Mesoporous activated carbon material and preparation method and application thereof

A technology for activated carbon and raw materials, applied in the field of mesoporous activated carbon materials and their preparation, can solve the problems of cumbersome process, limited popularization and application, high activation yield, and achieve the effect of simplifying the preparation process, good application prospect and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0073] The present invention also provides a kind of preparation method of mesoporous activated carbon, comprises the following steps:

[0074] A) After mixing the activated carbon raw material, the alkali-soluble nanoparticle template and the alkali activator, a mixed powder is obtained;

[0075] B) Under protective gas conditions, the mixed powder obtained in the above steps is activated to obtain a powder.

[0076] In the present invention, the selection, composition and structure of the raw materials in the above-mentioned preparation method, and the corresponding optimization principles, can preferably correspond to the selection, composition and structure of the aforementioned mesoporous activated carbon raw materials, and the corresponding optimization principles, and will not be repeated here. Let me repeat them one by one.

[0077] In the invention, firstly, the active carbon raw material, the alkali-soluble nano particle template agent and the alkali activator are m...

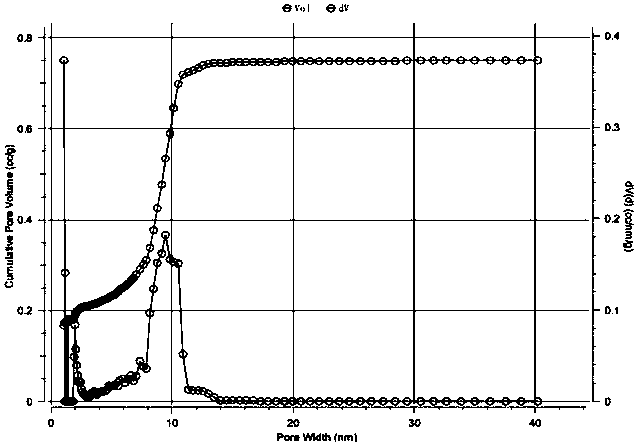

Embodiment 1

[0122] Weigh 100g of petroleum coke and pulverize it until the particle size D50 is 10 μm with a jet mill, and pre-disperse the pulverized material and 200 g of nano-silica with a particle size of about 5 nm by ball milling, and mix the pre-dispersion mixture and the activator potassium hydroxide according to 1 : 2 mass ratio for mixing, after mixing evenly, heat up to 600°C in an activation furnace with nitrogen protection for 3 hours of activation treatment, cool to room temperature after the reaction, and use dilute hydrochloric acid to remove the activator and impurities in the obtained carbon material, to remove Washing with ionic water to neutrality, drying after washing to obtain petroleum coke-based mesoporous activated carbon.

[0123] The petroleum coke-based mesoporous activated carbon prepared in Example 1 of the present invention was characterized.

[0124] see figure 1 , figure 1 SEM scanning electron micrograph of the mesoporous activated carbon prepared for E...

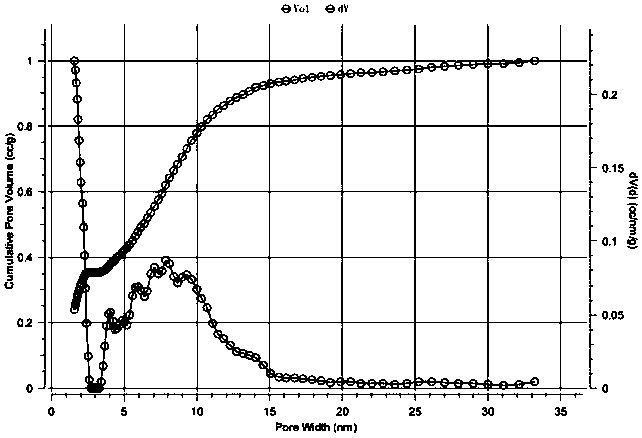

Embodiment 2

[0129] Weigh 100g of coal tar pitch with a particle size D50 of 30μm, pre-disperse the pulverized material and 500g of nano-silica with a particle size of about 20nm by ball milling, then heat to 130°C until the mixture becomes a slurry material, and stir for 3 hours until mixed Uniformly, carbonize the material at 500°C for 1 h under a nitrogen atmosphere, use a jet mill to crush the carbide to a particle size D50 of 30 μm, mix the pulverized material and the activator sodium hydroxide according to a mass ratio of 1:3, and mix After uniformity, heat up to 700°C in an activation furnace protected by nitrogen for 2 hours of activation treatment. After the reaction, cool to room temperature, use dilute hydrochloric acid to remove the activator and impurities in the obtained carbon material, wash with deionized water until neutral, and after washing Dry to obtain petroleum coke-based mesoporous activated carbon.

[0130] The petroleum coke-based mesoporous activated carbon prepar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com