Deodorizing and antibacterial 3D (three-dimensional) printing reed fiber composite material and preparation method and application thereof

A reed fiber, 3D printing technology, applied in the direction of additive processing, can solve the problem that reed plants cannot be used more effectively and reasonably, and achieve the effect of good deodorization and antibacterial function, good mechanical properties, and good adsorption and purification effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

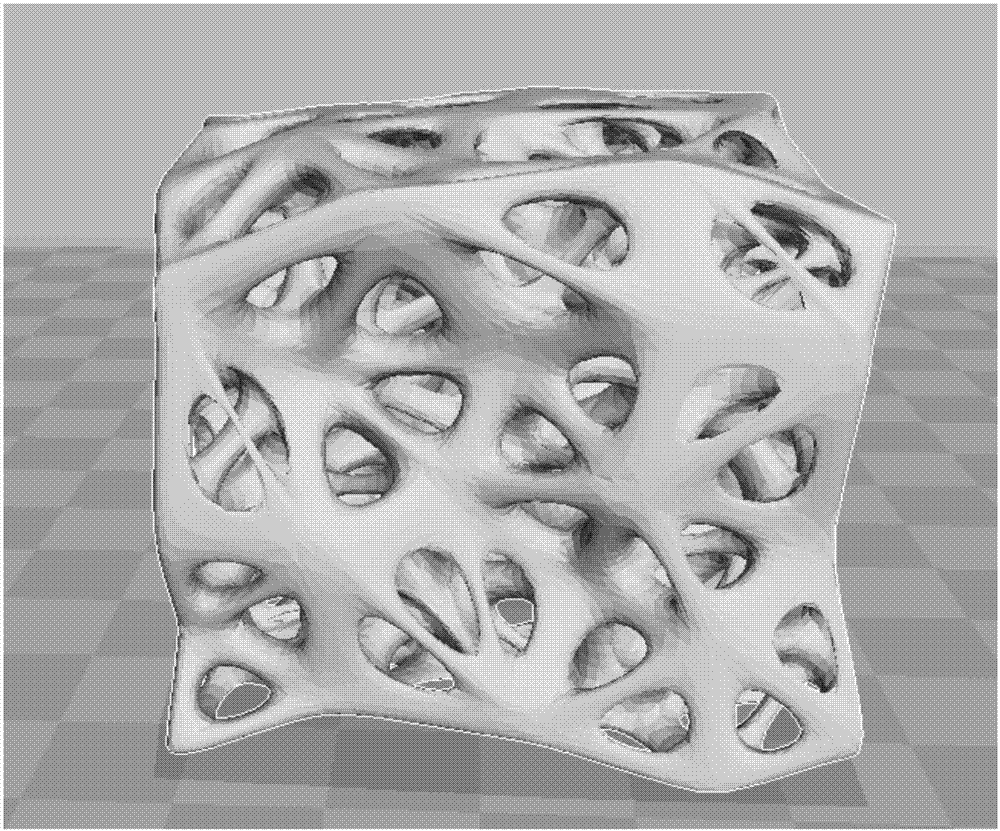

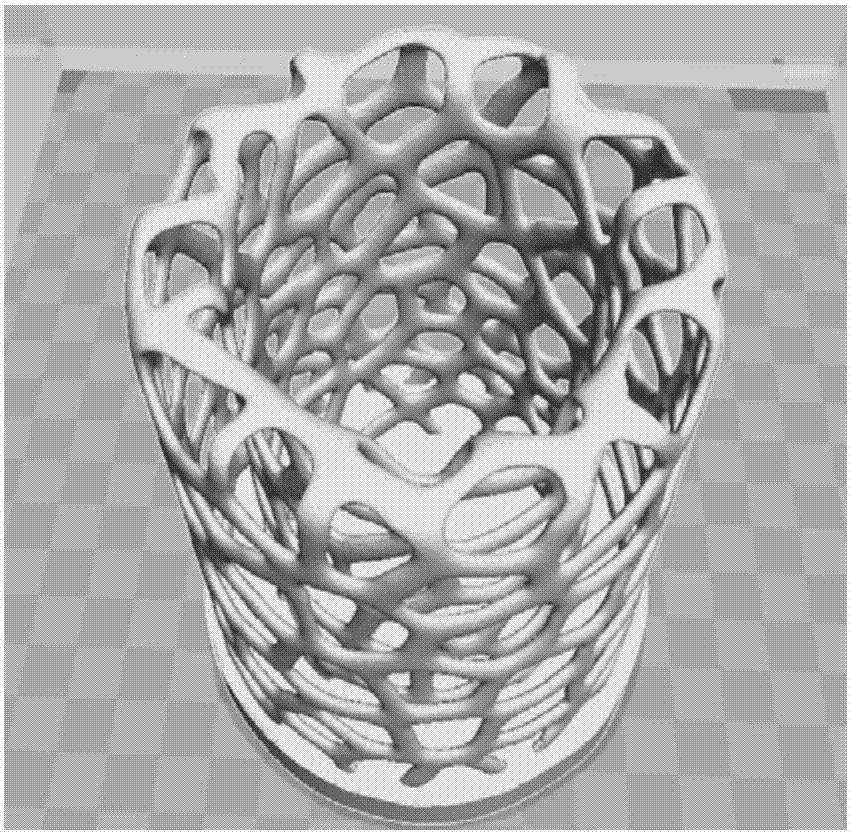

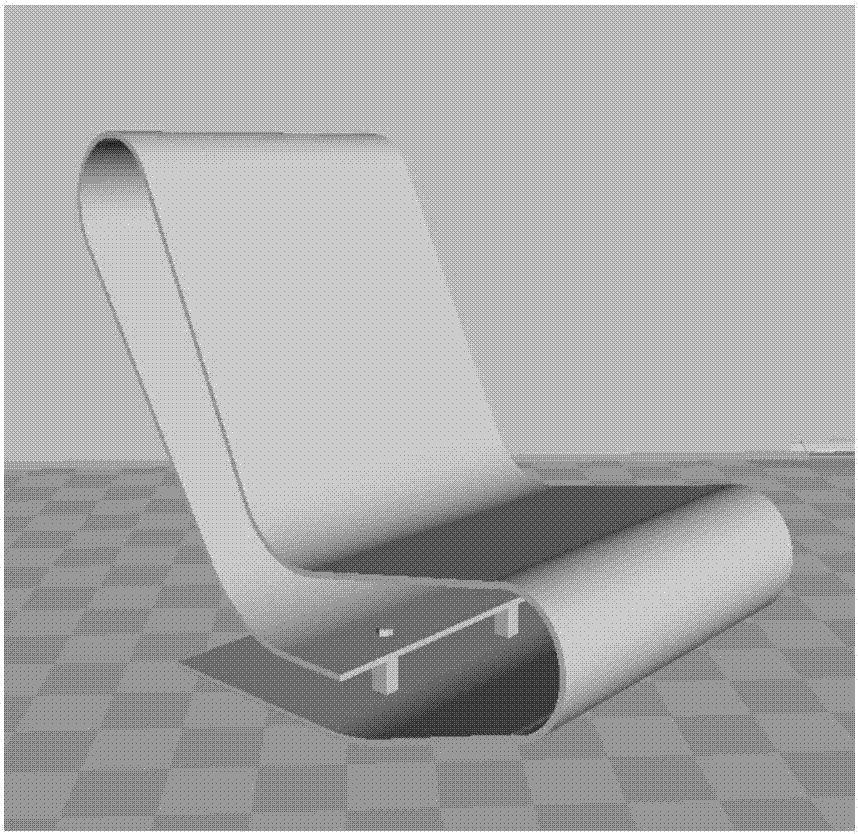

Image

Examples

Embodiment 1

[0043] The components of the deodorant and antibacterial 3D printed reed fiber composite material in this embodiment are calculated in parts by weight:

[0044] Polymer: 61 parts by weight of polycaprolactone polymer with relative molecular weight of 51000;

[0045] Reed fiber: 20 parts by weight of reed fiber with a size not less than 300 mesh;

[0046] Coupling agent: 0.1 parts by weight coupling agent KH-590;

[0047] Toughening agent: 2 parts by weight of thermoplastic elastomer SEBS;

[0048] Activated carbon: 15 parts by weight of bamboo nano activated carbon powder with an average microporosity of 90%;

[0049] Antibacterial agent: 2 parts by weight of chitosan antibacterial agent.

[0050] The preparation method of the present embodiment composite material is as follows:

[0051] First, 20 parts by weight of reed fibers are added to a sodium hydroxide solution with a mass concentration of 8% and soaked for 20 minutes. After taking it out, place it in an oven with a...

Embodiment 2

[0054] The components of the deodorant and antibacterial 3D printed reed fiber composite material in this embodiment are calculated in parts by weight:

[0055] Polymer: 53 parts by weight of polycaprolactone polymer with relative molecular weight of 51000;

[0056] Reed fiber: 15 parts by weight of reed fiber with a size not less than 300 mesh;

[0057] Coupling agent: 0.2 parts by weight coupling agent KH-550;

[0058] Toughening agent: 4 parts by weight of thermoplastic elastomer SEBS;

[0059] Activated carbon: 25 parts by weight of bamboo nano activated carbon powder with an average microporosity of 90%;

[0060] Antibacterial agent: 3 parts by weight of chitosan antibacterial agent.

[0061] The preparation method of the present embodiment composite material is as follows:

[0062] First, 15 parts by weight of reed fibers are added to a sodium hydroxide solution with a mass concentration of 9% and soaked for 20 minutes, and after taking it out, place it in an oven wi...

Embodiment 3

[0065] The components of the deodorant and antibacterial 3D printed reed fiber composite material in this embodiment are calculated in parts by weight:

[0066] Polymer: 54 parts by weight of polylactic acid polymer with a relative molecular weight of 110,000;

[0067] Reed fiber: 20 parts by weight of reed fiber with a size not less than 300 mesh;

[0068] Coupling agent: 0.2 parts by weight coupling agent KH-550;

[0069] Toughening agent: 4 parts by weight of thermoplastic elastomer SEBS;

[0070] Activated carbon: 20 parts by weight of fruit shell nano activated carbon powder with an average microporosity of 90%;

[0071] Antibacterial agent: 2 parts by weight of chitosan antibacterial agent.

[0072] The preparation method of the present embodiment composite material is as follows:

[0073] First, 20 parts by weight of reed fibers are added to a sodium hydroxide solution with a mass concentration of 9% and soaked for 20 minutes. After taking it out, place it in an ove...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com