Ethylene urea/polyacrylonitrile formaldehyde-removing nanofiber membrane prepared by electrostatic spinning method as well as preparation method and application of ethylene urea/polyacrylonitrile formaldehyde-removing nanofiber membrane

A nanofiber membrane, electrospinning technology, applied in electrospinning, separation methods, fiber processing and other directions, can solve the problems of secondary pollution of indoor air, furniture surface marks, furniture surface damage, etc., to effectively capture, The effect of increasing compatibility and improving catalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

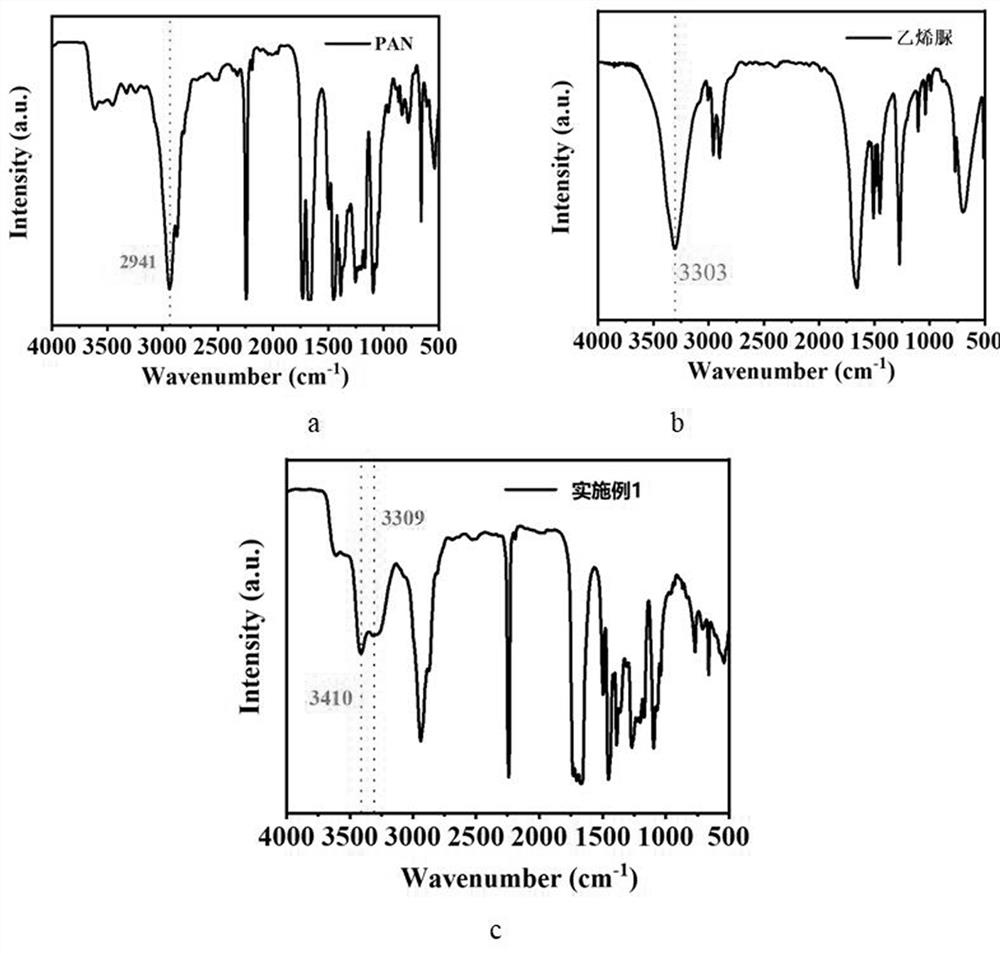

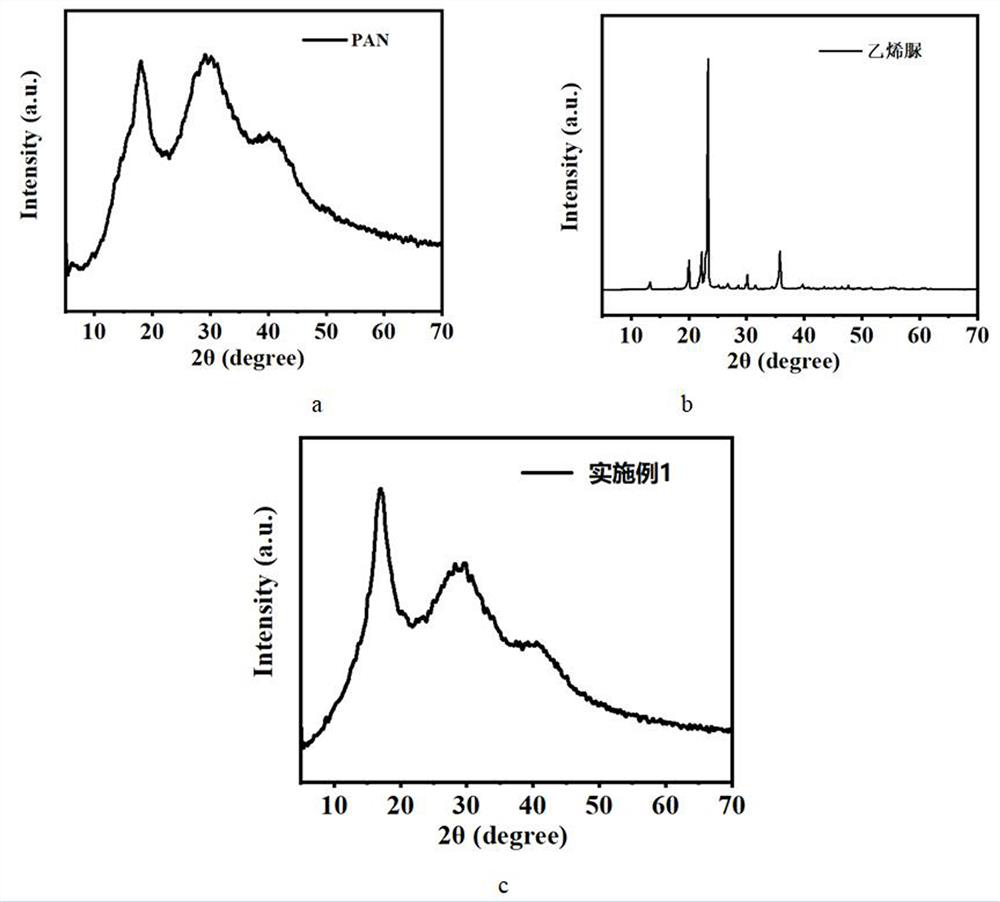

Embodiment 1

[0023] A method for preparing an ethylene urea / polyacrylonitrile formaldehyde-removing nanofiber membrane by an electrospinning method of the present embodiment includes the following steps:

[0024] The polyacrylonitrile raw material was put into an oven, dried at 50°C for 8 hours, 16 grams of dried polyacrylonitrile and 4 grams of ethylene urea were added to 80 grams of N-N dimethylformamide solution, and the solution was heated at 60 ℃. Stir at ℃ for 10 h to obtain an electrospinning solution;

[0025] The obtained electrospinning solution was transferred to a syringe for electrospinning to obtain a nanofiber membrane; then the obtained nanofiber membrane was transferred to a blast thermostat, and dried at 60° C. for 6 hours to remove the solvent. The electrospinning conditions were as follows: the electrospinning positive voltage was 20kV, the flow rate was 0.08ml / h, the electrospinning receiving distance was 10cm, the indoor ambient humidity was 25%, and aluminum foil was...

Embodiment 2

[0030] A method for preparing an ethylene urea / polyacrylonitrile formaldehyde-removing nanofiber membrane by an electrospinning method of the present embodiment includes the following steps:

[0031] Put the polyacrylonitrile raw material in an oven, dry it at 70°C for 6 hours, take 14 grams of dried polyacrylonitrile and 8 grams of ethylene urea and add it to 80 grams of N-N dimethylformamide solution, and at 50 Stir at ℃ for 6 h to obtain an electrospinning solution;

[0032] The obtained electrospinning solution was transferred to a syringe for electrospinning to obtain a nanofiber membrane; then the obtained nanofiber membrane was transferred to a blast thermostat, and dried at 40° C. for 12 hours to remove the solvent. The electrospinning conditions were as follows: the electrospinning positive voltage was 12kV, the flow rate was 0.1ml / h, the electrospinning receiving distance was 20cm, the indoor ambient humidity was 40%, and aluminum foil was used as the receiving subst...

Embodiment 3

[0034] A method for preparing an ethylene urea / polyacrylonitrile formaldehyde-removing nanofiber membrane by an electrospinning method of the present embodiment includes the following steps:

[0035] Put the polyacrylonitrile raw material into an oven, dry it at 60 °C for 7 hours, take 10 grams of dried polyacrylonitrile and 10 grams of ethylene urea and add it into 80 grams of N-N dimethylformamide solution, at 55 °C Stir for 8h under the condition to obtain the electrospinning solution;

[0036] The obtained electrospinning solution was transferred to a syringe for electrospinning to obtain a nanofiber membrane; then the obtained nanofiber membrane was transferred to a blast thermostat, and dried at 50° C. for 8 hours to remove the solvent. The electrospinning conditions were as follows: the electrospinning positive voltage was 16kV, the flow rate was 0.09ml / h, the electrospinning receiving distance was 16cm, the indoor ambient humidity was 30%, and aluminum foil was used as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com