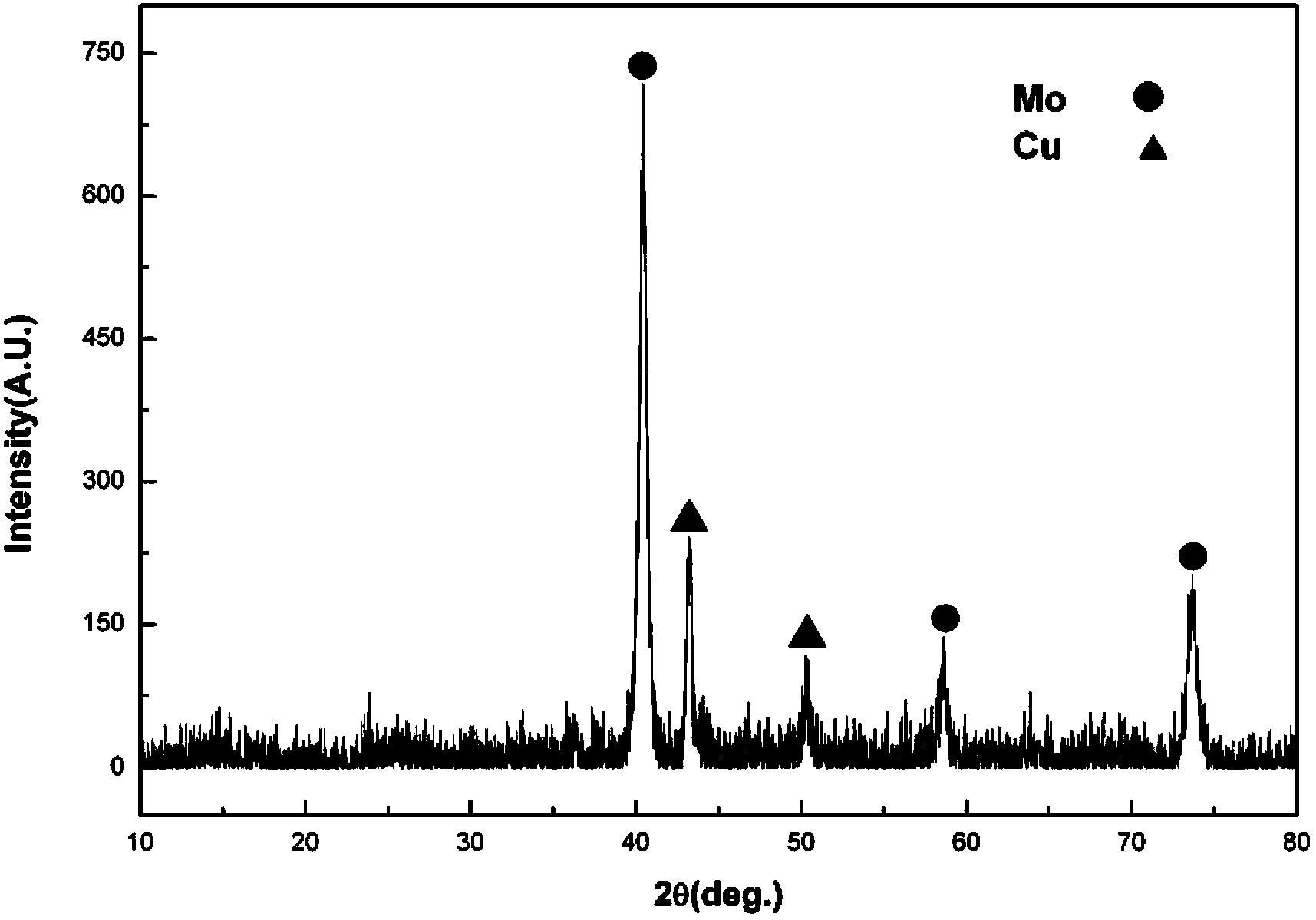

Method for reducing and preparing nano molybdenum-copper composite powder with low temperature

A method for reducing and preparing nano molybdenum-copper composite powder with low temperature comprises two steps: step 1, preparing molybdenum-copper oxide precursor, and step 2, preparing nano molybdenum-copper composite powder. In step 1, a water solution of molybdenum salt and an ammonia water solution of copper salt are mixed, the mixed solution is heated through micro-wave heating for fast concentration, and resolvents are removed to obtain molybdenum-copper oxide precursor powder; and in step 2, molybdenum-copper oxide precursor powder is heated to be 325 to 400 DEG C, calcined, taken out of a stove, cooled by air, and then heated to 525 to 625 DEG C for reducing after being placed in an H2 atmosphere, so as to obtain nano molybdenum-copper composite powder. The nano molybdenum-copper composite powder prepared according to the method has the advantages that the specific surface area is large; the crystal grains are fine and the purity is high. As molybdenum-copper oxide precursor powder is prepared by combining a simple and effective liquid phase chemical method with micro-wave heating, and nano molybdenum-copper composite powder is prepared through calcining and reducing, the method provided by the invention is simple and fast; the process is easy to control; the powder yield is large; the efficiency is high; the reducing temperature of powder is greatly reduced; and suitability for industrialized mass production is realized.

Owner:CENT SOUTH UNIV

An air-cooled compressor for shale gas recovery

ActiveCN111677643BInefficient recyclingLow costPump testingPositive displacement pump componentsElectric machineryEngineering

The invention discloses an air-cooled compressor for shale gas recovery, which includes a compression device and an oil-gas separation device; machine, the air-cooled compressor for shale gas recovery includes a compression rod, a sealing ring, a rotating shaft and a piston; A crankshaft is installed on the right side of the outer side wall of the cylinder body and the crankshaft runs through the right side of the outer side wall of the cylinder block. The other end of the crankshaft is equipped with a crankshaft connecting rod, and the other end of the crankshaft connecting rod is installed with a second motor. An air intake valve is installed on the left side of the outer wall; the air outlet pipe communicates with the air intake valve. The air-cooled shale gas recovery compressor of the present invention can perform compression and separation simultaneously or continuously, can greatly improve the low efficiency of shale gas recovery and utilization, reduce costs, is safe and reliable, and can run for a long time.

Owner:德耐尔能源装备有限公司

TiO2/ethylene urea/polyacrylonitrile formaldehyde-removing nanofiber membrane as well as preparation method and application thereof

ActiveCN114657703AFully spreadAvoid harmGas treatmentDispersed particle separationSpinningAcrylonitrile

The invention belongs to the field of nanofiber membrane preparation, and relates to a TiO2 / ethylene urea / polyacrylonitrile formaldehyde removal nanofiber membrane as well as a preparation method and application thereof. The preparation method comprises the following steps: drying a polyacrylonitrile raw material, adding the dried polyacrylonitrile raw material and ethylene urea into N-N dimethylformamide, stirring until complete dissolution, adding nano titanium dioxide, and carrying out ultrasonic dispersion to obtain a spinning solution; and performing electrostatic spinning on the spinning solution to obtain a nanofiber membrane, and drying to remove the solvent to obtain the TiO2 / ethylene urea / polyacrylonitrile formaldehyde-removing nanofiber membrane. According to the invention, photocatalytic formaldehyde-removing substance TiO2 nanoparticles, a formaldehyde chemical trapping agent and a polymer polyacrylonitrile are compounded, then an electrostatic spinning method is adopted to prepare the formaldehyde-removing functional superfine fiber, and the high specific surface area of the superfine fiber is utilized to adsorb free formaldehyde gas in the air; the concentration of the formaldehyde gas around the TiO2 nanoparticles and the formaldehyde chemical trapping agent is increased, the formaldehyde removal efficiency is improved, and the polymer fibers are good in flexibility and wider in application range.

Owner:ZHONGYUAN ENGINEERING COLLEGE

A kind of preparation method of ordered mesoporous carbon catalyst for preparing p-aminophenol

ActiveCN107570157BAbundant and cheap raw materialsOrdered mesoporous structureOrganic compound preparationMetal/metal-oxides/metal-hydroxide catalystsPtru catalystActive agent

The invention discloses a preparation method for a para-aminophenol ordered mesoporous carbon catalyst. The preparation method is characterized in that chitosan is taken as a raw material, and non-precious metal compounds are used as a doping source, meanwhile, a triblock copolymer surfactant is added, after performing self-produced high pressure treatment under a high temperature hydrothermal condition, filtering is performed so as to obtain a dark brown solid product, the solid product is dried, ground, and then put into a tubular calcinator, and high temperature carbonization under inert gas atmosphere protection is performed, so as to obtain a high-stable metal-doped carbon-based catalyst with different ordered mesoporous structures. The catalytic efficiency of the high-stable metal-doped carbon-based catalyst for para-nitrophenol hydrogenation catalysis generating para-aminophenol is investigated. The operation process has the main characteristics that the biomass resource chitosan is used as a raw material and is environmentally friendly, cheap and available; the surfactant is added, so that the formation of the ordered mesoporous structure is effectively controlled, the effective contact area between the reactant and the catalyst is increased, and the reaction conditions are mild; an active center and a carbon material are generated simultaneously, so that the structureis more stable, and the reaction process operationis simple.

Owner:QINGDAO UNIV OF SCI & TECH

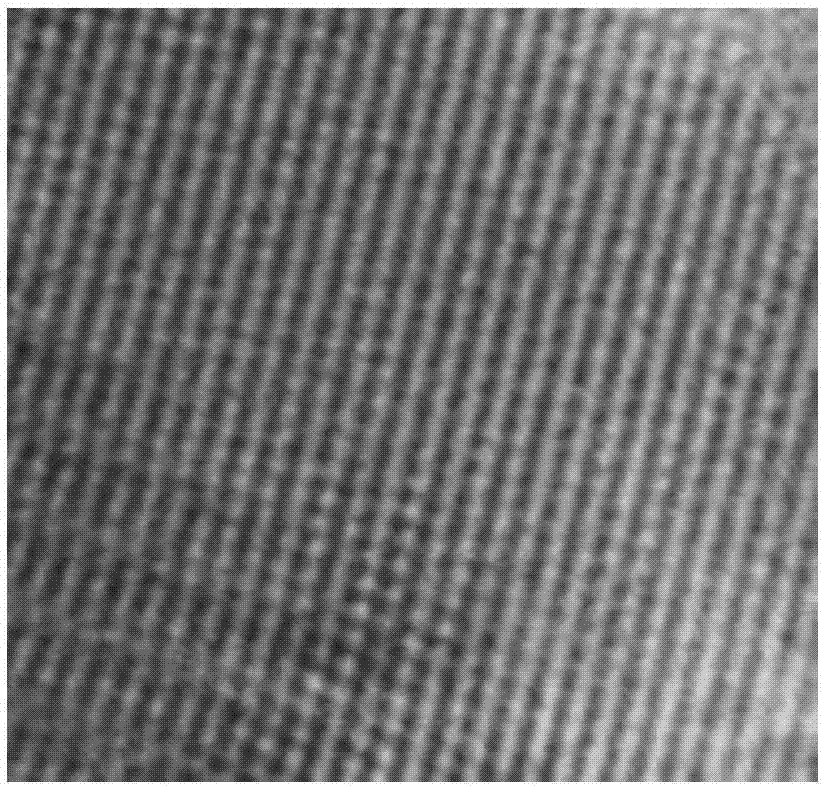

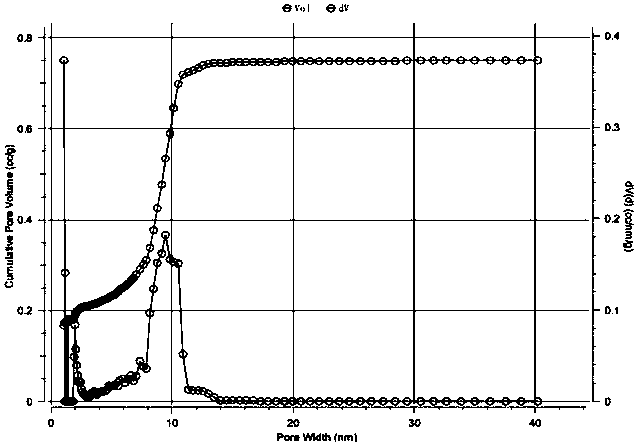

Mesoporous activated carbon material and preparation method and application thereof

ActiveCN111498844ADeveloped specific surface areaLarge specific surface areaCarbon compoundsActivated carbonHydrofluoric acid

The invention provides mesoporous activated carbon. The mesoporous activated carbon is obtained by activating an activated carbon raw material through a template method and an alkali activation method. An activated carbon material is prepared by using a combination of the template method and the chemical alkali activation method; a template agent is added in the process of preparing the activatedcarbon through chemical activation; a carbon source generates a large number of holes in alkali-activated pore-forming process, and an alkali activator can etch and remove the template agent in the high-temperature pore-forming process so as to allow a large number of nanometer pore diameters similar to the particle size of the template agent to be generated; and a part of mesopores become macropores due to the etching effect of alkali. According to the invention, the specific surface area of the activated carbon can be adjusted according to the proportion of the activator, an independent activating process is not needed, complex technological processes are reduced, the template does not need to be removed through hydrofluoric acid, environmental pollution is reduced, and production is facilitated. The mesoporous activated carbon provided by the invention has developed mesopores and larger specific surface area; preparation process is simplified; cost is reduced; environmental protection is realized; and the mesoporous activated carbon is more suitable for popularization and application in industrial large-scale production.

Owner:SHANDONG OBO NEW MATERIAL CO LTD

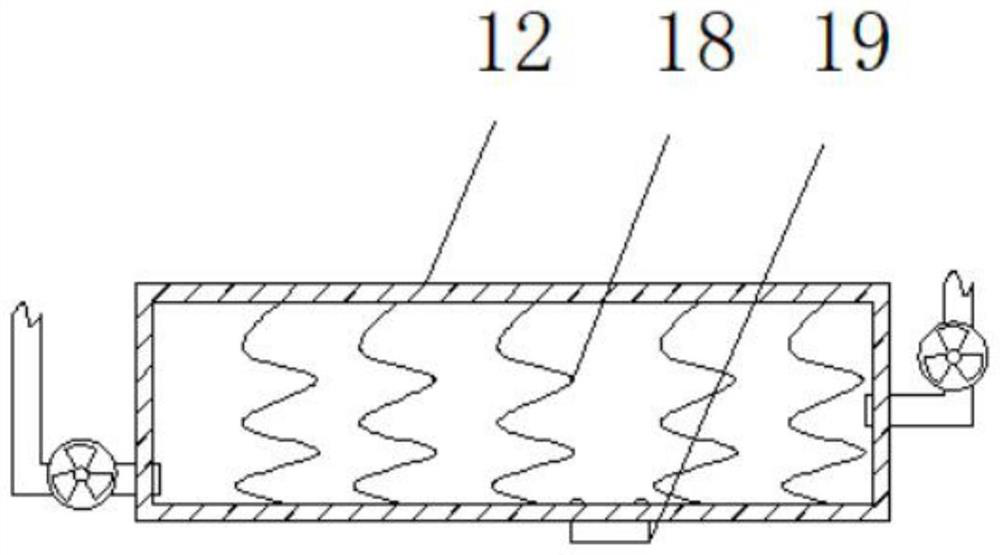

Water-cooling type compressor for shale gas recycling

InactiveCN111677645AReduce the temperatureReduce the risk of explosionPump testingPositive displacement pump componentsThermal insulationCompression device

The invention discloses a water-cooling type compressor for shale gas recycling. The water-cooling type compressor for shale gas recycling comprises a compression device and an oil-gas separation device. The compression device comprises a support base. A water cooling box is fixedly connected to the upper surface of the support base. The water cooling box is internally filled with thermal insulation cotton. A gas storage tank is mounted inside the water cooling box. A gas outlet pipe is connected to the right side wall of the gas storage tank in an inlaid manner. The oil-gas separation devicecomprises a cylinder body. A piston cylinder is in clearance connection to the inner side wall of the cylinder body. A crankshaft is mounted at the right side of the outer side wall of a piston rod and penetrates the right side of the outer side wall of the cylinder body. The other end of the crankshaft is provided with a crankshaft connecting rod. The other end of the crankshaft connecting rod isprovided with a second motor. A gas inlet valve is mounted at the left side of the outer side wall of the cylinder body. The gas outlet pipe communicates with the gas inlet valve. By means of the water-cooling type compressor for shale gas recycling, synchronous or continuous compression and separation can be achieved; the shale gas recycling efficiency can be greatly improved; the cost is lowered; safety and reliability are achieved; and the water-cooling type compressor can operate for a long time.

Owner:德耐尔能源装备有限公司

Carbon-based solid acid catalyst and preparation method thereof

InactiveCN102600893BHigh catalytic activityEasy to recycleOrganic-compounds/hydrides/coordination-complexes catalystsPorositySolid acid

The invention relates to preparation of a catalyst, in particular to a carbon-based solid acid catalyst and a preparation method thereof. The carbon-based solid acid catalyst has a pore size distribution of 3-50nm, a BET (Brunauer, Emmett and Teller) specific surface of 40-80m<2> / g and an acid value of 0.82-1.52mmol / g. The carbon-based solid acid catalyst is used for thermally decomposing granular carbon-based sulfonic acid under the temperature at 300 DEG C. The preparation method for preparing the carbon-based solid acid catalyst according to claim 1 is characterized by comprising the following steps of: preparing a modified coal precursor; preparing a compounding raw material; and carbonizing and sulfonating to obtain the solid acid catalyst. The carbon-based solid acid catalyst provided by the invention has the advantages that the preparation process is simple; the adopted raw materials are low in cost and easily obtained; based on a lyophobic amorphous carbon structure which is obtained by calcining an ultralow ash Taixi coal compound, a sulfo group is connected, and thus the carbon-based solid acid catalyst has porosity characteristic, developed mesopores, increased specific surface area and excellent heat stability; and the catalytic activity of the carbon-based solid acid catalyst is higher than that of the traditional acid catalyst, and the carbon-based solid acid catalyst is reusable and easy to be recovered.

Owner:NINGXIA UNIVERSITY

Ethylene urea/polyvinyl alcohol composite formaldehyde-removing fiber as well as preparation method and application thereof

PendingCN114606595AHarm reductionReduce pollutionMonocomponent synthetic polymer artificial filamentArtifical filament manufacturePolymer sciencePolyvinyl alcohol

The invention belongs to the field of preparation of composite fibers, and relates to an ethylene urea / polyvinyl alcohol composite formaldehyde-removing fiber as well as a preparation method and application thereof. Uniformly mixing polyvinyl alcohol, glycerol and ethylene urea, and standing to fully swell to obtain a spinning solution; and carrying out melt spinning on the spinning solution to obtain the ethylene urea / polyvinyl alcohol composite formaldehyde-removing fiber. According to the invention, polyvinyl alcohol is plasticized and modified by using a glycerol and ethylene urea composite plasticizer, and then the ethylene urea / polyvinyl alcohol composite formaldehyde-removing fiber is prepared by using a melt spinning process, so that some procedures in a solution spinning process, such as dissolution of a polymer, filtration of a spinning solution and recovery of a solvent, are omitted; meanwhile, no solvent participates in the spinning process, so that the harm to the environment is reduced. The method is simple in production process, small in environmental pollution and low in production cost.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Method for processing industrial wastewater by membrane separation/catalytic degradation composite process

ActiveCN102826694BShort processing cycleSimple processWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentChemical oxygen demandSeparation technology

The invention provides a method for processing industrial wastewater by a membrane separation / catalytic degradation composite process. The method comprises the following steps that 1, the industrial wastewater with the COD (chemical oxygen demand) greater than or equal to 10000mg / L is subjected to membrane separation treatment, and substances such as suspended matters, polymers and oil in sewage are removed; 2, filtrate after membrane separation is subjected to electric catalytic treatment, organic pollutants in water are degraded, and in addition, harmlessness or mineralization is realized for metal ions in the water; 3, the filtrate is further subjected to photoelectrocatalysis treatment, and pollutants in the water are degraded until the COD of the treated water is smaller than or equal to 90mg / L. The method has the advantages that the process is simple, the operation is safe, the control is easy, the membrane separation technology and the catalytic degradation technology are combined, the problems of time consumption, energy consumption and low efficiency of the simple membrane separation treatment method are solved, meanwhile, the difficult problem that useful matters in the sewage cannot be easily recovered and reutilized by the catalytic degradation treatment method is solved, and in addition, the obvious decontamination and purification efficiency is realized.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com