Patents

Literature

32results about How to "Good quality glaze" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

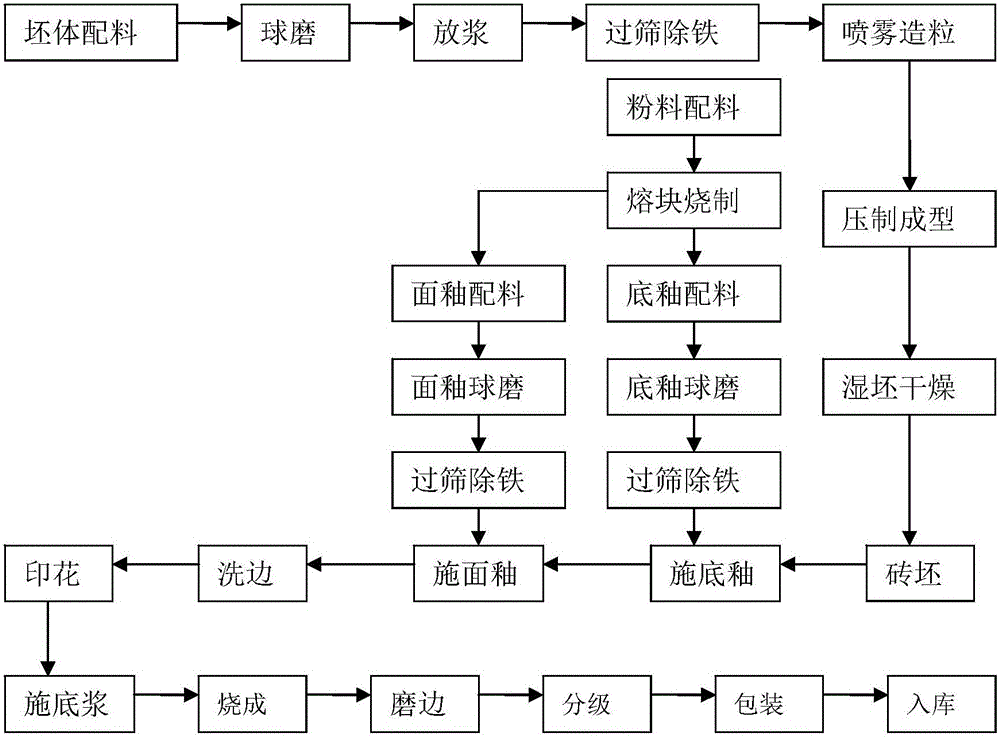

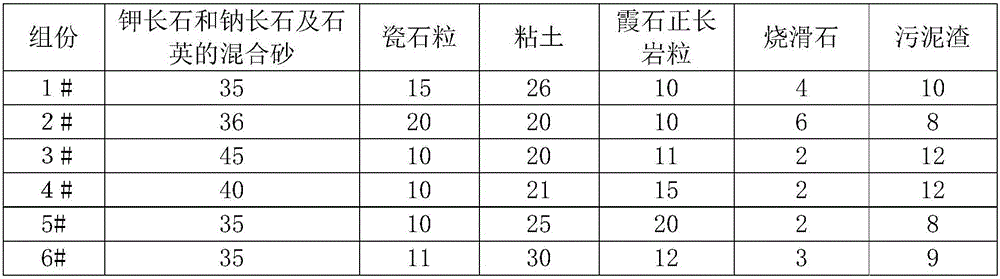

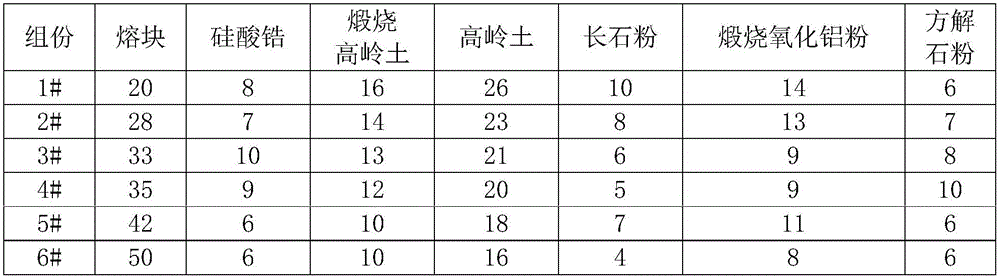

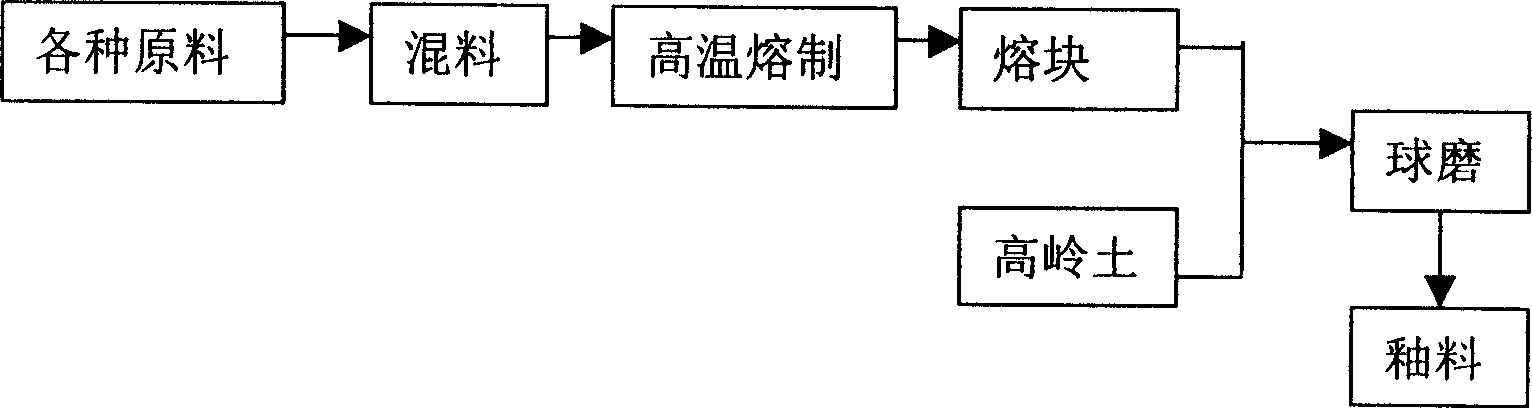

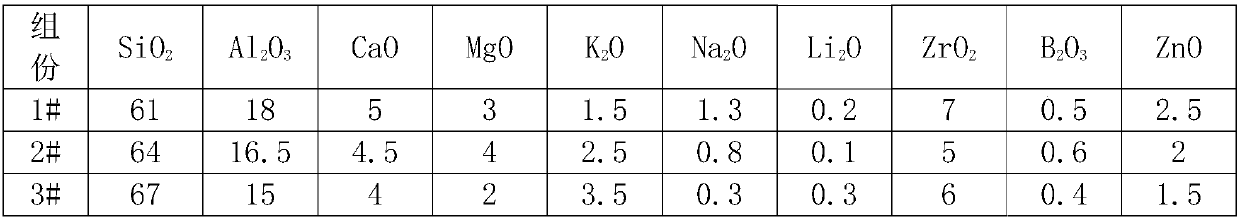

Resource-saving glazed ceramic tile having antiskid effect on surface and preparation method thereof

ActiveCN105837172AAchieve anti-slip effectGood quality glazeCeramic materials productionClaywaresBrickSludge

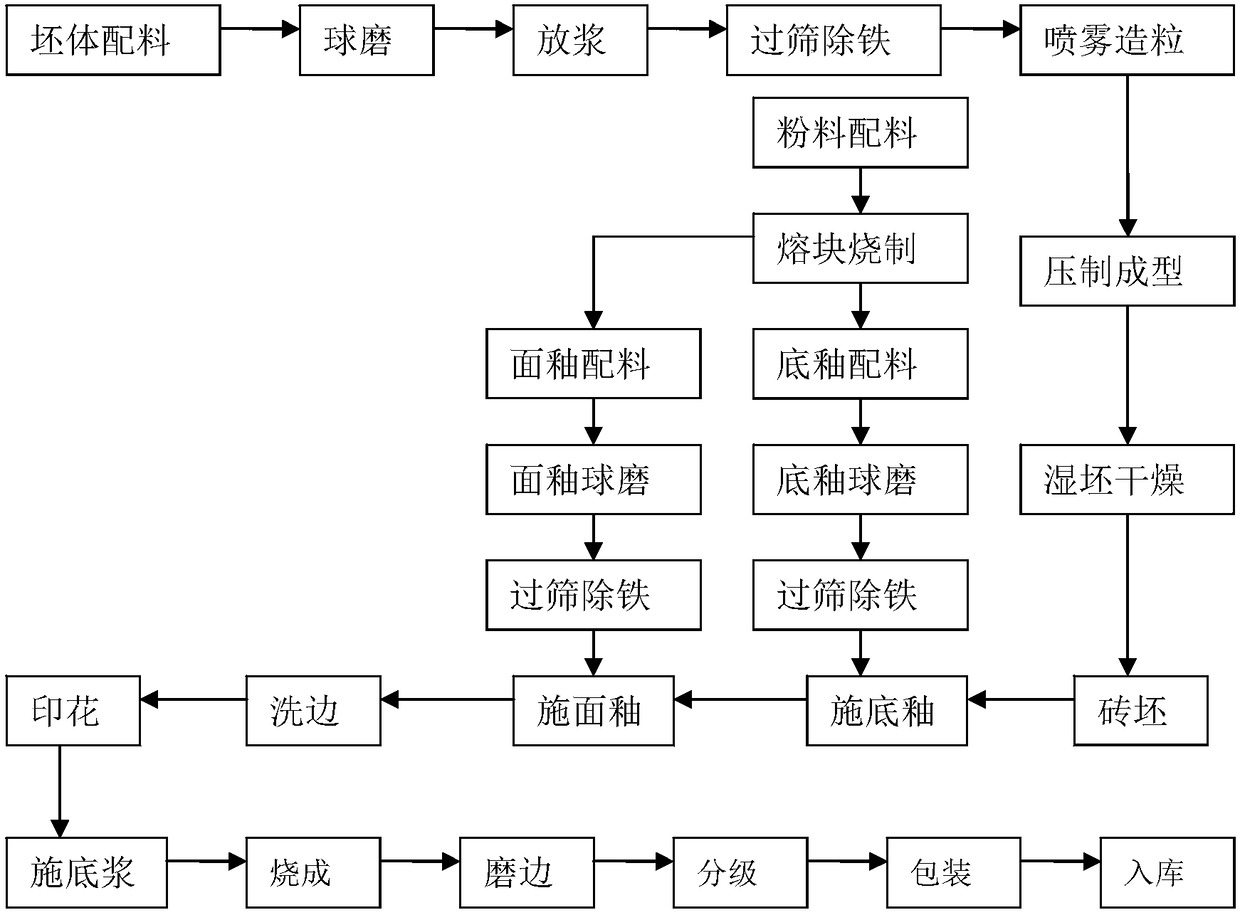

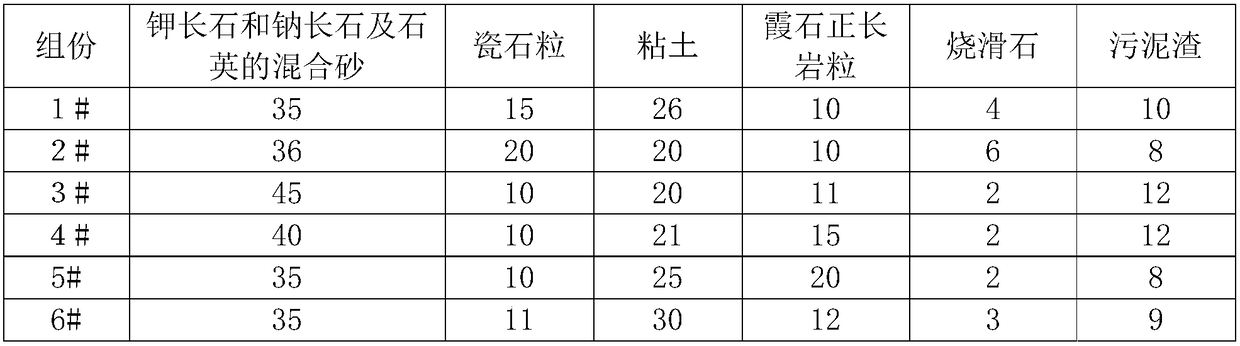

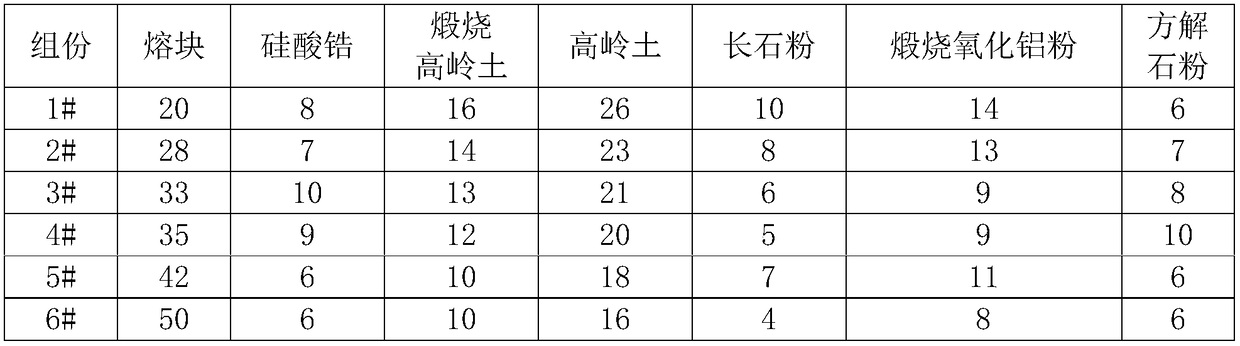

A resource-saving glazed ceramic tile having an antiskid effect on surface and a preparation method thereof. Without great change on production process of the glazed ceramic tiles, formula composition of a blank body, composition of ground and cover glaze frits and formula composition of ground and cover glaze are regulated and optimized focusedly, so that the glazed ceramic tile, which has excellent performance and the antiskid effect, can be prepared even large quantity sludge residue is added to the blank body. Through a high-magnification scanning electronic microscopy for observing the surface of glaze on the product, it is found that projects which are hard and needle-like and look like aluminum spinel crystal are formed on the surface, and the glaze is 0.8 in antiskid coefficient and is R12 in antiskid level when a less quantity of water is sprayed on the glaze. The glazed ceramic tile has good antiskid effect, can reach 4000 r / four grade in wear-resisting revolution through detection, and has good anti-wear performance, surface anti-fouling performance and water permeation resistance. The glaze has no defects such as needle pores, bubbles and the like, has clear decorative pattern grains and is highly stone-simulated. The technology has strong adaptability and is easy to promote in the field.

Owner:GUANGDONG WINTO CERAMICS +3

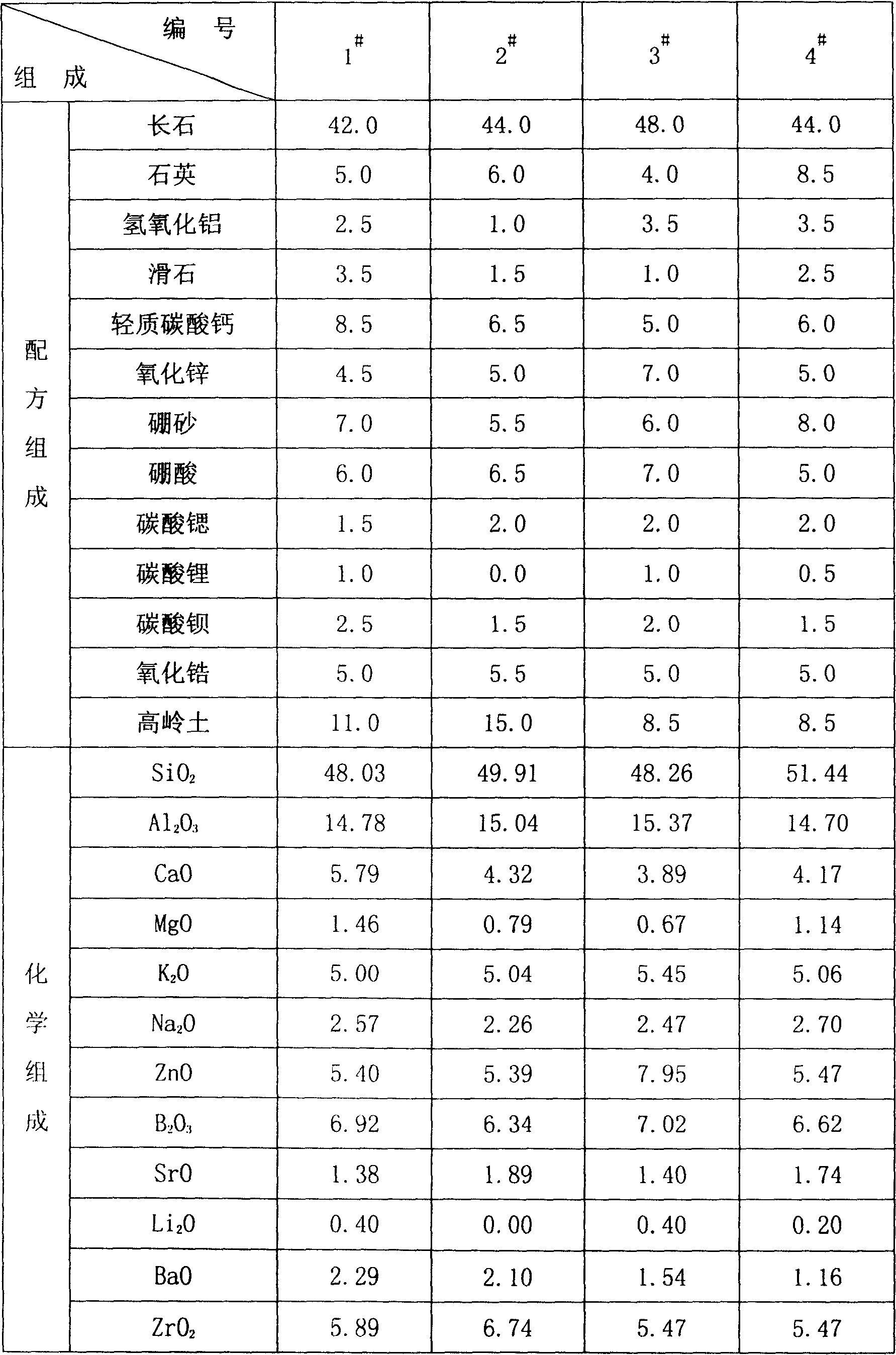

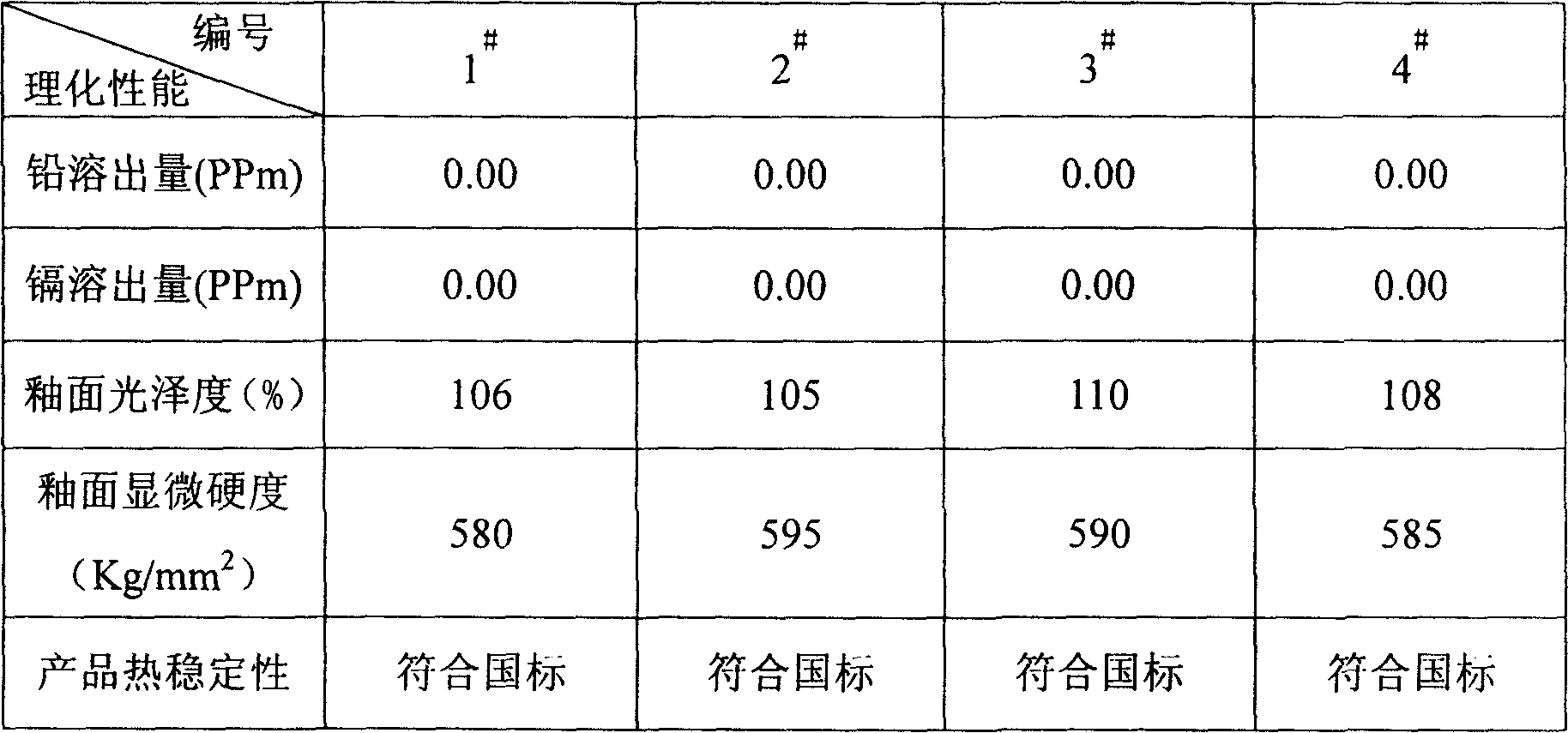

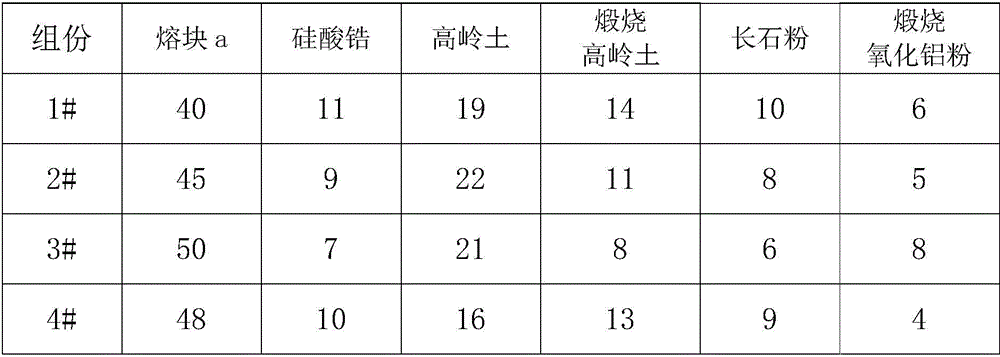

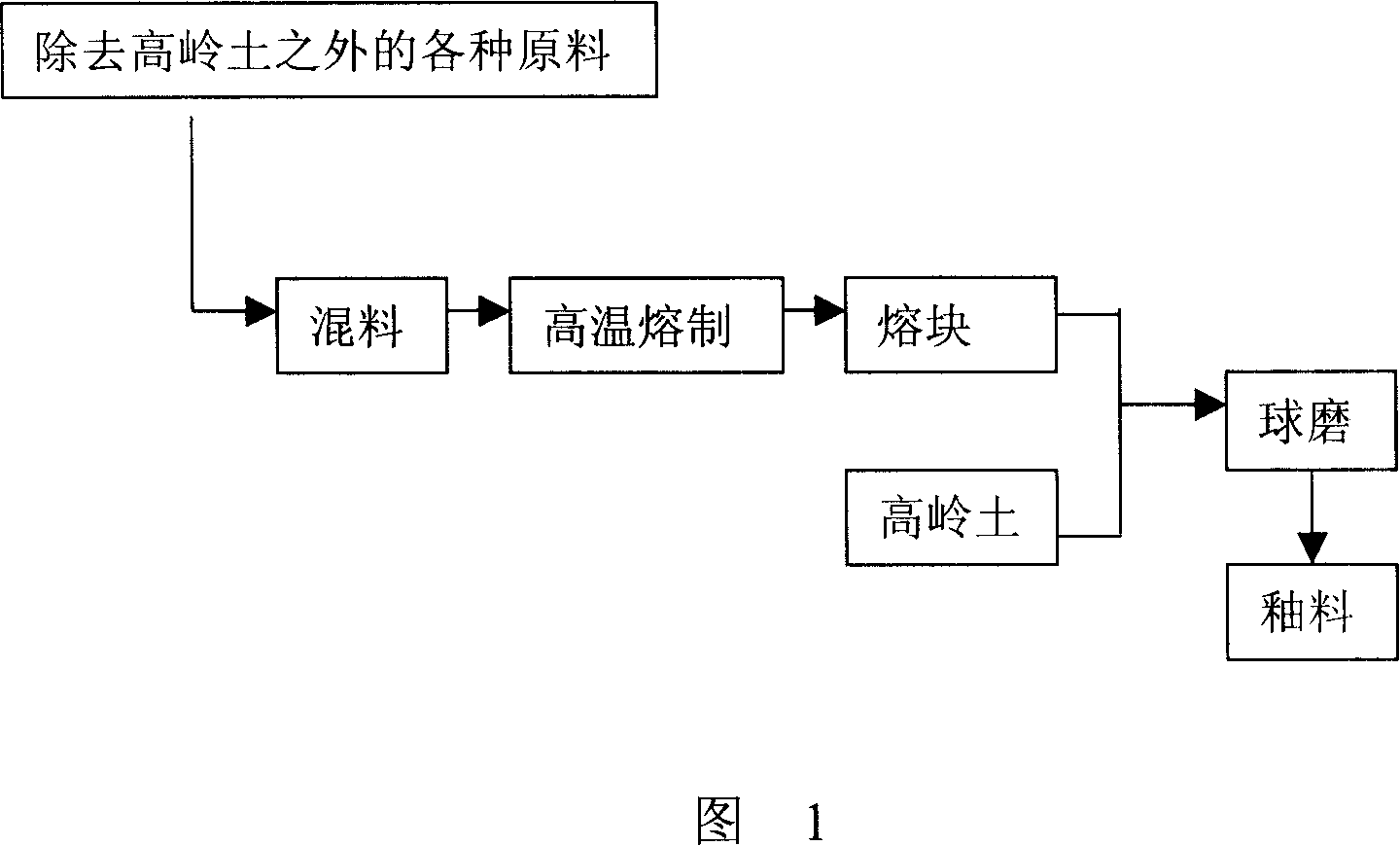

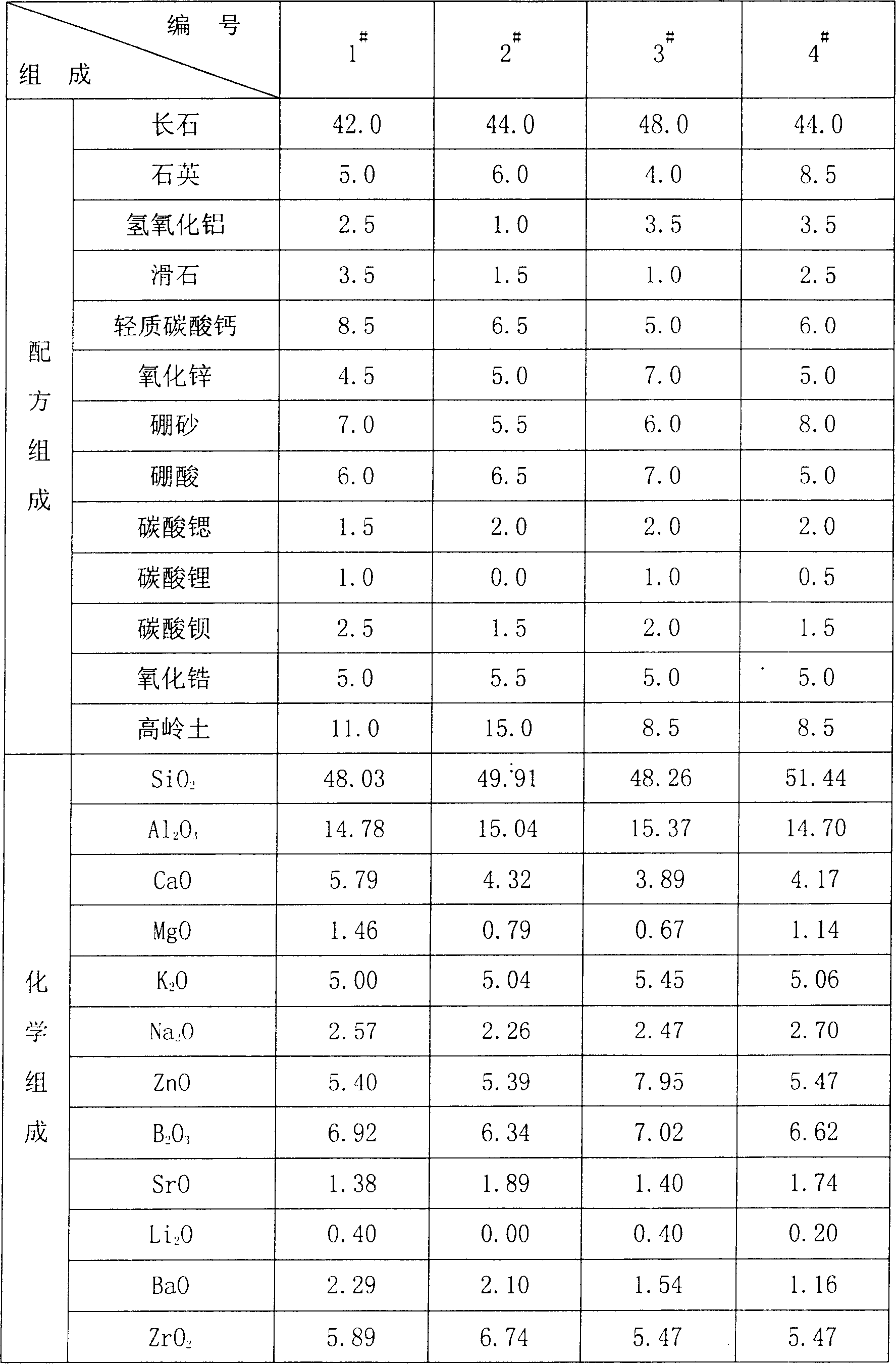

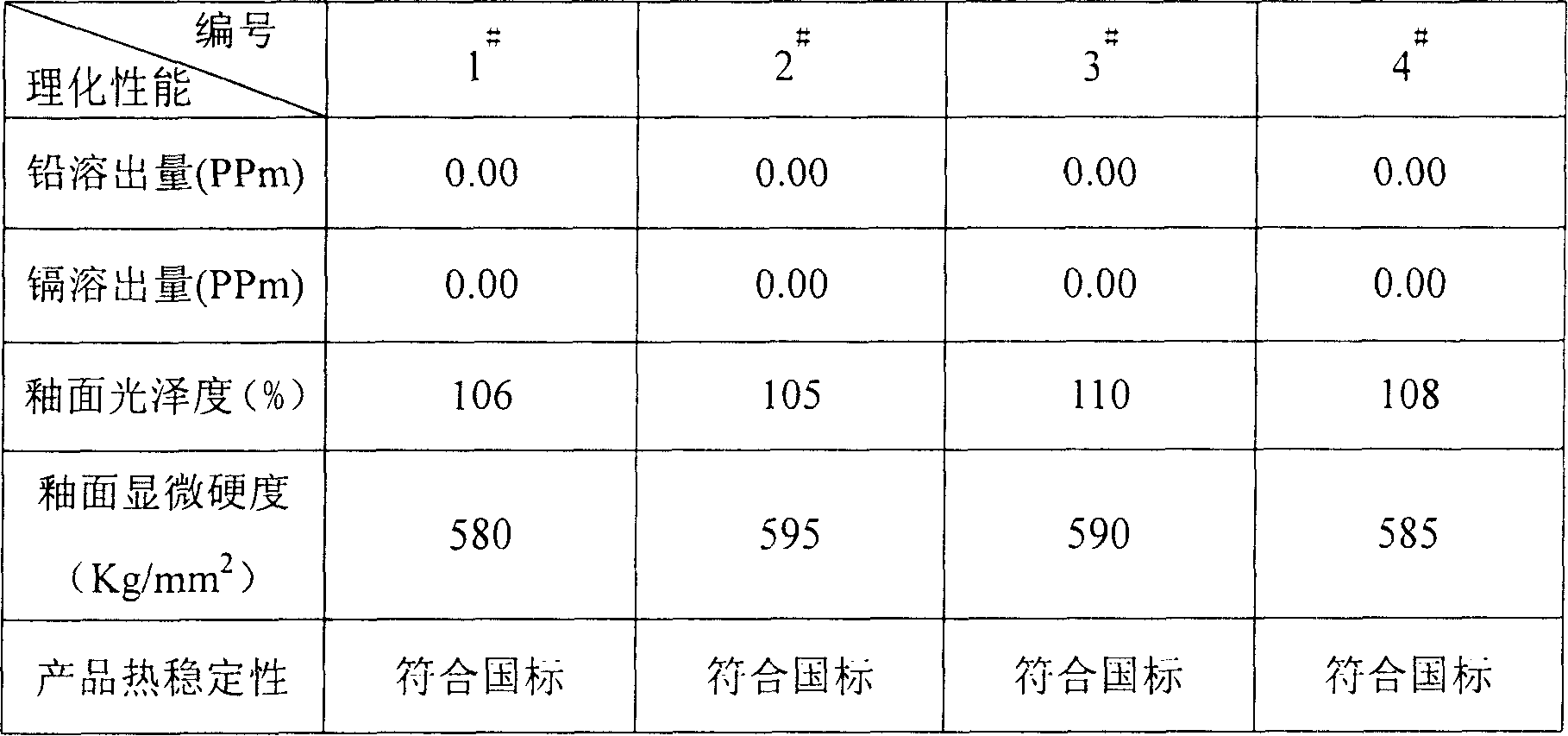

Leadfree fritted glaze suitable for secondary sintering

The invention discloses a leadless fritted glaze, which comprises the following parts: 35.0-60.0%SiO2, 14.0-18.0%Al2O3, 3.0-10.0%CaO, 0.0-5.0%MgO, 5.0-10.0%K2O, 2.0-5.0%Na2O, 5.0-10.0%ZnO, 4.0-12.0%B2O3, 1.0-5.0%SrO, 0.0-1.0 %Li2O, 0.0-8.0%BaO and 5.0-9.0%ZrO2. The invention solves masking problem for magnesium ceramic glaze surface, which prevents environmental pollution due to overcoming to flow lead and cadmium.

Owner:淄博硅元投资控股有限公司

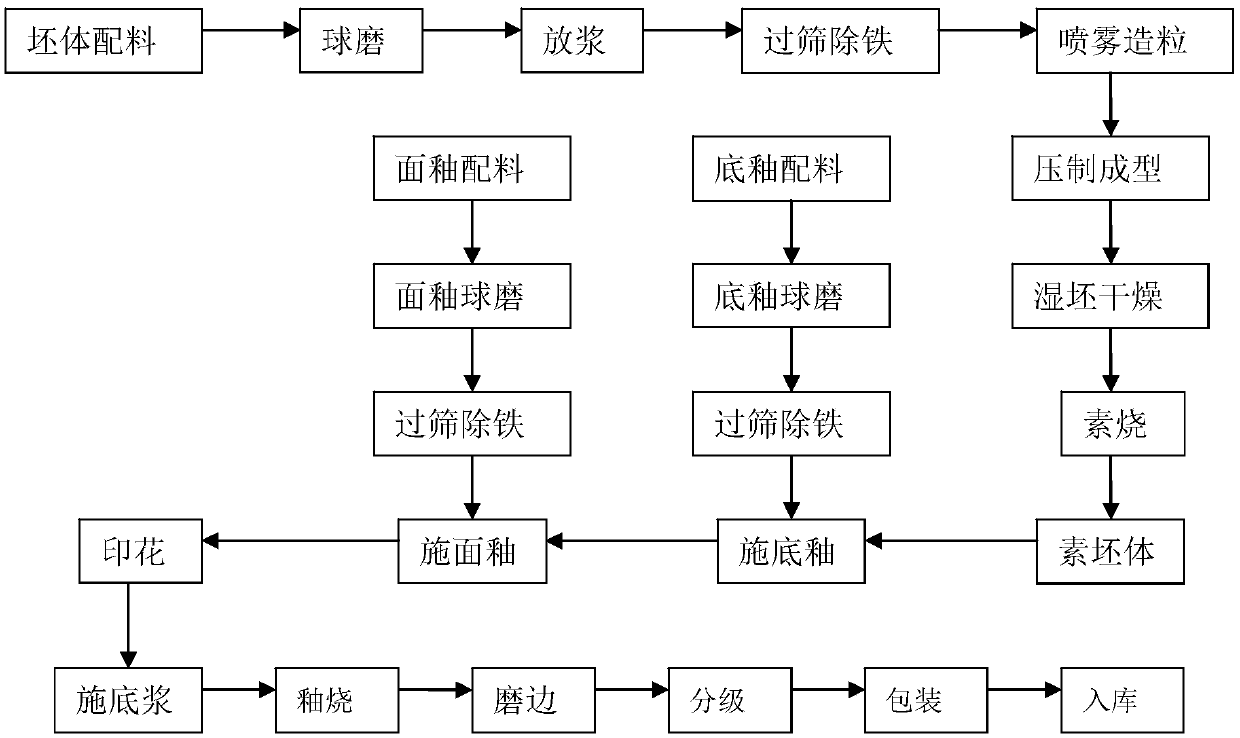

Pure black glazed tile produced by using waste glaze slip and preparation method of pure black glazed tile

The invention provides a pure black glazed tile produced by using waste glaze slip and a preparation method of the pure black glazed tile in order to overcome the defects. On the basis of greatly unchanging the existing production process of glazed tiles, by optimizing the composition of ground coat and cover coat frits, the formula composition of the ground coat, the formula composition of the cover coat, regulating and optimizing ground coat and cover coat technological processes, especially the preferable section of green body types, the fired pure black glazed tile is pure in color, and the chromaticity (L *, a *, b *) value of an unprinted product is measured by a WSD-3C type whiteness colorimeter, wherein the L * (lightness) value is 6.25 to 6.43 and is close to the L * (lightness) value of 5.0 of standard carbon black, the a * (redness) value is -0.03 to 1.60, and the b * (yellowness) value is 0.15 to 0.18. The glazed tile is carbon black like pure black, the glaze has good quality, is moisturized and bright, and has no pinholes, glaze bubbles and other defects, and the glazed tile has strong decorative effect and aesthetic feeling; meanwhile, the technology has strong universality and is easily popularized in the industry.

Owner:GUANGDONG WINTO CERAMICS +3

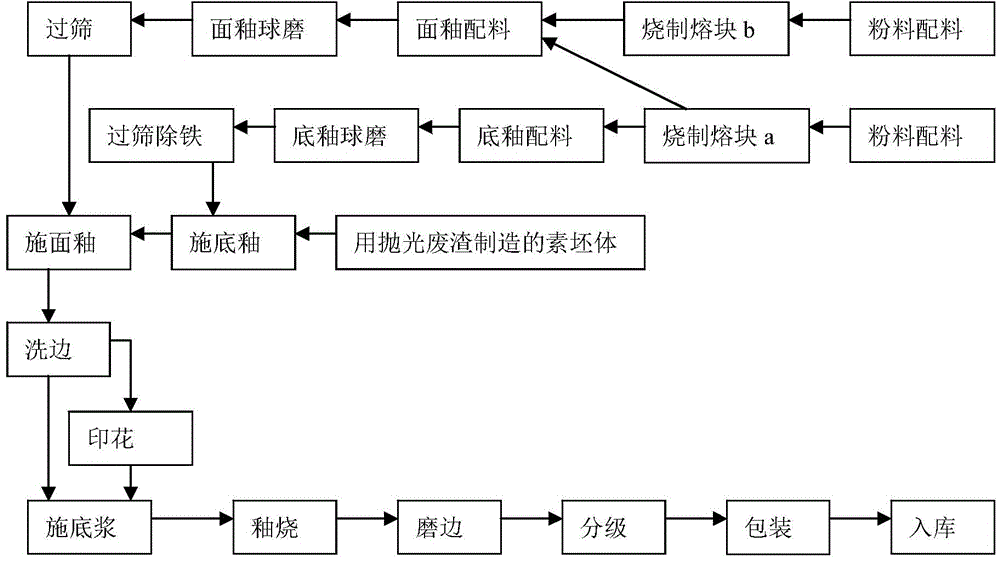

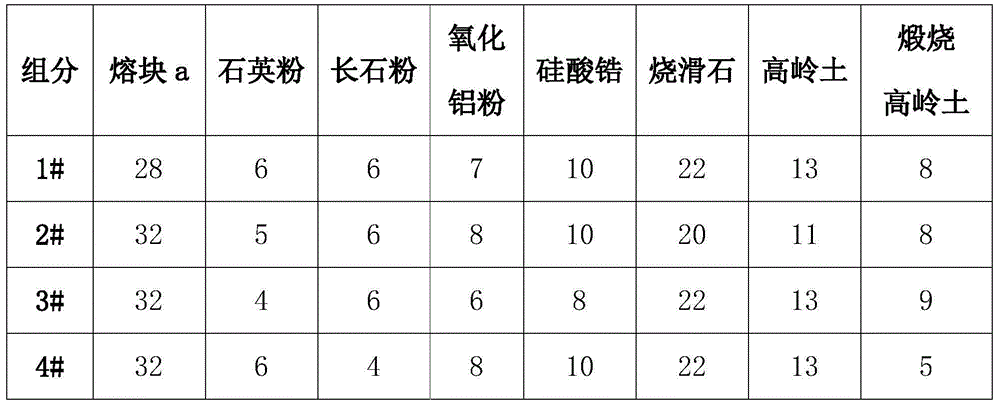

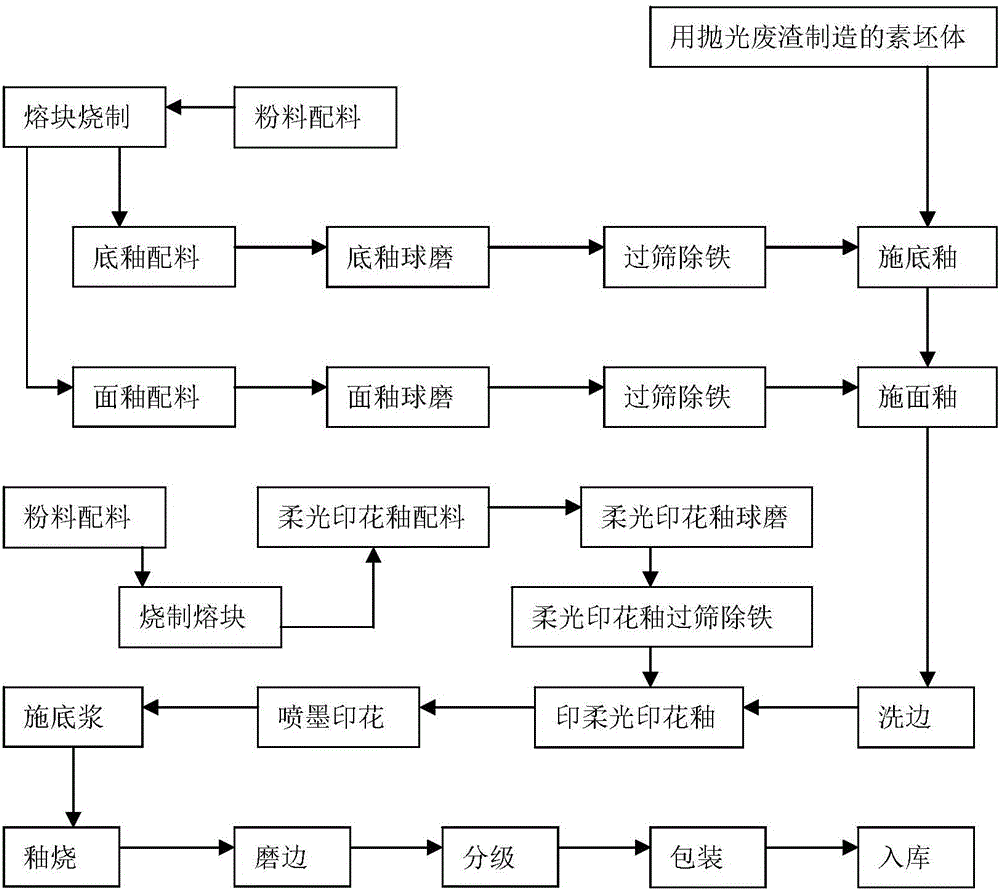

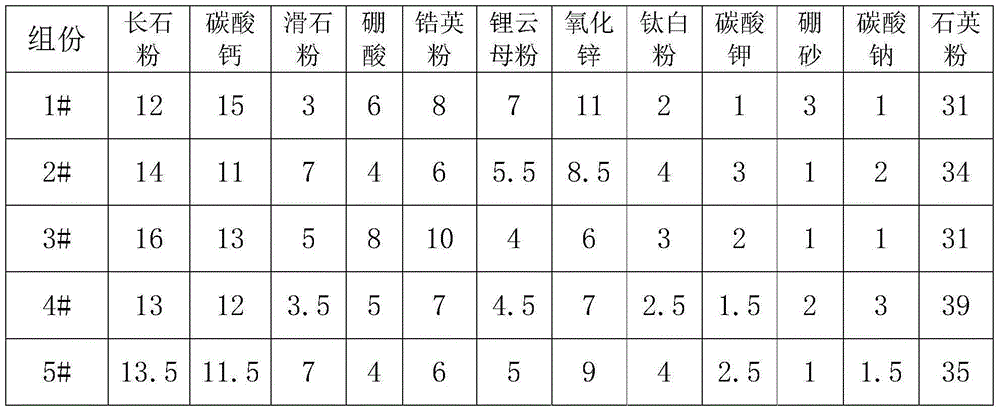

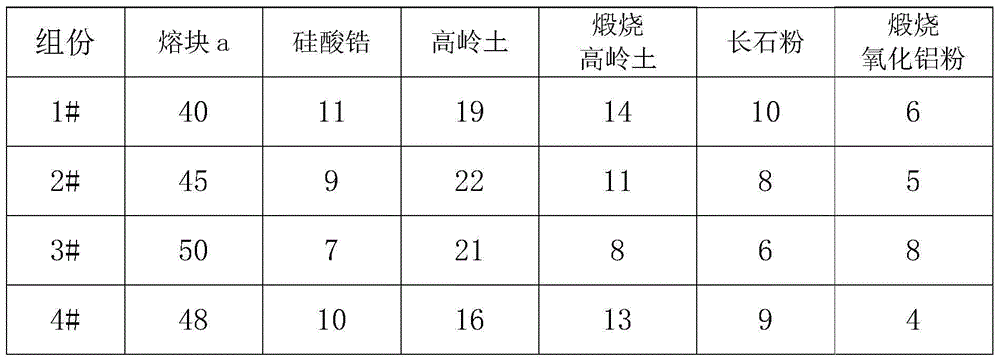

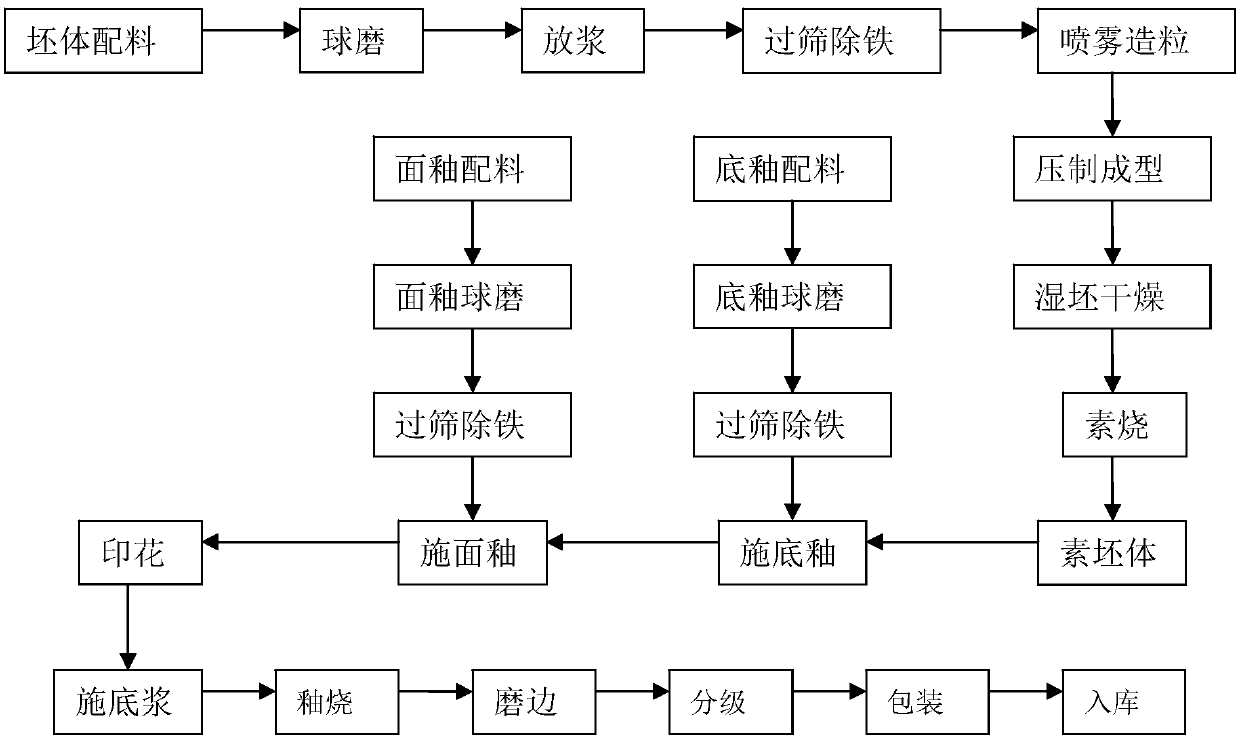

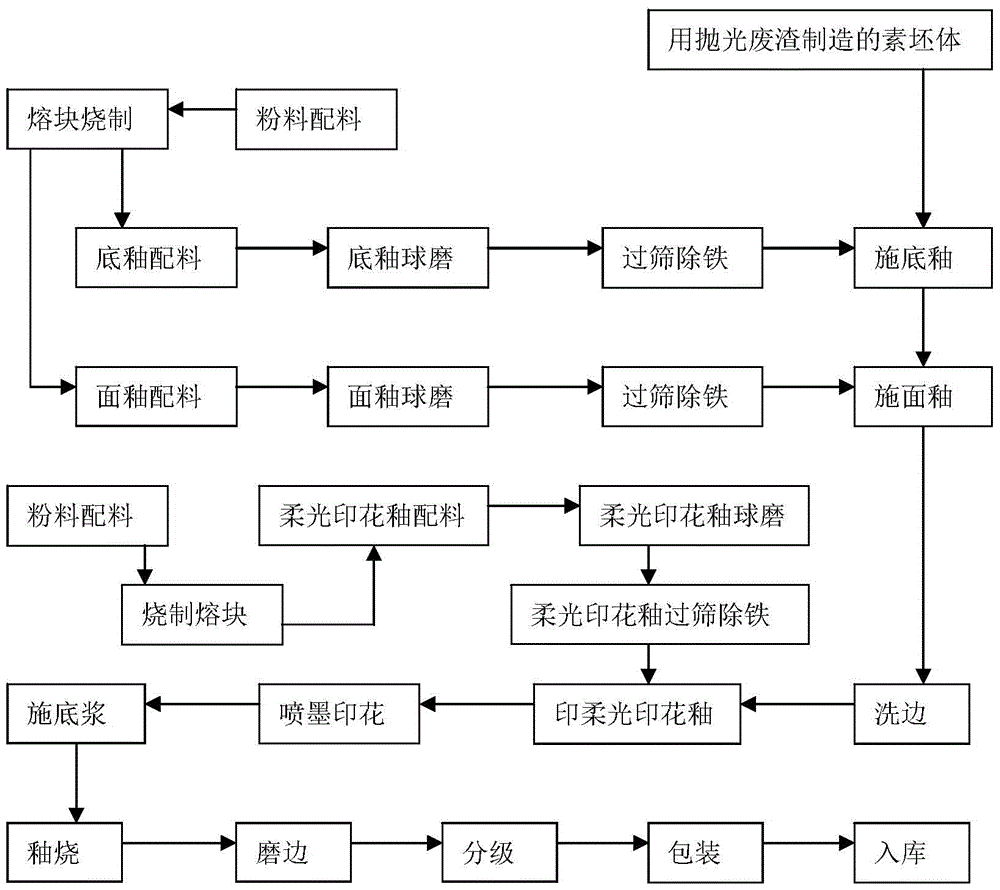

Matte background and glossy pattern glazed tile manufactured by using polished slag and preparation method of matte background and glossy pattern glazed tile

A prepared matte background and glossy pattern glazed tile product is enabled to have a surface with two special decorative effects, i.e., soft matte and highlight mirror-like effects, at the same time critically by virtue of optimization of types of biscuits, optimization of composition of a ground coat frit and a surface coat frit, optimization of composition of a ground coat and a surface coat, optimization of composition of a matte printing glaze frit, optimization of composition of matte printing glaze, adjustment and optimization of a pattern printing process and optimization of number of screen printing plates of the matte printing glaze and carving modes of an offset print roll on the basis of not significantly changing a conventional glazed tile production process. With organic combination with pattern design, the patterns at the soft matte parts and the highlight mirror-like parts of the tile are enabled to represent two different visual decorative effects at the same time. The difference of glossiness measured at the soft matte parts and the highlight mirror-like parts by using a WGG60-E4 gloss meter is greater than or equal to 50, so that the tile has a very unique visual effect and is strong in integral art aesthetic feeling. At the same time, the technology disclosed by the invention is good in universality and is easy to popularize in the industry.

Owner:GUANGDONG HONGHAI CERAMIC IND DEV +3

Preparation method of intermediate-temperature magnesium strengthening porcelain and product prepared from intermediate-temperature magnesium strengthening porcelain

The invention relates to a preparation method of an intermediate-temperature magnesium strengthening porcelain and a product prepared from the intermediate-temperature magnesium strengthening porcelain. The formula of the strengthening porcelain comprises the following billet materials and glaze materials by weight percent: the billet materials: 30% to 45% of sintered talc, 20% to 35% of raw talc, 5% to 15% of feldspar, 10% to 18% of kaolin, 3% to 5% of bentonite and 0% to 15% of quartz; the glaze materials: 20% to 40% of feldspar, 5% to 15% of calcite, 4% to 8% of kaolin, 0% to 15% of quartz, 3% to 5% of ZnO, 3% to 5% of BaCO and 20% to 35% of glass materials. The preparation method comprises the following steps: carrying preparation, molding, drying, billet biscuiting, glazing, drying and intermediate-temperature glaze firing on the billet materials and the glaze materials under the conditions that the biscuiting temperature of a billet is controlled within 1240 DEG C to 1260 DEG C, the heat preservation time of the billet is 30 minutes, the firing time of an intermediate-temperature glaze is 1100 DEG C and the firing time of the intermediate-temperature glaze is 30 minutes, thereby obtaining the strengthening porcelain with a good glaze surface quality and a high glossiness. Thus, the method has a wide application prospect.

Owner:JIANGXI GALOBAL CERAMIC CO LTD

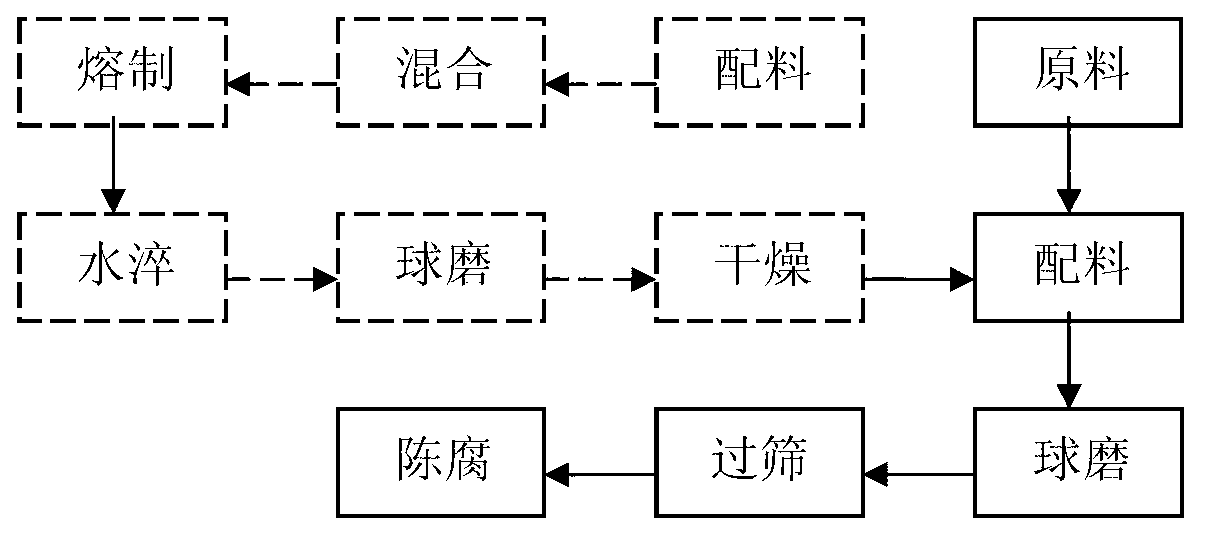

Method for preparing iron tailing into ceramic frit glaze

Provided is a method for preparing iron tailing into ceramic frit glaze. The method for preparing iron tailing into ceramic frit glaze regards iron tailing as raw materials, is free of adding other ceramic pigment or, colorant except for iron, and prepares ceramic frit glaze which is abundant in color and good in effect. The method for preparing iron tailing into ceramic frit glaze explores a novel path for iron tailing resources with high technology and high added value. The dosage of the iron tailing in the ceramic frit glaze is large, and the iron tailing is in integral utilization. The method for preparing iron tailing into ceramic frit glaze utilizes affluent iron and other microelements in the iron tailing to tint for glaze, replaces the expensive ceramic pigments, greatly lowers the cost of the ceramic frit glaze, selects and provides novel direction for ceramic frit glaze raw materials and the ceramic pigments, and lowers the dependent degree to high quality non-metal mineral resources compared with the current ceramic glaze production. The iron tailing and parts of the raw materials are initially melted to frits to use, so that firing temperature range of the glaze is expanded, and ceramic glaze surface quality is improved. A series of unfavorable influences to the preparation process in the process of applying the iron tailing in a ceramic green body are overcome. The method for preparing iron tailing into ceramic frit glaze has the advantages of being simple in process, optimum in glaze quality, and applicable to industrialized mass production.

Owner:UNIV OF SCI & TECH BEIJING +2

Method for manufacturing anti-slip glazed tile

The invention relates to a method for manufacturing an anti-slip glazed tile, which comprises the following steps: step1) printing; selecting a dried ceramic green body, printing on the surface of the ceramic green body to form a printing layer; Step2) coating high temperature transparent frit; coating the high temperature transparent frit particles with particle size of less than or equal to 20 meshes on the surface of the printed green body in the step1); step3)roasting in kiln; roasting the green body of the high temperature transparent frit particles coated in the step2) under the roller-way kiln oxidation atmosphere, wherein the roasting temperature is 1150-1230 DEG C and the roasting period is 80-120 minutes; and step4) edge rounding grinding; after cooling the roasted green body in the step 3), rounding and grinding edge to obtain the anti-slip glazed tile finished product. Compared with the prior art, the anti-slip glazed tile has anti-slip projection on the surface, the friction area is larger, the anti-slip effect is good, the glaze quality is good, and the anti-slip glazed tile has no influence to decorative effect on the printing layer.

Owner:广东金牌陶瓷有限公司

Flambe furry tiger skin fancy glaze, ceramic product and preparation method thereof

The invention relates to the technical field of ceramics and particularly relates to a flambe furry tiger skin fancy glaze, a ceramic product and a preparation method thereof. The flambe furry tiger skin fancy glaze includes the following raw materials: feldspar, quartz, Suzhou earth, titanium oxide, glass powder, calcite, boron frit, strontium carbonate, nickel oxide, chromium titanium antimony yellow, cerium praseodymium yellow, tin oxide, and neodymium oxide. A biscuited ceramic green body is applied by the flambe furry tiger skin fancy glaze in a soak-glazing manner, and when the glaze is dried, the ceramic green body is subjected to glaze firing. The prepared glaze slurry has good process performances and allows glaze application in a one-time soak-glazing manner. The fired glaze surface has good quality. A fired bottle has a smooth and flat surface and has no defects.

Owner:江苏省宜兴彩陶工艺厂

Magnesia porcelain and preparation method thereof

The invention discloses a magnesia porcelain and a preparation method thereof. The magnesia porcelain is prepared by using a billet material and a glaze material, wherein the billet material comprisesthe following components in percentage by weight: 30-45% of burnt talc, 20-35% of raw talc, 5-15% of feldspar, 10-18% of kaolin, 3-5% of bentonite and 0-15% of quartz, and the sum of the weight percentages of the components is 100%; and the glaze material comprises the following components in percentage by weight: 20-40% of feldspar, 5-15% of calcite, 4-8% of kaolin, 0-15% of quartz, 3-5% ZnO, 0-5% of BaCO3 and 20-35% of glass frit, and the sum of the weight percentages of the components is 100%. According to the magnesia porcelain, the quality of the glaze surface is good, the glossiness ishigh, the raw material cost is low, and the production process is simple.

Owner:HUNAN KARPERY INDAL

High-glossiness reinforced magnesia porcelain and preparation method thereof

The invention discloses a strengthened magnesia porcelain with high gloss and a preparation method thereof. The strengthened magnesia porcelain is composed of the following raw materials according to mass percentage: 60-70% of talc, 10-15% of Chaozhou bentonite, and 8-8% of Longyan kaolin 10%, quartz 2‑6%, potassium feldspar 5‑12%. Grind talc, Chaozhou bentonite, Longyan kaolin, quartz, and potassium feldspar respectively, pass through a 200‑400 mesh sieve, weigh them according to the mass percentage, and then form, dry, and fire to obtain strengthened magnesia porcelain. The firing temperature range is 1250-1300°C, the holding time is 0.5-8h. The invention adopts natural mineral raw materials, and through repeated batching tests, the raw materials in the magnesia green body are well matched, and the strengthened magnesia porcelain products with good glaze quality and high gloss are produced, and the performances of the reinforced magnesia porcelain products reach GB / T3532‑1995 According to the standard requirements, the whiteness of its products is above 86 degrees, and the edge impact strength is 0.693J / cm 2 . Thermal shock resistance: 180‑20°C without cracking once. It effectively eliminates the pinholes in the glaze and improves the brightness of the glaze, so it has a broad market prospect.

Owner:DEHUA HENGHAN ARTS

Special luminous pearlescent pigment for ceramic firing

The invention discloses a special luminous pearlescent pigment for ceramic firing. The pigment is characterized in that the pigment comprises a sheet substrate, the substrate is coated with a high-refractive-index coat, and the high-refractive-index coat is coated with a layer of a coloring agent to form a metal oxide composite coat. The coloring agent is ferric oxide. The sheet substrate is synthetic mica composed of a long-afterglow luminous material and a base flux. The special luminous pearlescent pigment is optically variable, and has the advantages of good brightness and color saturation, high brightness, intelligible pattern, color variety, excellent glaze quality, strong mechanical performances, and high chemical stability; and the coating of the inorganic metal oxide-ferric oxide makes the pigment have a high stability and not fade under high temperature firing conditions.

Owner:许志永

Method for preparing iron tailing into ceramic frit glaze

Provided is a method for preparing iron tailing into ceramic frit glaze. The method for preparing iron tailing into ceramic frit glaze regards iron tailing as raw materials, is free of adding other ceramic pigment or, colorant except for iron, and prepares ceramic frit glaze which is abundant in color and good in effect. The method for preparing iron tailing into ceramic frit glaze explores a novel path for iron tailing resources with high technology and high added value. The dosage of the iron tailing in the ceramic frit glaze is large, and the iron tailing is in integral utilization. The method for preparing iron tailing into ceramic frit glaze utilizes affluent iron and other microelements in the iron tailing to tint for glaze, replaces the expensive ceramic pigments, greatly lowers the cost of the ceramic frit glaze, selects and provides novel direction for ceramic frit glaze raw materials and the ceramic pigments, and lowers the dependent degree to high quality non-metal mineral resources compared with the current ceramic glaze production. The iron tailing and parts of the raw materials are initially melted to frits to use, so that firing temperature range of the glaze is expanded, and ceramic glaze surface quality is improved. A series of unfavorable influences to the preparation process in the process of applying the iron tailing in a ceramic green body are overcome. The method for preparing iron tailing into ceramic frit glaze has the advantages of being simple in process, optimum in glaze quality, and applicable to industrialized mass production.

Owner:UNIV OF SCI & TECH BEIJING +2

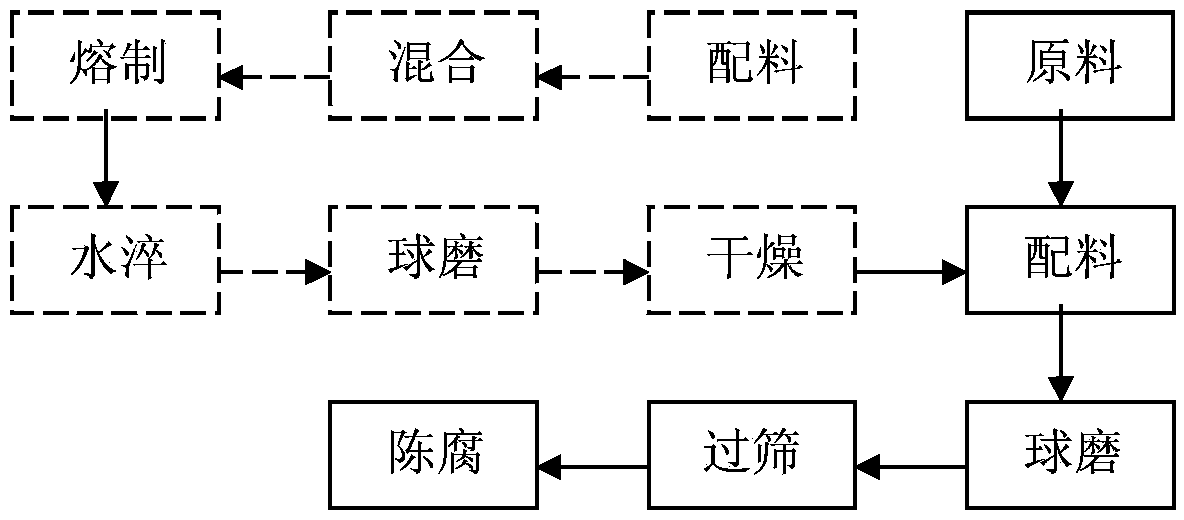

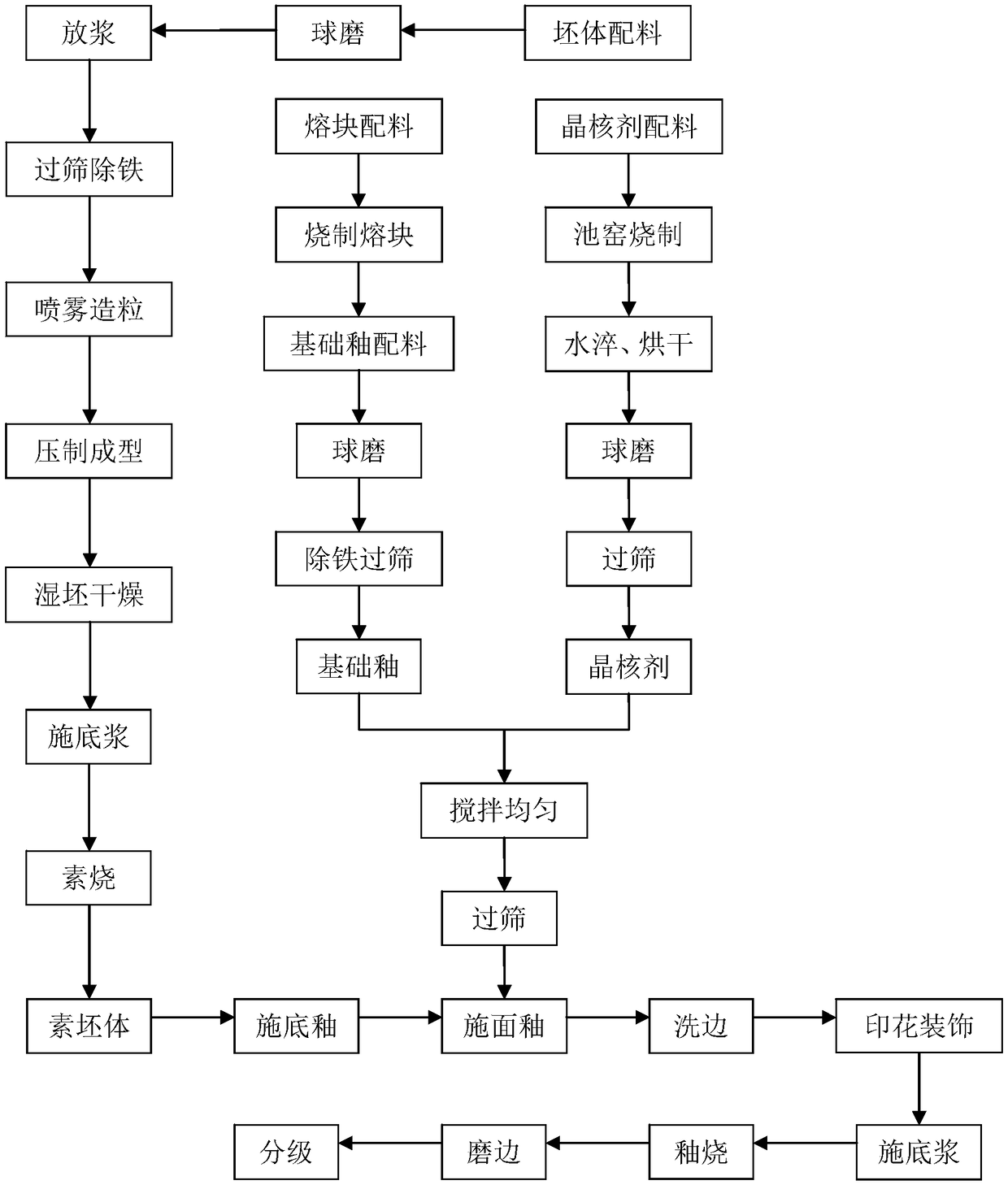

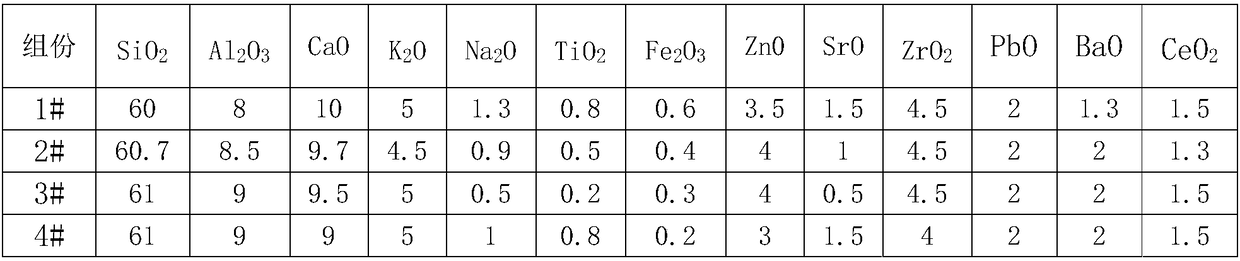

Crystalline glazed tile capable of durably producing negative ions and preparation method thereof

The invention provides a crystalline glazed tile capable of durably producing negative ions and a preparation method thereof. In the invention, without significant change on a production process of glazed tiles in the prior art, the method mainly pays attention to formulas and compositions of a frit, a basic glaze, a nucleation agent and a surface glaze, fineness of the basic glaze and the nucleation agent, and optimization on a sintering process and the like, so that a large number of silver crystals, in the size of a rice grain, are formed on the surface of the glaze tiles, wherein the crystals emit a bright silver light under irradiation by oblique light or lamp light, while the glaze base surrounding the crystals are matte, so that the whole tile looks like a starry night. In addition,there are a plurality of photo-catalytic semiconductor microcrystalline mineral, which cannot be seen by naked eyes, such as SrTiO3 and CaO.TiO2, in the surface glaze, wherein the minerals can be reacted with oxygen in air to generate oxygen negative ions durably, quantity of the inductively generated negative ions in air reaching 538 / s*cm<2>. The product is a decorative material which integratesdecorative and artistic properties and health-functional effects.

Owner:GUANGDONG WINTO CERAMICS +3

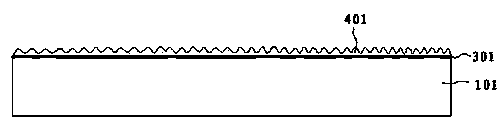

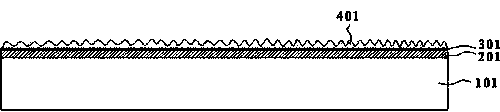

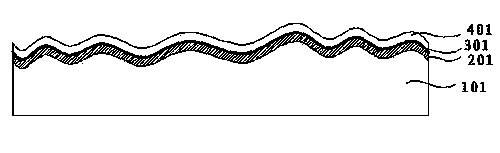

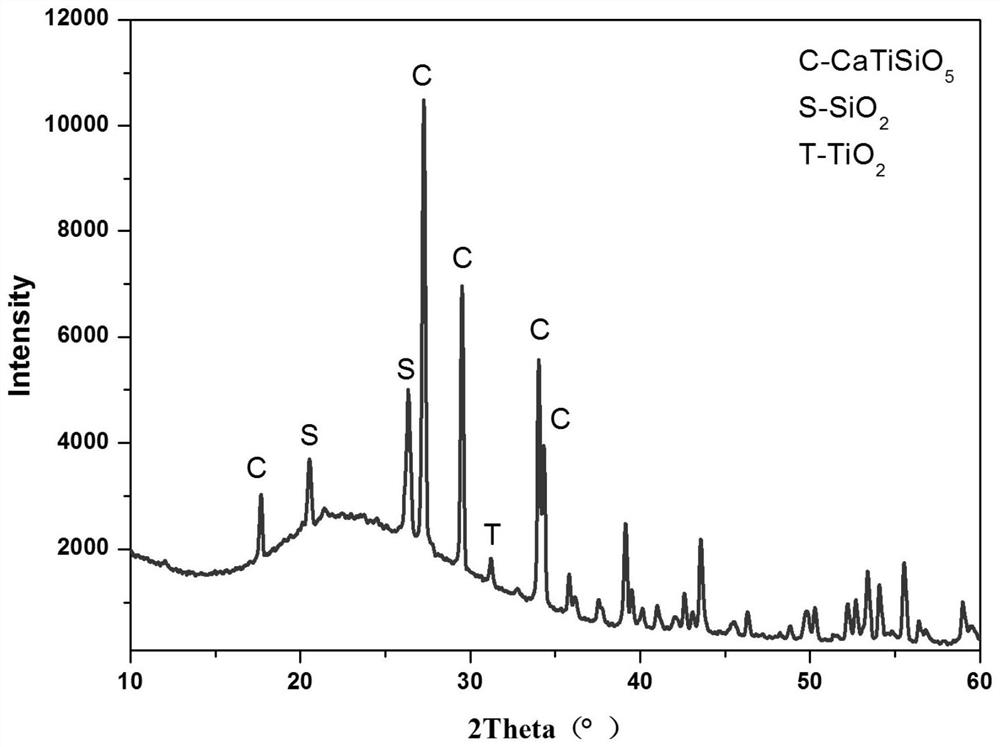

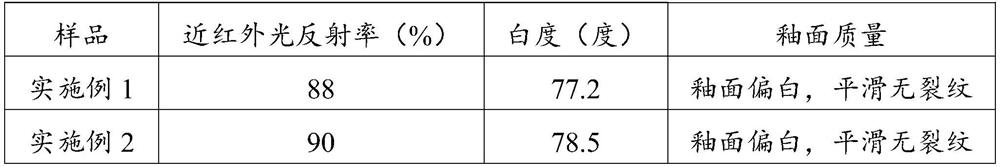

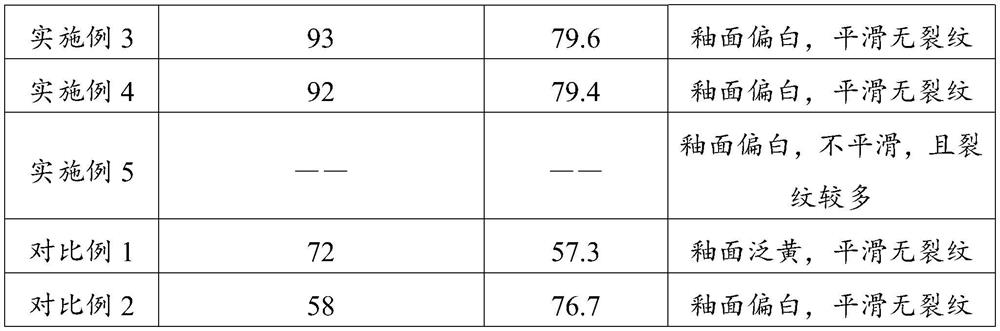

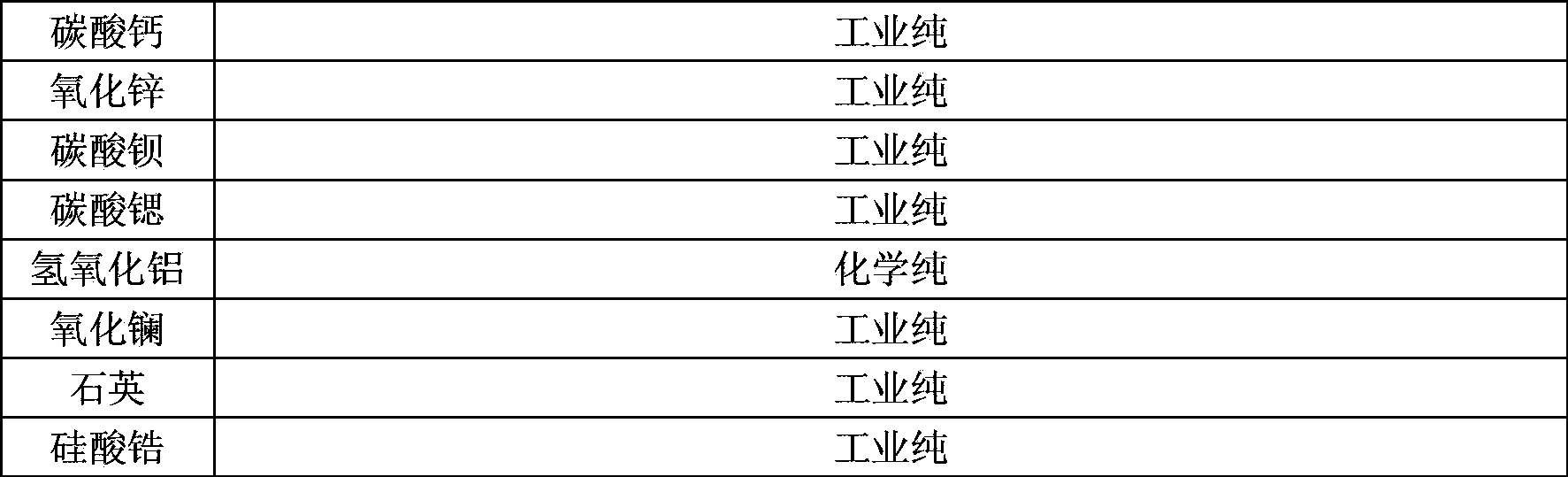

Ceramic glaze with infrared reflection, light glazed exterior wall tile and preparation method of light glazed exterior wall tile

PendingCN114249534ALower firing temperatureAchieve high near-infrared light reflection functionIr reflectionFrit

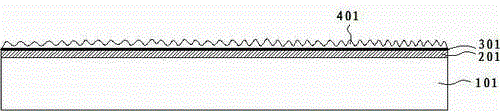

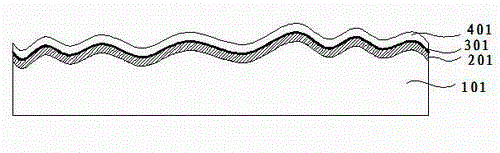

The invention belongs to the technical field of architectural ceramics, and particularly discloses a ceramic glaze with infrared reflection, a light glazed exterior wall tile and a preparation method of the light glazed exterior wall tile. The ceramic glaze contains calcite, quartz, titanium dioxide and titanite frit, and the titanite frit is prepared from the following raw materials: calcite, titanium dioxide, quartz and wollastonite; the light glazed exterior wall tile comprises a light green body layer, a sealing cover glaze layer, a near-infrared reflecting glaze layer and a transparent protective glaze layer from bottom to top, wherein the near-infrared reflecting glaze layer is formed by firing ceramic glaze. Ceramic glaze with a near-infrared light reflection function is applied to the light glazed exterior wall tile, a tile body is endowed with good near-infrared light reflection performance, meanwhile, the sealing cover glaze layer is added between the light green body layer and the near-infrared reflection glaze layer, gas generated by a high-temperature reaction in the light green body layer can be effectively sealed under the glaze layer, and the light glazed exterior wall tile has the good near-infrared light reflection performance. The defects of glaze pinholes, glaze cracks and the like are prevented, and the function of the near-infrared reflection glaze layer and the surface quality of the transparent protection glaze layer are guaranteed.

Owner:FOSHAN OCEANO CERAMICS

High-temperature high-grade magnesia porcelain preparation method

The invention relates to a high-temperature high-grade magnesia porcelain preparation method, wherein the billet material comprises, by weight, 30-45% of burned talc, 20-35% of raw talc, 5-15% of feldspar, 10-18% of kaolin, 3-5% of bentonite, and 0-15% of quartz, and the glaze material comprises, by weight, 20-40% of feldspar, 5-15% of calcite, 4-8% of kaolin, 0-15% of quartz, 3-5% of ZnO, 0-5% ofBaCO3, and 20-35% of frit. According to the preparation method, billet material and glaze material preparation, molding, drying, biscuit firing of billet body, glazing, drying, and medium temperatureglaze burning to obtain the product, wherein the biscuit firing temperature is 1280-1300 DEGC, the thermal insulation is 30 min, the medium temperature glaze burning temperature is 1200 DEGC, and thethermal insulation is 30 min. According to the present invention, with the preparation method, the product with advantages of good glaze surface quality and high glossiness is obtained so as to achieve broad application prospects.

Owner:叶剑

Porcelain body glaze repairing method

The invention relates to the high voltage electrical porcelain production technology field, specifically relating to a porcelain body glaze repairing method which comprises the following steps: a. mixing two parts of resin type electrical porcelain repairing agents, one part of curing type electrical porcelain repairing agent and pigment to prepare a repairing mixture; b. cleaning a place to be repaired with acetone, and drying the place with a blower; c. diluting the repairing mixture with acetone to a degree that a mixed solution of the repairing mixture and the acetone can pass through a filter screen of 50-70 meshes, then allowing the mixed solution to pass through a filter screen of 50 meshes, adding the mixed solution into a spray gun after filtering, and using the spray gun to spray the mixed solution on the place to be repaired. Preferably, a step d of drying a spraying position with a hot air blower is provided after the step c. Preferably, high pressure gas used in the spray gun in the step c is oxygen, nitrogen or acetylene, and the porcelain body glaze repairing method has the advantages of good quality and flattening of glaze repairing, a larger repairing area of unit repairing agent and raw material saving.

Owner:HENAN DEXIN ELECTROCERAMICS

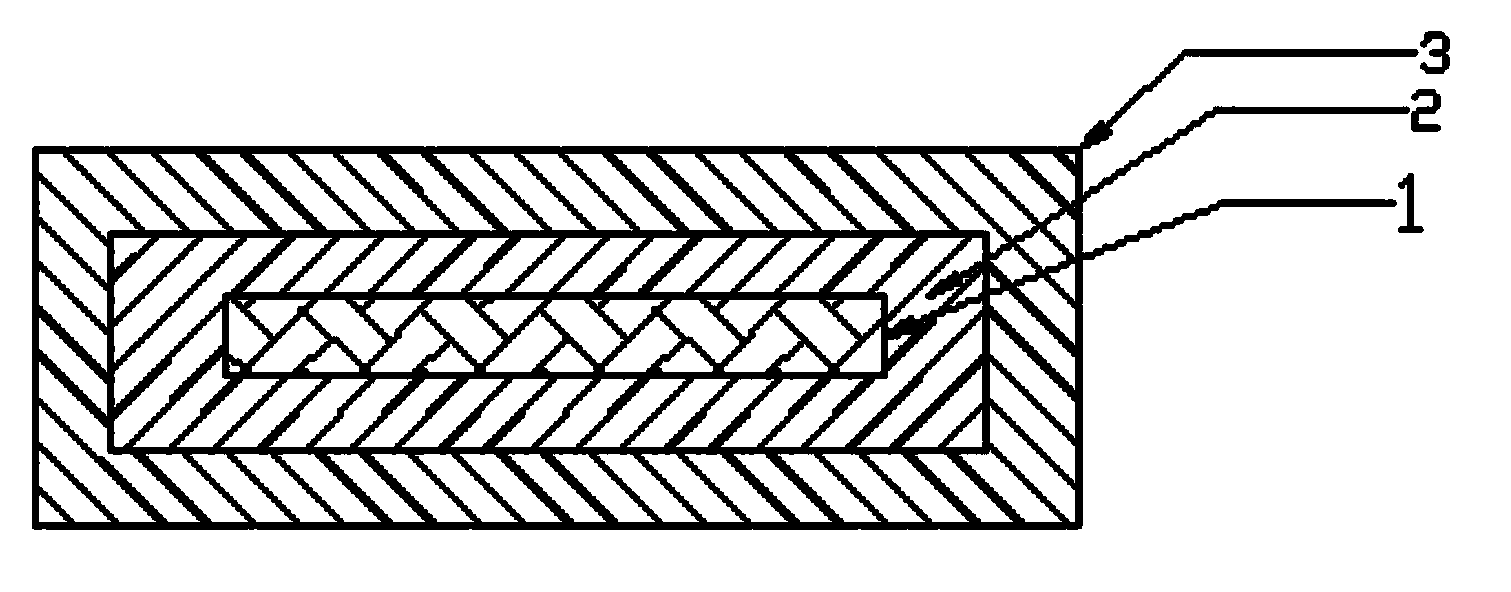

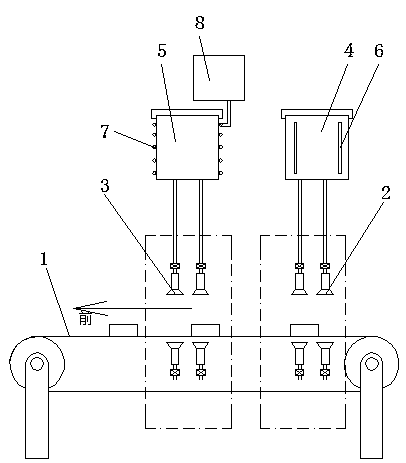

Secondary glaze spraying device for ceramic body

InactiveCN108858705APrevent thinningGood quality glazeCeramic shaping apparatusMaterials scienceCeramic glaze

The invention relates to the equipment applied to the field of ceramic production and provides a secondary glaze spraying device for a ceramic body. The secondary glaze spraying device comprises a conveying belt; a plurality of groups of glaze sprayers are installed at the middle of the conveying belt from back to front according to the running direction of the ceramic body; the plurality of groups of glaze sprayers can be used for spraying glaze to the ceramic body; each glaze sprayer is connected with a glaze slip groove through a pipeline; the secondary glaze spraying device is characterized in that the plurality of groups of glaze sprayers sequentially include a first group of glaze sprayers and a second group of glaze sprayers from back to front; the first group of glaze sprayers areconnected with the first glaze slip groove through pipelines; the second group of glaze sprayers are connected with a second glaze slip groove through pipelines; the side surface or the inner surfaceof the first glaze slip groove is provided with a heating component; the heating component can be used for heating glaze slip inside the first glaze slip groove; thus, the secondary glaze spraying device for the ceramic body has the advantages that a formed glaze surface is relatively large in thickness and good in quality.

Owner:长葛市金福祥金属材料有限公司

Preparation method of jade-green Jinxing chestnut tea transmutation glaze ceramic container

InactiveCN112409023AThe changing glaze formula is unique and novelGood glaze performanceGlazeComposite material

The invention relates to a preparation method of a jade-green Jinxing chestnut tea transmutation glaze ceramic container. The preparation method comprises the following steps: (1) preparing a blank; (2) biscuiting; (3) preparing glaze; (4) glazing; (5) glaze firing; (6) inspecting. The glaze is unique in color and texture, good in finished product quality and integrally environment-friendly and safe.

Owner:江苏省宜兴彩陶工艺厂

Low-temperature high-grade magnesia porcelain preparation method

The invention relates to a low-temperature high-grade magnesia porcelain preparation method, wherein the billet material comprises, by weight, 32% of burned talc, 26% of raw talc, 10% of feldspar, 15%of kaolin, 4% of bentonite, 10% of quartz, and 3% of calcium carbonate, and the glaze material comprises, by weight, 24% of feldspar, 14% of calcite, 6% of kaolin, 14% of quartz, 3% of ZnO, 4% of BaCO3, 25% of frit, and 5% of strontium oxide. According to the preparation method, billet material and glaze material preparation, molding, drying, biscuit firing of billet body, glazing, drying, and medium temperature glaze burning to obtain the product, wherein the biscuit firing temperature is 1120-1180 DEGC, the thermal insulation is 30 min, the medium temperature glaze burning temperature is 1100 DEGC, and the thermal insulation is 30 min. According to the present invention, with the preparation method, the product with advantages of good glaze surface quality and high glossiness is obtained so as to achieve broad application prospects.

Owner:王必胜

Microcrystal-reinforced transparent leadless fritted glaze and preparation method thereof

The invention discloses a microcrystal-reinforced transparent leadless fritted glaze and a preparation method thereof, belonging to the field of ceramic glaze processing. The microcrystal-reinforced transparent leadless fritted glaze, prepared by the invention, comprises the chemical components in percentage by weight: 45.0-55.0% of SiO2, 5.0-7.0% of Al2O3, 0.1-0.2% of Fe2O3, 2.0-11.0% of CaO, 1.0-1.5% of MgO, 2.0-4.0% of K2O, 0.5-2.0% of Na2O, 0-3.0% of Li2O, 7.0-9.0% of ZnO, 3.0-5.0% of BaO, 2.0-2.6% of SrO, 5.0-10.0% of B2O3, 3.0-6.0% of ZrO2, and 0-1.0% of La2O3. The lead element in the fritted glaze is replaced with a composite solvent of alkali metal, alkaline-earth metal and a small amount of rare earth elements, the lead release is zero, thus the damage of the lead element in high-grade household porcelains represented by fine-bone china to a human body is thoroughly eliminated; and the prepared product is good in glaze glossiness and thermal stability, and high in transparency.

Owner:SHAANXI UNIV OF SCI & TECH

Method for manufacturing anti-slip glazed tile

The invention relates to a method for manufacturing an anti-slip glazed tile, which comprises the following steps: step1) printing; selecting a dried ceramic green body, printing on the surface of the ceramic green body to form a printing layer; Step2) coating high temperature transparent frit; coating the high temperature transparent frit particles with particle size of less than or equal to 20 meshes on the surface of the printed green body in the step1); step3)roasting in kiln; roasting the green body of the high temperature transparent frit particles coated in the step2) under the roller-way kiln oxidation atmosphere, wherein the roasting temperature is 1150-1230 DEG C and the roasting period is 80-120 minutes; and step4) edge rounding grinding; after cooling the roasted green body in the step 3), rounding and grinding edge to obtain the anti-slip glazed tile finished product. Compared with the prior art, the anti-slip glazed tile has anti-slip projection on the surface, the friction area is larger, the anti-slip effect is good, the glaze quality is good, and the anti-slip glazed tile has no influence to decorative effect on the printing layer.

Owner:广东金牌陶瓷有限公司

A kind of antibacterial glaze and its preparation method and application

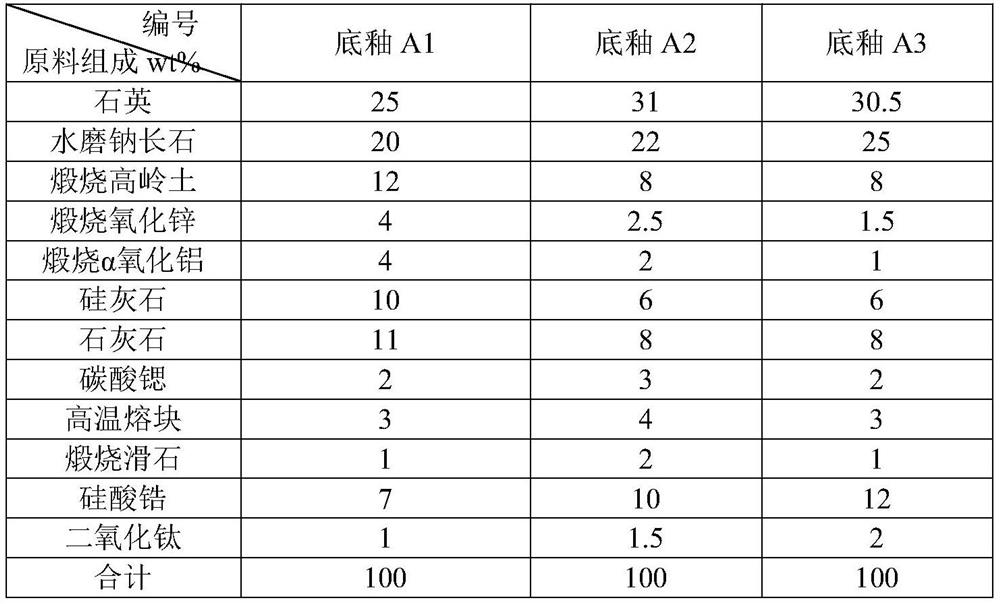

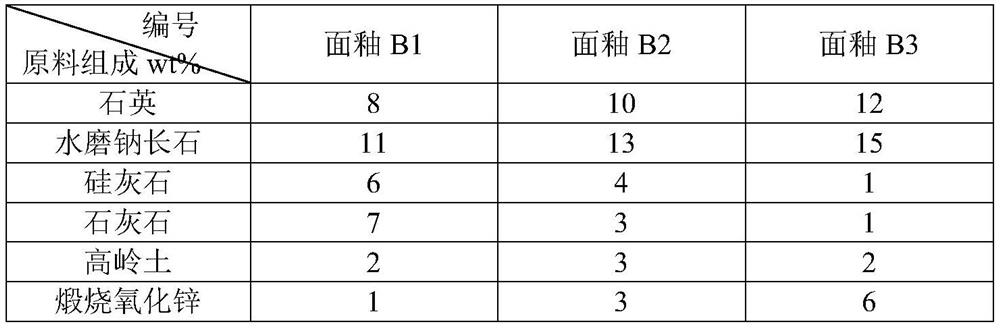

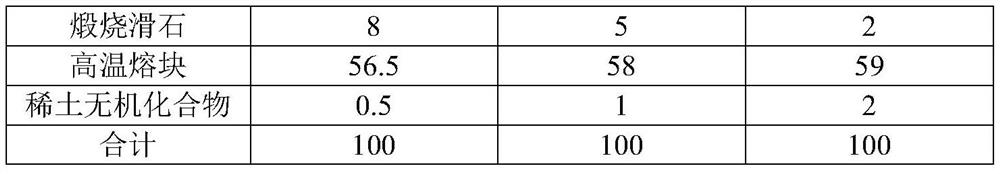

The invention discloses an antibacterial glaze, which is composed of a bottom glaze and a surface glaze; the composition of the bottom glaze is 7-12wt% of zirconium silicate, 1-2wt% of titanium dioxide, and the balance is the basic bottom glaze; The composition of the glaze is 0.5-2wt% of rare earth inorganic compound and the rest is basic surface glaze. The rare earth inorganic compound contains titanium dioxide with a content of ≥16wt% and thorium dioxide with a content of ≥15wt%. In addition, the preparation method and application of the antibacterial glaze are also disclosed. The invention obtains a glaze layer capable of radiating far-infrared rays through formula design, so that the sanitary ceramic products have antibacterial and antibacterial effects, thereby effectively improving the antibacterial effect of the antibacterial sanitary ceramics, and better solving the problems of environment optimization and purification.

Owner:JINGDEZHEN CERAMIC UNIV

A kind of preparation method of medium-temperature magnesia strengthened porcelain and its prepared product

The invention relates to a preparation method of an intermediate-temperature magnesium strengthening porcelain and a product prepared from the intermediate-temperature magnesium strengthening porcelain. The formula of the strengthening porcelain comprises the following billet materials and glaze materials by weight percent: the billet materials: 30% to 45% of sintered talc, 20% to 35% of raw talc, 5% to 15% of feldspar, 10% to 18% of kaolin, 3% to 5% of bentonite and 0% to 15% of quartz; the glaze materials: 20% to 40% of feldspar, 5% to 15% of calcite, 4% to 8% of kaolin, 0% to 15% of quartz, 3% to 5% of ZnO, 3% to 5% of BaCO and 20% to 35% of glass materials. The preparation method comprises the following steps: carrying preparation, molding, drying, billet biscuiting, glazing, drying and intermediate-temperature glaze firing on the billet materials and the glaze materials under the conditions that the biscuiting temperature of a billet is controlled within 1240 DEG C to 1260 DEG C, the heat preservation time of the billet is 30 minutes, the firing time of an intermediate-temperature glaze is 1100 DEG C and the firing time of the intermediate-temperature glaze is 30 minutes, thereby obtaining the strengthening porcelain with a good glaze surface quality and a high glossiness. Thus, the method has a wide application prospect.

Owner:JIANGXI GALOBAL CERAMIC CO LTD

Resource-saving glazed ceramic tile with anti-skid effect on surface and preparation method thereof

ActiveCN105837172BAchieve anti-slip effectGood quality glazeCeramic materials productionClaywaresBrickSludge

A resource-saving glazed ceramic tile having an antiskid effect on surface and a preparation method thereof. Without great change on production process of the glazed ceramic tiles, formula composition of a blank body, composition of ground and cover glaze frits and formula composition of ground and cover glaze are regulated and optimized focusedly, so that the glazed ceramic tile, which has excellent performance and the antiskid effect, can be prepared even large quantity sludge residue is added to the blank body. Through a high-magnification scanning electronic microscopy for observing the surface of glaze on the product, it is found that projects which are hard and needle-like and look like aluminum spinel crystal are formed on the surface, and the glaze is 0.8 in antiskid coefficient and is R12 in antiskid level when a less quantity of water is sprayed on the glaze. The glazed ceramic tile has good antiskid effect, can reach 4000 r / four grade in wear-resisting revolution through detection, and has good anti-wear performance, surface anti-fouling performance and water permeation resistance. The glaze has no defects such as needle pores, bubbles and the like, has clear decorative pattern grains and is highly stone-simulated. The technology has strong adaptability and is easy to promote in the field.

Owner:GUANGDONG WINTO CERAMICS +3

Low-temperature-fired jade-like lemon yellow glaze and preparation method of ceramic container of low-temperature-fired jade-like lemon yellow glaze

The invention relates to a low-temperature-fired jade-like lemon yellow glaze and a preparation method of a ceramic container of the low-temperature-fired jade-like lemon yellow glaze. The glaze is prepared from (1) 65 to 72 parts of opacifying frit, (2) 18 to 22 parts of transparent frit, (3) 7 to 10 parts of Suzhou clay, (4) 1.5 to 1.8 parts of titanium yellow material and (5) 0.3 to 0.5 part of a wrapping yellow material. The method for preparing the ceramic container by using the glaze comprises the following steps: (1) adding the raw materials, balls and water into a ball mill according to a ratio of 1: 1.3: 1.3, conducting , taking a grinding product out of a cylinder, conducting sieving and attracting iron; and (2) applying the product obtained in the step (1) onto a green body having been subjected to high-temperature biscuit firing at 1200 DEG C by using a glaze dipping method, and carrying out firing by using oxidizing flame of a roller kiln. According to the invention, high-quality raw materials are selected, and a reasonable ceramic production method and a reasonable sintering process are adopted, so the product has the advantages of high transparency, high strength, high compactness, aging resistance, corrosion resistance, leakage resistance, good thermal stability, no cracking, no deformation and the like, and is free of the defects of pinholes, glaze shrinkage, orange glaze, blank bubbles and the like; and energy consumption and production cost are reduced, and large-batch production of ceramic products can be met.

Owner:江苏省宜兴彩陶工艺厂

Ceramic multi-effect heatproof glaze

The invention relates to the technical field of ceramic production, and specifically relates to a ceramic multi-effect heatproof glaze. The glaze is composed of the following components in percentage by weight: 5 to 40% of phosphorus pentoxide, 5 to 20% of sodium oxide, 10 to 30% of silicon dioxide, 5 to 10% of aluminum (III) trioxide, 20 to 30% of boron oxide, 5 to 20% of ferric oxide, 5 to 20% of manganese oxide, and 1 to 3% of mixing agent. The invention aims to provide a ceramic multi-effect heatproof glaze having the advantages of high stability and excellent quality.

Owner:陆伟明

Fine stoneware brick made from recovered ceramic solids and its preparation method

Owner:GUANGDONG HONGYU NEW MATERIALS CO LTD +3

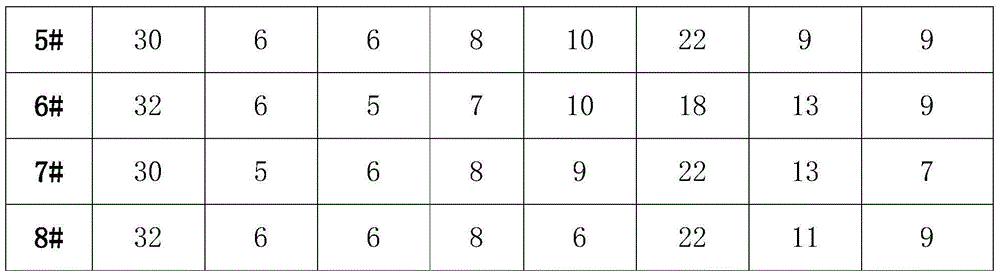

Soft mirror glazed tile made of polishing waste residue and preparation method thereof

A prepared matte background and glossy pattern glazed tile product is enabled to have a surface with two special decorative effects, i.e., soft matte and highlight mirror-like effects, at the same time critically by virtue of optimization of types of biscuits, optimization of composition of a ground coat frit and a surface coat frit, optimization of composition of a ground coat and a surface coat, optimization of composition of a matte printing glaze frit, optimization of composition of matte printing glaze, adjustment and optimization of a pattern printing process and optimization of number of screen printing plates of the matte printing glaze and carving modes of an offset print roll on the basis of not significantly changing a conventional glazed tile production process. With organic combination with pattern design, the patterns at the soft matte parts and the highlight mirror-like parts of the tile are enabled to represent two different visual decorative effects at the same time. The difference of glossiness measured at the soft matte parts and the highlight mirror-like parts by using a WGG60-E4 gloss meter is greater than or equal to 50, so that the tile has a very unique visual effect and is strong in integral art aesthetic feeling. At the same time, the technology disclosed by the invention is good in universality and is easy to popularize in the industry.

Owner:GUANGDONG HONGHAI CERAMIC IND DEV +3

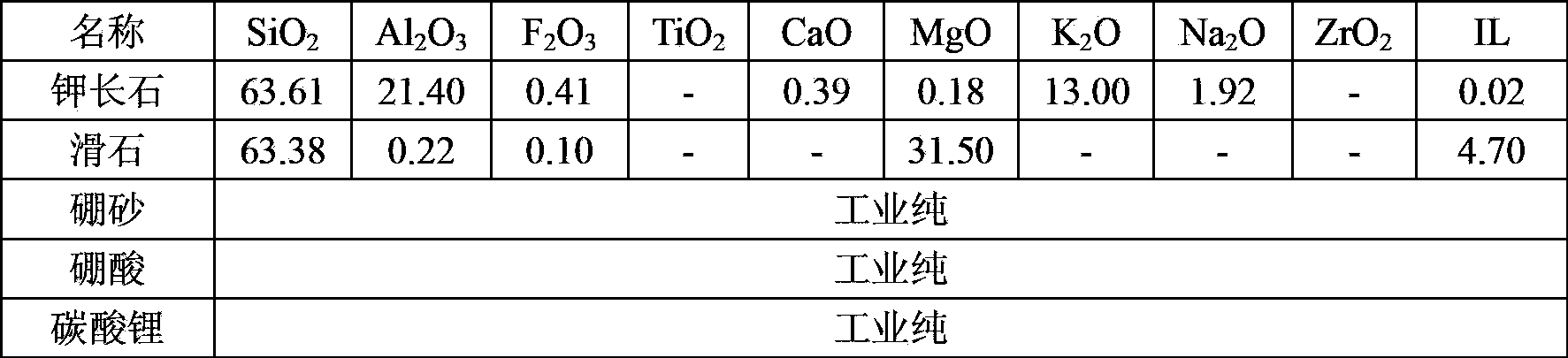

Medium and high temperature sintered coarse crystalline Fe-Ti glaze and its prepn process

The present invention is medium and high temperature sintered coarse crystalline Fe-Ti glaze and its preparation process. The coarse crystalline Fe-Ti glaze has TiO2 as crystallizing agent, stable crystal form with CaO, Fe2O3 and TiO2, good crystallizing effect even at high temperature and greatly lowered glaze material cost. The glaze material is prepared with feldspar 45 weight portions, quartz 15-20 weight portions, calcite 12-18 weight portions, titanium dioxide 5-8 weight portions, talcum 2-5 weight portions, iron red 5-10 weight portions and kaolin 5-10 weight portions, and through ball milling the material, sieving, adding water into the glaze slurry to 40-49 Be deg, sieving the glaze slurry, applying to biscuit, and sintering at 1250-1350 deg.c in a kiln.

Owner:HUNAN HUALIAN CHINA IND

Leadfree fritted glaze suitable for secondary sintering

The invention discloses a leadless fritted glaze, which comprises the following parts: 35.0-60.0%SiO2, 14.0-18.0%Al2O3, 3.0-10.0%CaO, 0.0-5.0%MgO, 5.0-10.0%K2O, 2.0-5.0%Na2O, 5.0-10.0%ZnO, 4.0-12.0%B2O3, 1.0-5.0%SrO, 0.0-1.0 %Li2O, 0.0-8.0%BaO and 5.0-9.0%ZrO2. The invention solves masking problem for magnesium ceramic glaze surface, which prevents environmental pollution due to overcoming to flow lead and cadmium.

Owner:淄博硅元投资控股有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com