Device and method for deeply treating coal gasification wastewater

A technology for coal gasification wastewater and advanced treatment, applied in the directions of oxidized water/sewage treatment, water/sewage treatment, chemical instruments and methods, etc., can solve the problem that the effluent from biochemical treatment cannot meet the discharge or reuse standards, mass transfer efficiency, and reaction efficiency. And the problems of low utilization efficiency, inability to effectively remove refractory organics, etc., to achieve the effects of excellent treatment effect, improved ozone utilization rate, and short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

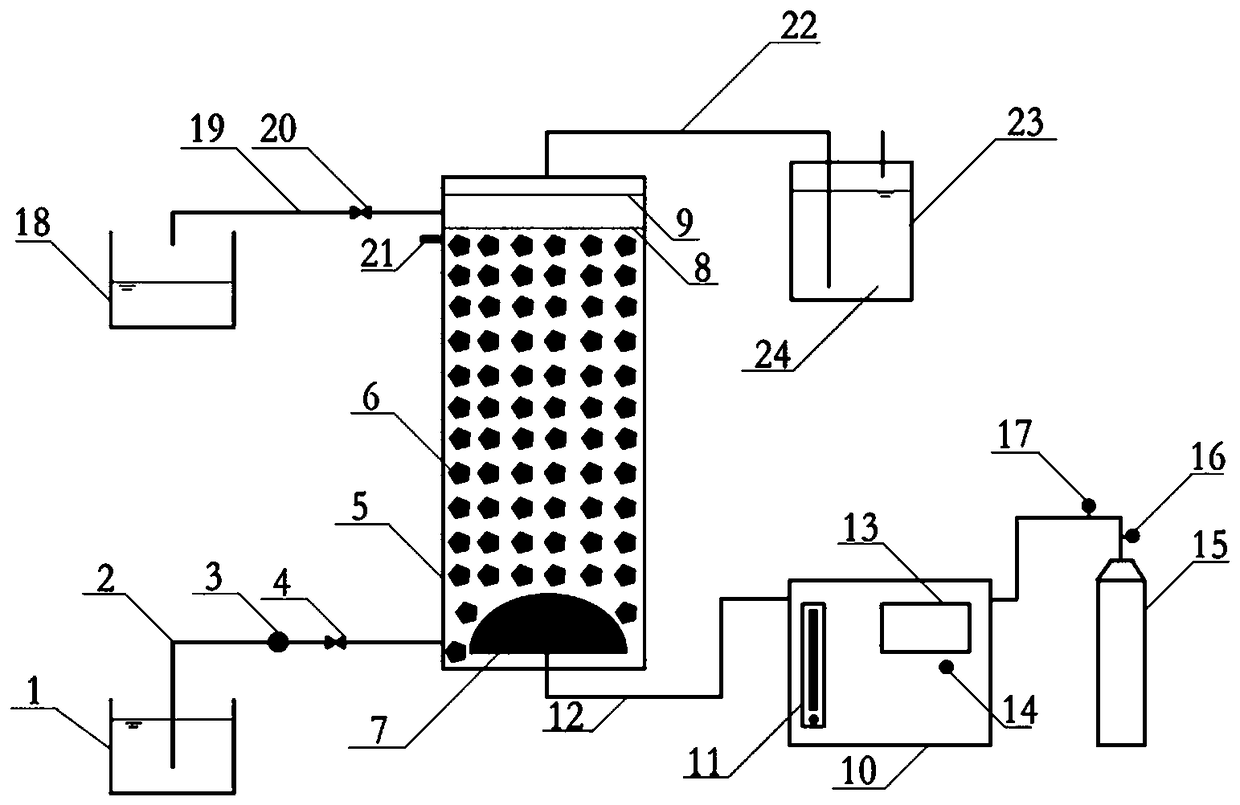

[0030] figure 1 A schematic structural view of the coal gasification wastewater advanced treatment device of this embodiment is shown. Such as figure 1 As shown, the device includes a water storage tank 1, an advanced treatment reactor 5, an ozone generator 10, a gas cleaning tank 23 and a clear water tank 18, wherein the water storage tank 1 communicates with the advanced treatment reactor 5 through a water inlet pipe 2, and the water inlet pipe 2 A water pump 3 is installed on it and a water inlet valve 4 is installed. When the water pump 3 and the water inlet valve 4 are opened, the waste water in the storage tank 1 can enter the advanced treatment reactor 5 through the water inlet pipe 2 through the bottom of the advanced treatment reactor 5; The air inlet of ozone generator 10 connects oxygen tank 15, and oxygen tank 15 is provided with valve 16 and pressure stabilizer 17, opens valve 16, and the oxygen in the oxygen tank 15 enters in the ozone generator 10, produces ozo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com