Carbon-based solid acid catalyst and preparation method thereof

A carbon-based solid acid and catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, organic compounds/hydrides/coordination complex catalysts, etc., to achieve increased specific surface area, high catalytic activity, and thermal stability good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] The first step, the preparation of the precursor of the modified coal: crush 20 g of Taixi coal with an ash content of 3.5% until it passes through a 200 mesh sieve, put it into a polytetrafluoroethylene beaker, and measure it according to the ratio of 30:4:4:15 Add distilled water, hydrofluoric acid with a mass concentration of 40%, perchloric acid with a mass concentration of 99%, and hydrochloric acid with a mass concentration of 36%, and stir evenly at room temperature for 24 hours, filter, wash with water until neutral, and store at 120 Drying at ℃, the measured ash content is 0.61%;

[0017] The second step, compounding: mix the deashed Taixi coal, sodium humate as a binder, calcium oxide as a pore-forming agent, and distilled water in a mass ratio of 100:25:8:40 Evenly, after natural air-drying, put it in an oven and bake at 120°C for 2 hours, cool to room temperature, and then grind to below 200 mesh for later use;

[0018] The third step, carbonization: put 20...

Embodiment 2-7

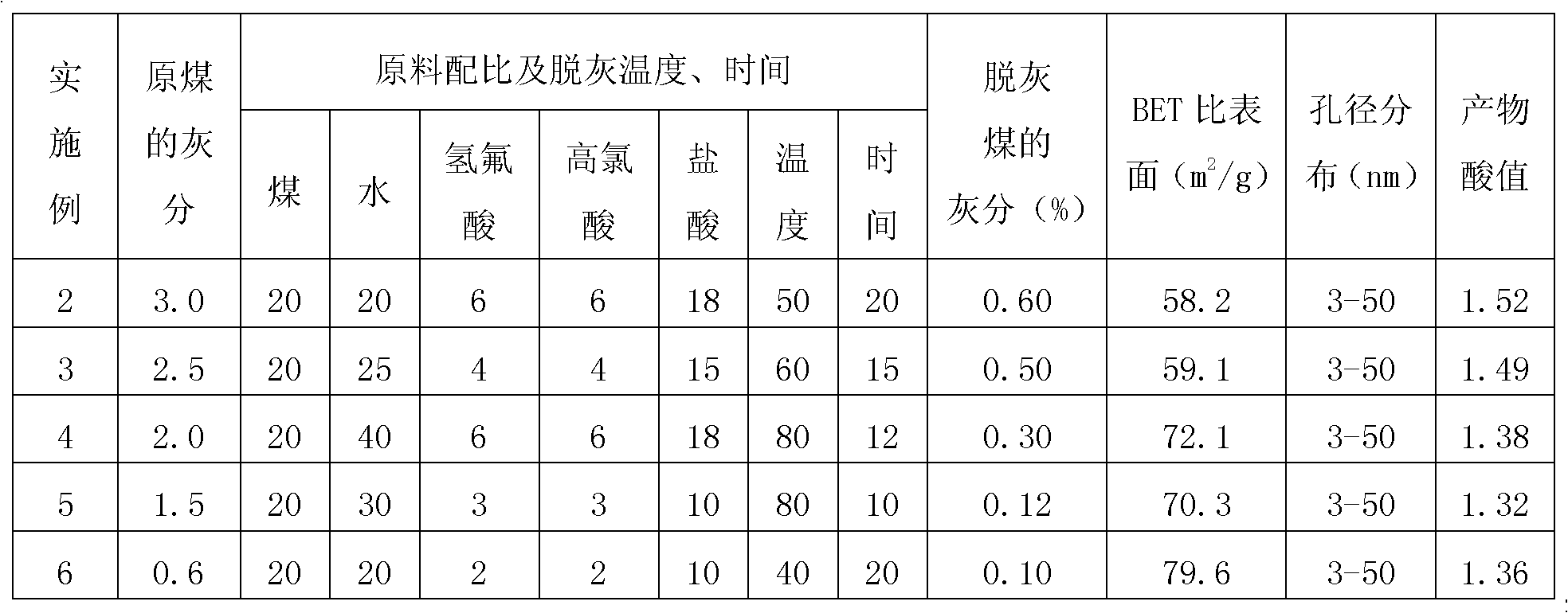

[0022] On the basis of the process steps in the above-mentioned Example 1, step 1: the preparation conditions of the modified coal precursor are changed, and the process technical conditions of other steps remain unchanged, and the examples 2-6 are shown in the following table.

[0023]

[0024] The unit of the ash content of raw coal in the above-mentioned embodiment is mass percentage, and the amount of coal, water, hydrofluoric acid, perchloric acid, hydrochloric acid is to measure by weight, and the concentration of hydrofluoric acid, perchloric acid, hydrochloric acid is identical with embodiment 1, The unit of temperature is °C, the unit of time is hour, and the unit of product acid value is mmol / g.

Embodiment 7-12

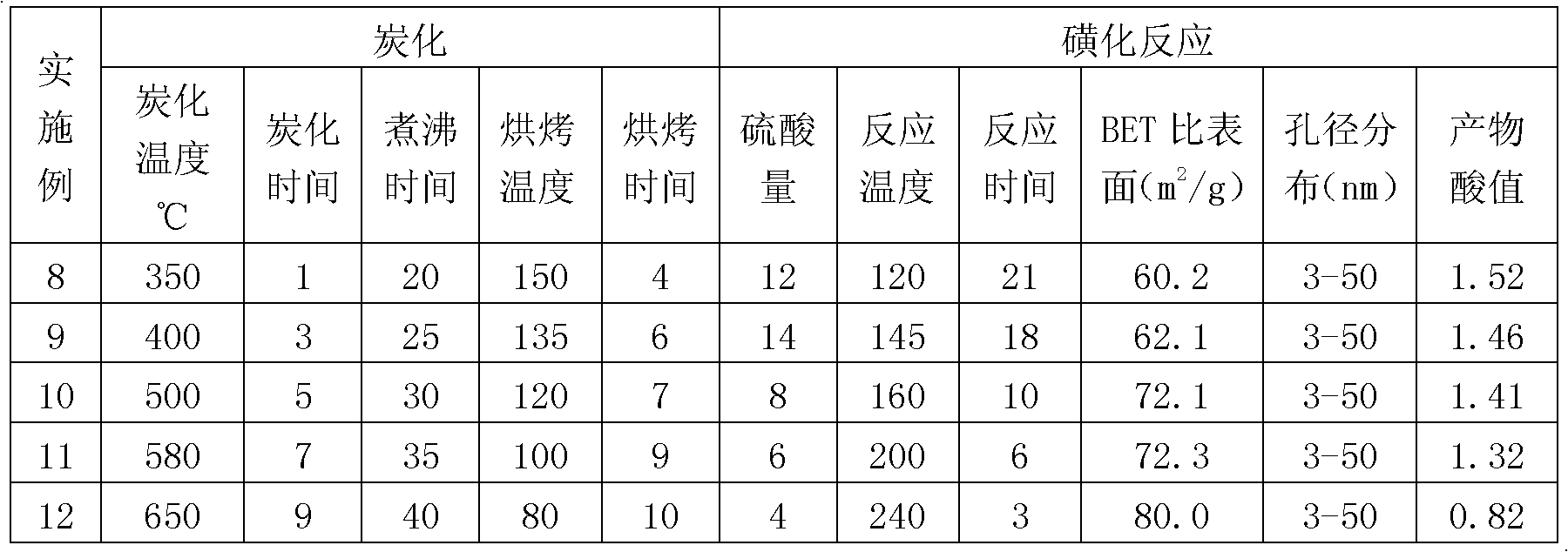

[0026] On the basis of any of the above-mentioned embodiments of 2-6, only the process conditions in the carbonization and sulfonation steps are changed, and the specific implementation methods are shown in the following table on the basis that the conditions of other steps are constant;

[0027]

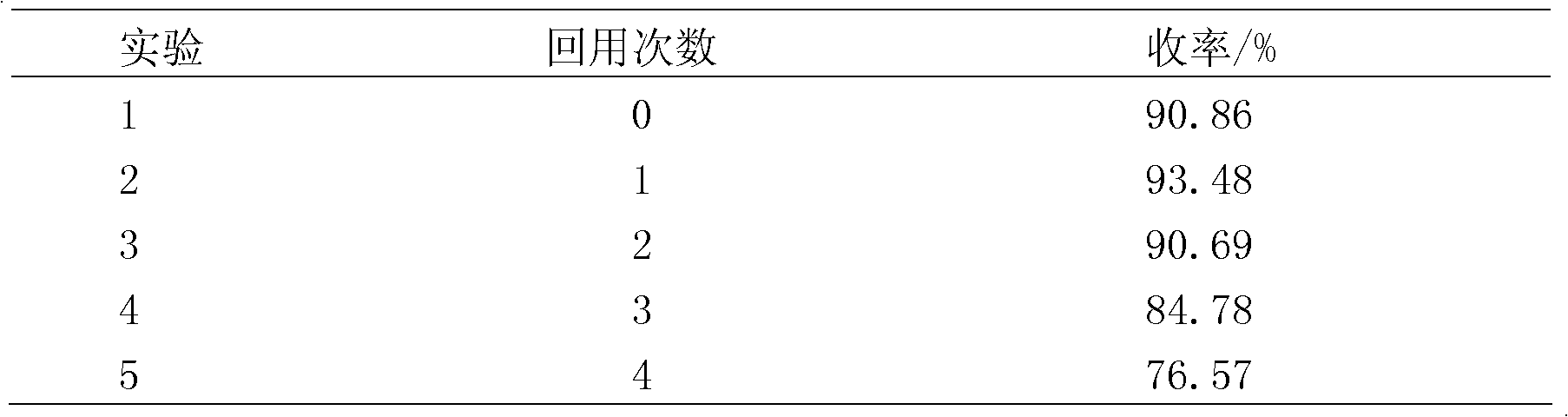

[0028] With the charcoal-based solid acid catalyst that above-mentioned embodiment obtains, the specific implementation mode that is used to catalyze ketal (aldehyde) reaction is as follows:

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com