Separator for fuel cell, and fuel cell comprising same

A fuel cell and separator technology, which is applied to fuel cell components, fuel cells, fuel cell grouping, etc., can solve the problems of battery performance degradation, electrodes cannot provide reaction gas, and battery performance degradation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0100] [Structure of fuel cell stack]

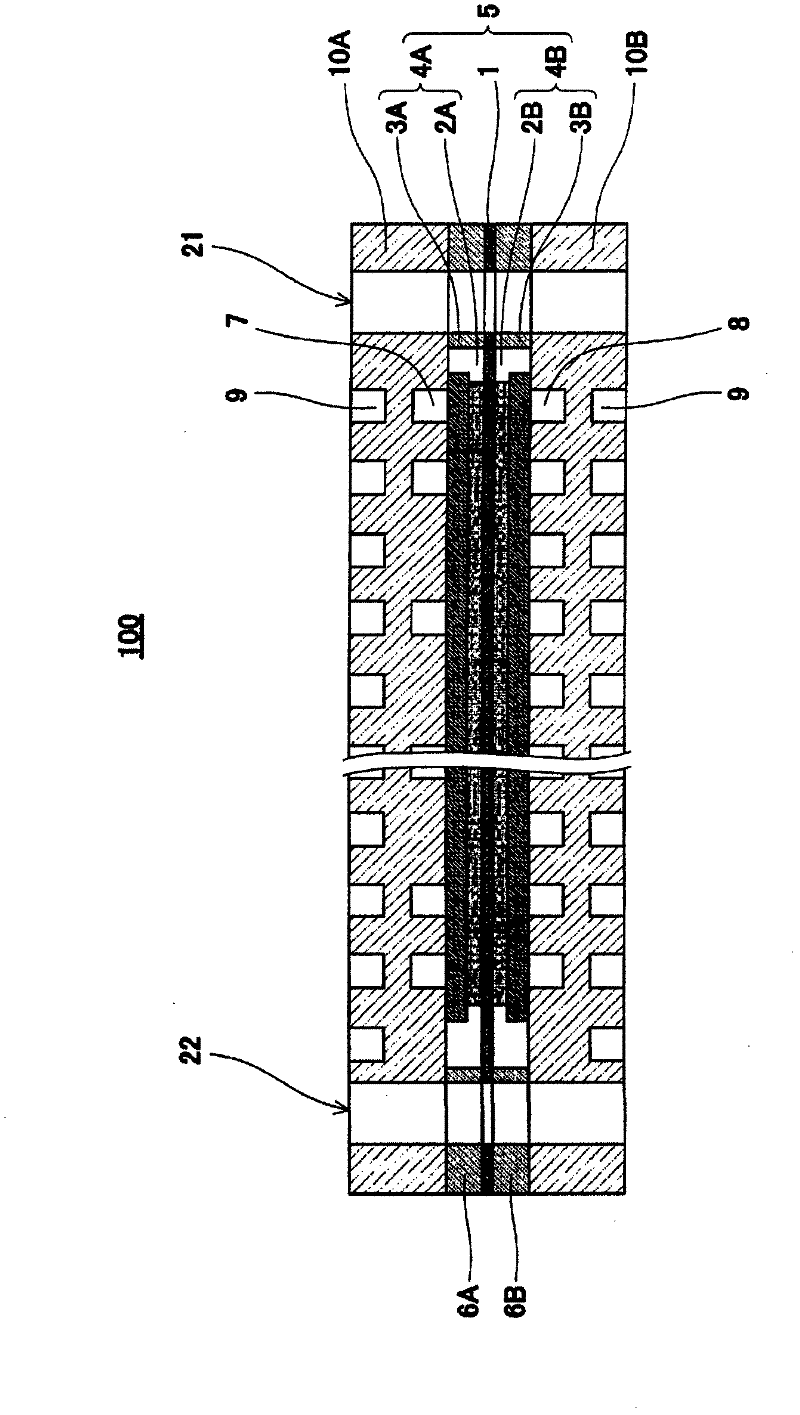

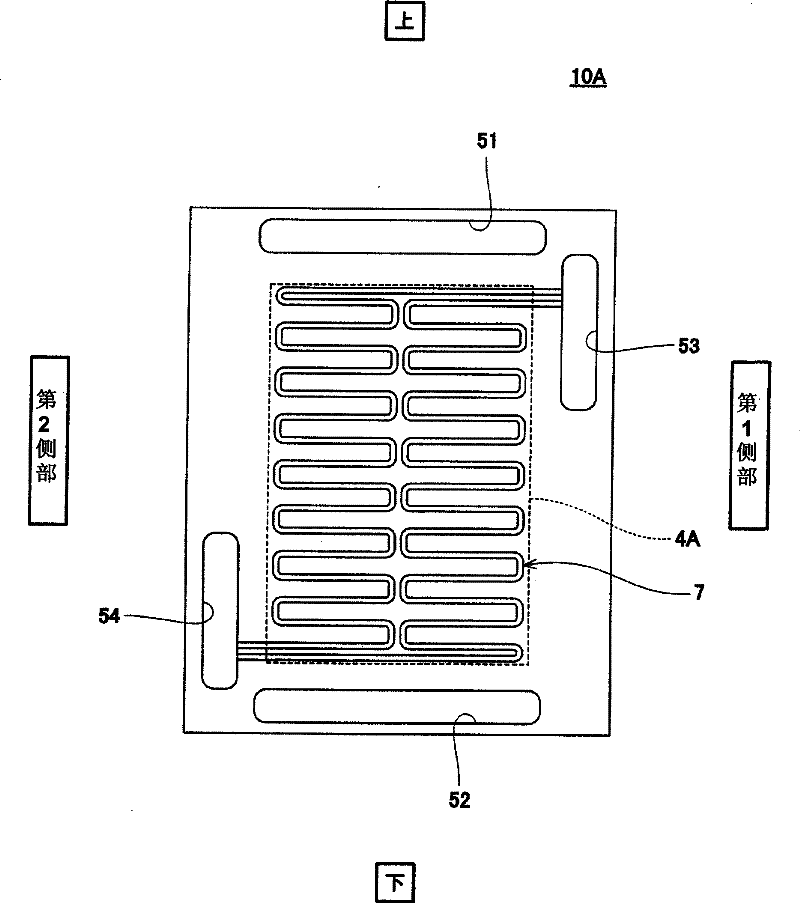

[0101] figure 1 is a cross-sectional view schematically showing the schematic structure of the fuel cell according to Embodiment 1 of the present invention. Also, in figure 1 In , a part of the fuel cell is omitted.

[0102] Such as figure 1 As shown, the fuel cell 100 according to Embodiment 1 is a single cell (cell), and includes an MEA (Membrane-Electrode-Assembly: electrolyte layer-electrode assembly) 5, gaskets 6A, 6B, an anode separator 10A, and a cathode Partition 10B.

[0103] The MEA 5 has a polymer electrolyte membrane (electrolyte layer; for example, Nafion (trade name) manufactured by DuPont, USA) 1 that selectively transports hydrogen ions, an anode 4A, and a cathode 4B.

[0104] The polymer electrolyte membrane 1 has a substantially quadrangular (here, rectangular) shape. An anode 4A and a cathode 4B (these are referred to as gas diffusion electrodes) are respectively arranged on both surfaces of the polymer electroly...

Embodiment approach 2

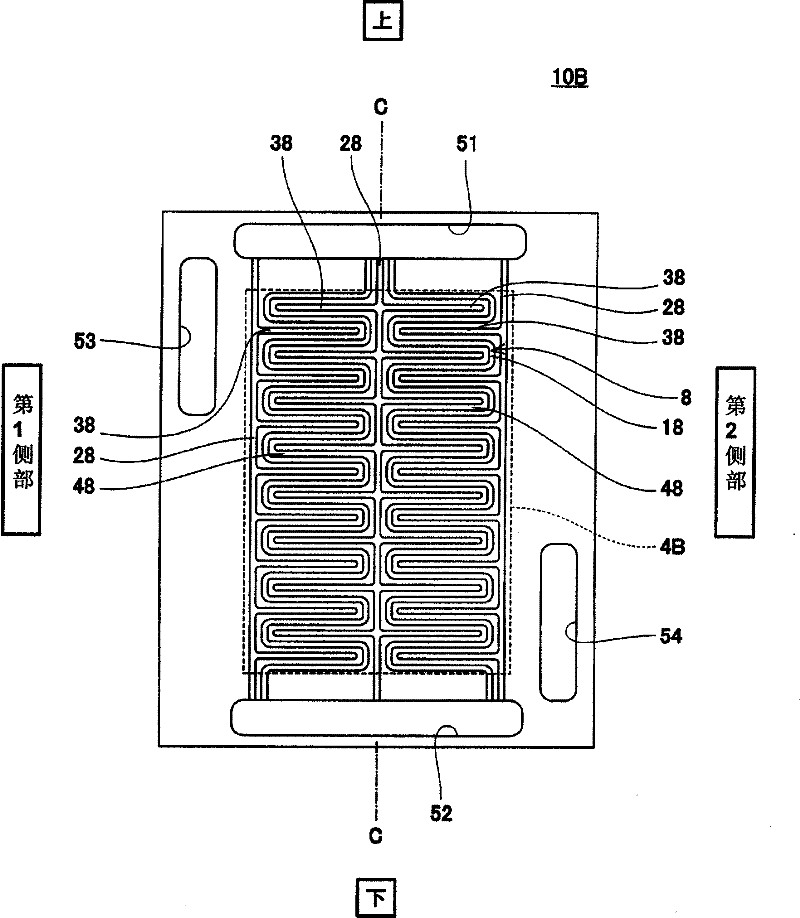

[0134] Figure 4 It is a schematic diagram showing a schematic structure of a fuel cell separator according to Embodiment 2 of the present invention.

[0135] Such as Figure 4 As shown, the fuel cell separator (cathode separator) 10B according to the second embodiment has the same basic structure as the fuel cell separator (cathode separator) 10B according to the first embodiment. In the second embodiment, the oxidizing gas flow path 8 is not provided in line symmetry with respect to the central axis C, and the shape of the first main gas flow path 18 is different from that of the first embodiment. Specifically, among the two first main gas flow paths 18, 18, the first main gas flow path 18 formed on the first side with respect to the central axis C is the same as that of the fuel cell 100 according to Embodiment 1. The cathode separator 10B is formed in the same manner. On the other hand, the first main gas passage 18 formed on the second side with respect to the central ...

Embodiment approach 3

[0138] Figure 5 It is a schematic diagram showing a schematic structure of a fuel cell separator according to Embodiment 3 of the present invention.

[0139] Such as Figure 5 As shown, the fuel cell separator (cathode separator) 10B according to the third embodiment of the present invention has the same basic structure as the fuel cell separator (cathode separator) 10B according to the first embodiment. In Embodiment 3, the cross-sectional area (hereinafter simply referred to as the cross-sectional area of the flow path) perpendicular to the flow of the oxidizing gas in the grooves constituting the flow path of the first assist gas flow path 28 is smaller than that of the first assist gas flow path 28 . The main gas flow path 18 and the second assist gas flow path 38 are different from the first embodiment in that the cross-sectional areas of the flow paths are formed to be small. Specifically, in Embodiment 3, the flow width of the first assist gas flow path 28 is forme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Proton conductivity | aaaaa | aaaaa |

| Proton conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com