Method for reducing and preparing nano molybdenum-copper composite powder with low temperature

A composite powder, molybdenum copper technology, applied in the field of powder metallurgy preparation, can solve the problems of high equipment requirements, complex process, simple process, etc., and achieve the effect of short nucleation time, high purity and uniform nucleation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Weigh 12.36g of ammonium paramolybdate and 10.95g of copper nitrate, measure 150ml of concentrated ammonia water (25~28%), configure the aqueous solution of ammonium paramolybdate, the ammonia solution of copper nitrate, mix and add H 2 O is configured as 1L mixed solution.

[0024] (2) Divide the solution prepared in (1) into four equal parts, place them in a microwave oven (700W) for rapid concentration, and obtain molybdenum copper oxide precursor powder.

[0025] (3) Calcining the precursor powder prepared in (2) in air at a calcination temperature of 350° C. and a calcination time of 0.75 h to obtain a molybdenum-copper oxide composite powder.

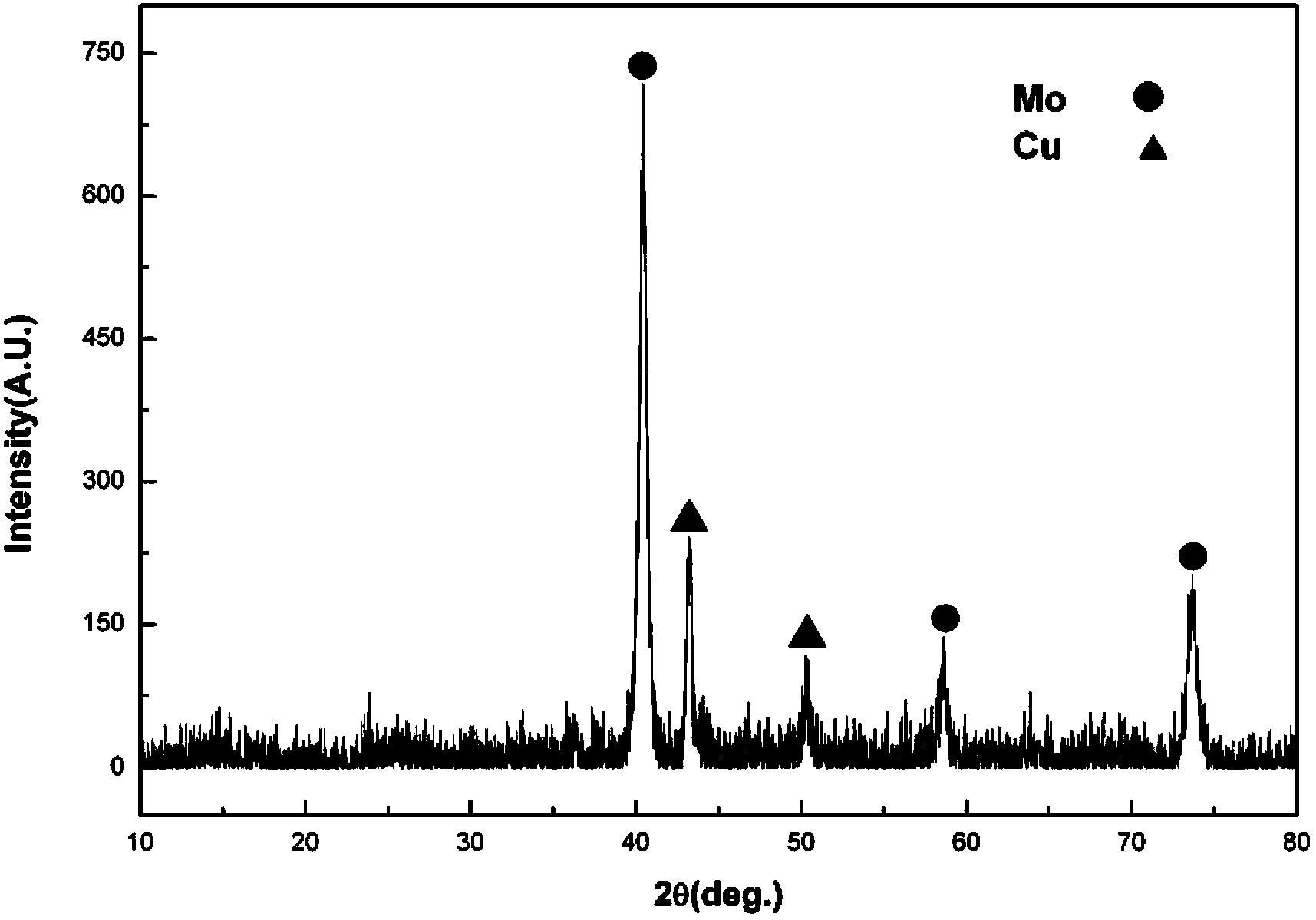

[0026] (4) The composite powder prepared in (3) was heated in H 2 Insulated at 575°C for 2h to obtain 70Mo-30Cu nano-molybdenum-copper composite powder. See attached figure 1 ,Depend on figure 1 The obtained data was analyzed by Jade to obtain the half peak width, and the average crystal grain size was calculated as...

Embodiment 2

[0028] (1) Weigh 12.36g of ammonium paramolybdate and 6.39g of copper nitrate, measure 100ml of concentrated ammonia water (25~28%), configure the aqueous solution of ammonium paramolybdate, the ammonia solution of copper nitrate, mix and add H 2 O is configured as 1L mixed solution.

[0029] (2) Divide the solution obtained in (1) into five equal parts, place it in a microwave oven (700W) for rapid concentration, and obtain a molybdenum-copper oxide precursor powder.

[0030] (3) Calcining the precursor powder prepared in (2) in air at a calcination temperature of 350° C. and a calcination time of 0.75 h to obtain a molybdenum-copper oxide composite powder.

[0031] (4) The composite powder prepared in (3) was heated in H 2 Insulated at 575°C for 2h to obtain 80Mo-20Cu nano-molybdenum-copper composite powder.

Embodiment 3

[0033] (1) Weigh 17.96g of ammonium paramolybdate and 20g of copper nitrate, measure 500ml of concentrated ammonia water (25~28%), configure the aqueous solution of ammonium paramolybdate, the ammonia solution of copper nitrate, mix and add H 2 O is configured as 1L mixed solution.

[0034] (2) Divide the solution prepared in (1) into four equal parts, place them in a microwave oven (700W) for rapid concentration, and obtain molybdenum copper oxide precursor powder.

[0035] (3) The precursor powder prepared in (2) was calcined in air at a calcination temperature of 400° C. and a calcination time of 0.5 h to obtain a molybdenum-copper oxide composite powder.

[0036] (4) The composite powder prepared in (3) was heated in H 2 Insulated at 600°C for 2h to obtain 65Mo-35Cu nano-molybdenum-copper composite powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com