Leadfree fritted glaze suitable for secondary sintering

A lead-free frit and secondary firing technology, applied in the field of improved lead-free frit glaze, can solve the problems of dullness, adaptability limitation, and many glaze defects, and achieve high yield, high strength and thermal stability. Effects of stability, good glaze quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

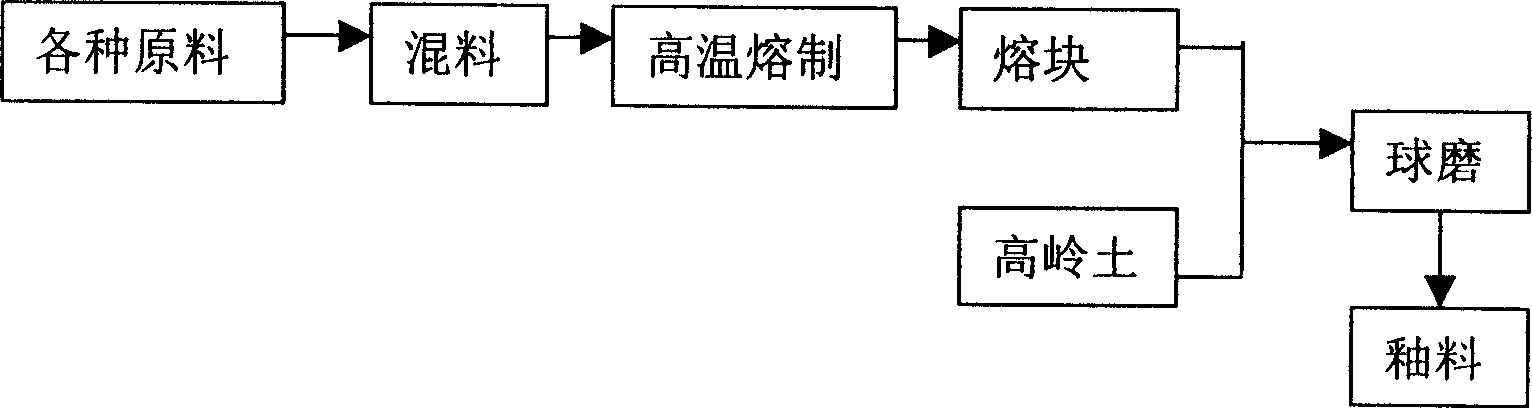

Method used

Image

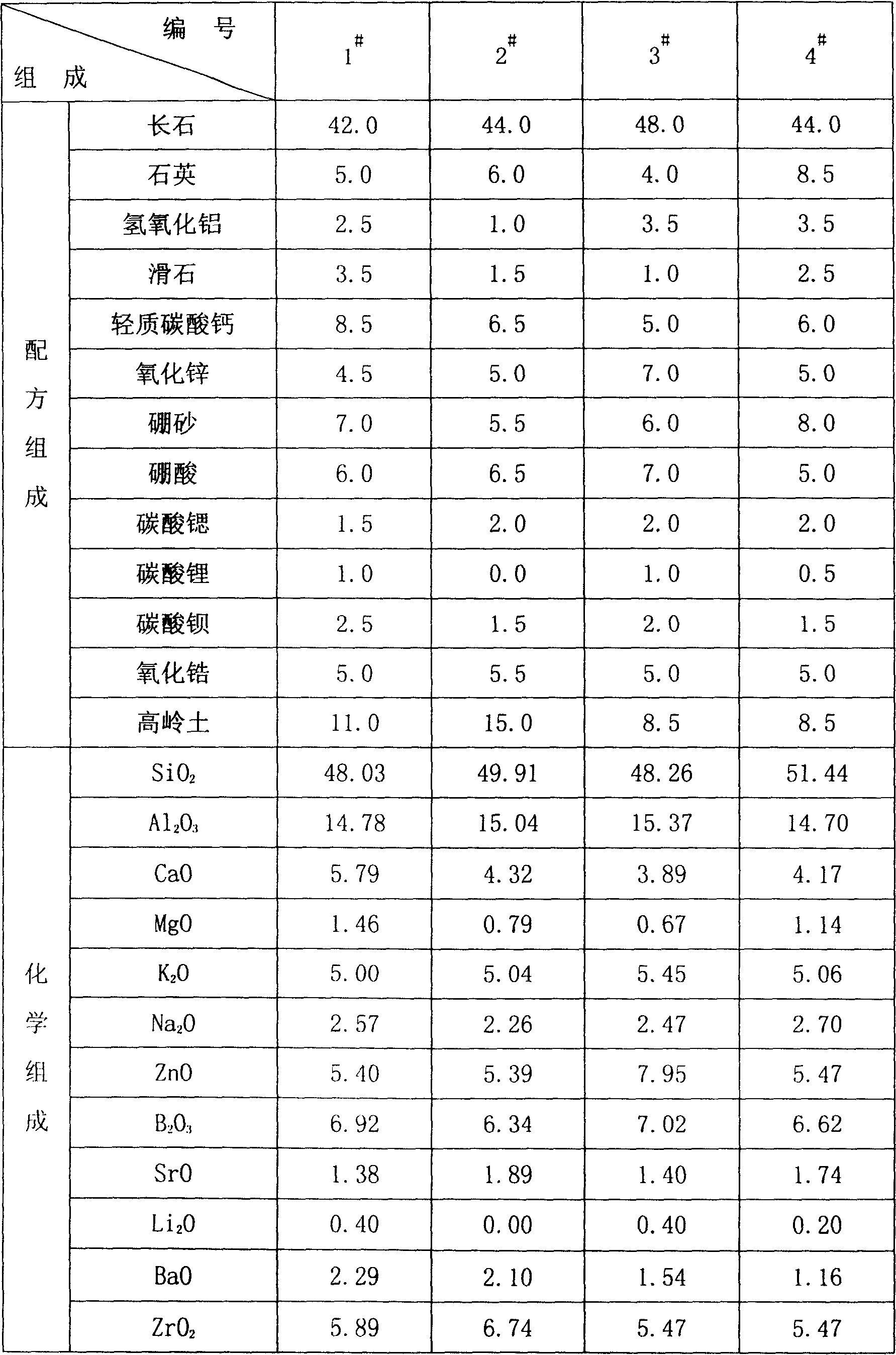

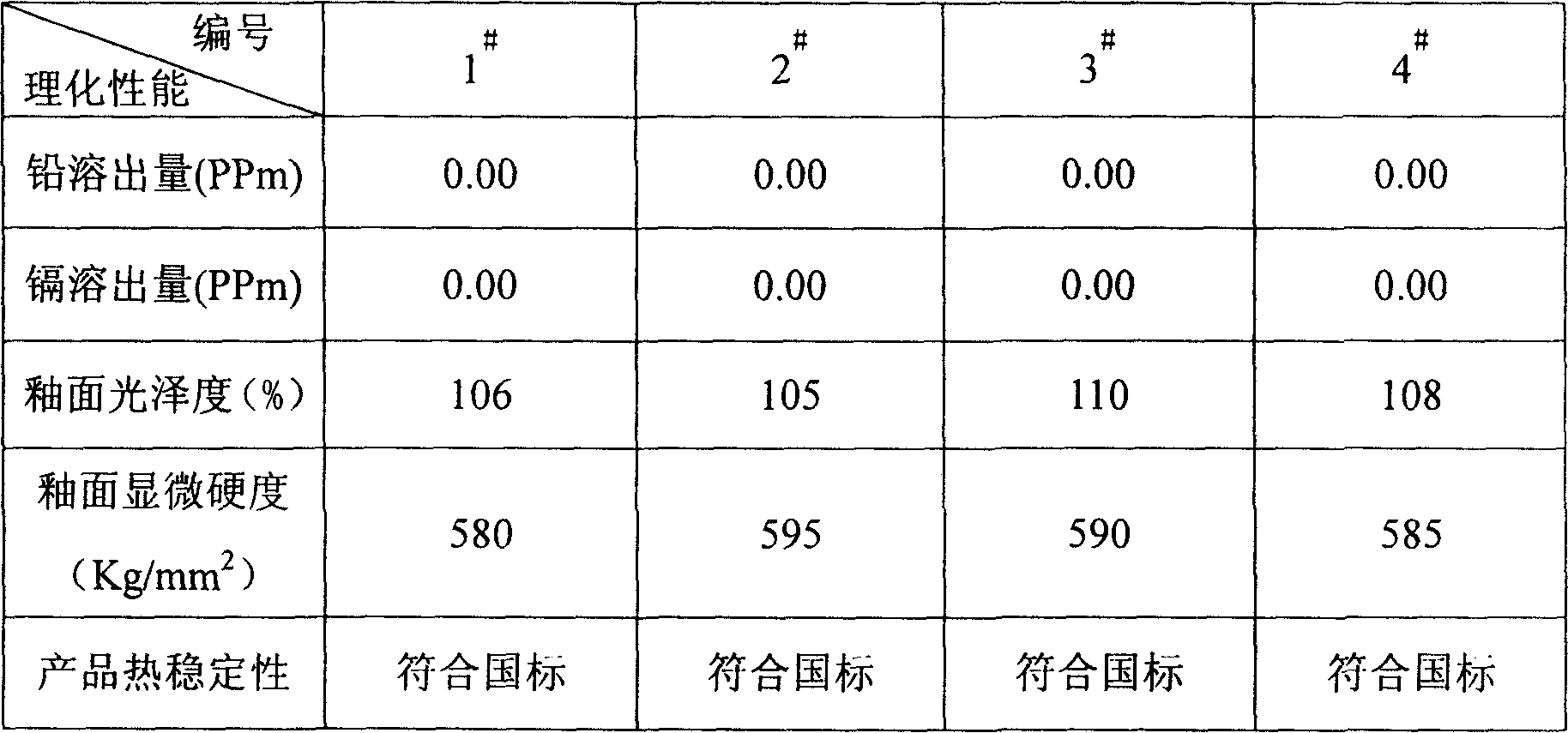

Examples

Embodiment 5

[0044] The present invention is applicable to the lead-free frit glaze that second firing is used, and the weight percentage of its batching raw material is composed of:

[0045] Feldspar 35.5%, Quartz 15.0%, Talc 3.5%, Light Calcium Carbonate 6.0%, Zinc Oxide 3.0%, Borax 8.0%, Boric Acid 2.0%, Lithium Carbonate 2.0%, Barium Carbonate 8.0%, Kaolin 10.0% and Zirconia 7.0% %.

Embodiment 6

[0047] The present invention is applicable to the lead-free frit glaze that second firing is used, and the weight percentage of its batching raw material is composed of:

[0048] Feldspar 38.0%, Quartz 12.0%, Aluminum Hydroxide 5.0%, Talc 5.0%, Light Calcium Carbonate 5.0%, Zinc Oxide 2.0%, Borax 10.0%, Boric Acid 4.0%, Strontium Carbonate 2.0%, Barium Carbonate 3.0%, Kaolin 6.0% and zirconia 8.0%.

Embodiment 7

[0050] The present invention is applicable to the lead-free frit glaze that second firing is used, and the weight percentage of its batching raw material is composed of:

[0051] Feldspar 52.0%, Quartz 7.0%, Talc 1.0%, Light Calcium Carbonate 5.5%, Zinc Oxide 1.0%, Borax 6.0%, Boric Acid 2.0%, Strontium Carbonate 0.5%, Barium Carbonate 5.0%, Kaolin 15.0% and Zirconia 5.0 %.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com