Stable-type cloth trolley for spinning

A cloth cart and stable technology, applied in the field of cloth carts, can solve problems affecting production efficiency, unstable cloth roll transportation, etc., and achieve the effect of increasing reloading time, less thickness, and maintaining stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

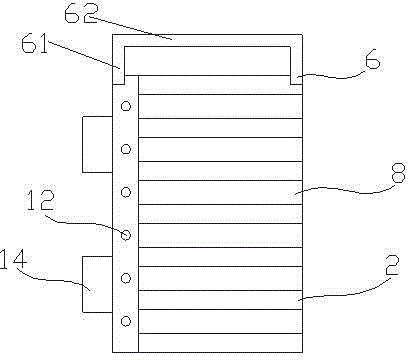

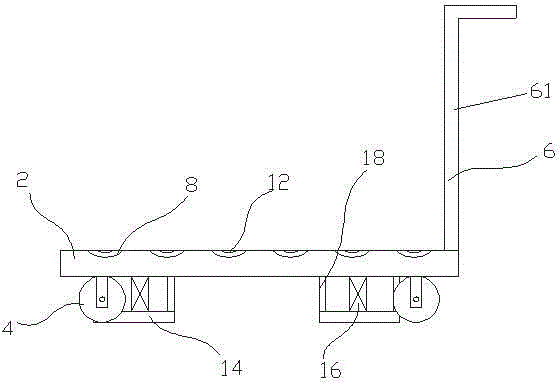

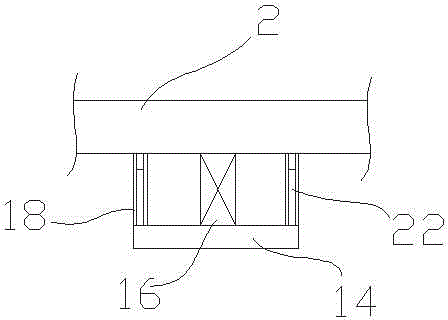

[0022] The present invention will now be further described in detail in conjunction with the accompanying drawings and embodiments. These drawings are all simplified schematic diagrams, only illustrating the basic structure of the present invention in a schematic manner, so it only shows the composition related to the present invention.

[0023] like Figure 1-4 As shown, a stable fabric vehicle for weaving includes a horizontally extending vehicle board 2 , a pulley 4 located at the bottom of the vehicle board 2 , and a strip handle 6 extending upward from the vehicle board 2 . The surface of the car plate 2 is provided with a plurality of cylindrical grooves 8 arranged side by side in a horizontal direction. The axes of each cylindrical groove 8 are parallel to each other and along the horizontal direction. The central angle of the arc-shaped cross section of the groove wall of the groove 8 is less than 180°.

[0024] Specifically, the bottom four corners of the vehicle boa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com