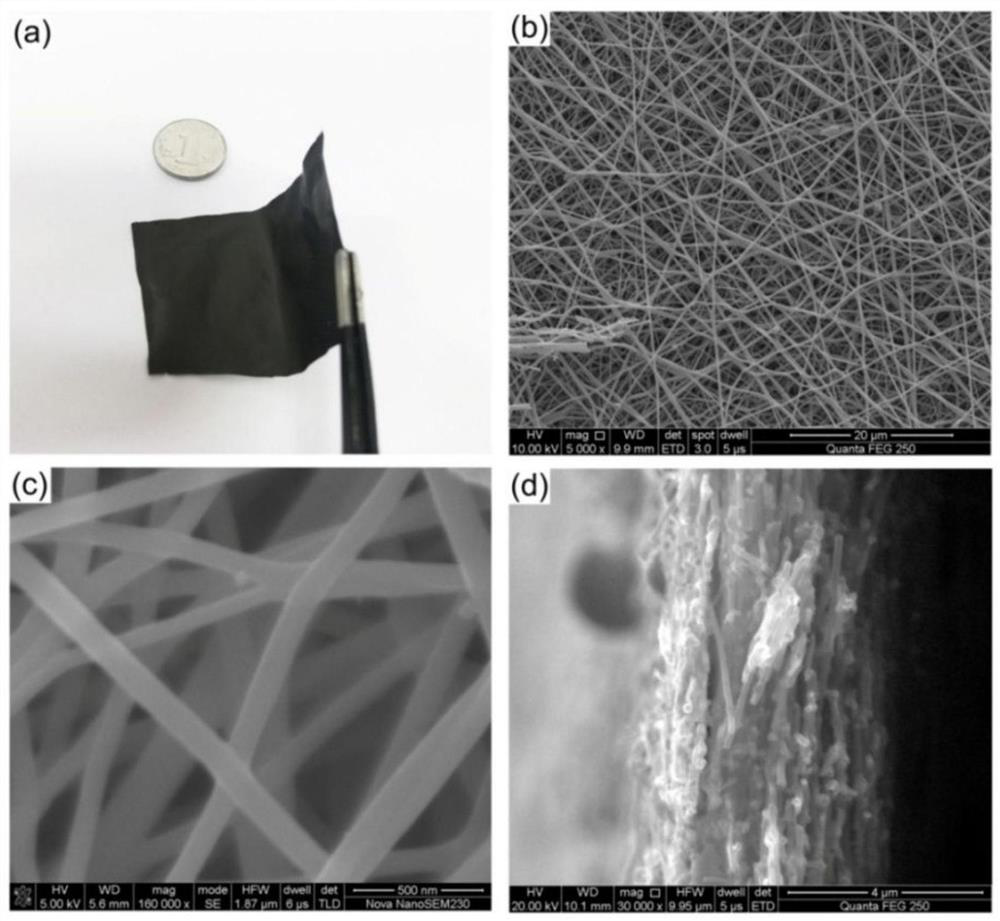

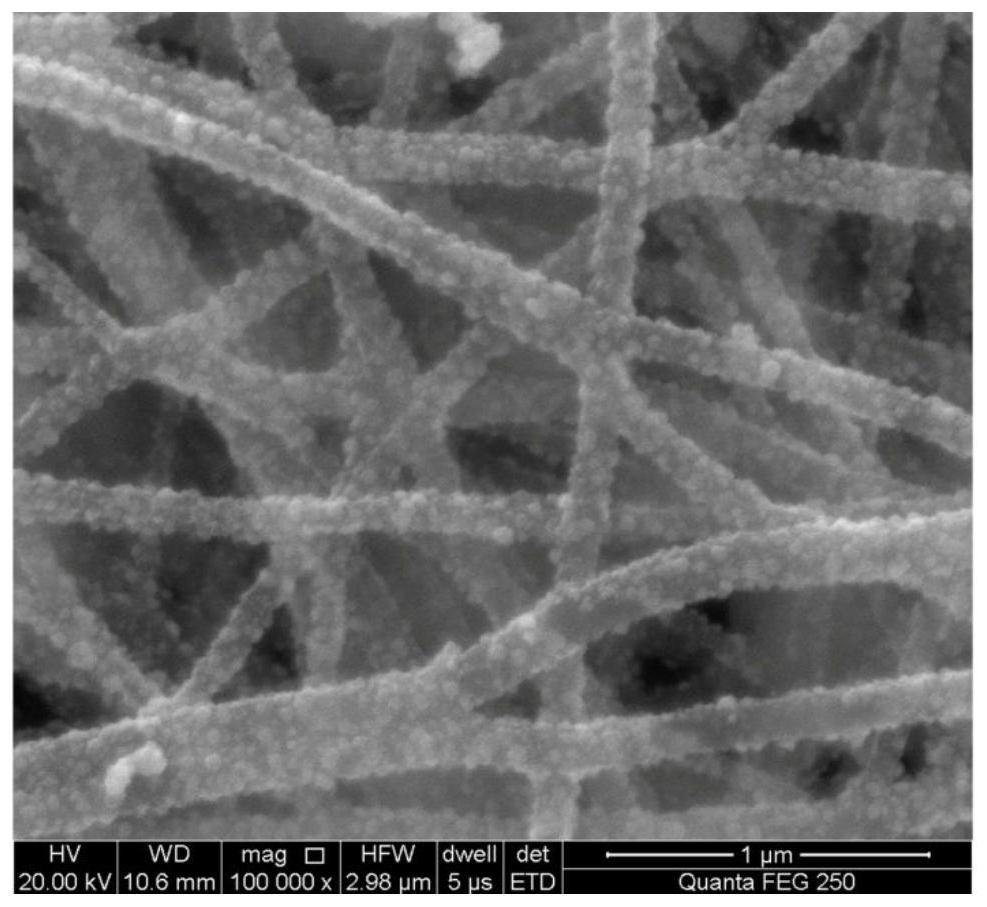

Integrated PtCu/carbon nanofiber catalyst layer, preparation method thereof and application thereof in fuel cell

A carbon nanofiber and catalytic layer technology, applied in nanotechnology, nanotechnology, battery electrodes, etc., can solve the problems of poor uniformity of the fuel cell catalytic layer and low assembly efficiency of membrane electrodes, and achieve good catalyst uniformity and load stability. High sex, favorable effect of exposure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] 1. Preparation of electrospinning precursor body fluid

[0063]Weigh 150mg of boric acid and slowly add it to 13.35g of N,N-dimethylformamide solvent (DMF), stir for 10min, obtain a transparent solution after fully dissolving, weigh polyacrylonitrile (PAN, MW=90000), slowly Added to the above transparent solution, stirred for 6 hours to fully dissolve to obtain a viscous and transparent electrospinning precursor liquid; the mass fraction of boric acid in the boron source is 1 wt%, and the mass fraction of PAN in the polymer carbon source is 10 wt%.

[0064] 2. Electrospinning

[0065] Inject the electrospinning precursor fluid obtained in Step 1 into a plastic syringe with a stainless steel needle, and put the syringe into the electrospinning inner frame with a step-by-step propulsion device. The stainless steel needle is connected to the positive pole of the DC high-voltage power supply, and the steel A constant DC voltage was applied between the needle and the ground...

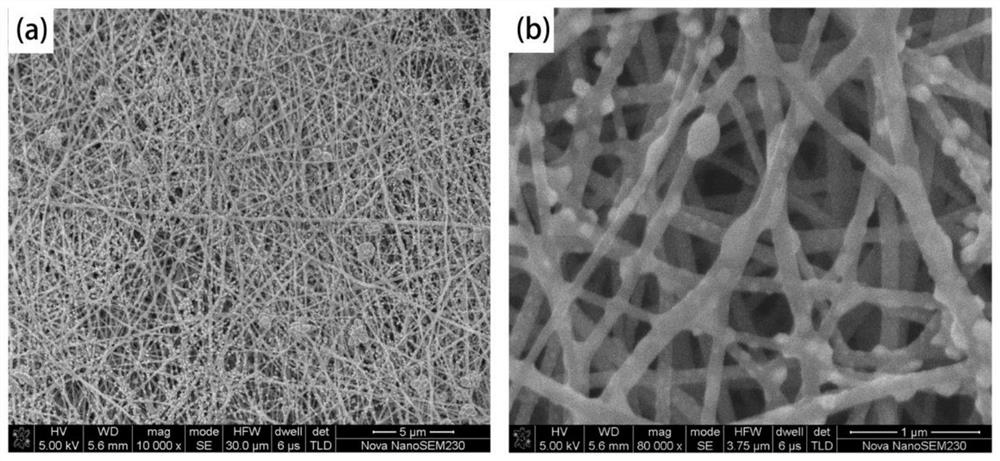

Embodiment 2

[0084] 1. Preparation of electrospinning precursor body fluid

[0085] Weigh 100g of boric acid and slowly add it to 8.9kg of N,N-dimethylformamide solvent (DMF), stir for 30min, obtain a transparent solution after fully dissolving, weigh polyacrylonitrile (PAN, MW=90000), slowly Add to the above transparent solution, stir for 12 hours to fully dissolve to obtain a viscous and transparent electrospinning precursor liquid; the mass fraction of boric acid in the boron source is 1 wt%, and the mass fraction of PAN in the polymer carbon source is 10 wt%.

[0086] 2. Electrospinning

[0087] Put the electrospinning precursor solution obtained in step 1 into the solution tank, and connect the conductive wire to the positive electrode. A constant DC voltage is applied between the receiving devices, and the tape-carrying receiving device receives composite nanofibers. The conductive thread is made of wear-resistant conductive material, the solution feeding speed is 100mL / h, the cons...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com